Efficient reformer for autothermal reforming of methane

A technology of autothermal reforming and reformer, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as failure to achieve reforming effect, increase device complexity, increase cost input, etc., and achieve improved Heat transfer efficiency, increased heat absorption, effect of increased residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

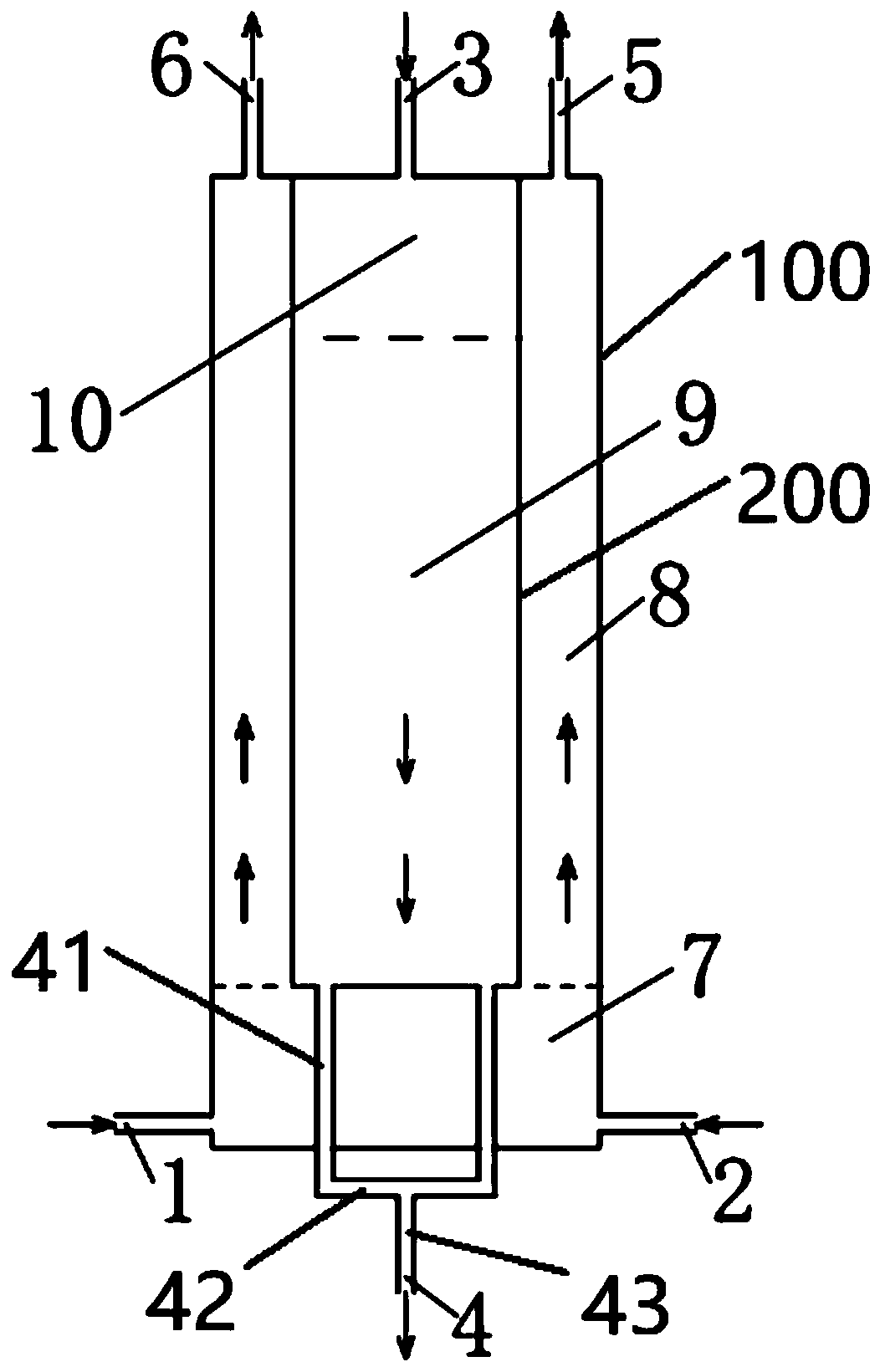

[0029] see figure 1 As shown, the present invention provides a high-efficiency reformer for methane autothermal reforming, which includes an outer cylinder 100 and an inner cylinder 200; the outer cylinder 100 and the inner cylinder 200 are cylindrical cylinders arranged concentrically.

[0030] The annular space between the outer cylinder 100 and the inner cylinder 200 includes a combustion chamber 8 on the upper part for combustion and heat supply and a combustion buffer chamber 7 on the lower part; the cylindrical space inside the inner cylinder 200 includes a reforming chamber on the upper part. The buffer chamber 10 and the reforming chamber 9 located at the lower part of the reforming buffer chamber 10 are used for reforming and producing hydrogen.

[0031] The two ends of the bottom of the combustion buffer chamber 7 are provided with combustion raw material inlets 1, 2; the inlet direction of the combustion raw material inlets 1, 2 is perpendicular to the axial directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com