Overhead rail-mounted spiral high-efficiency flatting system

A rail-type and spiral technology, applied in the field of overhead rail-type spiral high-efficiency closing system, can solve the problems of high labor intensity, low efficiency and high cost of manual leveling, and achieve good closing effect, high efficiency and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

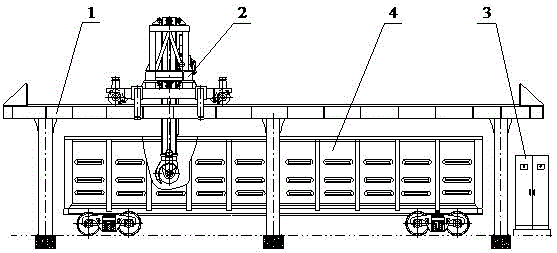

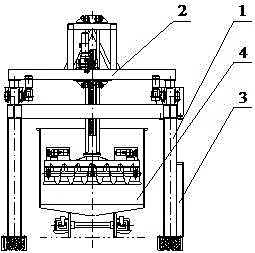

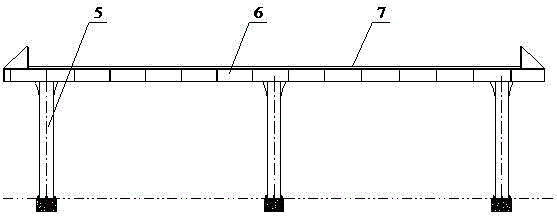

[0029] The present invention proposes an elevated rail-type spiral high-efficiency unwinding system, which adopts high-altitude support rails similar to workshop bridge cranes, and the spiral unwinding machine walking on the rails can efficiently carry out sharp-edged material piles formed during loading leveling work.

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0031] An elevated rail-type spiral high-efficiency liquidation system provided by the present invention is composed as follows: figure 1 , figure 2 As shown, it includes: supporting door frame and track 1, screw unwinding machine 2, and electrical control system 3. The unwinding system adopts the operation method similar to the bridge crane in the workshop. The screw unwinding machine 2 walks on the aerial track supported by the supporting gantry, and performs unwinding operations on the materials in the train compartment 4 above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com