Negative pressure soda liquor absorption technique for oxides of nitrogen waste gas

A technology for lye absorption and nitrogen oxides, which is applied in the fields of emission reduction, energy saving and environmental protection, can solve the problems of high storage and transportation costs, low value of salt products, and large airflow resistance, and achieves high utilization rate, good effect, and reduced The effect of acid depletion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

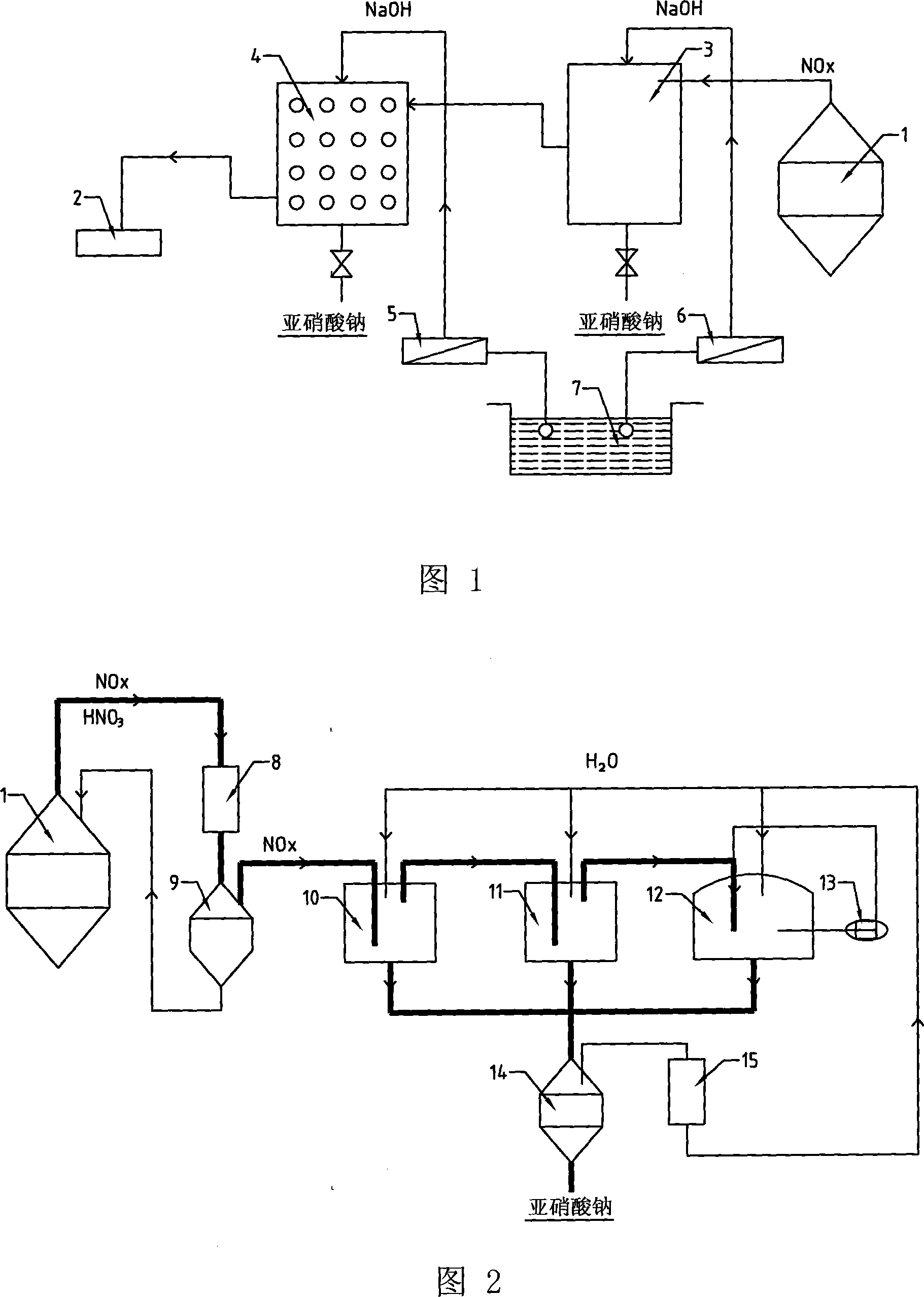

[0027] This embodiment is: a nitrogen oxide waste gas negative pressure lye absorption process, which is mainly composed of a combination of condensation recovery section, negative pressure absorption section and comprehensive recovery section; its process flow is as follows:

[0028] a Condenser 8 is used in the condensation recovery section to combine the nitric acid evaporated by the reaction heat of nitration reactor 1 and the NO produced by nitration reaction XThe gas is condensed, and the evaporated nitric acid is condensed into dilute nitric acid and enters the receiving tank 9 for recovery; the inlet temperature of the condenser is controlled to be 80-90°C, the outlet temperature is ≤40°C, and the pressure is minus 0.05-0.1Mpa; the dilute nitric acid recovered by the receiving tank 9 is Return to nitration reactor 1 to supplement the acid consumption of nitration reactor 1; non-condensable NO X The gas enters the negative pressure absorption section;

[0029] The b ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com