Mixture for improving quality of rice noodles, preparation method and application thereof

A technology of mixture and rice flour, applied in the field of food processing, can solve the problems of easy sticking, easy to break, sticky soup, etc., and achieve the effect of high transparency, not easy to stick, and broken.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The raw material formula of the mixture to improve the quality of rice noodles: 0.1 kg of potato esterified cross-linked starch, 0.01 kg of soybean polysaccharide, and 0.01 kg of monoglyceride. The raw materials are directly mixed evenly. Potato esterified cross-linked starch, soybean polysaccharide and monoglyceride are all food grade.

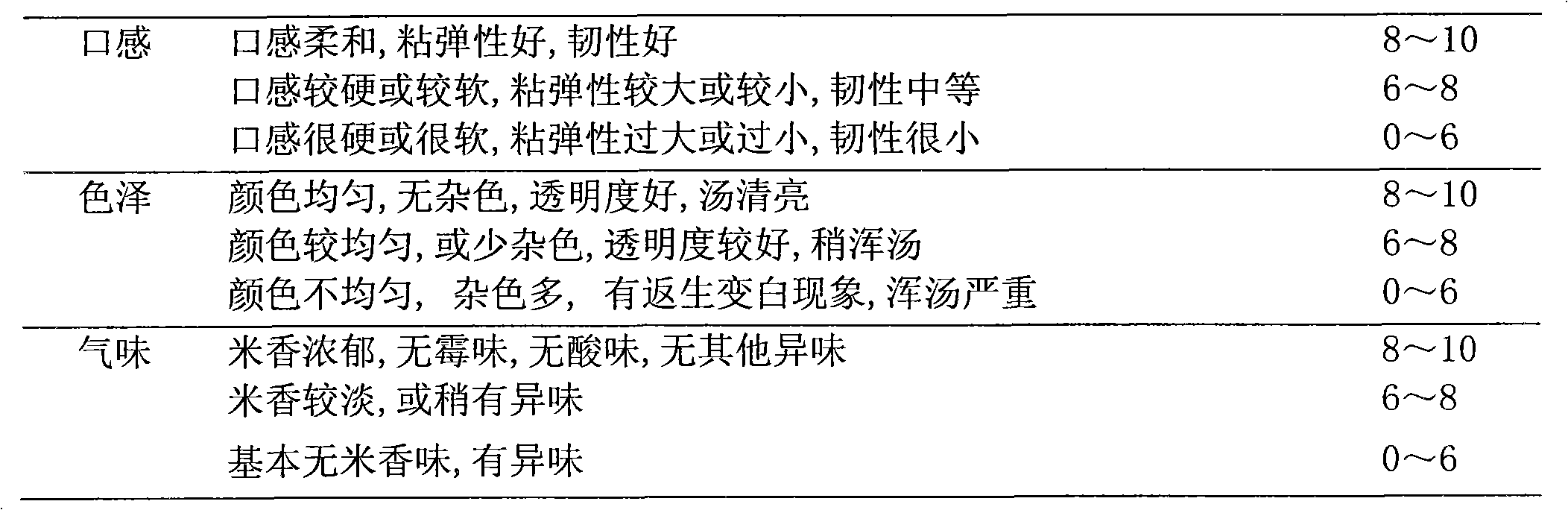

[0032] Weigh 10 kg of rice, remove impurities and wash, soak in clean water for 24 hours, drain the water, add the above-mentioned mixture to improve the quality of rice noodles, stir evenly in a mixer, and then grind the slurry to make the moisture content 40%. The screw extruder gelatinizes and extrudes into vermicelli, cools naturally at room temperature for 1 hour, re-steams at 0.6MPa steam pressure for 4 minutes, cools naturally at room temperature again for 15 minutes, cut into shreds, and dried with hot air until The moisture content can be reduced to about 13.5%. The cooking quality, cooking loss and stripping rate of the obtaine...

Embodiment 2

[0038] Preparation of the mixture: 0.4 kg of potato esterified cross-linked starch, 0.05 kg of soybean polysaccharide, 0.1 kg of monoglyceride, and 0.1 carrageenan. The raw materials are directly mixed uniformly. Potato esterified cross-linked starch, soybean polysaccharide and monoglyceride are all food grade.

[0039] Weigh 10 kg of rice, remove impurities and wash, soak in clean water for 24 hours, drain the water, add the above-mentioned mixture to improve the quality of rice noodles, stir evenly in a mixer, and then grind the slurry to make the moisture content 40%. The screw extruder gelatinizes and extrudes into vermicelli, cools naturally at room temperature for 1 hour, re-steams at 0.6MPa steam pressure for 4 minutes, cools naturally at room temperature again for 15 minutes, cut into shreds, and dried with hot air until The moisture content can be reduced to about 13.5%. The cooking quality, cooking loss and stripping rate of the obtained rice noodles were measured, and...

Embodiment 3

[0045] Preparation mixture: 0.4 kg of potato esterified cross-linked starch, 0.1 kg of soybean polysaccharide, 0.1 kg of monoglyceride, and 0.1 kg of sodium alginate, and the raw materials are directly mixed uniformly. Potato esterified cross-linked starch, soybean polysaccharide, monoglyceride and sodium alginate are all food grade.

[0046] Weigh 10 kg of rice, remove impurities and wash, soak in clean water for 24 hours, drain the water, add the above-mentioned mixture to improve the quality of rice noodles, stir evenly in a mixer, and then grind the slurry to make the moisture content 40%. The screw extruder gelatinizes and extrudes into vermicelli, cools naturally at room temperature for 1 hour, re-steams at 0.6MPa steam pressure for 4 minutes, cools naturally at room temperature again for 15 minutes, cut into shreds, and dried with hot air until The moisture content can be reduced to about 13.5%. The cooking quality, cooking loss and stripping rate of the obtained rice noo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com