Vacuum angle seat valve

An angle seat valve, vacuum technology, applied in the direction of lift valve, valve details, valve device, etc., to achieve the effect of low cost, light weight, and ease the difficulty of model selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

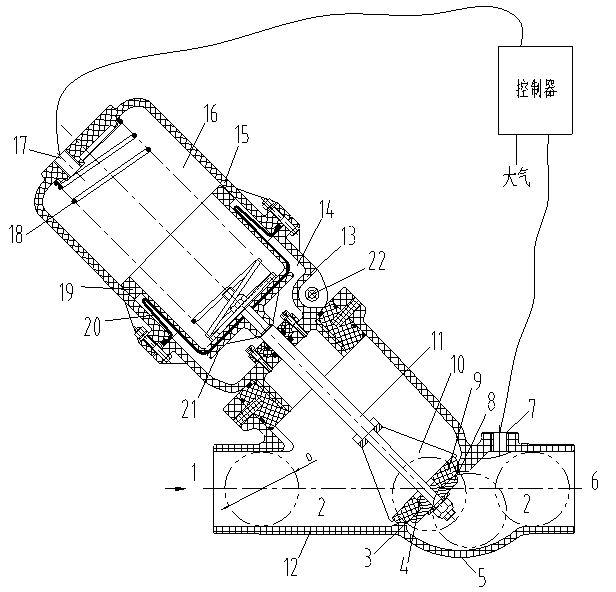

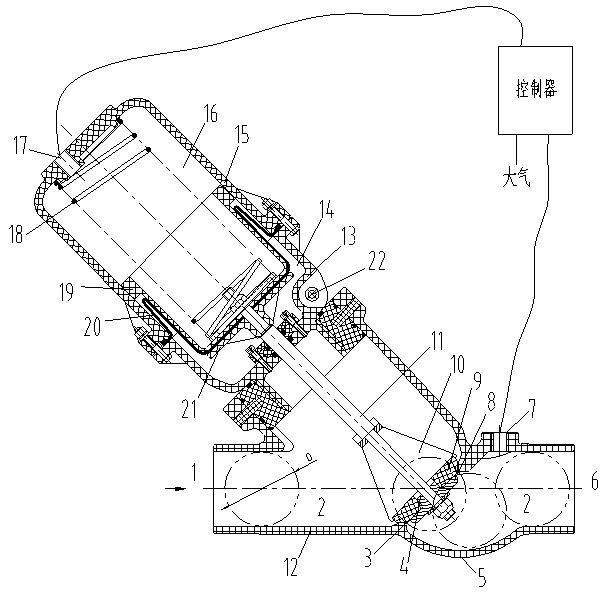

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] figure 1 Among them, the vacuum angle seat valve is mainly composed of a valve body 12, a control cavity 15, a free cavity 13, a valve core 4, a spring 18, a rubber diaphragm 20, a piston cylinder 19 and corresponding connecting, fastening and sealing components. 12. The control cavity 15 and the free cavity 13 are sealed at intervals to form the medium cavity 2, the free cavity 14 and the control cavity 16 respectively; usually the inlet 1 of the valve is connected to the medium to be transported, and the outlet 6 is connected to the vacuum source. Due to the action of the spring 18, the free state of the valve is closed, separating the conveyed medium from the vacuum source.

[0023] When the valve needs to be opened to transport medium, another vacuum controller 23 connects the vacuum port 7 with the control chamber interface 17. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com