Exhaust gas turbine with closed nozzle ring

A technology for exhaust gas turbines and nozzle rings, applied to stators, engine components, machines/engines, etc., can solve problems such as gaps and weakened seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

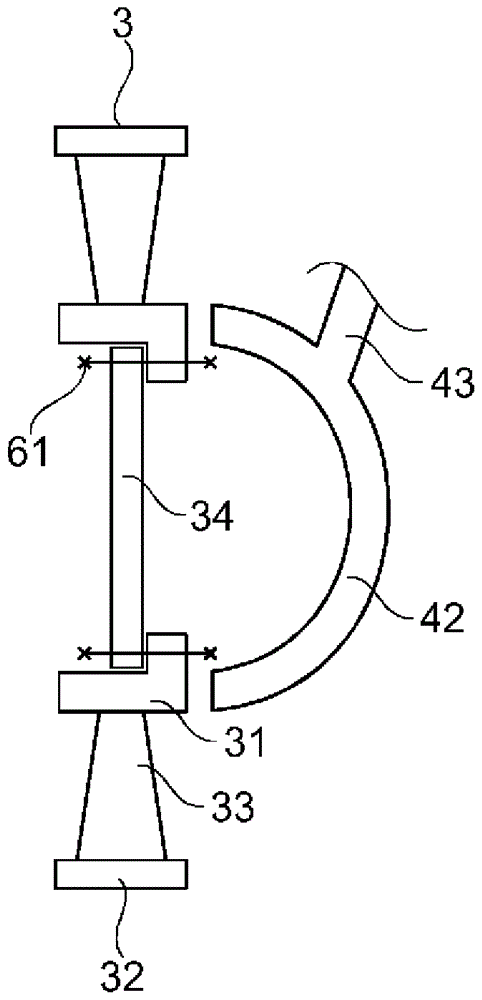

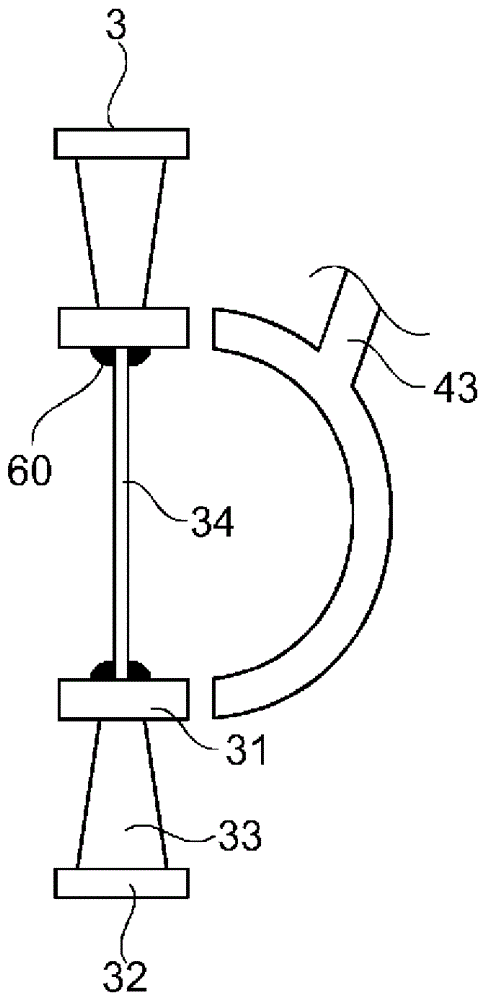

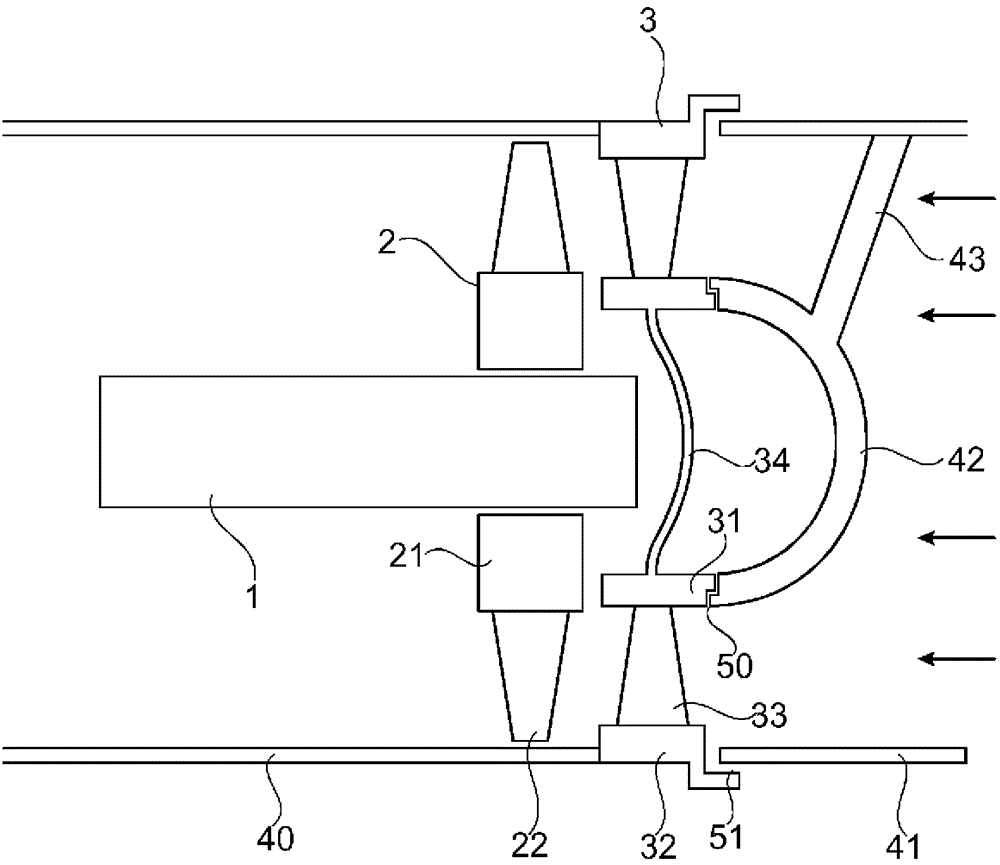

[0024] figure 1 An axially flowing exhaust gas turbine is shown in the schematic illustration of a shaft section. The outward orientation of the exhaust gas turbine is limited by the two-part outer gas inlet housing 40 , 41 which is tubular in shape. The turbine wheel 2 is arranged concentrically in the outer gas inlet housings 40 , 41 and is mounted rotatably by the shaft 1 . The turbine wheel 2 has a hub body 21 and rotor blades 22 . The cylindrical hub body 21 is arranged axially around the shaft 1 . The rotor blades 22 are fixed on the outer cylindrical surface of the hub body 21 and distributed in the circumferential direction. In order to ensure collision-free rotation of the turbine wheel 2 , the length of the rotor blades 22 is dimensioned such that there is a gap between the radially outer ends of the rotor blades 22 and the outer gas inlet housings 40 , 41 . Upstream of the turbine wheel 2 there is a nozzle ring 3 which is arranged concentrically to the turbine w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com