Exhaust device for pouring steel pipe concrete and its construction method

A technology of steel pipe concrete and exhaust device, which is applied in the direction of construction, building structure, and building material processing, etc., which can solve the problems of uneven concrete pouring, uneven concrete pouring, uneven stress and force, etc., and achieve increased construction Difficulty, manpower saving, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

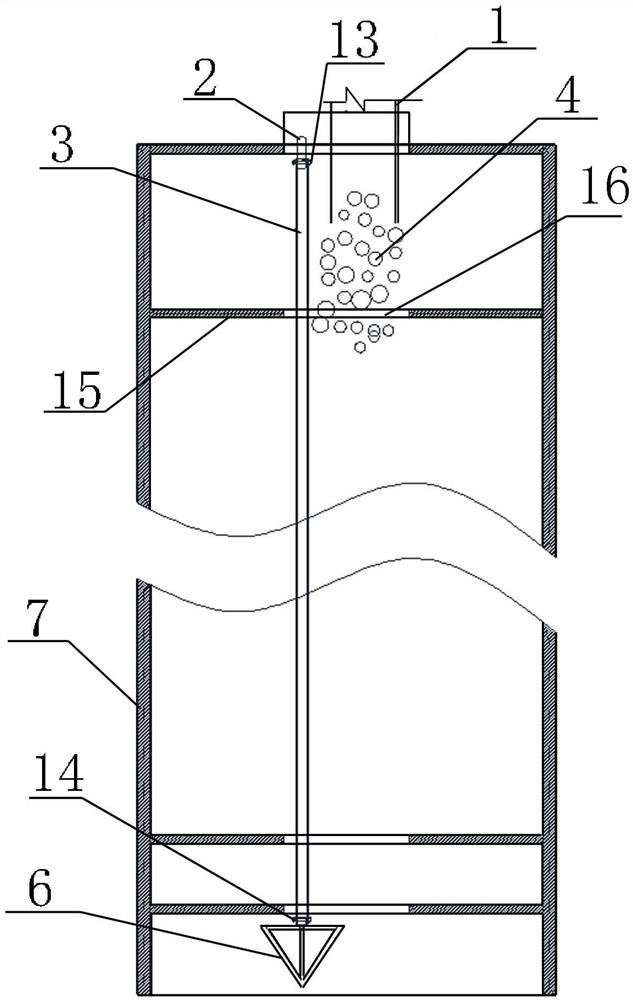

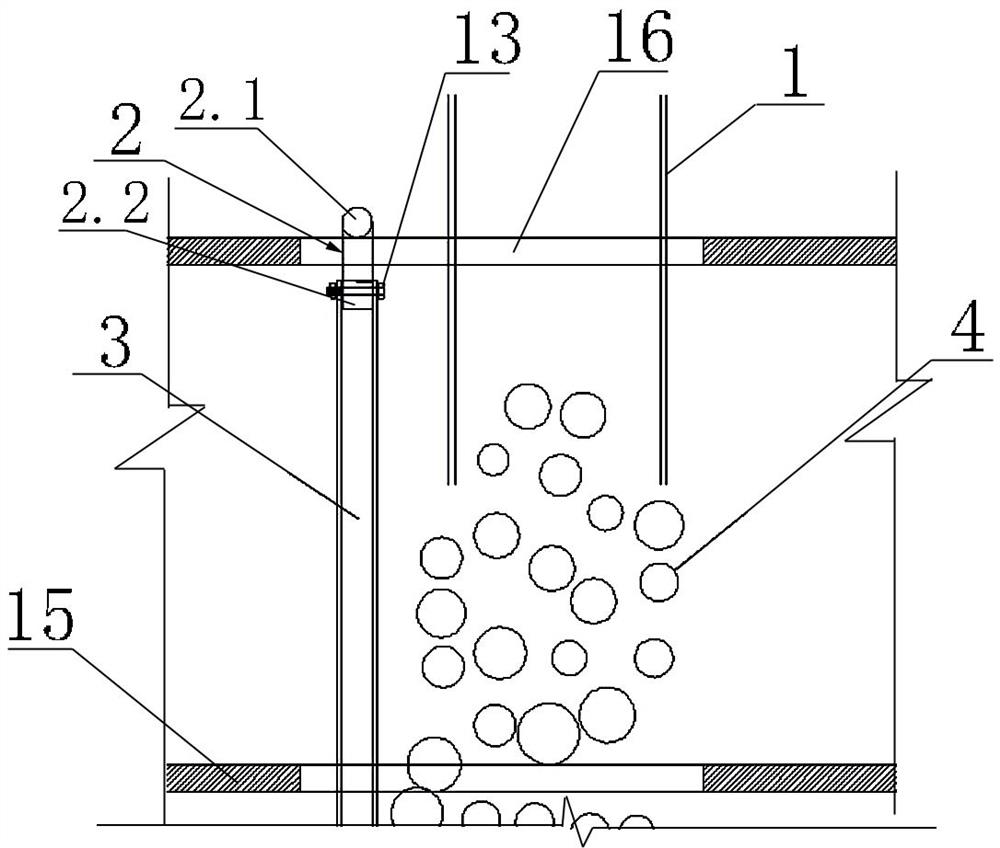

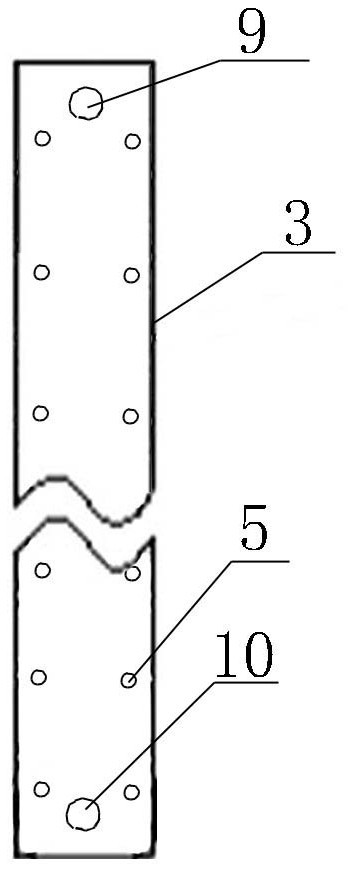

[0035] In the present embodiment, when the steel pipe concrete is pouring, the intimate and uniformity of concrete grout is realized by the exhaust device. The lower cone 6 of the exhaust pipe device uses the weight of the entire device to prevent the exhaust pipe 3. Tilt; at the top of the exhaust pipe 3 is connected to the fixing frame 2 by the bolt 2, the horizontal position of the exhaust pipe device is determined by the fixing frame 2, and the concrete pouring, the exhaust hole 5 on the exhaust pipe 3 is from the inside. The outer gradual tilt is gradually tilted to prevent the exhaust hole 5 from being blocked during concrete, and the vent hole 5 guides the column bottom air from being discharged in the exhaust pipe 3 until the grout is completed.

[0036] Such as Figure 1-8 As shown, such a steel pipe concrete pouring exhaust device is disposed in the pipe of the steel pipe 7; including a fixing frame 2, an exhaust pipe 3, and a lower cone 6; the fixing frame 2 is T-shaped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com