Efficient flame burner

A flame nozzle and high-efficiency technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve the problems of insufficient flame length and insufficient combustion of combustible gas, improve combustion effect, reduce flame off-fire phenomenon, and increase flame length. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

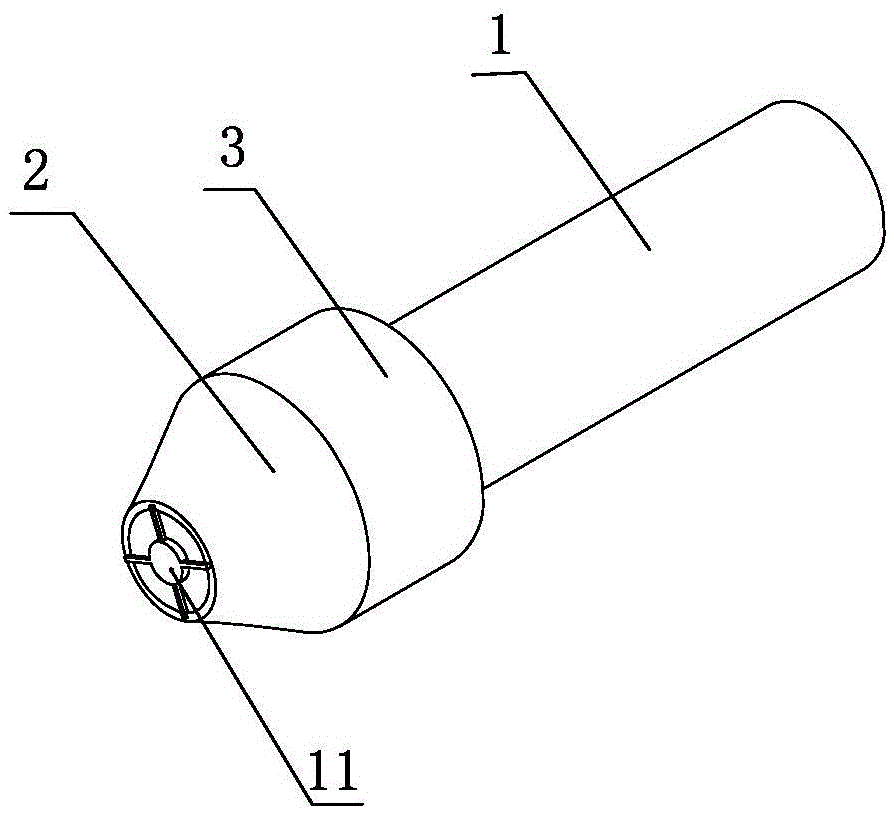

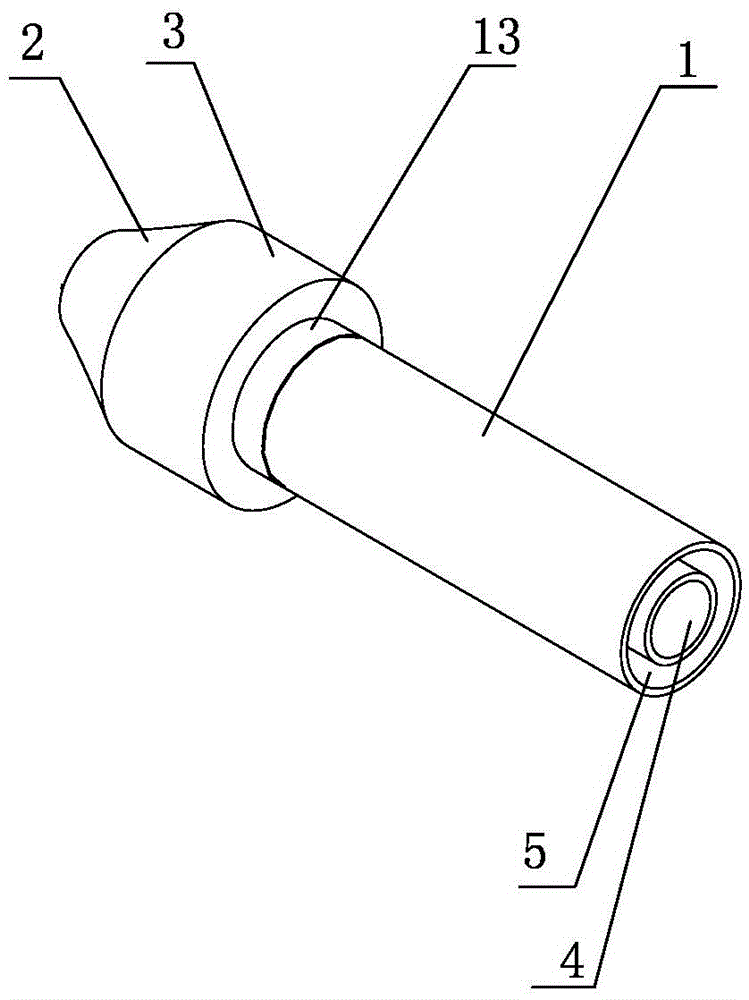

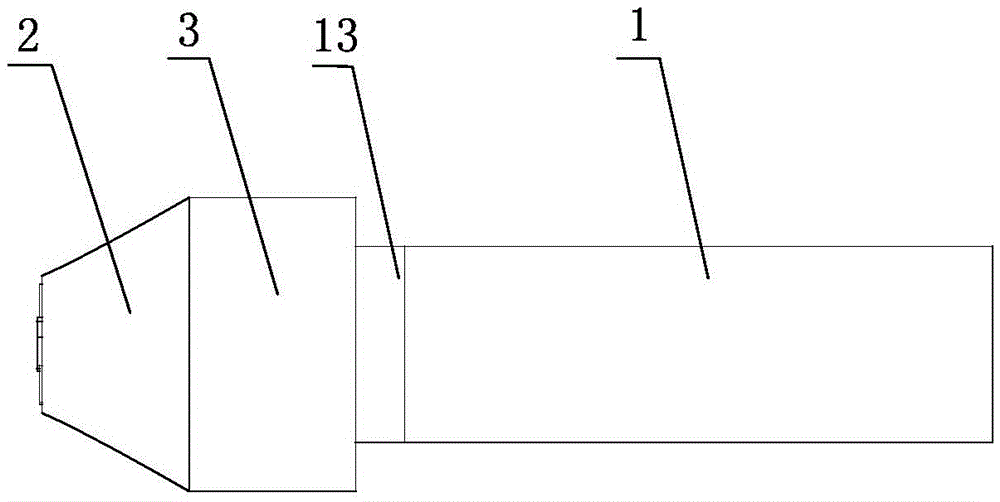

[0027] Such as figure 1 As shown, a high-efficiency flame nozzle includes a sleeve 1, a gas mixing mechanism and an injection pipe 2; the sleeve 1 includes a gas pipe 4 and a combustion-supporting pipe 5, and the combustion-supporting pipe 5 is set on the gas pipe 4 The outside of the gas tube 4 is used to connect combustible gas, and the combustion tube 5 is used to connect oxygen or air; the end of the gas tube 4 is longer than the end of the combustion tube 5, and the gas tube The end of 4 is provided with volatilization tube 6, and described volatilization tube 6 is cylindrical hollow structure, communicates with gas pipe 4, is evenly provided with through hole 7 around volatilization tube 6, and the end of described volatilization tube 6 is provided with end cap, The combustible gas volatilizes to the surrounding side through the through hole 7 of the volatilization tube 6 . Because the end of the gas pipe 4 is longer than the end of the combustion-supporting pipe 5, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com