Production system for H-shaped steel

A production system, H-shaped steel technology, applied in the direction of metal rolling, etc., can solve the problems of difficult rolling of rectangular billets, limited specification range, and reduced efficiency, and achieve the effect of large reduction, expanded specification range, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The production system of the H-shaped steel of the present invention will be described in detail below with reference to the accompanying drawings.

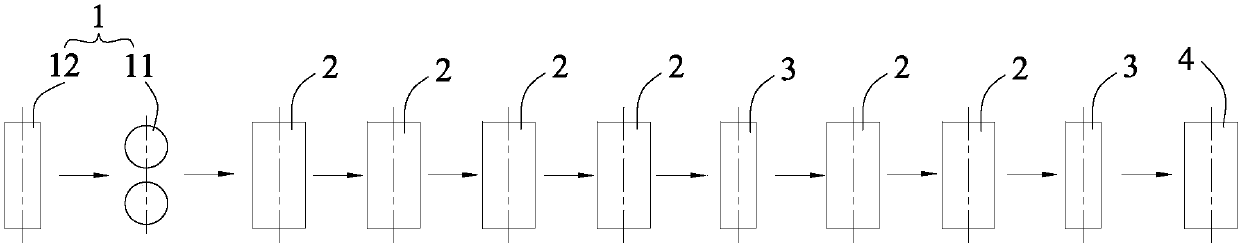

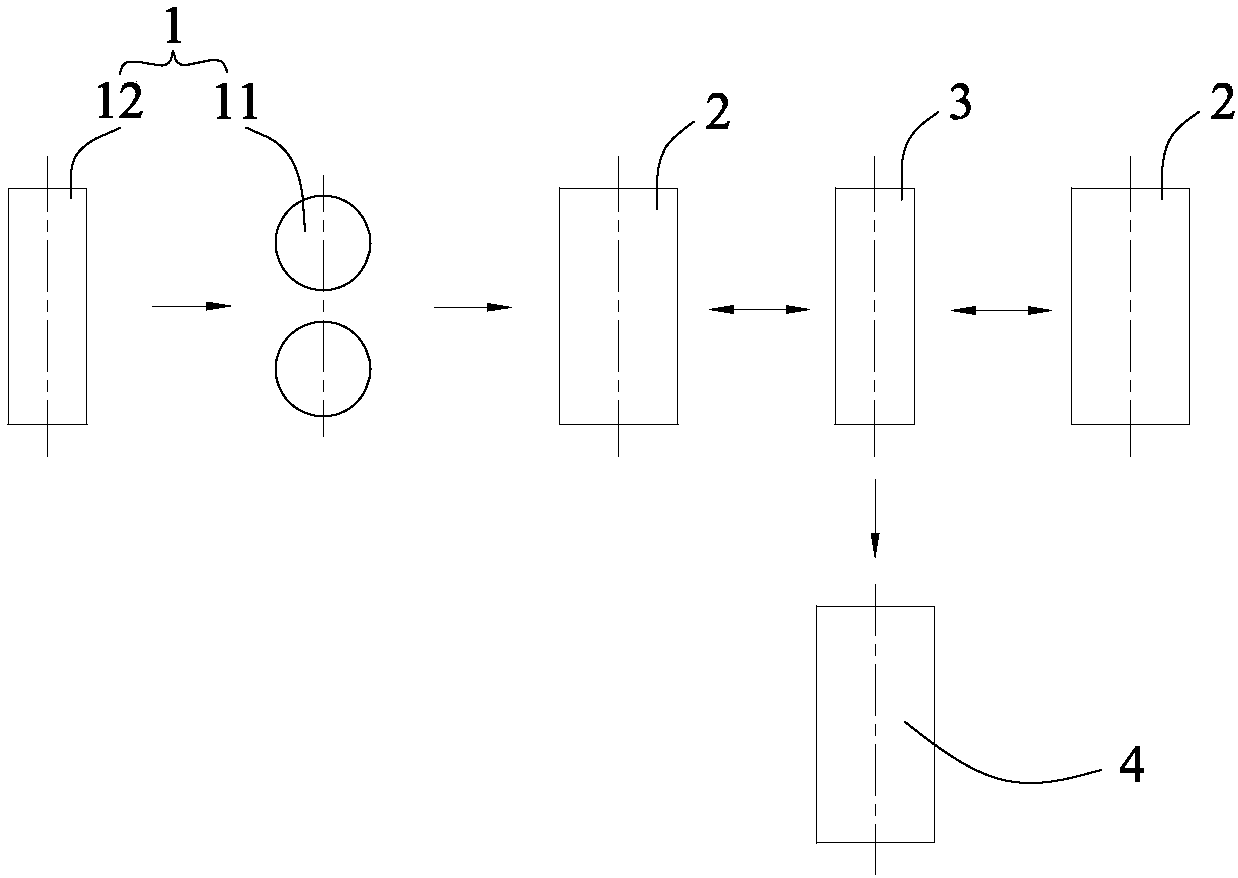

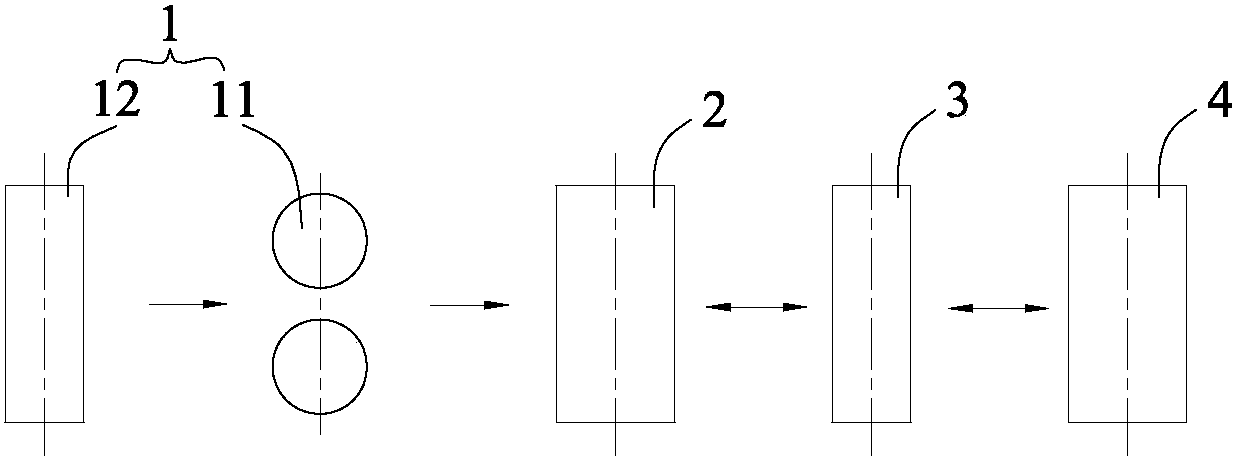

[0042] refer to Figure 1 to Figure 12 , The production system of H-shaped steel according to the present invention includes a roughing rolling unit 1 , an X-pass universal rolling mill 2 , an edger 3 and an H-pass universal rolling mill 4 .

[0043] The roughing mill 1 includes at least one two-roll mill 11 , and each two-roll mill 11 includes two first horizontal rolls 111 . Or, in another embodiment, the roughing mill 1 may include at least one two-roll mill 11 and at least one vertical roller mill 12, each two-roll mill 11 includes two first horizontal rolls 111, each vertical roller mill 12 includes two a first vertical roller 121.

[0044] The continuous casting slab used to produce H-shaped steel is firstly rolled by the roughing rolling mill 1 to form an intermediate billet 5 .

[0045] The X-groove universal ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com