Electricity thick liquid torch trigger device

A technology of plasma and ionization, applied in the field of plasma torch, can solve the problems affecting the service life of the pole core 20a, unsatisfactory structural design, etc., and achieve the effect of increasing the flame temperature and flame length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

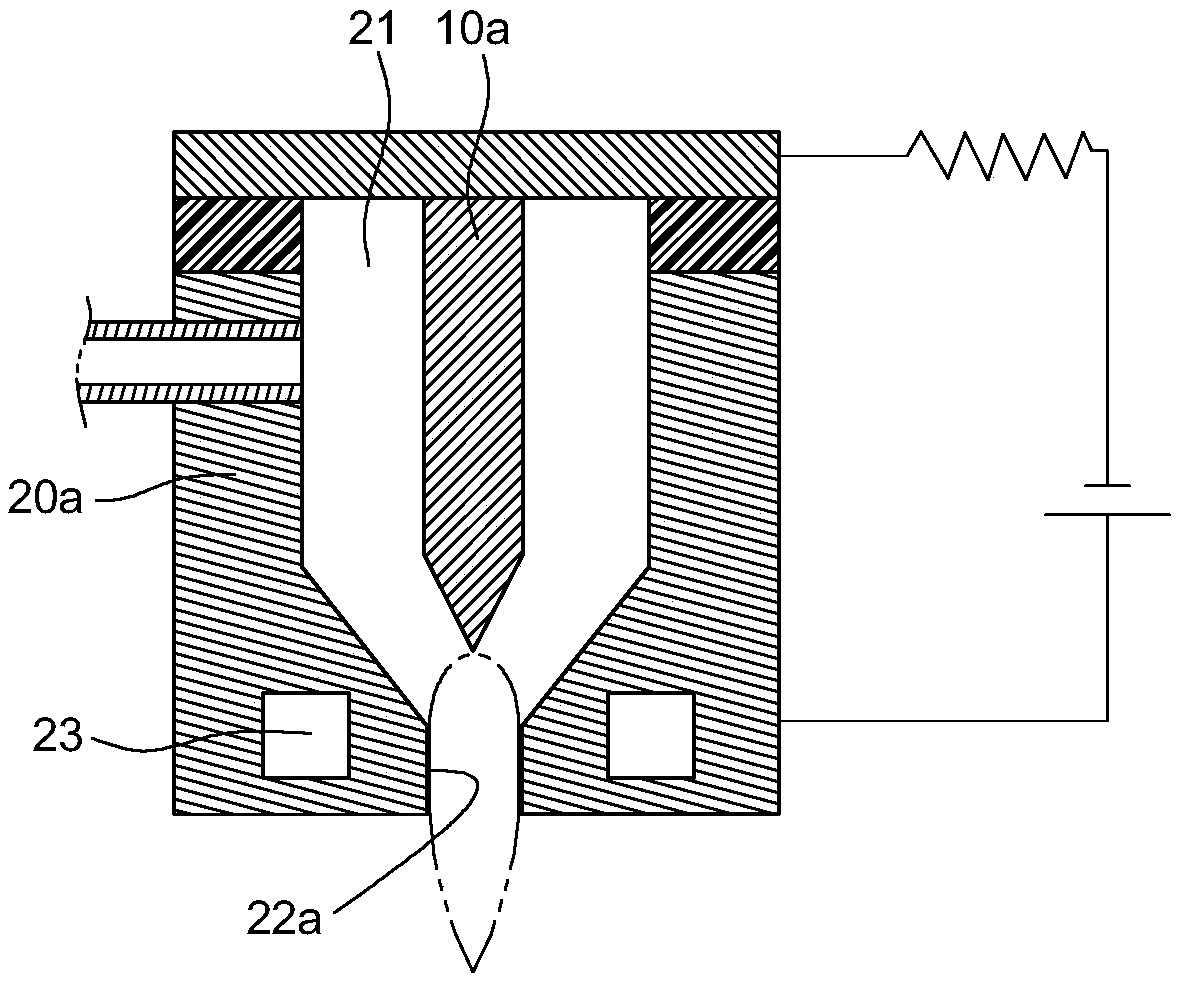

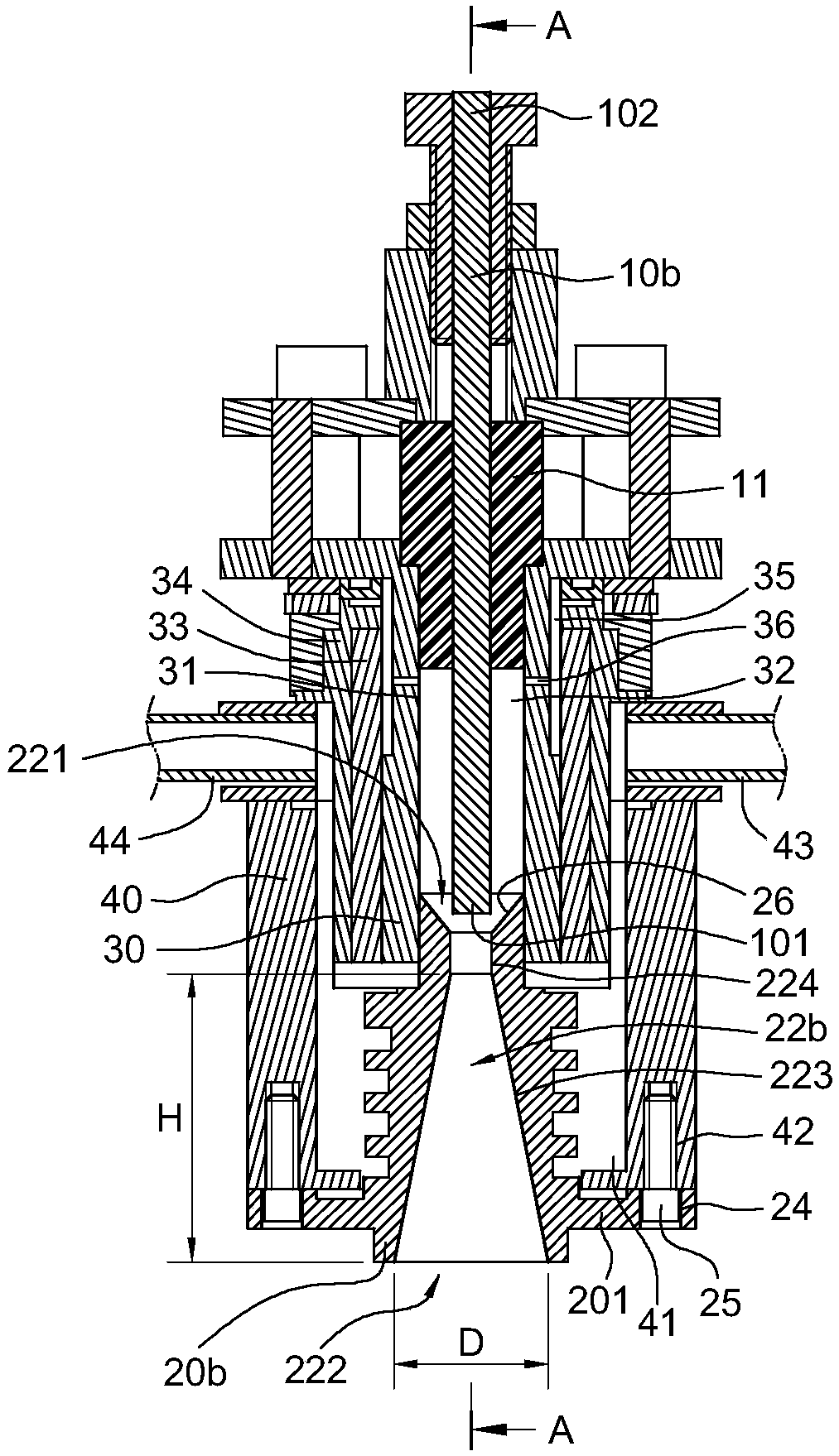

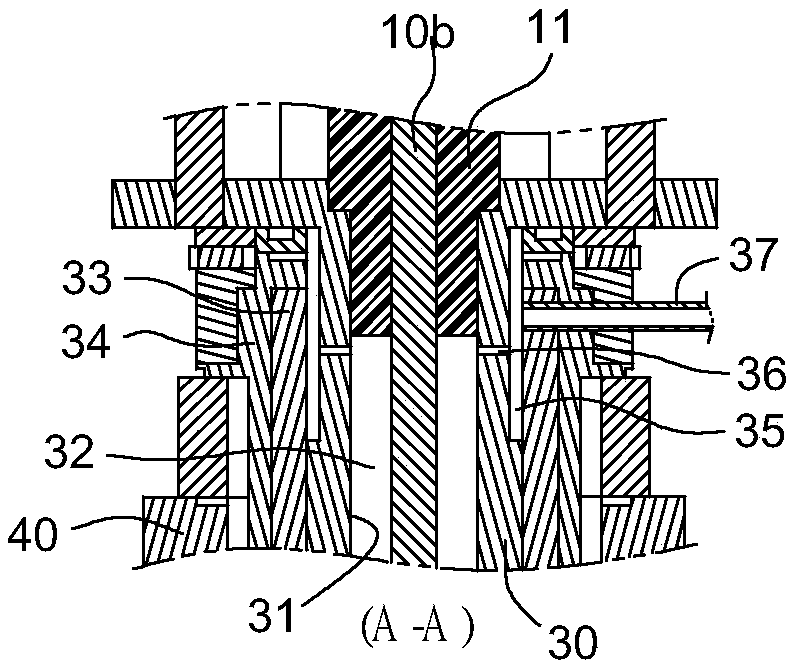

[0021] First, please incorporate the figure 2 and image 3 , discloses a preferred embodiment of a plasma torch excitation device provided by the present invention, and illustrates that the plasma torch excitation device includes a pole core frame 30, a pole rod 10b and a pole core 20b, wherein:

[0022] The pole core frame 30 is roughly made into a seat tube shape, so that the pole core frame 30 has a hollow chamber 31 . In practice, the pole 10b is made of conductive metal into a bar shape, so that the pole 10b has an ion projecting end 101 and an electric connection end 102, and the pole 10b is fixed by being held in the middle by an insulating sleeve 11 On the pole core frame 30, and the ion projecting end 101 of the pole rod 10b can be implanted in the chamber 31, thereby forming a gas collection groove 32 surrounding the pole rod 10b and the surrounding walls of the chamber 31, And the power-connecting end 102 of the pole rod 10b protrudes out of the core frame 30 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com