Aluminium sectional material spraying system and spraying method thereof

An aluminum profile, spraying device technology, applied in coating, spray booth, spraying device and other directions, can solve the problems of low manual operation efficiency, difficult industrial production, difficult operation, etc., to save labor, save equipment space, increase The effect of containment sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

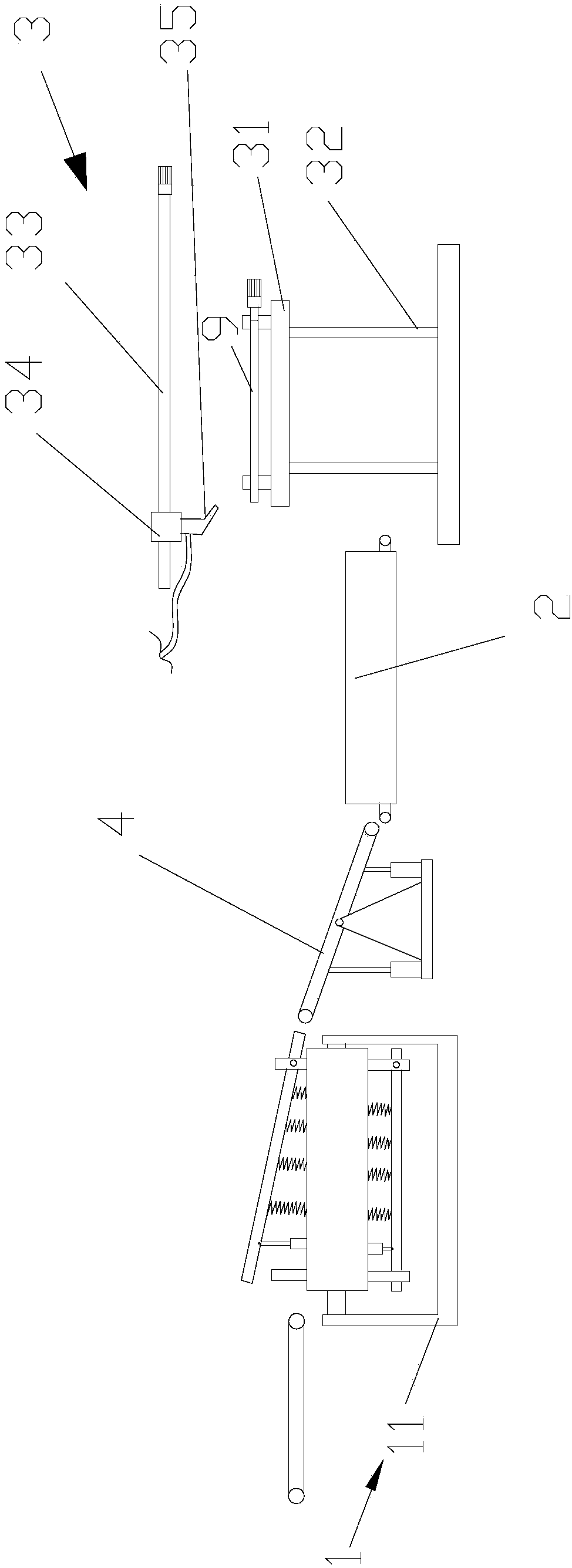

[0057] like figure 1 As shown, this embodiment discloses an aluminum profile spraying system, including a cleaning / oxidation tank 1, a drying oven 2, and a spraying device 3. The cleaning / oxidation tank 1 is used to clean and oxidize the surface of aluminum profiles, and the drying box 2 is used After drying the cleaned and oxidized aluminum profiles, the spraying device 3 is used for spraying the dried aluminum profiles.

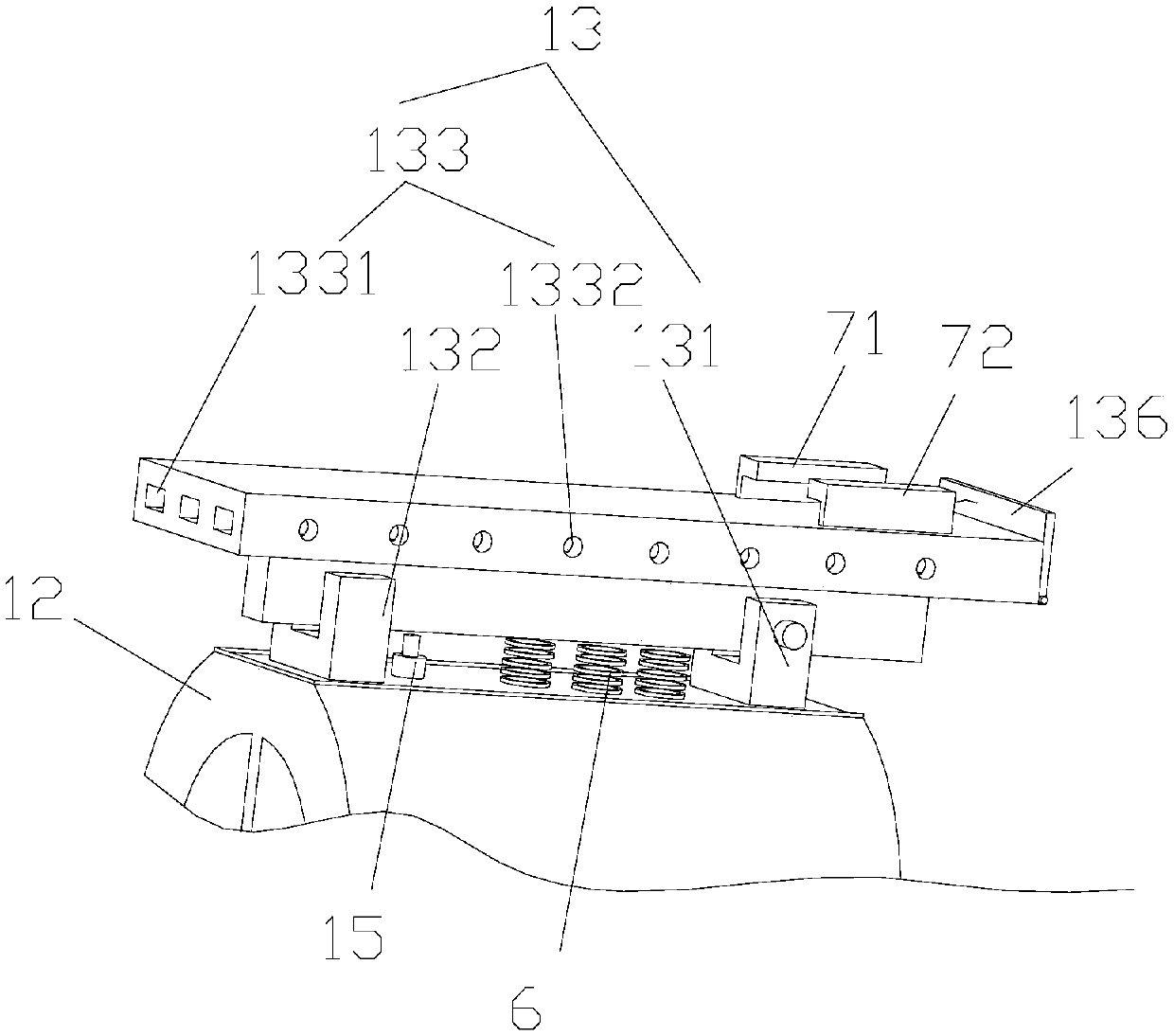

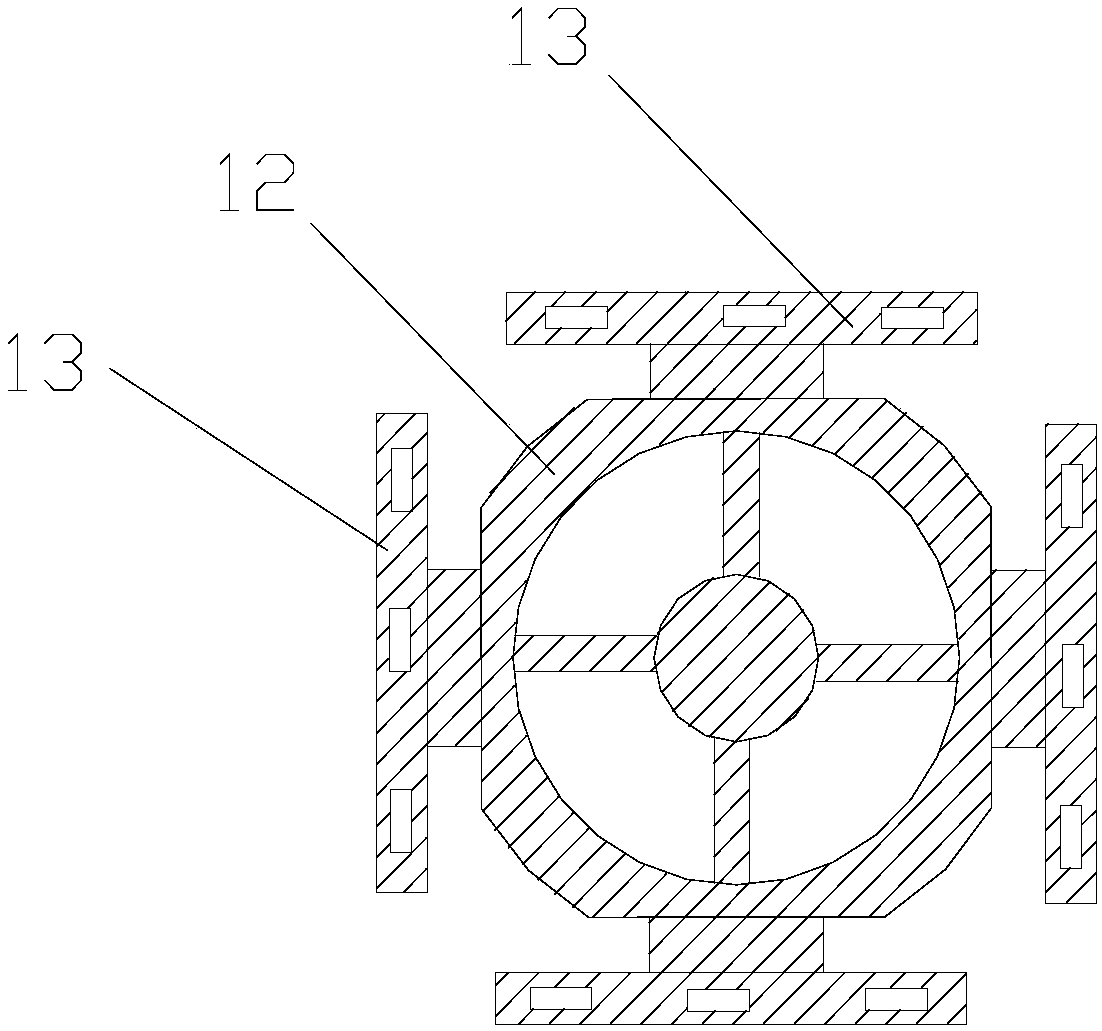

[0058] like Figure 1-3 As shown, the cleaning / oxidation tank 1 includes a tank body 11 , a drum 12 , an aluminum profile storage frame assembly 13 , a first driving mechanism, and a first lifting mechanism 15 . The drum 12 is rotationally connected with the tank body 11, and the first driving mechanism is used to drive the drum 12 to rotate. A plurality of aluminum profile storage frame assemblies 13 surround the surface of the drum 12 around the center axis of the drum 12 .

[0059] Each aluminum profile storage frame assembly 13 all comprises a first ...

Embodiment 2

[0101] This embodiment discloses a method for spraying using the above-mentioned aluminum profile spraying system, including the following steps:

[0102] Step 1. The cast aluminum profile is transported to the storage through hole in the aluminum profile storage plate 133 opposite to the position of the transmission device through the conveying device. After middle, the drum 12 is driven to rotate by the first driving mechanism until the next aluminum profile receiving plate 133 is opposite to the position of the conveying device, when the next cast aluminum profile is transported to the next aluminum profile through the conveying device. In the receiving through holes in the profile receiving plate 133, according to the above sequence, until each receiving through hole in the aluminum profile receiving plate 133 is accommodated with aluminum profiles;

[0103] Step 2: Add degreasing solution into the tank body 11, drive the roller 12 to roll in the tank body 11 containing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com