Concentrated and thin fuel-saving igniting coal powder burner

A pulverized coal burner, a technology for thick and thin pulverized coal, which is applied to burners, burners for burning powder fuel, combustion methods, etc., can solve problems such as affecting the safe and economical operation of power station boilers, difficult to guarantee coal quality, and unstable combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

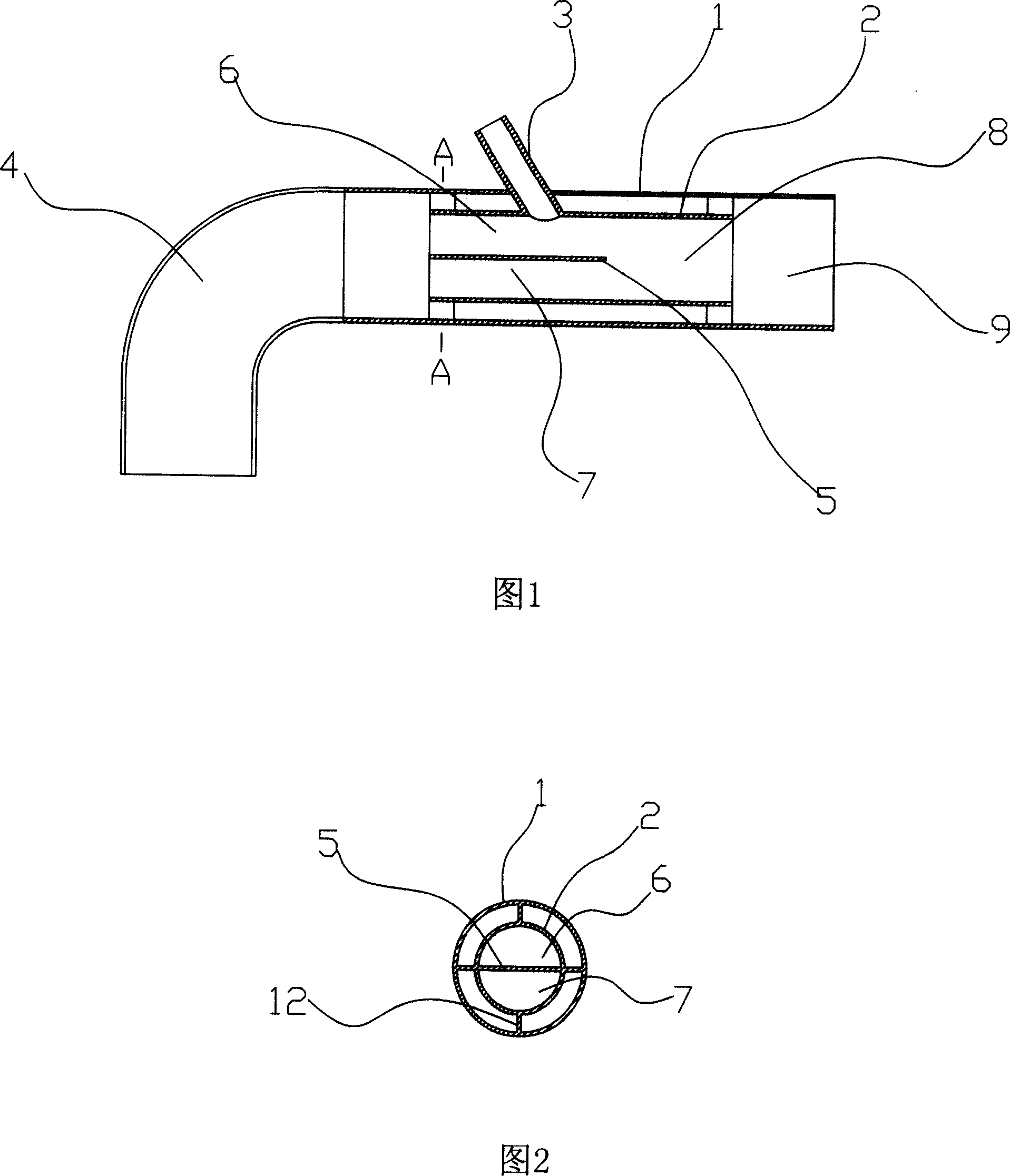

[0014] Referring to Figures 1 and 2, the present invention includes a burner body 1, a primary combustion chamber 2, and an ignition heat source injection port 3. The primary combustion chamber 2 is placed in the combustion body 1 and fixed by ribs 12. The burner body 1 The entrance is provided with a dense and thin coal powder separation device. In this embodiment, the thick and thin coal powder separation device is an elbow 4, and a separation partition 5 is provided in the primary combustion chamber 2, and the separation partition 5 is located in the primary combustion chamber 2 In the first half, it divides the first half of the first-stage combustion chamber 2 into upper and lower areas, which are respectively a dense coal powder area 6 and a light coal powder area 7. The powder area 6 is provided with an ignition heat source injection inlet 3, so that after the primary wind carries the pulverized coal into the elbow 4, due to the large inertia of the pulverized coal, most...

Embodiment 2

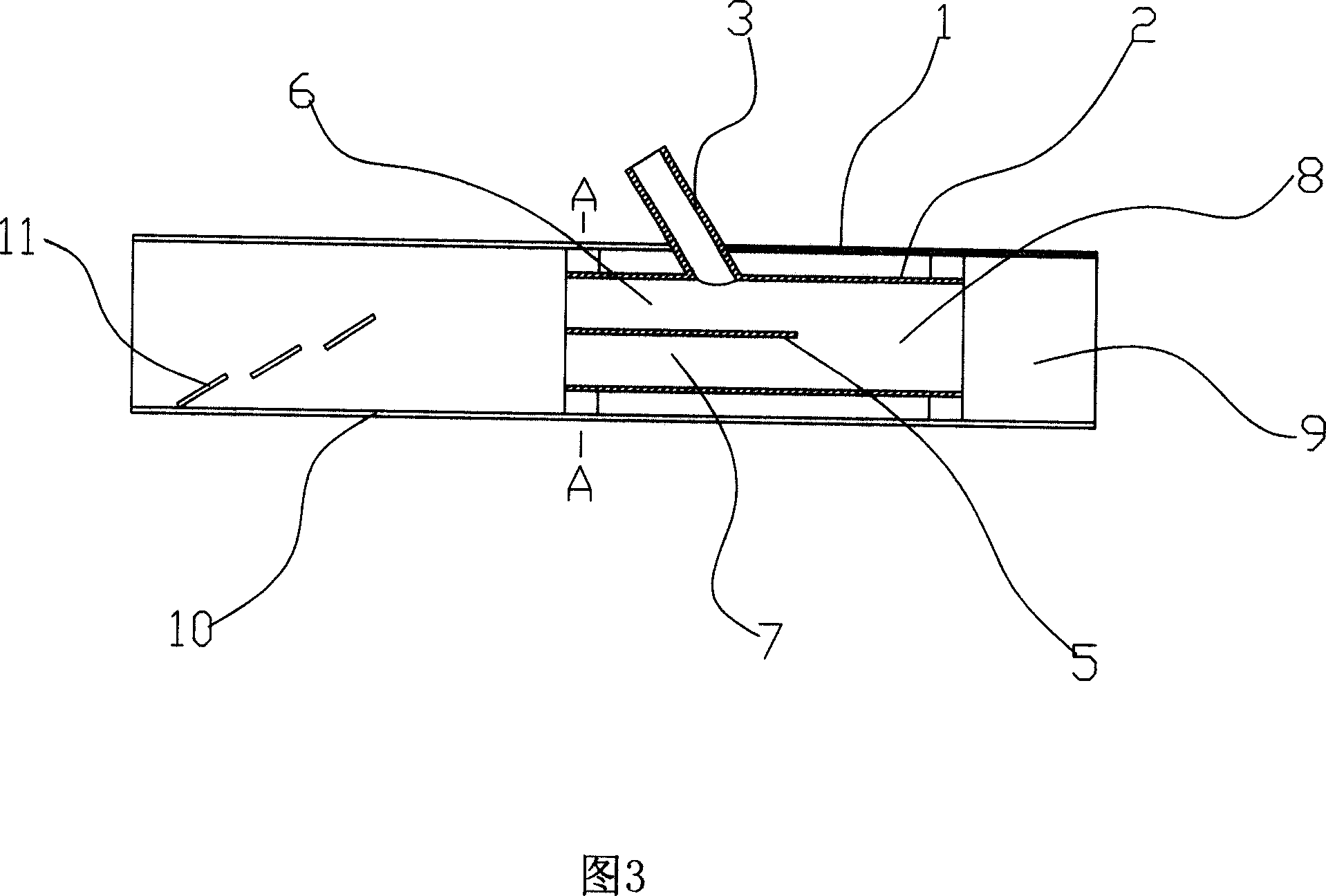

[0016] Referring to Fig. 3, the structure shown in this embodiment is the same as that of Embodiment 1 except that the structure of the thick-lean pulverized coal separation device is different from that shown in Embodiment 1.

[0017] In this embodiment, the thick and thin pulverized coal separation device is composed of a housing 10 and louvers 11 , and the louvers 11 are installed in the housing 10 . When the primary wind carries pulverized coal into the thick-lean separation device, a large amount of pulverized coal hits the louvers 11 due to inertia, and rebounds to the other side to make the concentration of pulverized coal on this side high, thereby achieving the effect of thick-lean separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com