A kind of multi-oxygen oblique flame burning method and burning device of flat glass melting furnace

A combustion device and flat glass technology, applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve problems such as fluctuations in kiln temperature and kiln pressure, uneven temperature distribution, and restrictions on spray gun layout, so as to reduce erosion and erosion, The effect of fully utilizing the heat and reducing the rising of the flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 1-5 The multi-oxygen combustion device and its combustion method using the inclined flame flat glass melting furnace of the present invention are described in detail.

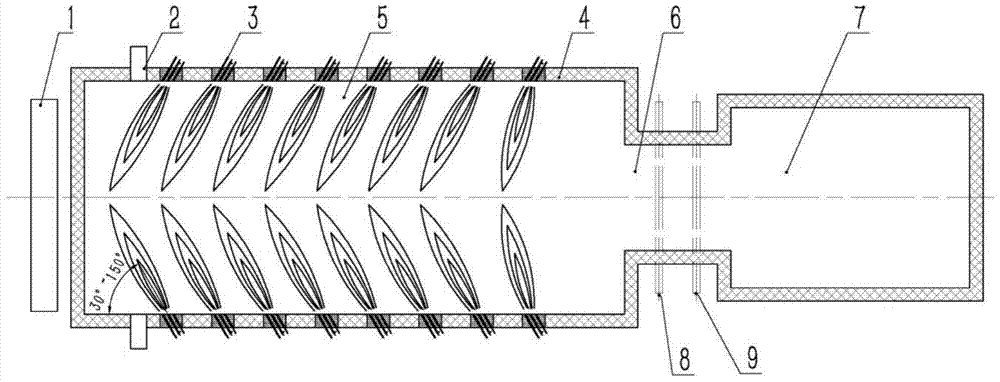

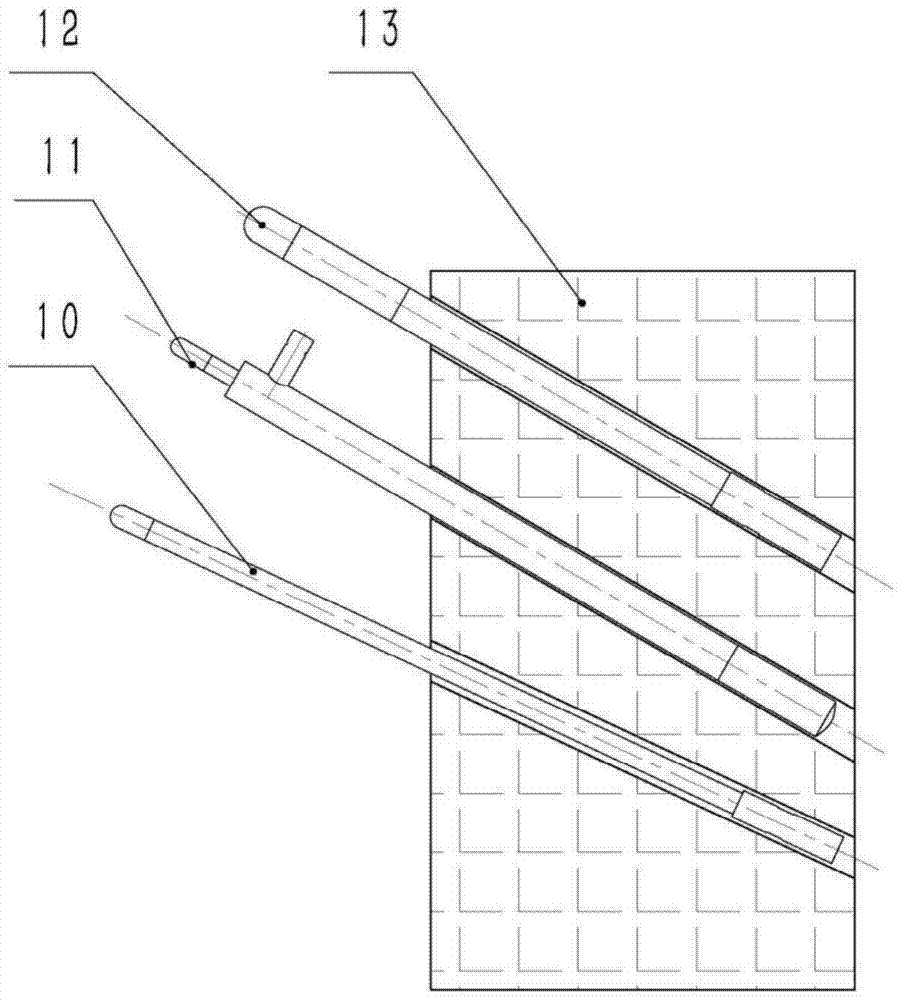

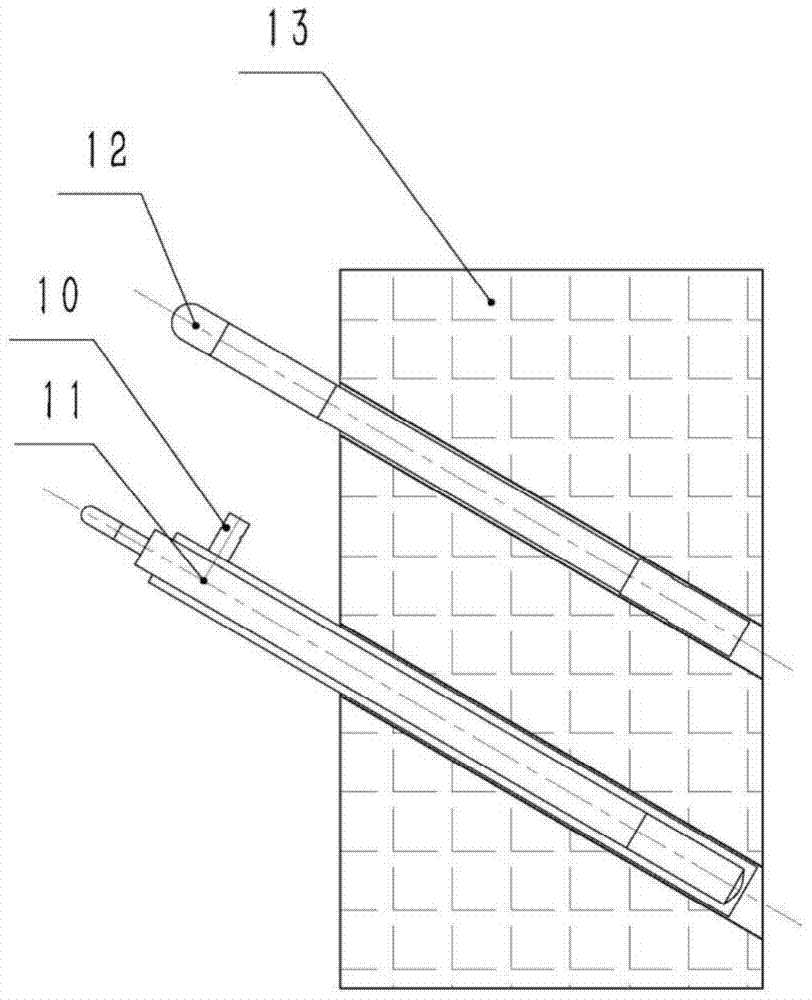

[0034]A multi-oxygen inclined-flame combustion device for a flat glass melting furnace, the multi-oxygen combustion device includes a feeding port 1, a melting part 5, a neck 6, and a cooling part 7 connected to each other in sequence; the outer side of the melting part 5 is provided with A parapet 4, the parapet 4 is respectively provided with a smoke outlet 2 at the left and right sides close to the feeding port 1; device 3, the angle between the flame of the multi-oxygen oblique flame burner 3 and the breast wall 4 is 30°-150°, the multi-oxygen oblique flame burner 3 includes a spray gun and a burner brick 13, and the burner Bricks are provided with inclined spray gun installation holes for the installation of the spray gun, and the spray gun includes oxygen spray guns 10, 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com