Preparation method of coal-saving agent used for nitrogen fixation type cement short kiln

A technology of coal-saving agent and cement, which is applied in the fields of coal-burning additives, energy-saving and emission-reduction. Heat transfer mode, effect of reducing kiln tail load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

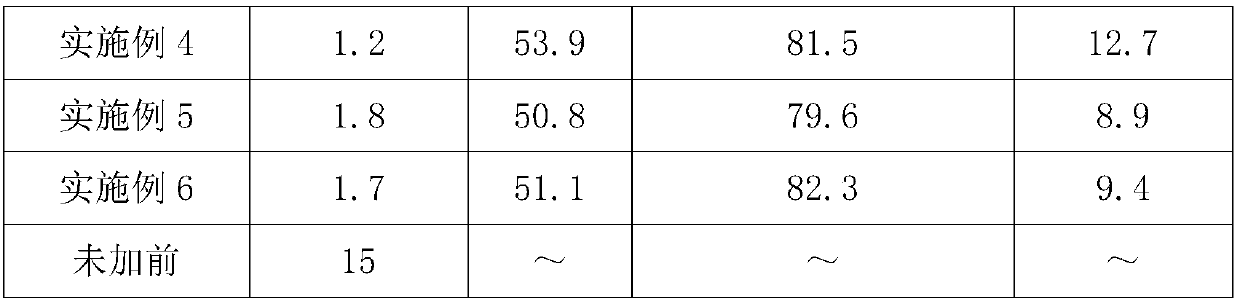

Examples

Embodiment 1

[0032] 1) The parts by weight are 36 parts of lanthanum vanadium allanite, 17 parts of magnesium hydroxide, 25 parts of monohydrate alumina, and mixed grinding to obtain a specific surface area ≥ 400m 2 / kg of mixture;

[0033] 2) Add 10 parts of polyphenylene sulfide, 8 parts of silicone oil, and 7 parts of zinc borate into the mixture obtained in step 1), and mix evenly to obtain a nitrogen-fixing cement short-kiln coal-saving agent.

Embodiment 2

[0035] 1) Mix and grind 30 parts by weight of leached ore, 10 parts of magnesium hydroxide, 20 parts of alumina trihydrate, and obtain a specific surface area of ≥ 400m 2 / kg of mixture;

[0036] 2) Add 14 parts of the mixture of polyphenylene sulfide and aromatic polyimide, 14 parts of silicone oil, and 6 parts of zinc borate to the mixture obtained in step 1), and mix evenly to obtain a nitrogen-fixing cement short kiln coal-saving agent .

[0037] The mass ratio of the polyphenylene sulfide to the aromatic polyimide is 1:1.

Embodiment 3

[0039] 1) Mix and grind 38 parts by weight of monazite, 19 parts of magnesium hydroxide, and 16 parts of monohydrated alumina to obtain a specific surface area of ≥ 400m 2 / kg of mixture;

[0040] 2) Add 8 parts of polyphenylene sulfide, 15 parts of a mixture of silicone oil and silicone resin, and 4 parts of zinc borate into the mixture obtained in step 1), and mix evenly to obtain a nitrogen-fixing cement short-kiln coal-saving agent.

[0041]The mass ratio of the silicone oil to the silicone resin is 2:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com