Fuel injection mechanism of vehicle-mounted gas bottle of liquefied natural gas vehicle

A technology for liquefied natural gas and vehicle-mounted gas cylinders, which is applied in the field of fuel filling mechanisms for vehicle-mounted gas cylinders of liquefied natural gas cars. It can solve the problems of complex structure of liquefied natural gas filling guns, lack of supporting facilities, and high overall cost, and achieve simple structure , low cost, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

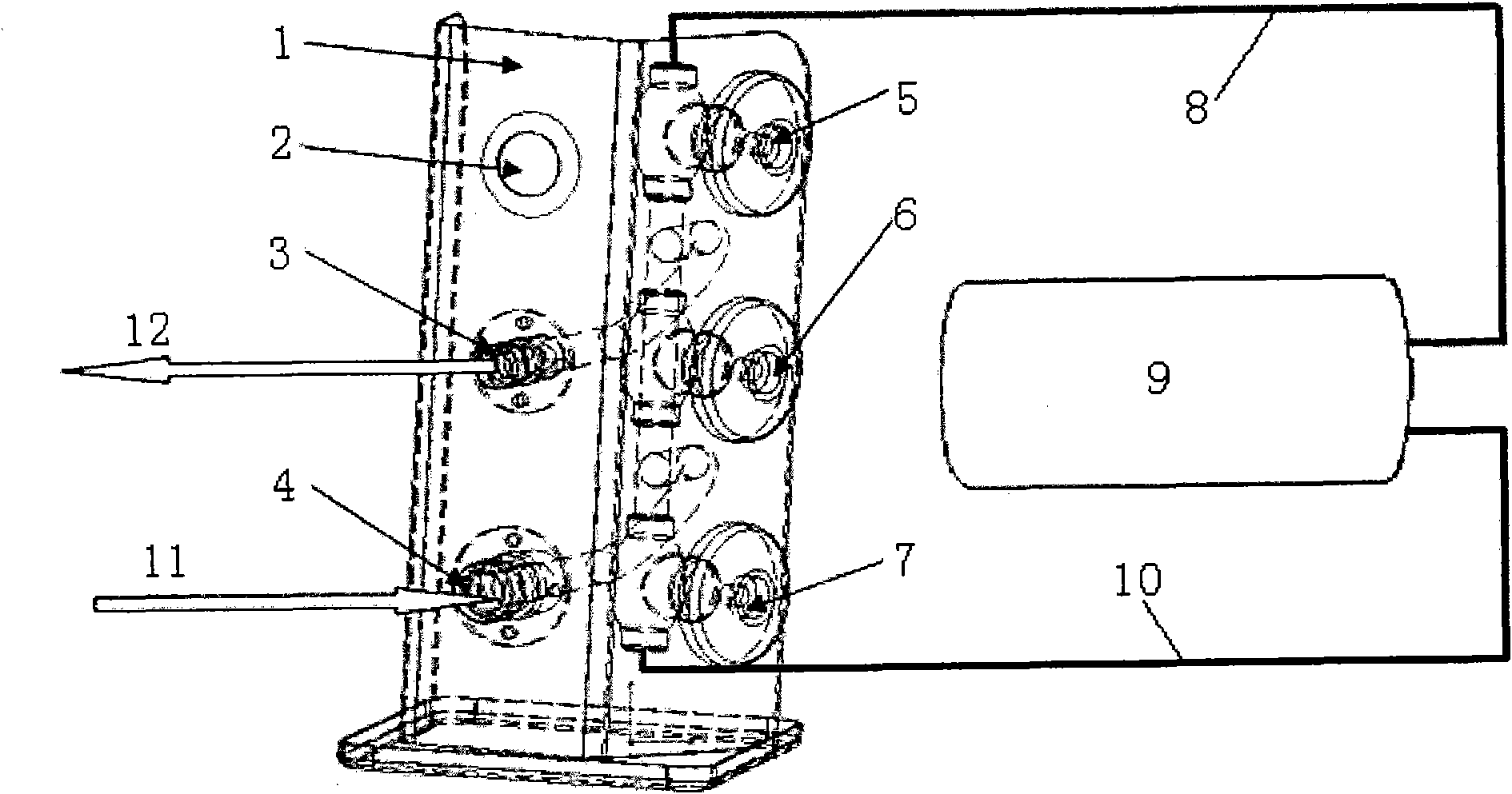

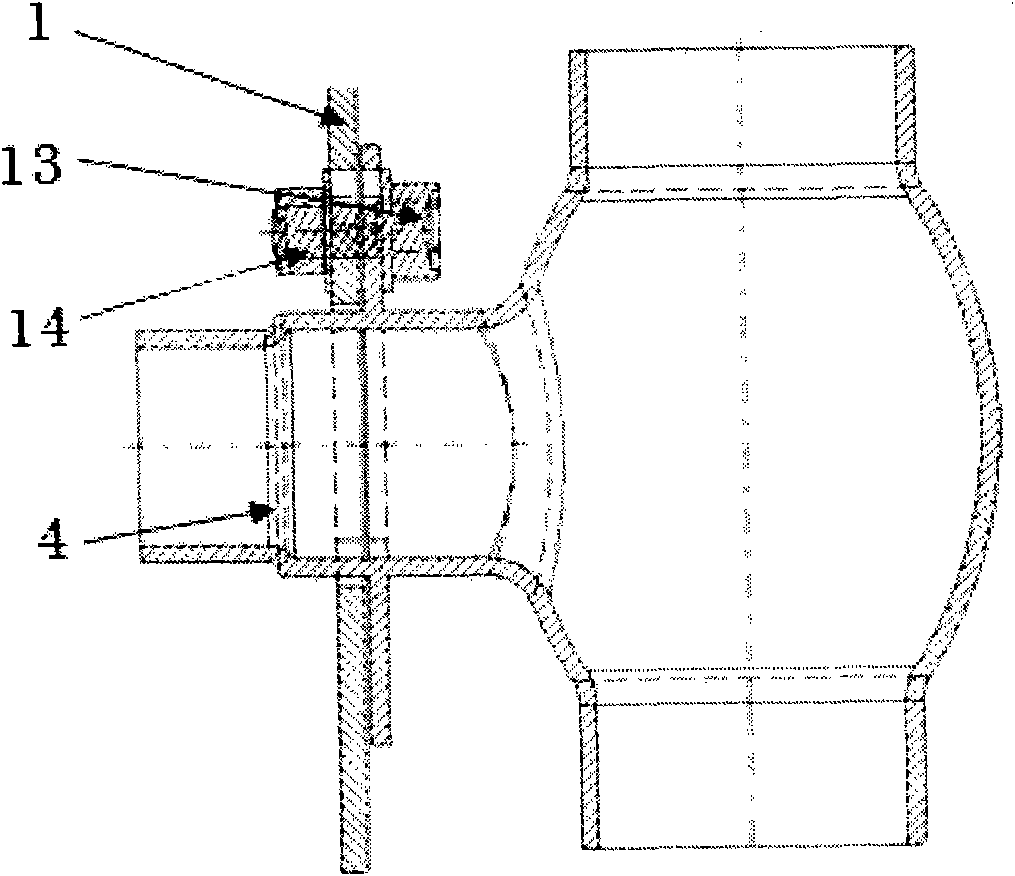

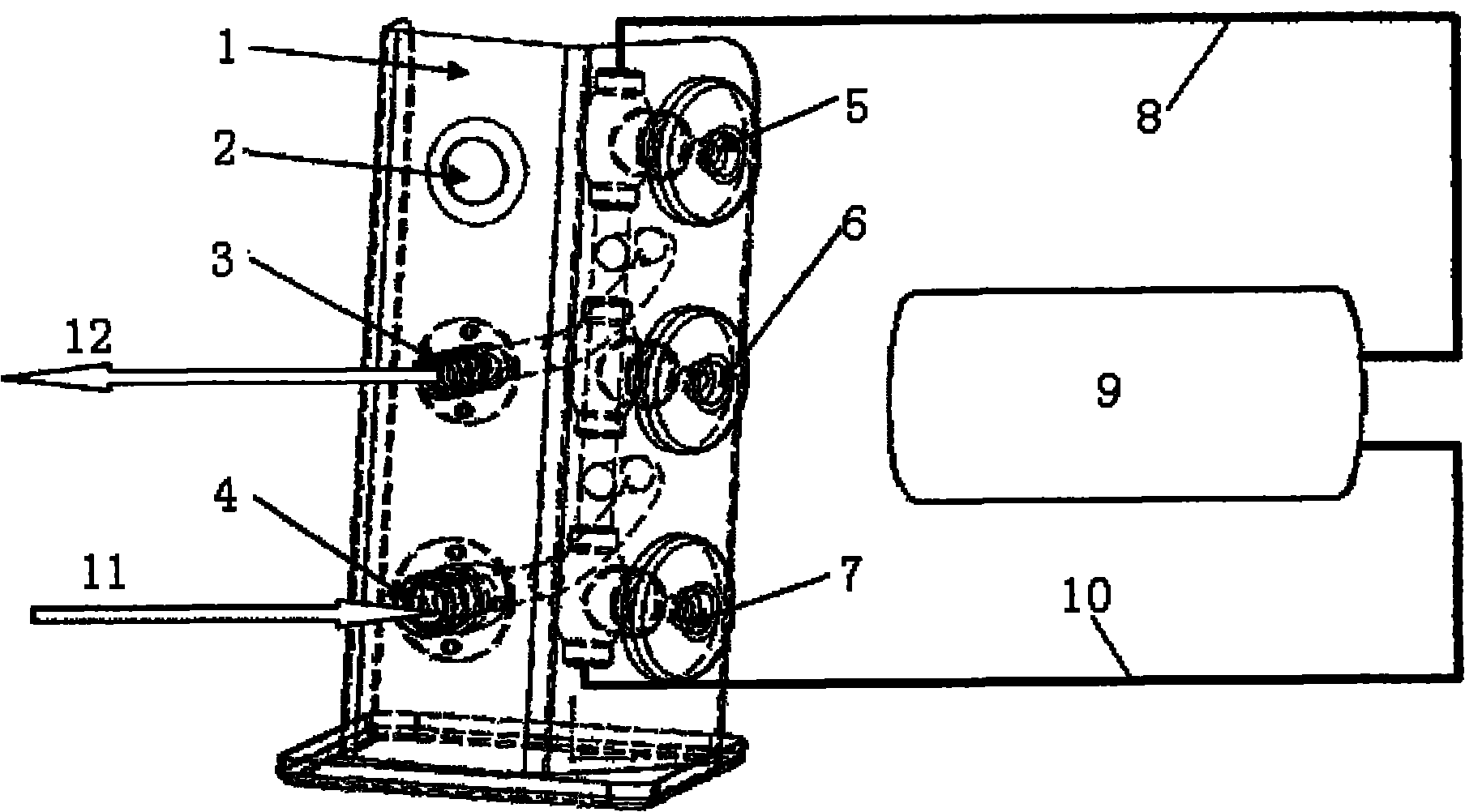

[0016] Such as Figure 1-2 As shown, it is mainly composed of two filling ports on the LNG filling panel frame, a pressure gauge and three control valves connected in series on the side. Its specific structure is as follows: 1 in the figure is a LNG filling panel frame with a pressure gauge 2, and in the LNG filling panel frame 1, a vehicle-mounted gas cylinder vent valve 5 and a filling station pipeline vent valve 6 are sequentially connected in series And the filling valve 7, the output end of the filling valve 7 is connected with the liquefied natural gas carrier gas cylinder 9 through the liquid inlet pipeline 10, and the liquefied natural gas carrier gas cylinder 9 is connected with the input end of the vehicle-mounted gas cylinder vent valve 5 through the venting pipeline 8 Connected to each other; between the vent valve 5 of the vehicle-mounted gas cylinder and the vent valve 6 of the pipeline of the filling station, a liquefied natural gas gas phase venting pipe is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com