A production process for reducing 4-methylimidazole content in ammonia caramel color

A methylimidazole and production process technology, which is applied in the production process field of reducing the content of 4-methylimidazole in ammonia caramel color, can solve the problems of high content of 4-methylimidazole, and achieve the promotion of healthy development, improvement of utilization rate, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

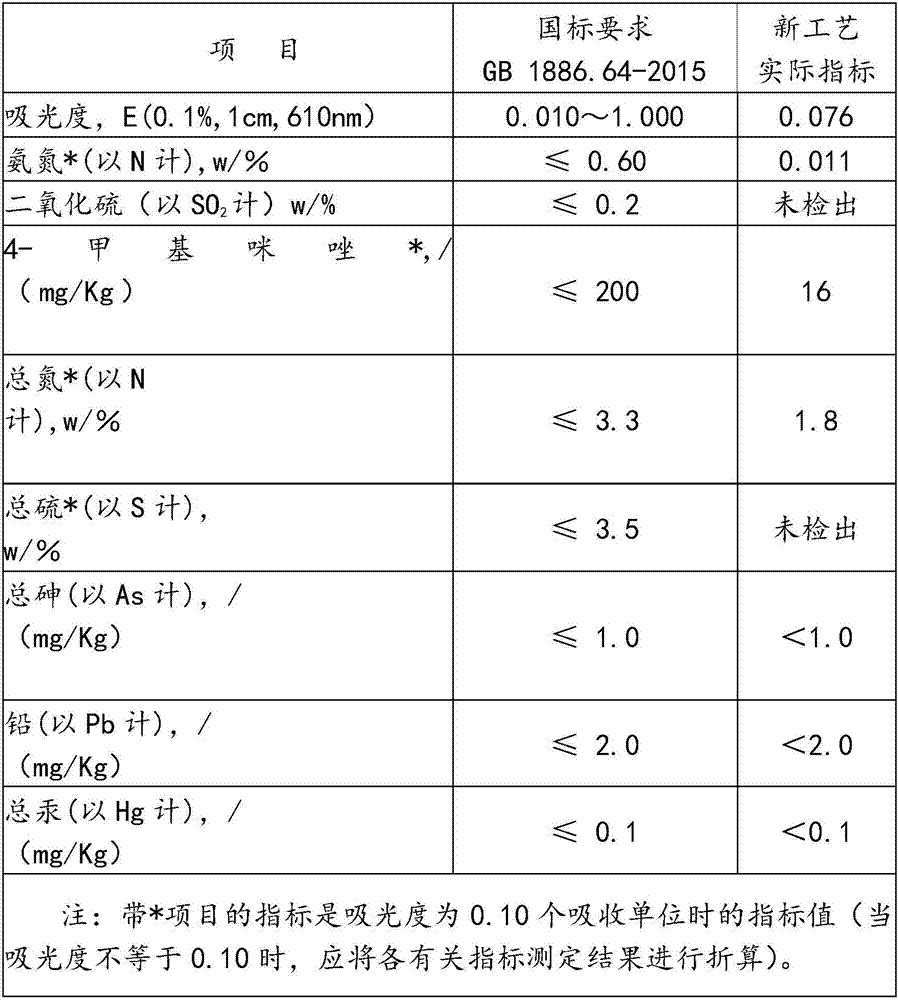

Embodiment 1

[0042] Production of 36Be, 20000EBC ammonia caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both measurement indicators of caramel color).

[0043] A production technique for reducing 4-methylimidazole content in ammonia caramel color, comprising the following steps:

[0044] 1), raw material metering and concentration: accurately weigh 7500Kg of maltose syrup (the amount of dry matter is 6000Kg) with a dry basis of 80%, and concentrate it in a reactor until the dry basis is 85%;

[0045] 2), catalyst preparation: accurately add 1020Kg of water and 380Kg of ammonium carbonate in the batching tank, fully stir evenly, and set aside;

[0046] 3) Heating reaction: Heat the material in the reactor directly with steam, raise the temperature of the material to 100°C, at this time, the dry basis of the material is 85%, continue to heat directly with steam, open the valve of the batching tank, and a...

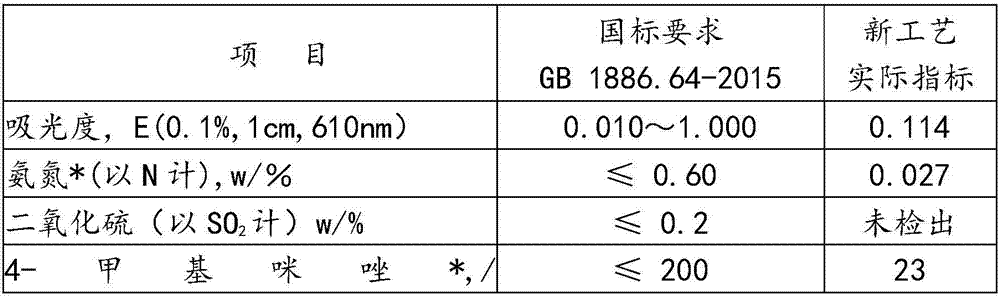

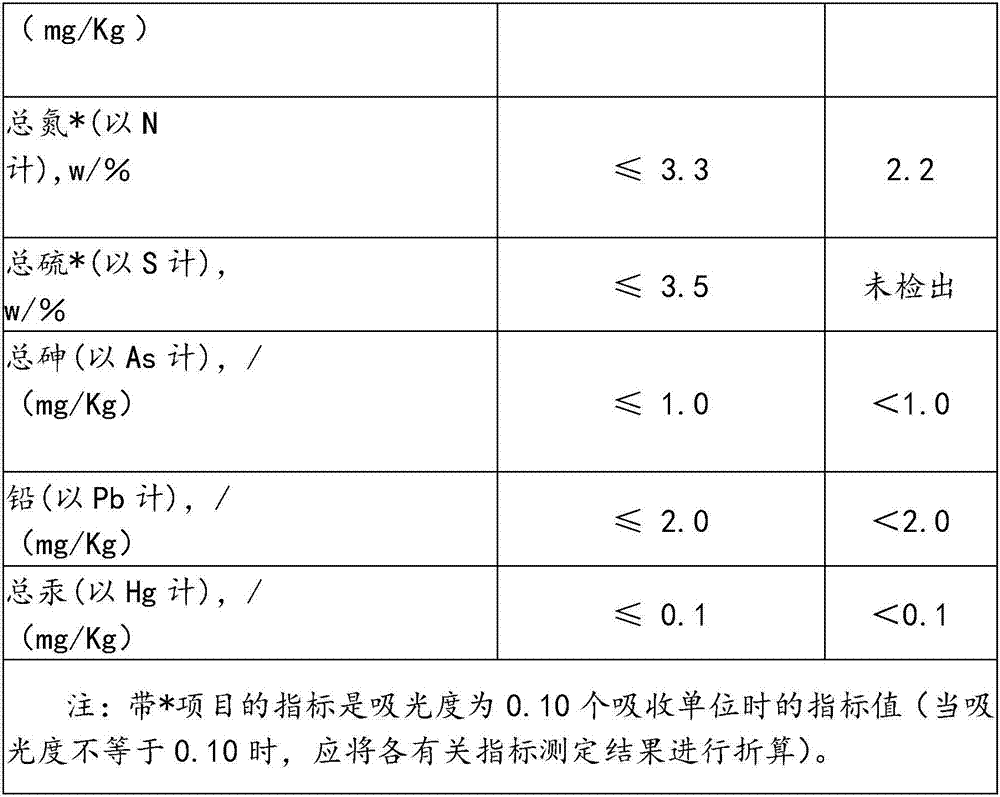

Embodiment 2

[0054] Production of 38Be, 30000EBC ammonia caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both measurement indicators of caramel color).

[0055] A production technique for reducing 4-methylimidazole content in ammonia caramel color, comprising the following steps:

[0056] 1), raw material metering and concentration: accurately take by weighing 8450Kg of fructose syrup (the amount of dry matter is 6000Kg) that is 71% on a dry basis, and concentrate in a reactor until the dry basis is 73%;

[0057] 2), the preparation of catalyst: accurately weigh 1080Kg content and be 25% ammonia solution into batching tank, stand-by;

[0058] 3) Heating reaction: Heat the material in the reactor directly with steam, and raise the temperature of the material to 100°C. At this time, the dry basis of the material is 73%. Continuously add ammonia solution catalyst in the medium, and the speed of adding cat...

Embodiment 3

[0067] Production of 33Be, 40000EBC ammonia caramel color (EBC is the color rate unit of caramel color; Be refers to the Baume value of caramel color, and color rate and Baume are both measurement indicators of caramel color).

[0068] A production technique for reducing 4-methylimidazole content in ammonia caramel color, comprising the following steps:

[0069] 1), raw material metering and concentration: accurately weigh 9836Kg of maltose syrup (the amount of dry matter is 6000Kg) with a dry basis of 61%, and concentrate it in a reactor until the dry basis is 65%;

[0070] 2), the preparation of catalyst: in batching tank, total amount is mixed with 480Kg liquid ammonia solution, stand-by;

[0071] 3) Heating reaction: Heat the material in the reactor directly with steam, and raise the temperature of the material to 100°C. At this time, the dry basis of the material is 65%. Continuously add the liquid ammonia solution catalyst in the reactor, and the speed of adding the cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com