Chip layout structure of half-bridge IGBT module

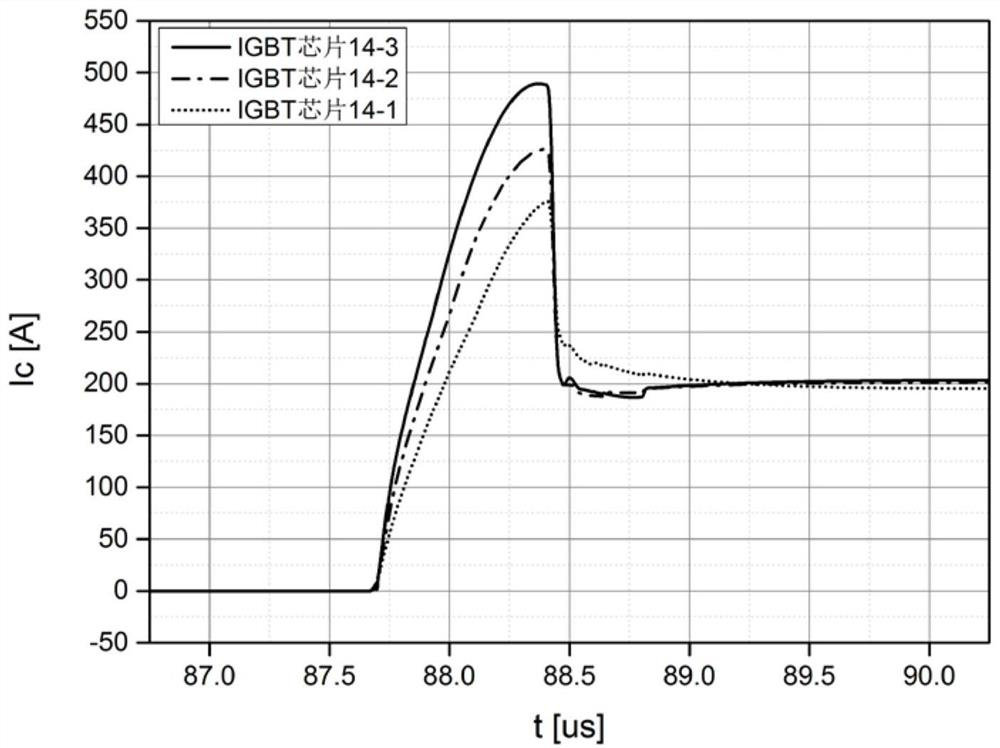

A chip layout and chip technology, applied in semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve problems such as large difference in the peak value of turn-on current, reducing the rate of difference in peak value of turn-on current between chips, and easy bonding process. , to reduce the impact, facilitate long-term stable operation, and improve the current sharing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

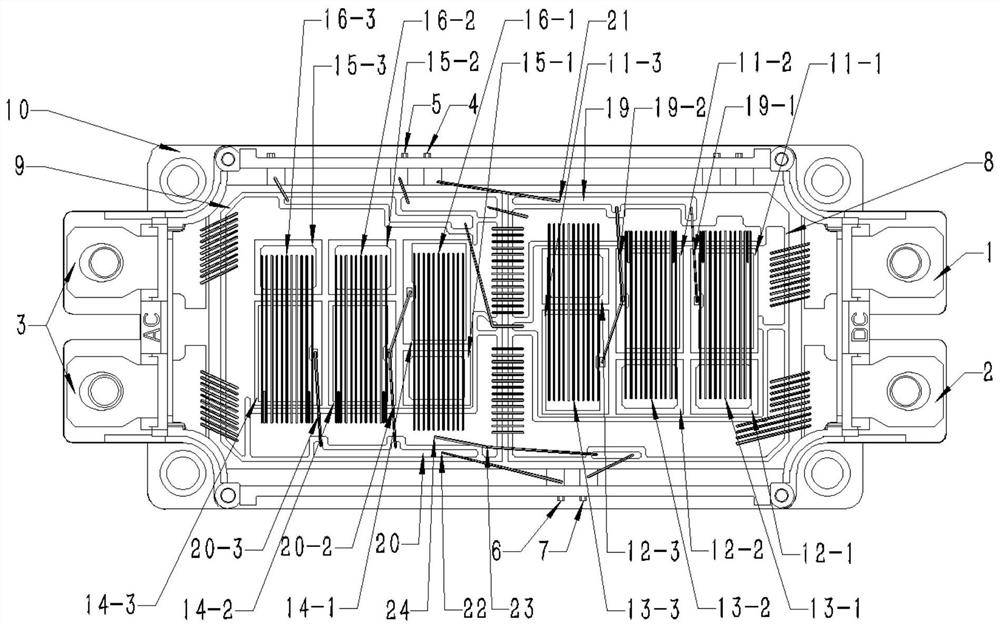

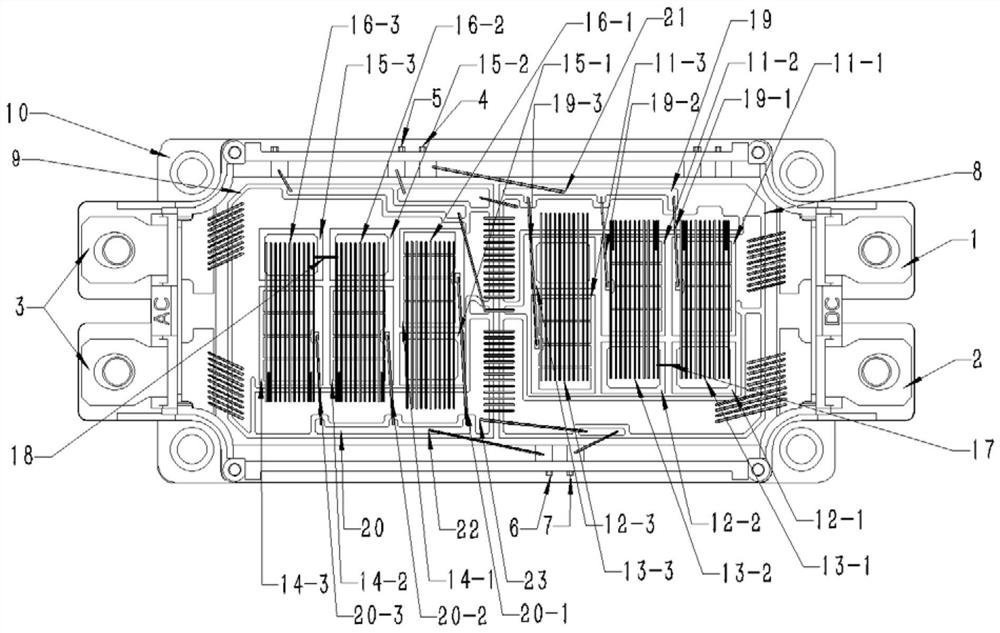

[0024] The present invention provides a new chip layout structure of the half-bridge IGBT module, by changing the position of the gate of the IGBT chip and the position of the gate bonding wire on the gate signal copper layer, so as to reduce the peak value of the turn-on current between the chips purpose of differential rate.

[0025] Concrete structure of the present invention is:

[0026]A chip layout structure of a half-bridge IGBT module, including a positive terminal, a negative terminal, and an output terminal connected to an external circuit when in use; an upper bridge signal terminal and its return line terminal, and a lower bridge signal terminal connected to a drive control circuit when in use and its return terminals. The upper and lower half bridges of the IGBT module are composed of three sets of IGBT chips and FRD chips connected in antiparallel to them. The upper bridge IGBT chip and the FRD chip are connected on the front side of the chip through the bondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com