Mixing and flow-homogenizing structural body

A structure and equalization layer technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as uneven distribution of air flow and uneven mixing of ammonia gas, and achieve enhanced flow equalization effect, uniform distribution, and increased mixing The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

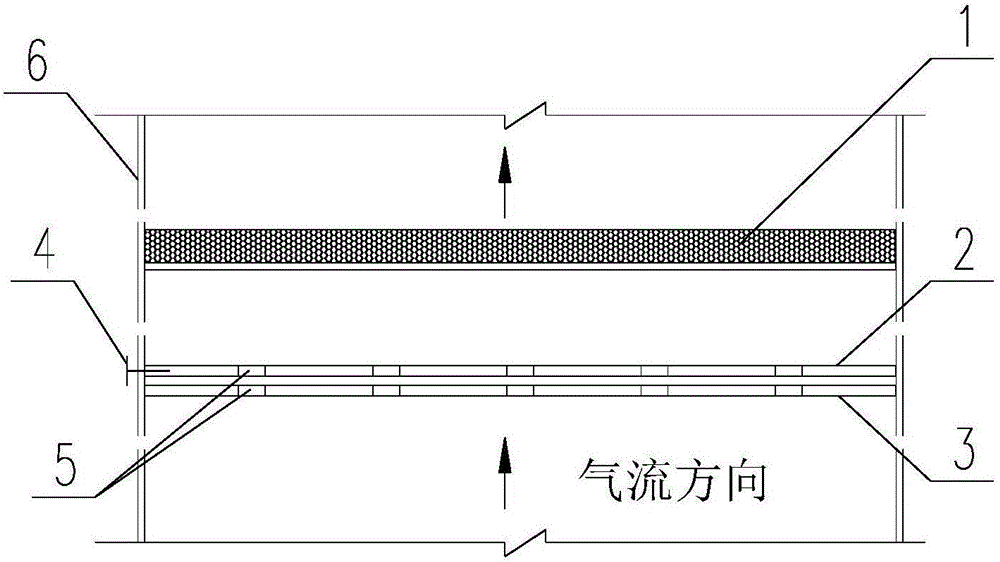

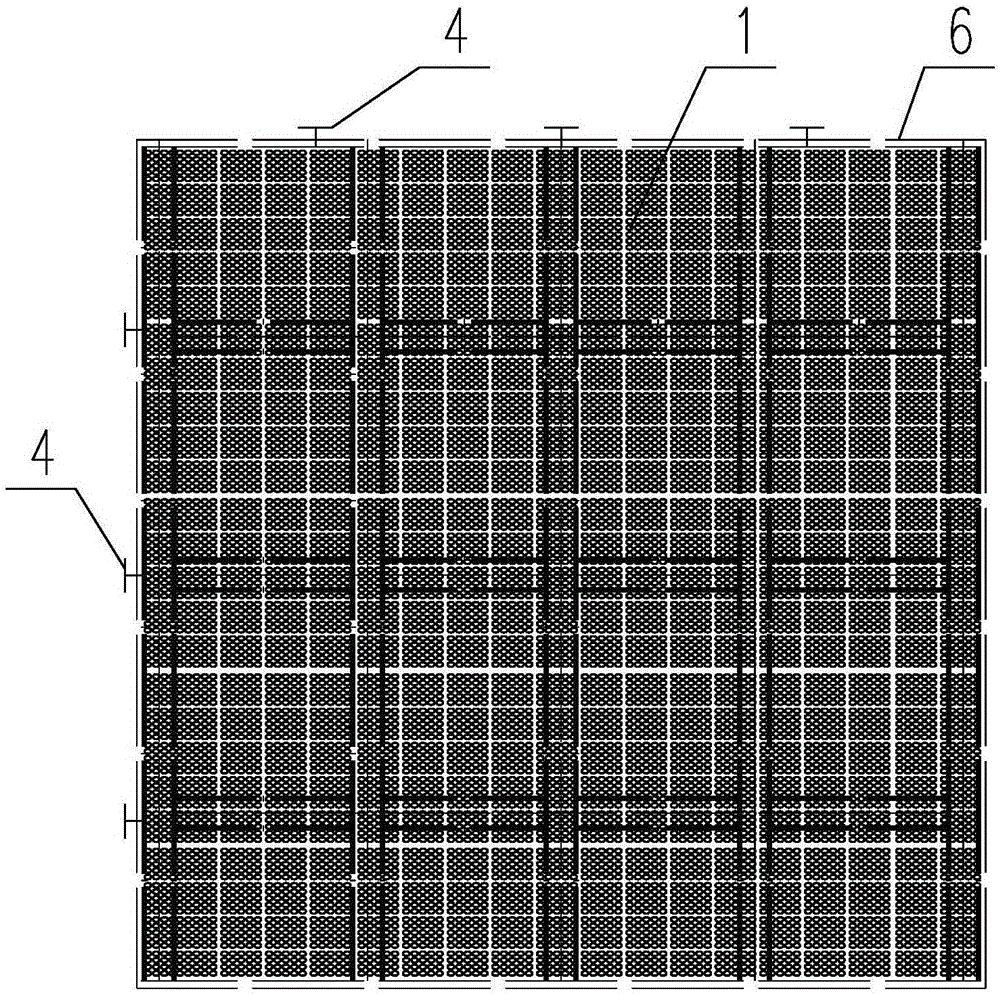

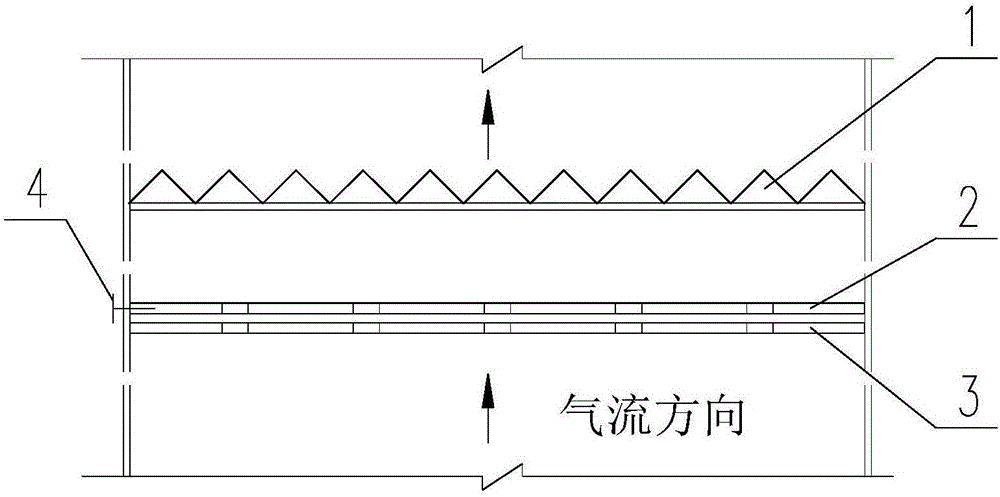

[0021] Such as Figure 1-Figure 3 As shown, a kind of mixing and equalizing structure of the present invention includes an orifice equalizing layer and a foamed metal equalizing layer 1 arranged in the air flow channel 6 perpendicular to the airflow direction, and the orifice equalizing layer is composed of an orifice The static layer 3 of the orifice plate is composed of the static layer 3 of the orifice plate; A plurality of flow equalization holes 5 are set on the corresponding position on the flow layer moving plate 2, and the orifice plate flow leveling layer moving plate 2 can slide along the horizontal and vertical short distances, and after sliding, it can change its position with the orifice plate leveling static plate 3. Corresponding to the degree of coincidence of the equalizing holes.

[0022] The metal foam equalizing layer 1 is ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com