Cooling equipment for large bar material

A technology for cooling equipment and rods, which is applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc. It can solve the problems that the cooling method cannot guarantee the cooling effect, etc., and achieves the improvement of rapid cooling capacity, variety, and convenient replacement quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

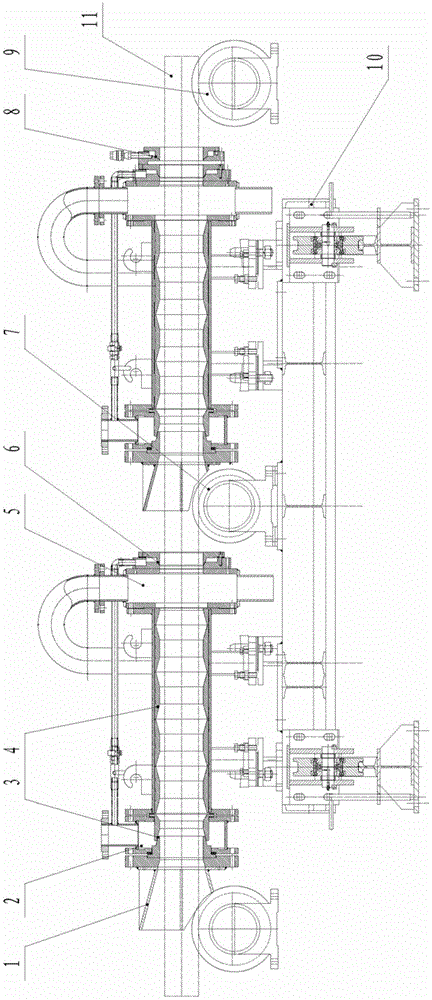

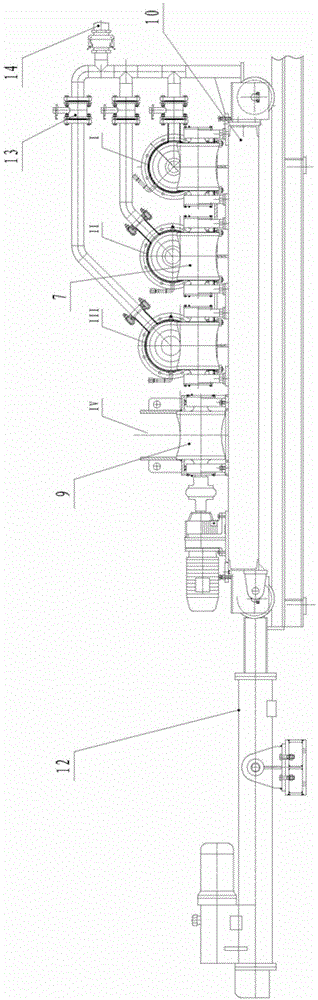

[0023] Such as figure 1 , figure 2 The structure of the present invention shown is a large-scale bar cooling equipment, which is used for cooling the bar 11 after rolling.

[0024] The large-scale bar cooling equipment of the present invention mainly includes front and rear rollers, a cooler (that is, a water-piercing body), a multi-station water-piercing trolley, a shifting drive device, a bypass roller table, a high-pressure water pump and a pipeline system, and instrument detection system, electrical control system and compressed air system.

[0025] More specifically, in order to solve the problems existing in the prior art and overcome its defects, and realize the purpose of the invention of rapid and sufficient cooling of the bar, the technical solution adopted by the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com