One-step folding forming method for honeycomb paper

A forming method and technology of honeycomb paper, applied in the direction of cardboard products, etc., can solve the problems of low production speed, difficulty in realizing the compounding of honeycomb paperboard multi-layer composite honeycomb paperboard and corrugated board, and difficulty in realizing high-speed uninterrupted continuous rolling flow operation, etc. , to achieve the effects of improving dimensional accuracy and shape accuracy, changing existing process forming methods, and quickly changing varieties and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited to the scope expressed by the examples. Parts and percentages in the examples are by dry weight unless otherwise stated.

[0019] This embodiment includes processes such as molding, gluing, folding, drying, and cutting. The following describes this embodiment in detail in conjunction with the accompanying drawings in the description:

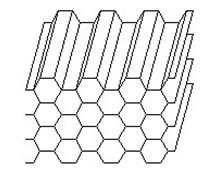

[0020] 1. First, press the base paper into a connected isosceles trapezoid with three sides equal to each other through gears, and press it into a positive V shape with a certain distance, and then press it into a reverse V shape with the same distance. The trapezoid has two 120-degree angles and Two 60-degree angles, see figure 1 ;

[0021] 2. Then apply glue on the outer surface of the upper bottom of the forward trapezoid on the left side of the positive V and on one side of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com