Liquid collecting ring on body part of thrust chamber of liquid rocket engine

A liquid rocket and liquid collecting ring technology, applied in the field of liquid collecting rings, can solve the problems of poor welding sealing performance of the thrust chamber body, and achieve the effects of high assembly clearance control accuracy, favorable flow sharing, and good strength and rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

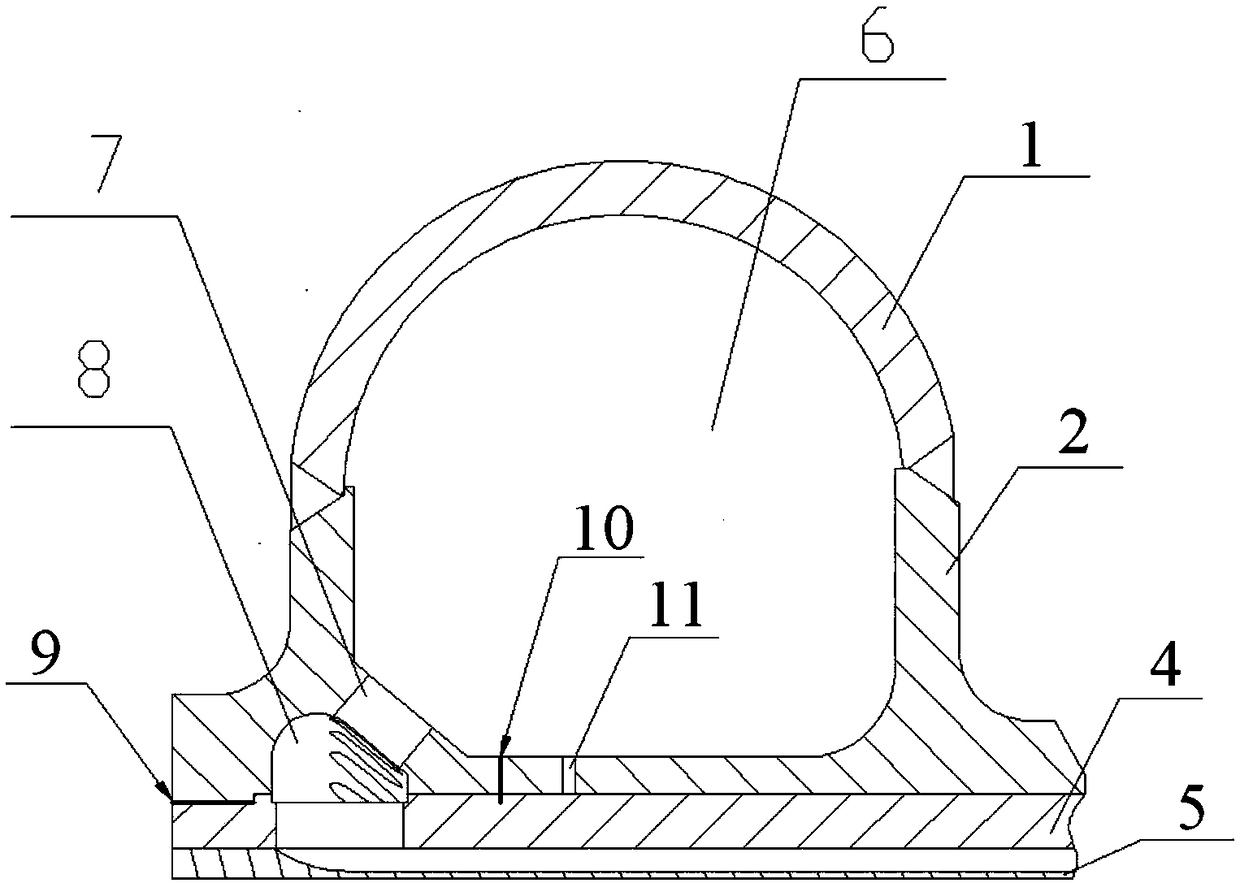

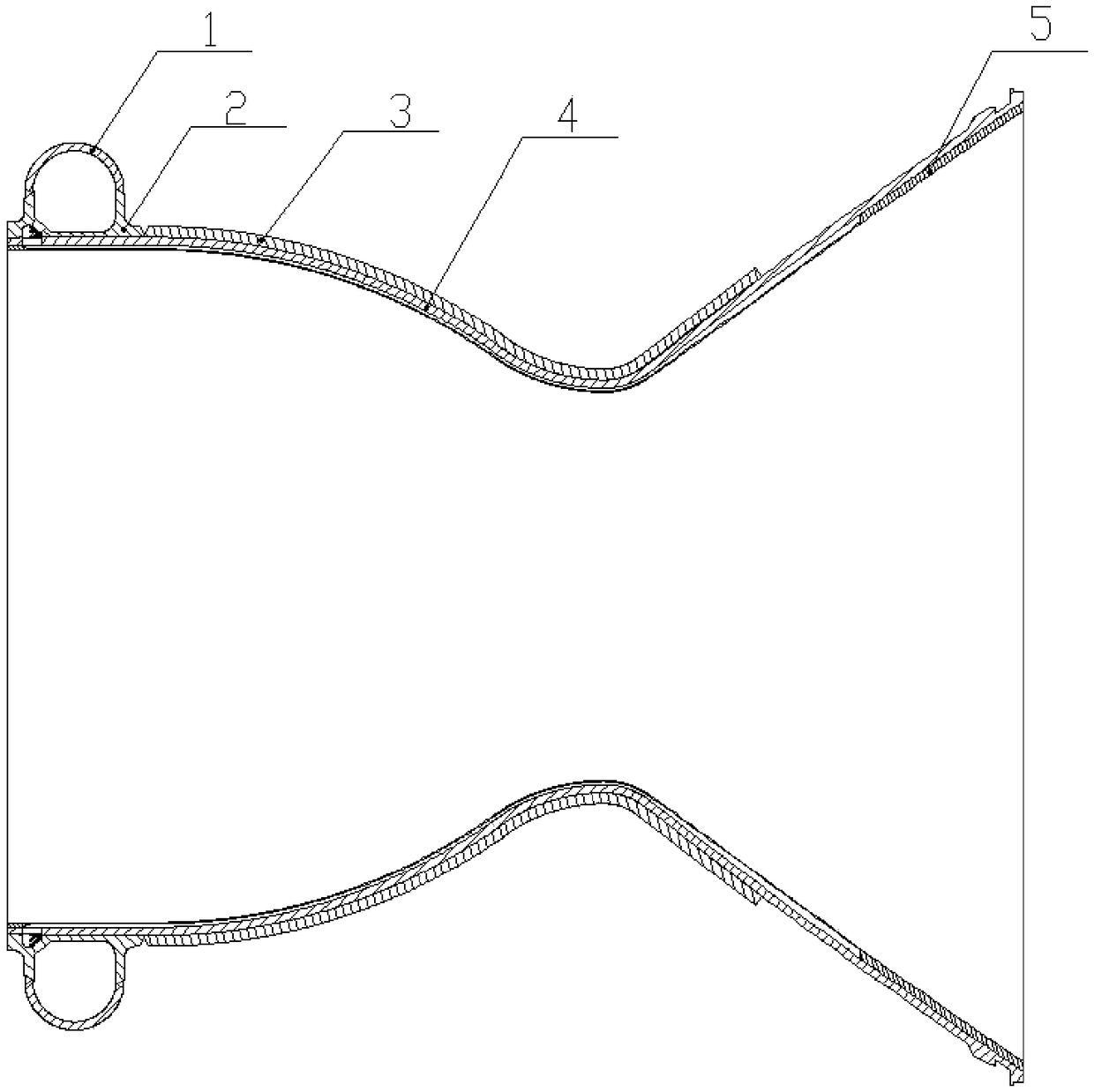

[0030] A liquid collecting ring on the body of a thrust chamber of a liquid rocket engine. A small collecting cavity is formed through a single hump-shaped liquid collecting groove 8 and the optimized design of radial holes 7 has good flow equalization capacity and small flow resistance loss; specifically, the liquid collecting Ring upper cover 1, liquid collecting ring lower cover 2; liquid collecting ring lower cover 2 is provided with radial hole 7, collection groove 8, leak detection hole 11. The entire liquid collecting ring is made of GH4169 material, wherein the liquid collecting ring lower cover 2 is integrally machined by forging, and the liquid collecting ring upper cover 1 and the liquid collecting ring lower cover 2 can be produced in parallel, which is beneficial to shorten the processing cycle.

[0031] The cross section of the liquid collecting ring upper cover 1 is semicircular; the cross section of the liquid collecting ring lower cover 2 has a concave U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com