Multi-injection-tube type fire sheet

A technology of ejector tubes and flakes, which is applied in the direction of gas fuel burners, combustion methods, combustion types, etc., can solve the problems affecting the ejection ability, the number of ejector tubes is small, and the premixed air is too much, so as to improve the flow uniformity effect, improvement of ejection ability, and effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

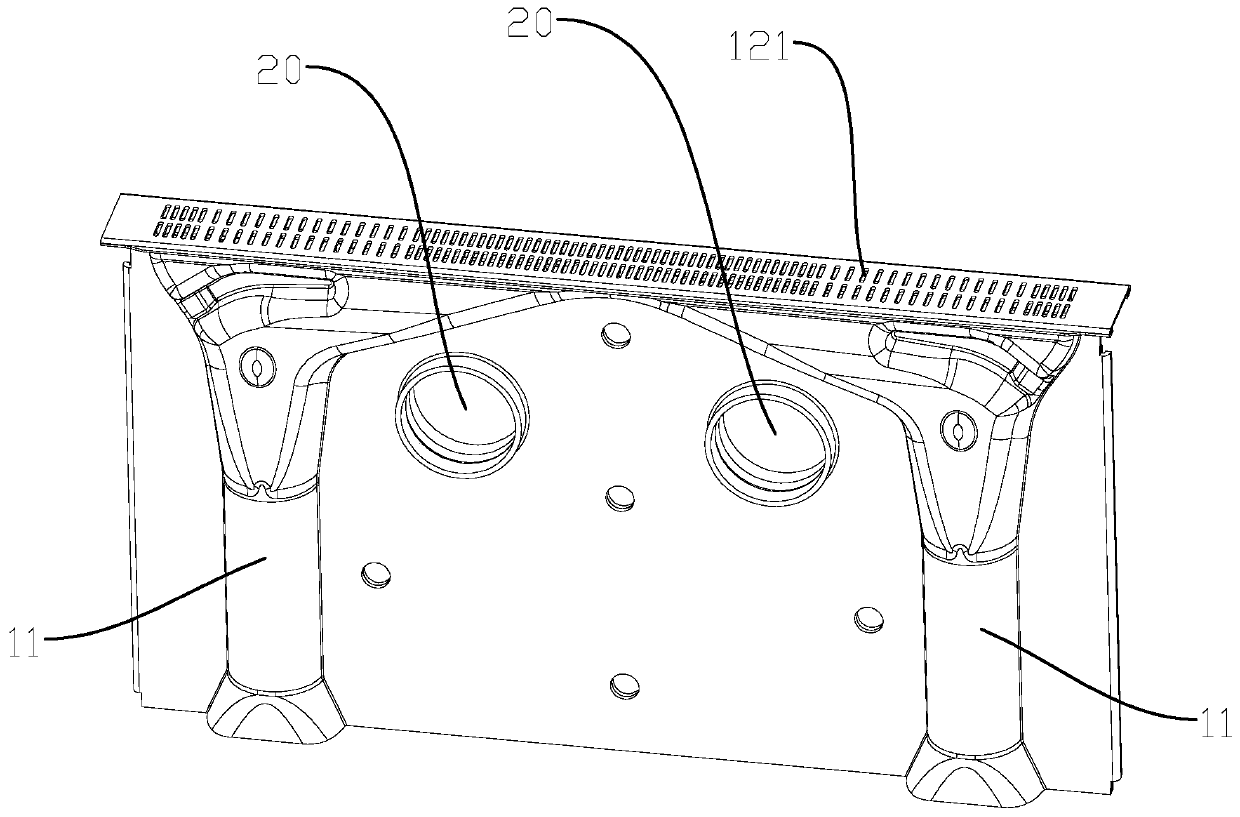

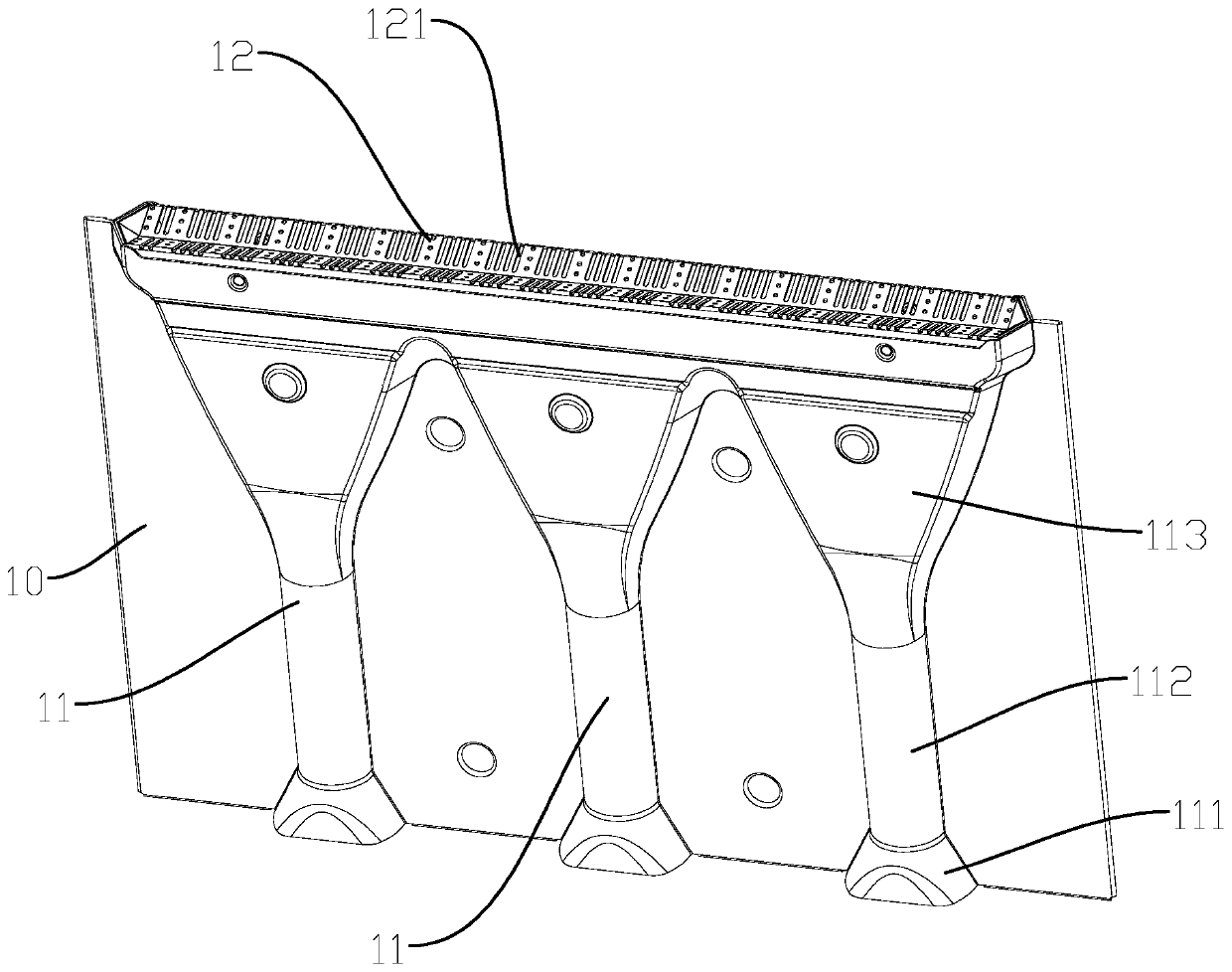

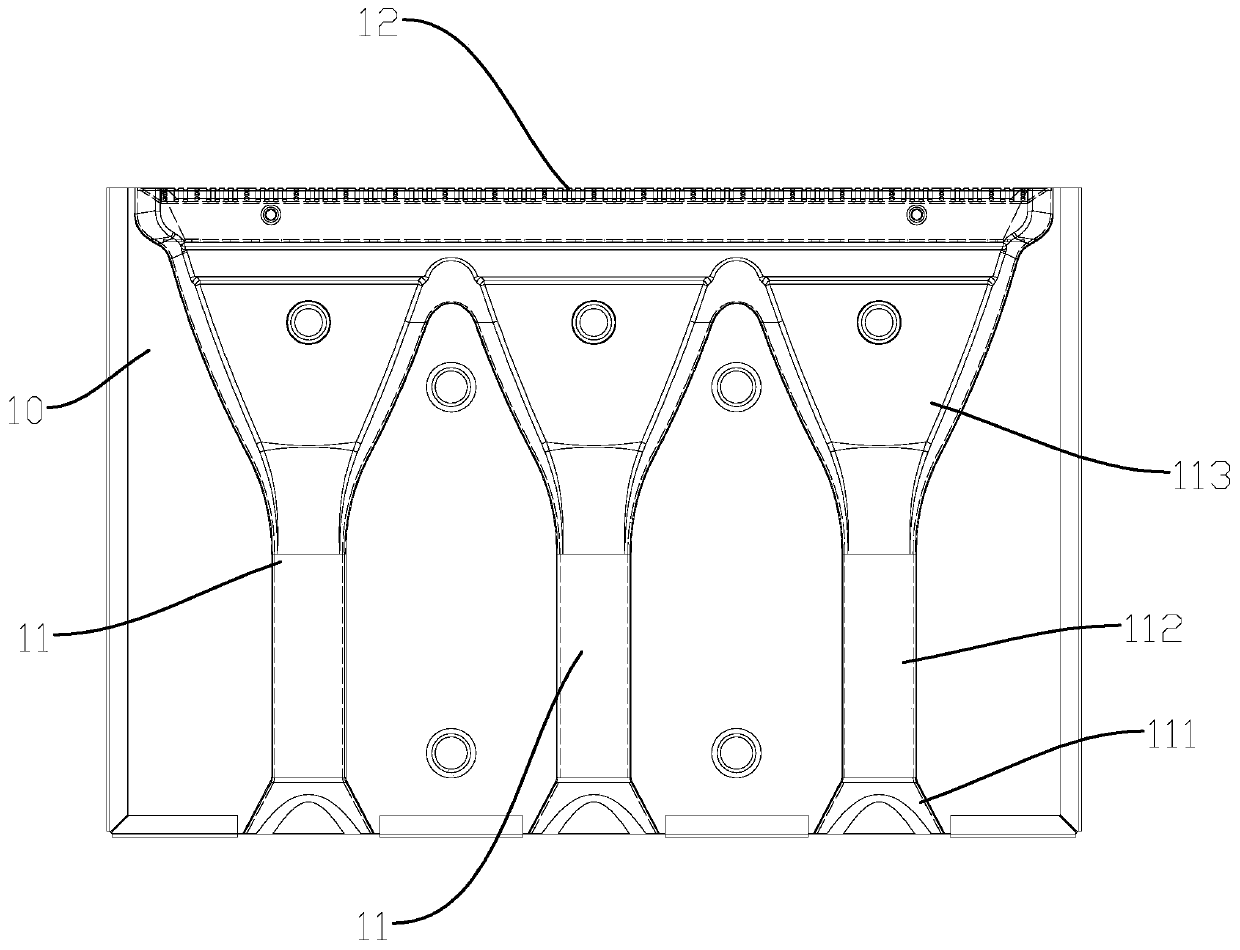

[0020] refer to Figure 2 to Figure 3 , a kind of multi-ejector tube type fire piece, comprises fire piece main body 10, and the top of fire piece main body 10 has combustion part 12, and combustion part 12 is provided with fire hole 121, is characterized in that: fire piece main body 10 is provided with from left to right Several vertical gas flow passages 11 evenly distributed to the right, the gas flow passage 11 includes an injection pipe and a gas chamber 113 located above the injection pipe and communicating with the injection pipe, the gas flow passage 11 is about its vertical central plane bilateral symmetry. In the present invention, since the gas flow channels 11 are evenly distributed, and each gas flow channel 11 is left-right symmetrical, it can effectively reduce the obstruction of the gas flow channels 11 to the air flow, improve the ejection ability, help to improve the air-fuel ratio, and effectively Improve the flow equalization effect of the fire piece, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com