The position and the sequence of versatile exhausting box and flow governor on the transfusional device

A technology of flow regulator and sorting method, which is applied in the direction of flow control, control/regulation system, instrument, etc. It can solve the problems of reverse pumping gas entry, danger of infusion pipeline, exhaust dead angle, etc., and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

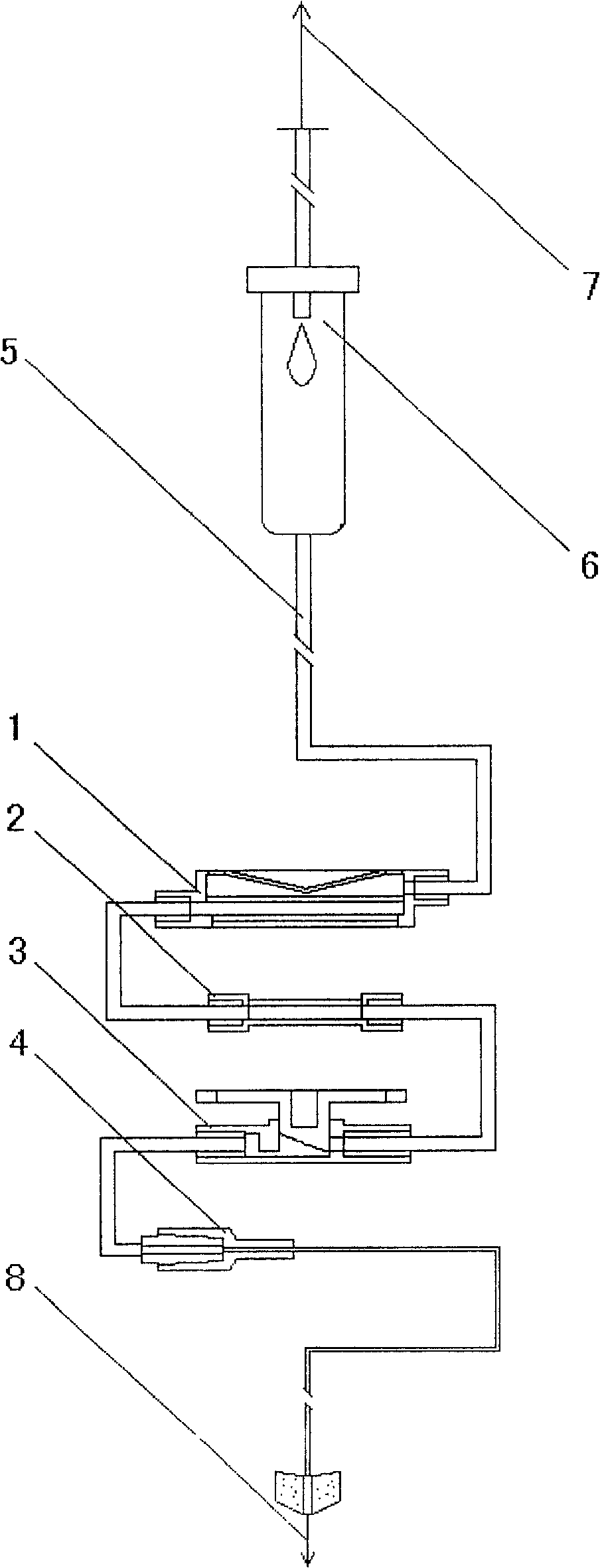

[0020] see figure 1 , the basic layout of the embodiment of this technical method comprises an exhaust filter (1), a universal exhaust box (2), a flow regulator (3), a venous needle interface (4), a dripping funnel (6), a bottle threading The needle (7), venous needle (8) and infusion line (5), the exhaust filter (1) are connected in series at the lower part of the infusion line (5), and the upstream of the exhaust filter (1) passes through the infusion line (5) Connect the drip funnel (6) and the bottle piercing needle (7), etc., and the downstream of the exhaust filter (1) is sequentially connected to the universal exhaust box (2) and the flow regulator (3) through the infusion pipeline (5) , venous needle interface (4) and venous needle (8), etc., in the form of gravity infusion, the flow regulator (3) controls the flow rate and closure of the overall pipeline.

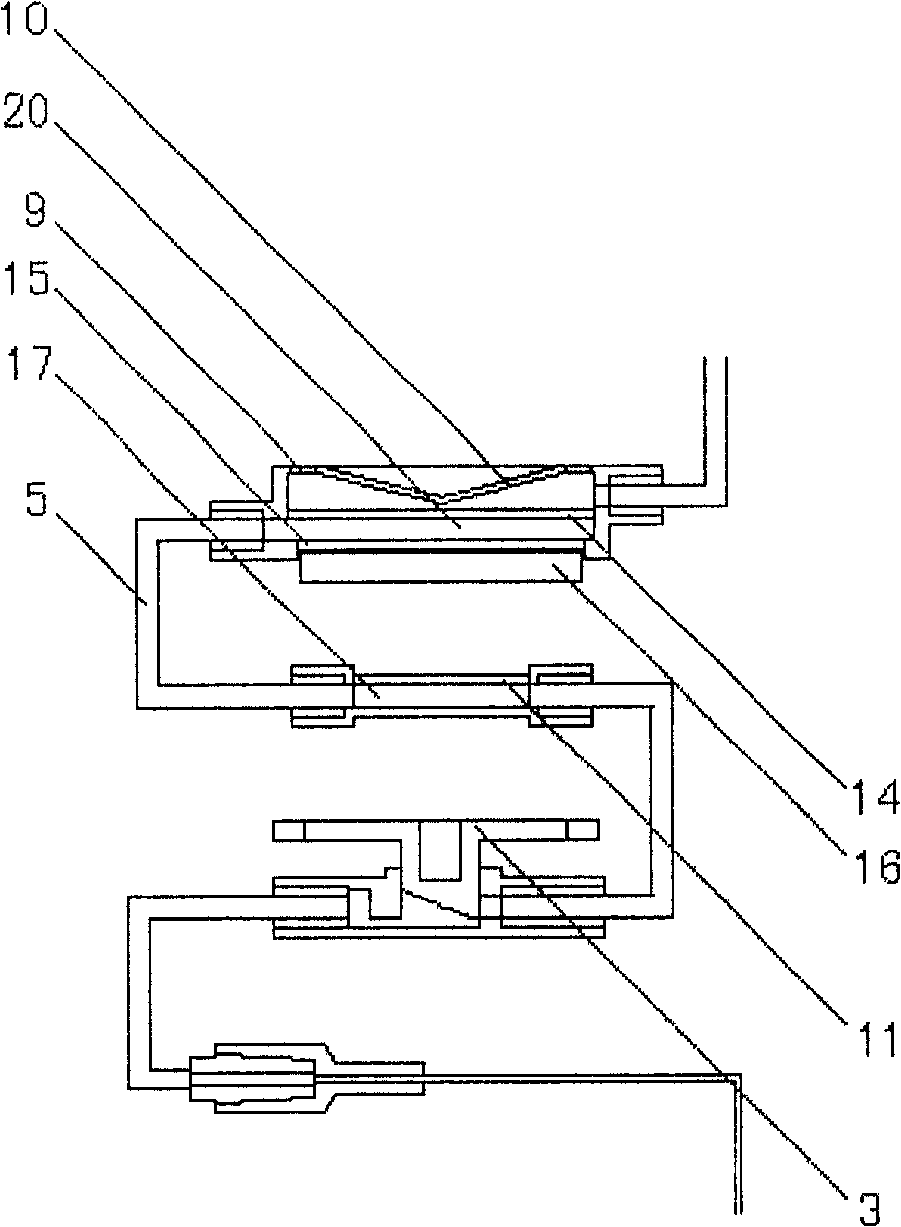

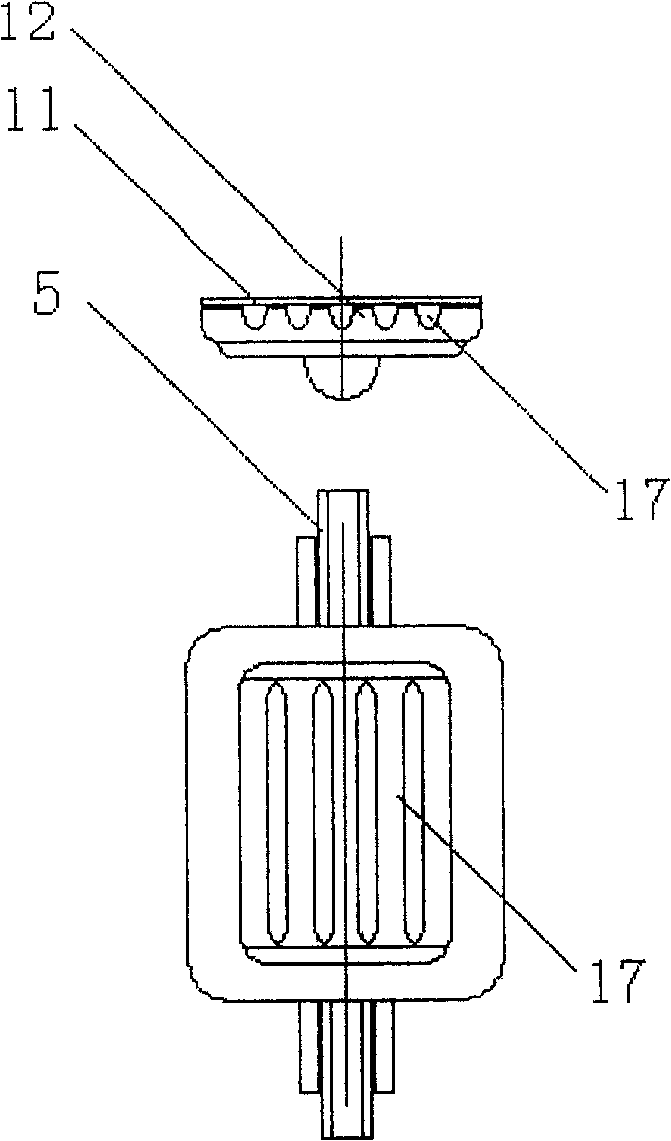

[0021] see figure 2 , this embodiment further elaborates the main forms of each structure on the basis of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com