Round steel rod continuous rolling method with diameter less than Phi 100 mm, and hole type system

A technology of elliptical pass and round steel, which is applied in the direction of metal rolling, guiding/positioning/alignment devices, etc. It can solve the problems of increased difficulty in operation and adjustment, large roll bounce, and large stand spacing, so as to avoid reduction. Excessively large, increase the effect of lateral pressure, and avoid the effect of local stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

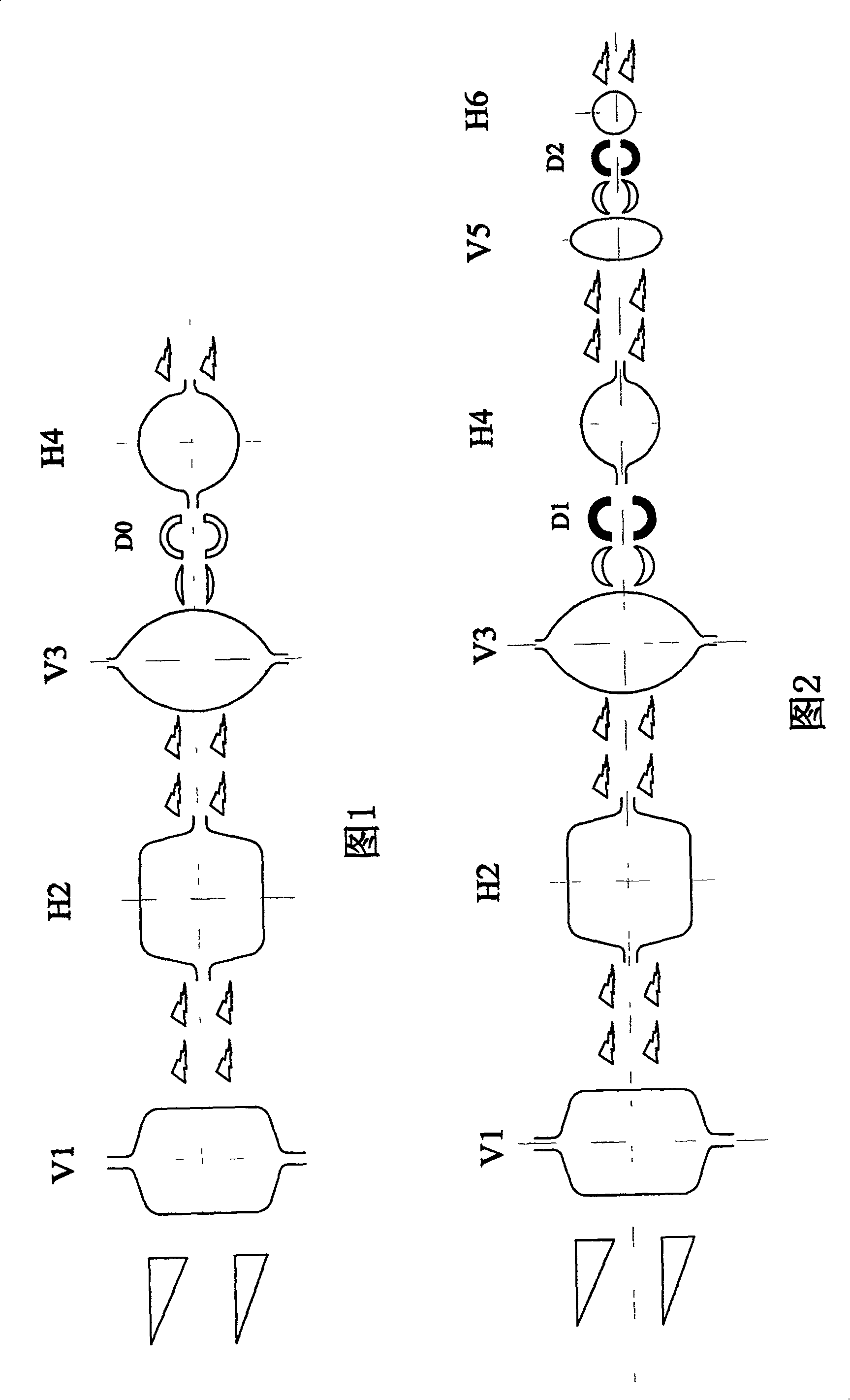

[0042] Referring to Fig. 2, the small-size round steel continuous rolling method of the present invention adopts the system of box V1-square H2-ellipse V3-circle H4-ellipse V5-circle H6, and the blank passes through the vertical rolling mill and the horizontal rolling mill alternately with six stands Finished products are produced by continuous rolling; entrance guide wheels D1 and D2 are set in front of the round hole type H4 frame and the finished product round hole type H6 frame.

[0043] see Figure 3 ~ Figure 8 , which shows the hole structure diagram of the box V1-square H2-ellipse V3-circle H4-ellipse V5-circle H6 system of the present invention.

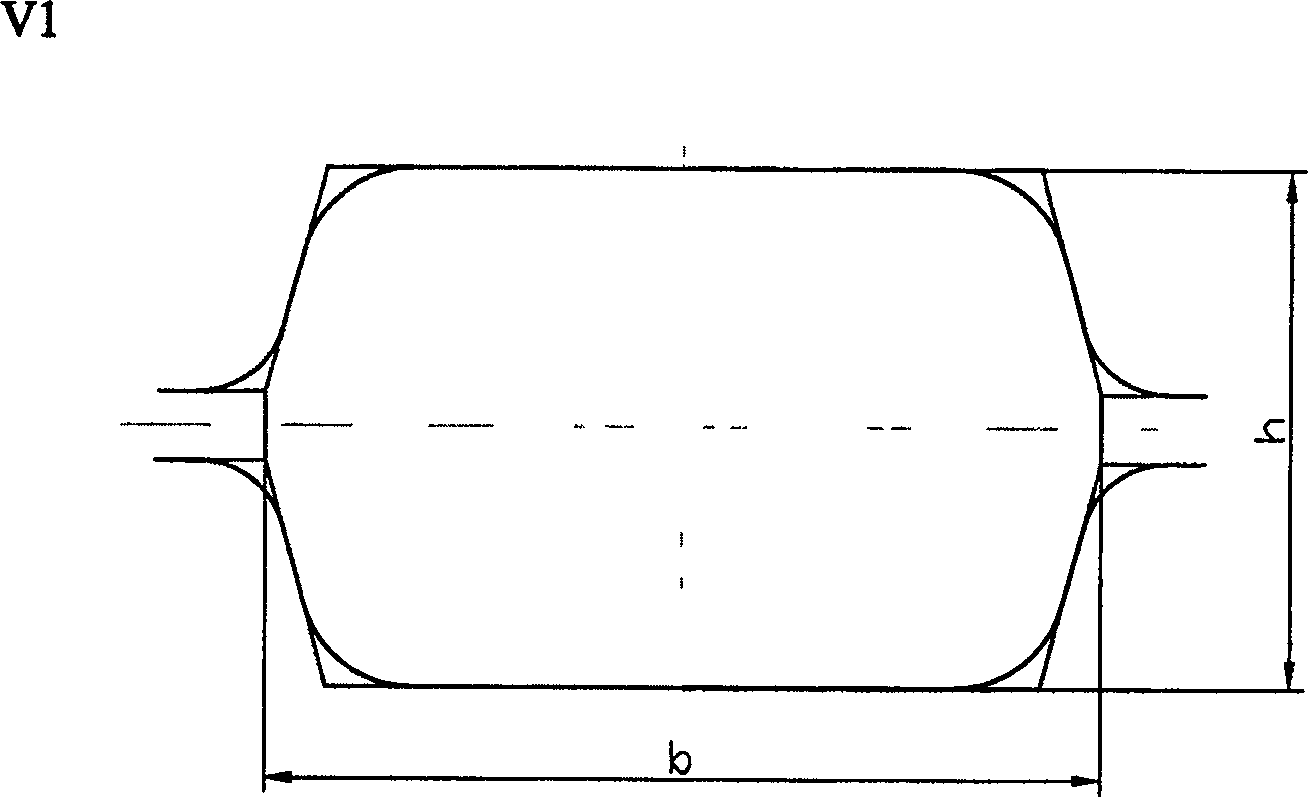

[0044] see image 3 , V1 rack pass is shallow groove flat box pass with straight pass sidewall.

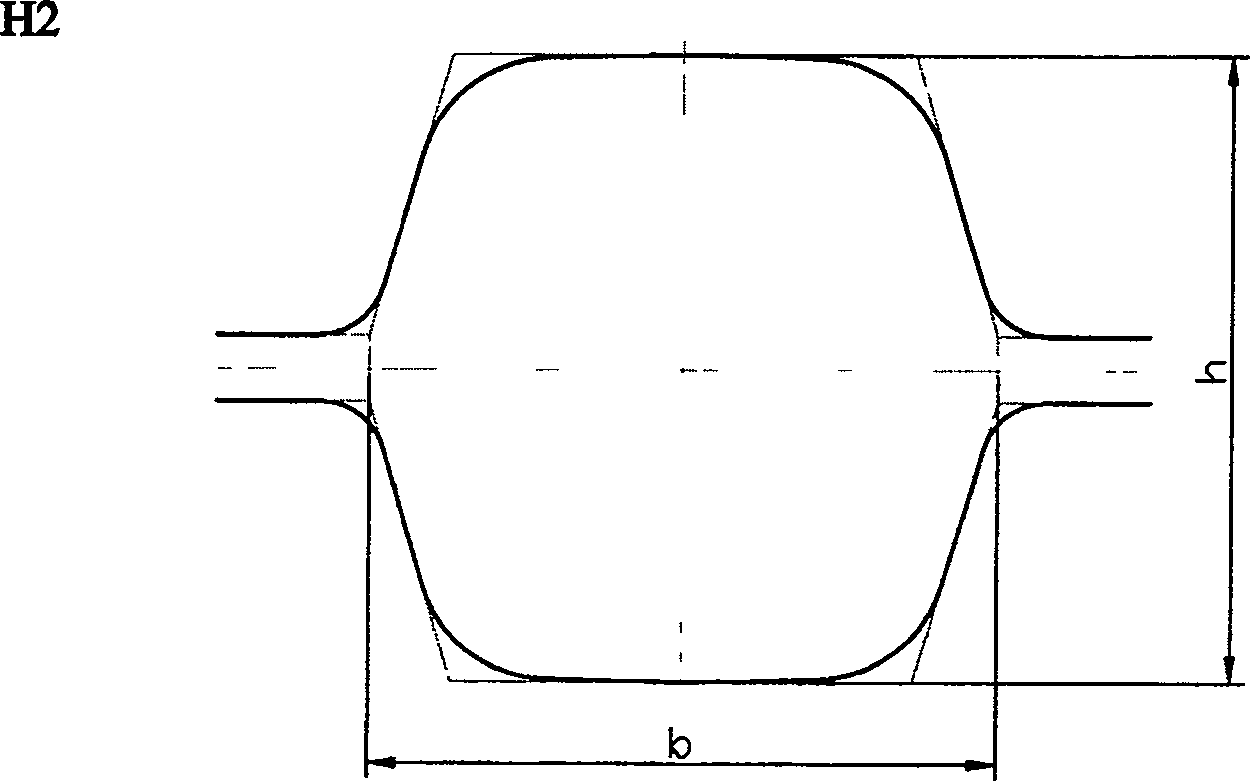

[0045] see Figure 4 , the H2 rack pass is a square pass with a straight pass side wall and a large-diameter arc groove bottom. Create good conditions for the parts to enter the finishing hole correctly and smoothly. In order...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com