Composite rubber vertical rod telescopic plug plate and use method thereof

A technology of compound rubber and plug board, which is applied in earth-moving drilling, lifting device, wellbore lining and other directions, can solve the problem of inconvenient installation of wooden boards or steel formwork, inconvenient installation of buried water stop belt, and easy damage to waterproof surrounding rock waterproof board and other problems, to achieve the effect of improving the sealing performance of the mold and the effect of closing the mold, improving the waterproof performance, and eliminating the hidden danger of water leakage in the tunnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

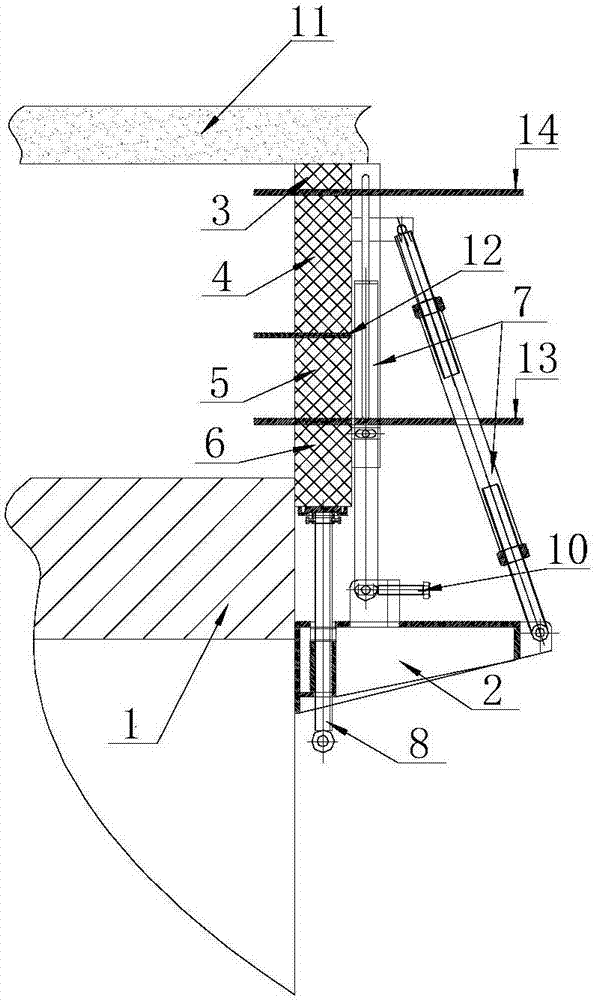

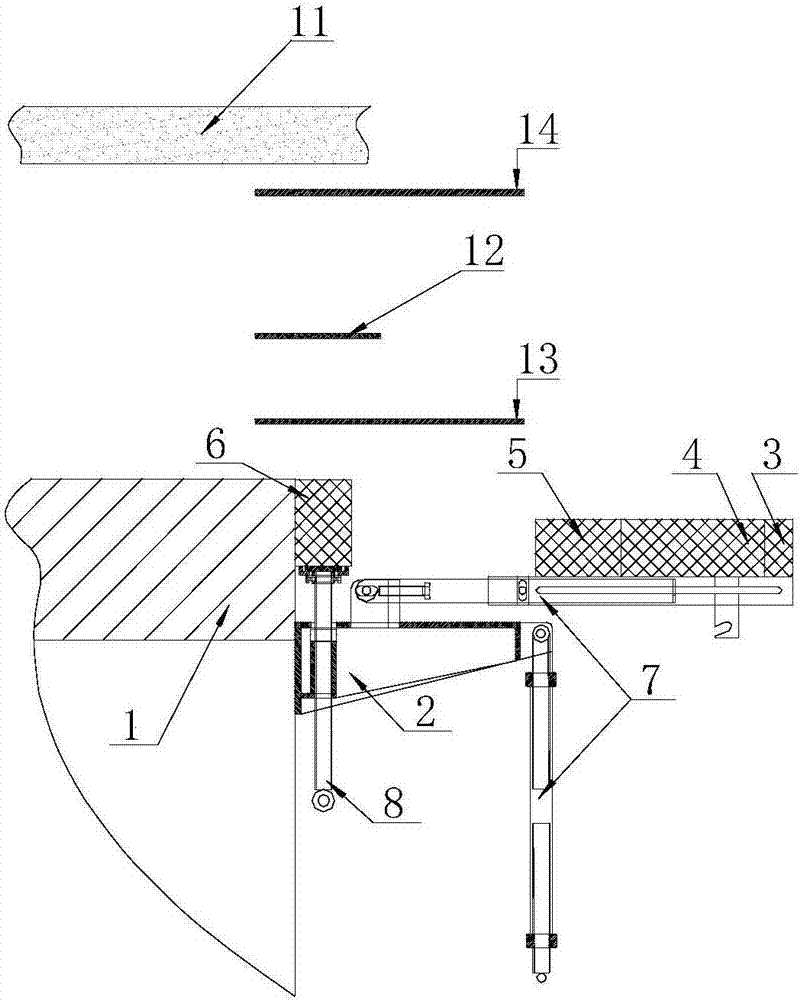

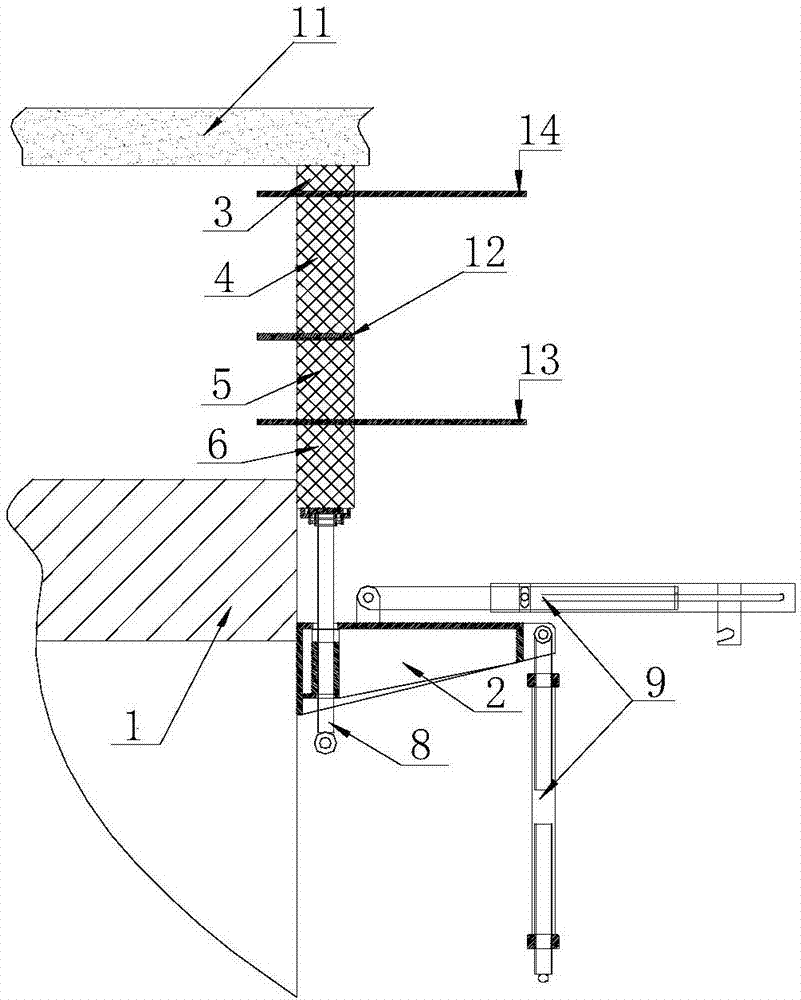

[0072] A composite rubber vertical pole telescopic plug plate, which includes a trolley 1, a rubber baffle, a back-mounted waterstop, and a waterstop 12. A support base 2 is fixedly connected to the trolley 1, and a lifting mechanism 8 is connected to the support base 2, through which the lifting mechanism 8 can push the rubber baffle above it. There are at least two groups of rubber baffles, and multiple groups of rubber baffles are stacked and arranged below the tunnel roof 11 from bottom to top. The back-adhesive waterstop is set between the tunnel roof 11 and the uppermost rubber baffle, and the waterstop 12 is set between two adjacent rubber baffles; if there is a reinforcement layer reserved on the previously poured concrete, it can The upper and lower layers of rubber baffles at the corresponding positions clamp the reinforcement layer.

Embodiment 2

[0074]On the basis of Embodiment 1, the telescopic mechanism adopts a manual lifting mechanism 8, which includes a fixed box 82, a fixed screw rod 81 and a fixed nut 83, and the fixed box 82 and the fixed nut 83 are installed in the support seat 2. The fixing nut 83 cannot rotate in the support seat 2 . The fixed box 82 and the fixed nut 83 can be connected as a whole, and can also be separated, as long as the fixed nut 83 cannot be rotated. The fixing screw 81 is sleeved in the fixing box 82 and the fixing nut 83 , the fixing screw 81 is threadedly connected with the fixing nut 83 , and the two ends of the fixing screw 81 pass through the upper surface and the lower surface of the support base 2 respectively. The upper end of the fixed screw 81 is connected with the bottom rubber baffle. By rotating the fixed screw 81, the fixed screw 81 can move along the axial direction of the fixed screw 81 on the support seat 2, thereby realizing the upward movement and downward movement ...

Embodiment 3

[0076] On the basis of Embodiment 1 or Embodiment 2, a lifting mechanism 7 is also provided. The lifting mechanism 7 is connected to the support base 2, and the lifting mechanism 7 is mainly used to fix the back-mounted waterstop on the 11 on top of the tunnel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com