Modified composite core rod and manufacturing method thereof

A composite mandrel and manufacturing method technology, which is applied in the direction of cable/conductor manufacturing, conductor, insulated cable, etc., can solve the problem that there is no mature manufacturing method for mass production of twisted composite mandrels, and the tension of each strand is difficult to achieve uniformity , complex manufacturing process and other issues, to achieve the effect of uniform force, improved flexibility, and improved bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

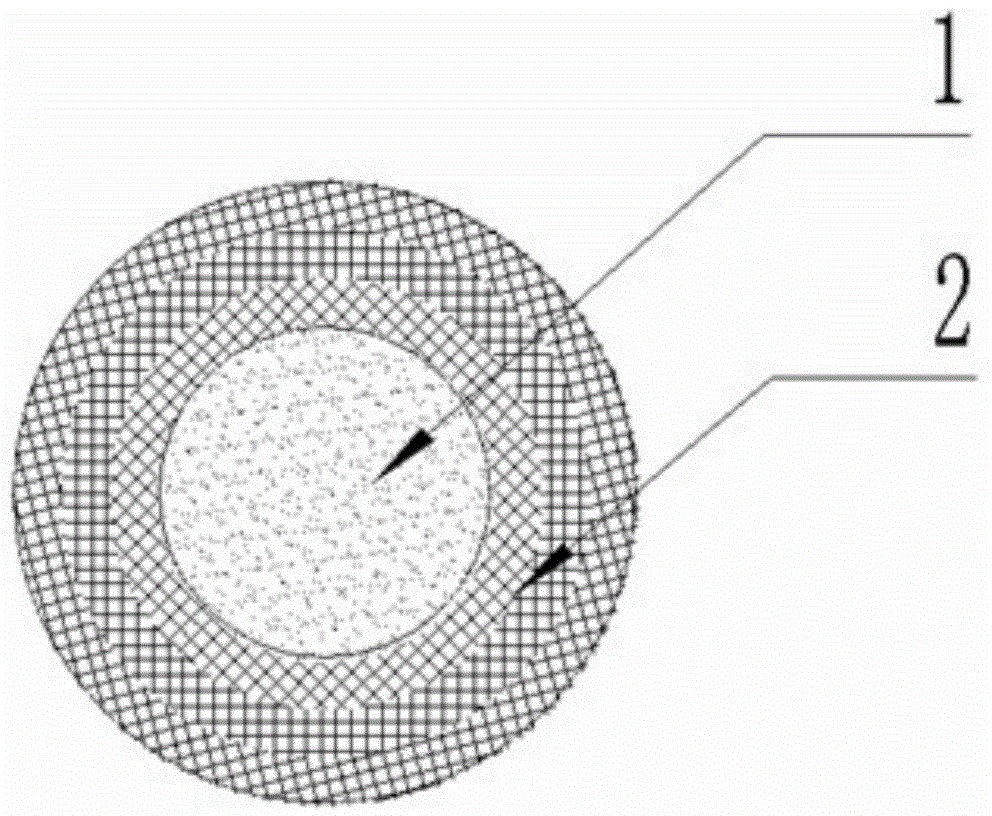

[0029] See figure 1 , a modified composite core of this embodiment, comprising a fiber inner core 1 and a fiber outer layer 2 wound or braided outside the inner core 1 and a thermosetting or thermoplastic material uniformly embedded in the fiber inner core 1 and fiber outer layer 2 High temperature resistant resin; fiber inner core 1 is composed of multiple longitudinal fibers with an outer diameter of 5.0-11.0 mm; fiber outer layer 2 has at least two layers; fiber inner core 1 and fiber outer layer 2 are cured by resin to form a whole; composite The outer diameter of the core is 10.0mm-20.0mm; the Tg of the high-temperature-resistant resin is ≥ 90°C, and the volume fraction of the resin is 25%-40%. The fibers of the fiber inner core 1 and the fiber outer layer 2 are high-strength fibers with a strength of 2000-6000 MPa and an elastic modulus of 30-250 GPa, consisting of a single fiber or a mixture of two or more fiber materials.

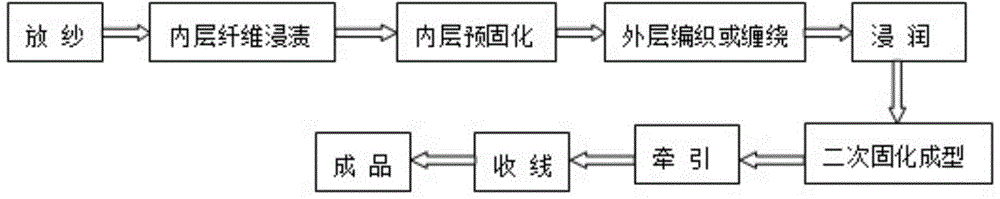

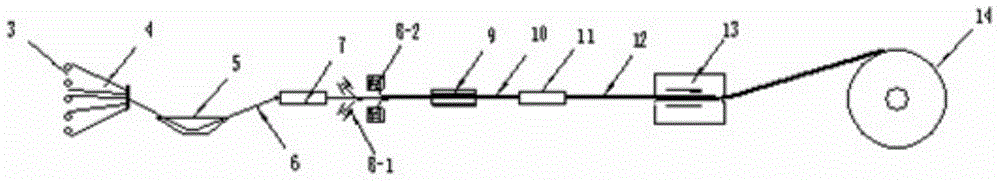

[0030] See figure 2 and image 3 , the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com