Preparation method of low monomer-residual acrylic ester modified aqueous polyurethane pressure-sensitive adhesive

A water-based polyurethane and monomer residue technology, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., to achieve excellent mechanical properties, good stability, and reduce monomer residue effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

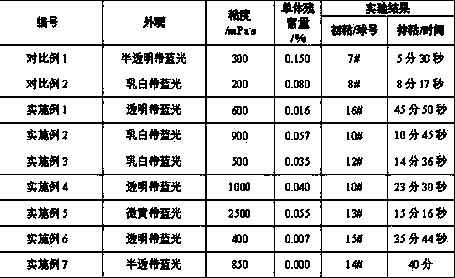

Examples

Embodiment 1

[0034] Example 1: Add 40g N210 (polyoxypropylene diol-1000, difunctionality), 200g 330N (polyoxypropylene triol-3000, trifunctionality) and 15g dihydroxypropionic acid (DMPA) into the reactor, mix and stir, put In a water bath at 90°C, after the solid particles are completely dissolved, vacuum dehydrate at a vacuum degree of -0.1Mpa for 1.0h. Cool down to 80°C, add 20g 1-methyl-2-pyrrolidone (NMP), 58g IPDI, 20g acrylate oligomer (viscosity 1000mpa s) and appropriate amount of dibutyltin dilaurate, react for 2h, add 3g trihydroxy Methylpropane (TMP), react for 1h; cool down to 50°C, first reduce the viscosity with an appropriate amount of acetone, then add 13g of triethylamine for neutralization and salt formation for 0.5h; slowly add 856g of water under stirring for high-speed emulsification for 0.5h, then 1g of ethylenediamine was chain-extended for 0.5h, and finally a colorless and transparent emulsion was obtained (theoretical solid content was 30%).

Embodiment 2

[0035] Example 2 : Under the operating conditions of Example 1, N210 and 330N are replaced by 199g polyadipate-1,4-butylene glycol ester diol (polyester-1000), and 15g dihydroxypropionic acid (DMPA) is replaced by 8g , adjust the amount of water added according to the theoretical solid content, and finally get a transparent emulsion with blue light (theoretical solid content is 30%).

Embodiment 3

[0036] Example 3 : under embodiment 1 operating conditions, N210 and 330N are replaced by 110g N210, 15g dihydroxypropionic acid (DMPA) is replaced by 4g, by theoretical solid content regulation water addition, finally obtain the emulsion (theoretical solid content) of transparent band blue light 30%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com