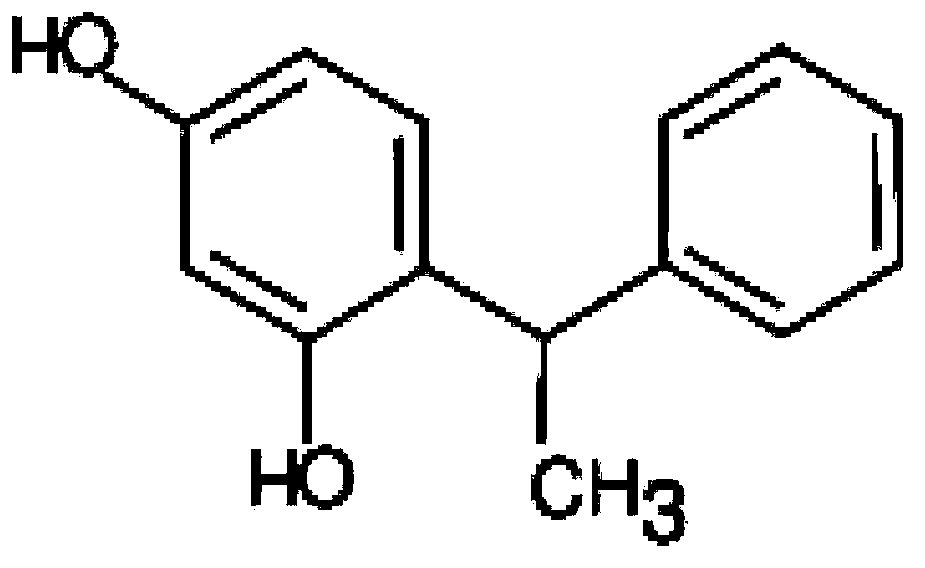

Nanostructured lipid carrier loaded with phenylethyl resorcinol, preparation method thereof and cosmetic containing same

A nanostructured lipid and carrier technology, applied in cosmetics, cosmetic preparations, toiletry preparations, etc., can solve the problems of poor stability and low bioavailability of phenylethyl resorcinol, reduce drug leakage, Strong transportation performance and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

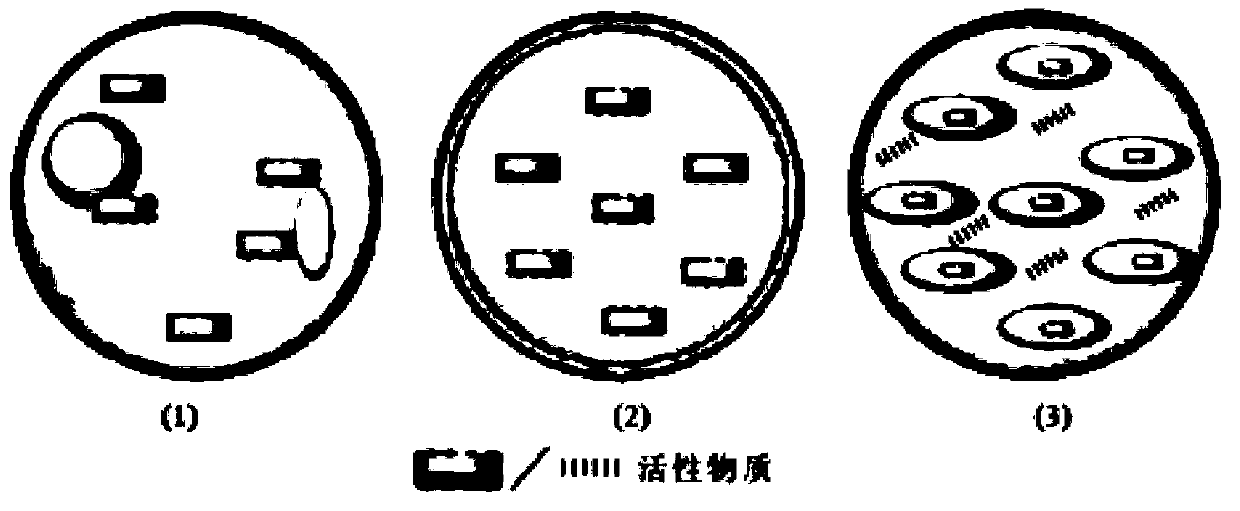

[0045] Through a suitable preparation process—such as the preparation method of the nanostructured lipid carrier described below, the lipid carrier of the above components can be nano-sized, preferably, the particle size of the nanostructured lipid carrier is between 50nm and 500nm , preferably between 100nm and 300nm, more preferably between 100nm and 210nm. In the following examples, the particle diameters of the prepared nanostructured lipid carriers are about 102 nm, 181 nm, 203 nm, and 205 nm. The active substance phenylethyl resorcinol has long-term stability in the nanostructured lipid carrier with such a particle size, and the release speed of the active substance from the nanostructured lipid carrier is relatively gentle. Such particle sizes are suitable for applications in the cosmetics industry.

[0046] Those skilled in the art can understand that the nanostructured lipid carrier with the above components and the above particle size can also be prepared by other s...

Embodiment approach

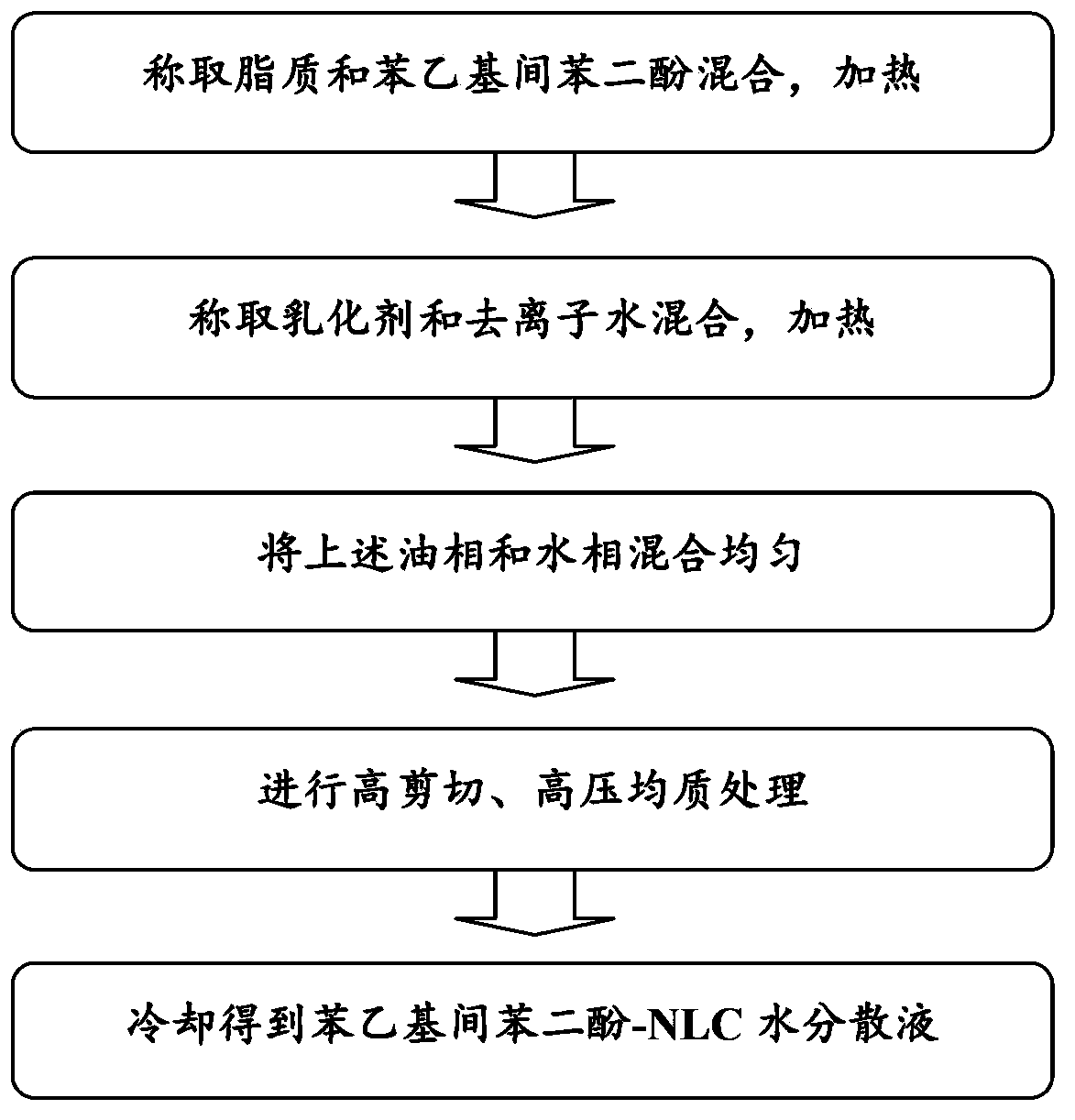

[0064] According to another main embodiment of the present invention, the preparation method of the nanostructured lipid carrier comprises the following steps:

[0065] (1) weighing phenylethyl resorcinol and the composite lipid material according to the weight percentage, mixing the phenylethyl resorcinol and the composite lipid material, heating and stirring, obtaining an oil phase at a temperature between 50°C and 80°C;

[0066] (2) Weigh the emulsifier and deionized water according to the weight percentage, mix the emulsifier and deionized water, heat and stir to obtain water with a temperature between 60°C and 80°C Mutually;

[0067] (3) adding the water phase into the oil phase, mixing and stirring to obtain colostrum through high-shear homogenization equipment, and then using a high-pressure homogenizer to homogenize the colostrum to obtain a high-temperature emulsion;

[0068] (4) Cool the high temperature emulsion to room temperature.

[0069] As an example, the k...

Embodiment 1

[0081] Embodiment 1: Preparation of phenylethylresorcinol nanostructured lipid carrier

[0082] Table 1 Composition Formulation

[0083]

[0084] Such as figure 1 Shown, the preparation steps of this embodiment are as follows:

[0085] 1. Weigh 1.0 grams of glyceryl monostearate, 1.0 grams of acetylated monoglycerides, 3.0 grams of glyceryl caprylate, and 0.5 grams of phenylethyl resorcinol into a beaker, and heat it in a water bath at 75°C as oily phase.

[0086] 2. Weigh 1.0 g ceteareth-6 olivate, 4.0 g cetearyl olivate, and 89.0 g deionized water into a beaker, and heat it in a water bath at 65°C as water Mutually;

[0087] 3. Add the water phase to the oil phase, stir evenly, and turn on the high-shear homogenization equipment for shearing. The high-shearing speed is 1000 rpm. At the same time, preheat with distilled water at 70°C to obtain colostrum;

[0088] 4. Inject the homogeneously stirred high-temperature emulsion system into a high-pressure homogenizer, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com