Continuous extrusion method of stacked assembling die with reversed cone angle and equipment

An extrusion method and combined mold technology, applied in the direction of metal extrusion molds, etc., can solve the problems of reducing the service life of the cavity, damaging the cavity, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

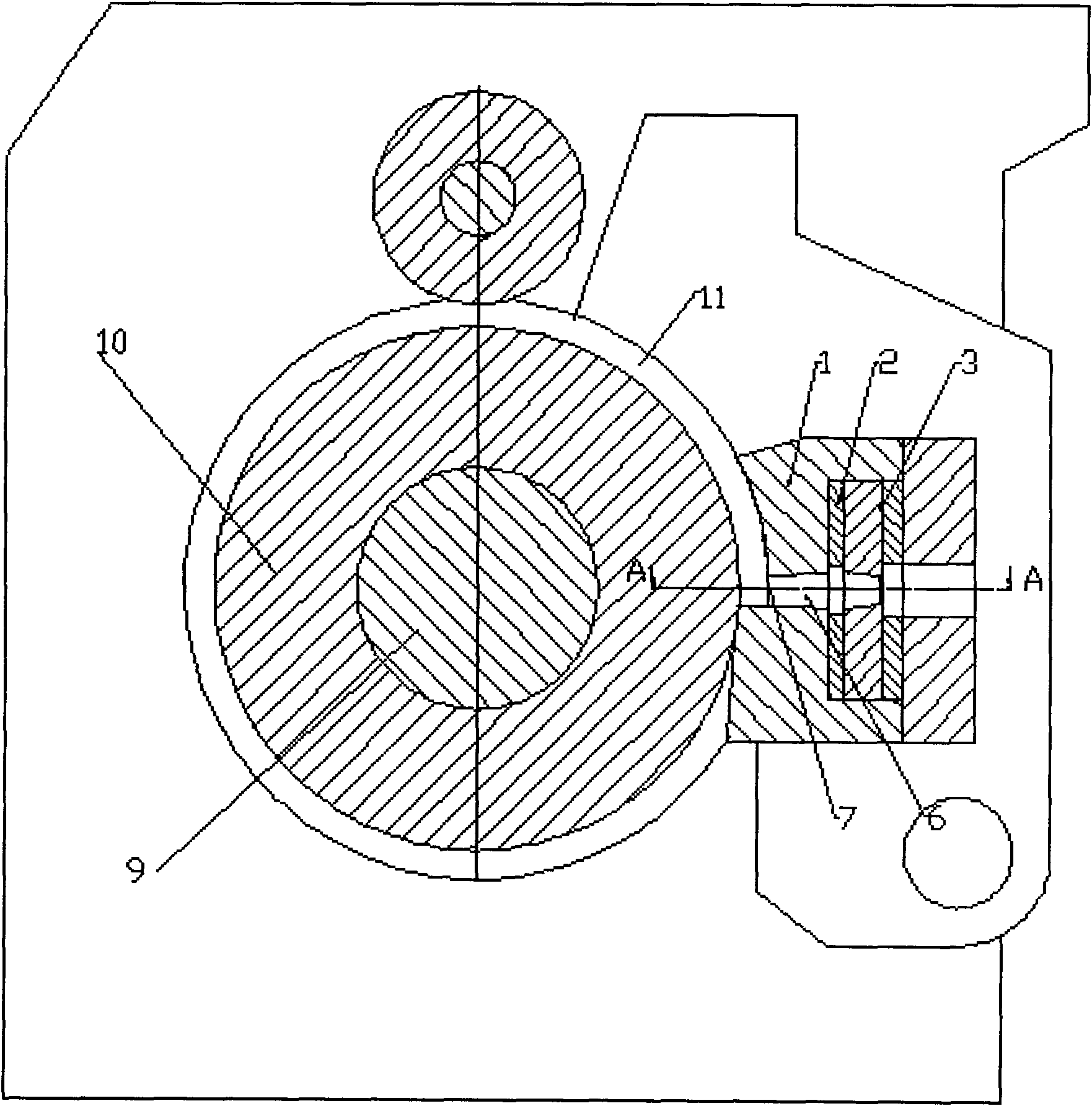

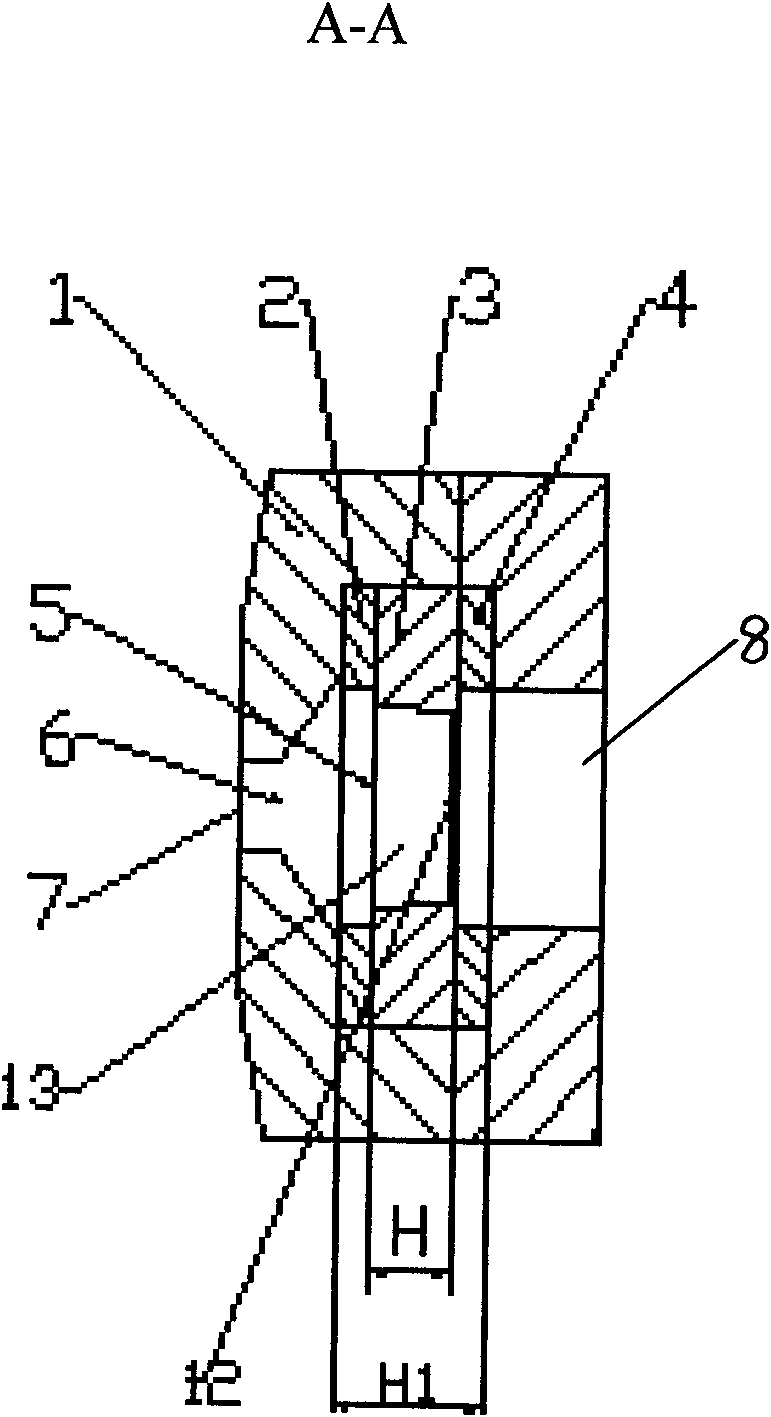

[0023] Such as figure 1 As shown in the continuous extrusion equipment with superimposed combined molds with inverted cone angles, an extrusion wheel 10 with a circumferential groove 11 is installed on the rotating shaft 9, and a mold assembly is installed in the cavity 1, and the mold assembly The total height remains unchanged. The mold assembly includes an inverted cone angle mold 3. On the blank inlet side of the inverted cone angle mold 3, there is a cone angle 13, and the angle is 1 to 10°. The height H of the inverted cone angle mold is the mold The total height H1 of the assembly, the cavity feed port 6 and the discharge port 8 are connected with the mold assembly, and the other end surface 7 of the feed port is connected with the groove 11 of the extrusion wheel.

Embodiment 2

[0025] The continuous extrusion equipment with stacked combined dies with inverted cone angles, the basic structure is the same as that of embodiment 1, the difference is that the die pad 2 is superimposed and installed in front of the inverted cone angle mold 3, and stacked behind the outlet 12 of the inverted cone angle mold 3 The mold pad 4 is installed, the mold pad 2, the inverted cone mold 3 and the mold pad 4 constitute the mold assembly, the total height H1 of the mold assembly is constant, and the height H of the inverted cone mold 3 varies with the product size, so The mold height H is different for products of different sizes, that is, non-equal height molds; the peripheral dimension of the mold pad 2 hole is 2 to 20 mm larger than the peripheral dimension of the reverse taper mold 3 inlet 5, and the peripheral dimension of the mold pad 4 hole is larger than The peripheral dimension of the outlet of the inverted taper mold 3 is 2 to 20 mm larger.

[0026] The height...

Embodiment 3

[0028] Adopt embodiment 1 ( figure 2 The shown cavity and mold) equipment carry out continuous extrusion of copper material, that is, the continuous extrusion method of superimposed combined mold with inverted cone angle: the height of the mold assembly of the inverted cone angle mold remains unchanged, and after the billet enters the mold assembly, The maximum sectional area of the extruded product can be 9 times larger than the sectional area of the billet, and at the same time, the height of the inverted cone die should be shortened as much as possible.

[0029] The 20mm copper rod is used as the blank on the 400 continuous extrusion machine to produce copper bars of various specifications from 25mm to 130mm in width, all using one cavity. During the production process, the inverted cone angle of the mold is 3°, and the inverted cone The height dimension H of the corner mold varies from 10mm to 47mm, keeping H1 unchanged at 47mm, and according to the size of the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com