Substrate transfer device for thin-film deposition apparatus

A technology for conveying substrates and films. It is used in conveyor objects, transportation and packaging, and gaseous chemical plating. It can solve problems such as poor maintenance performance, increased cost, and narrow spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

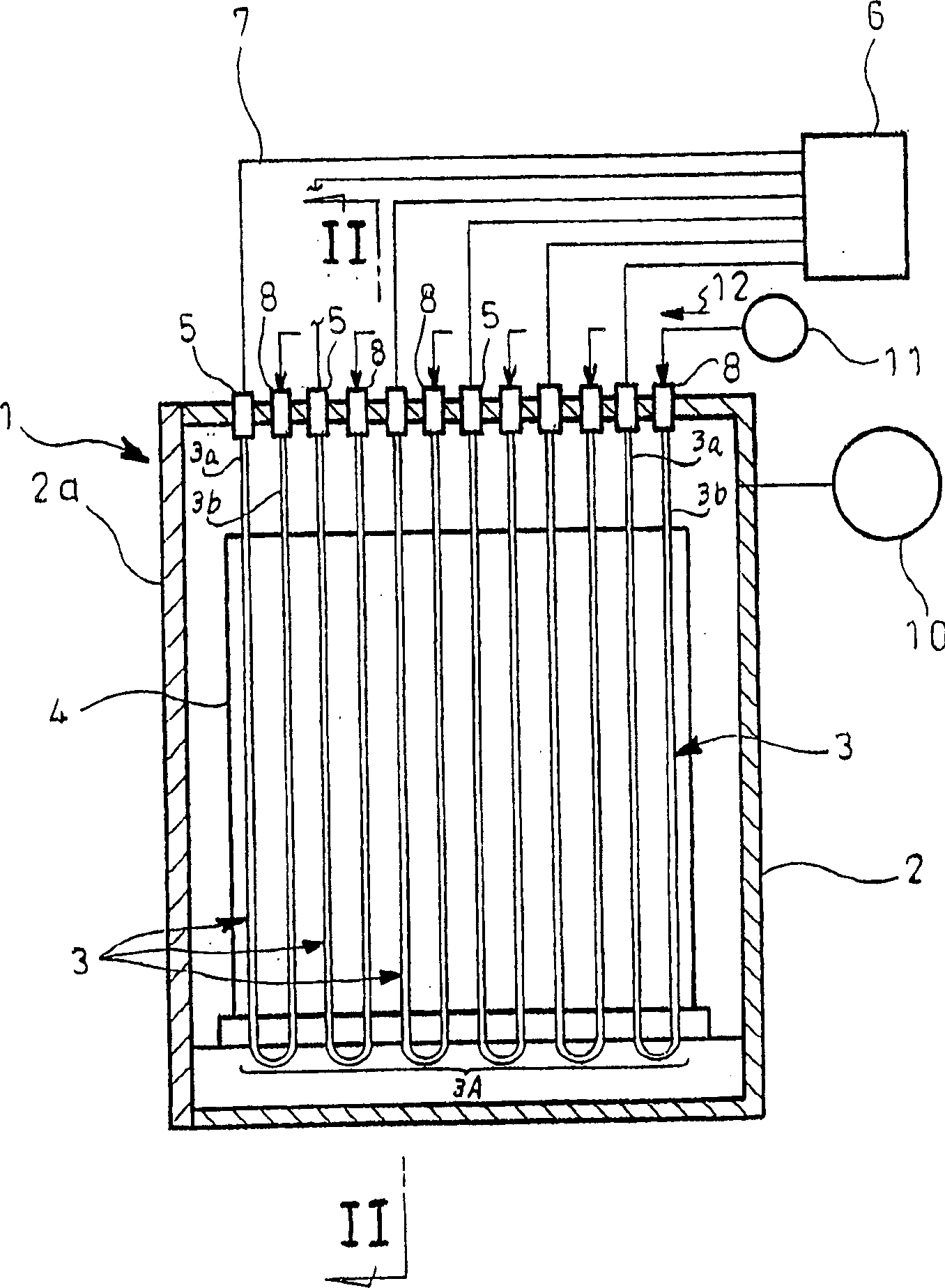

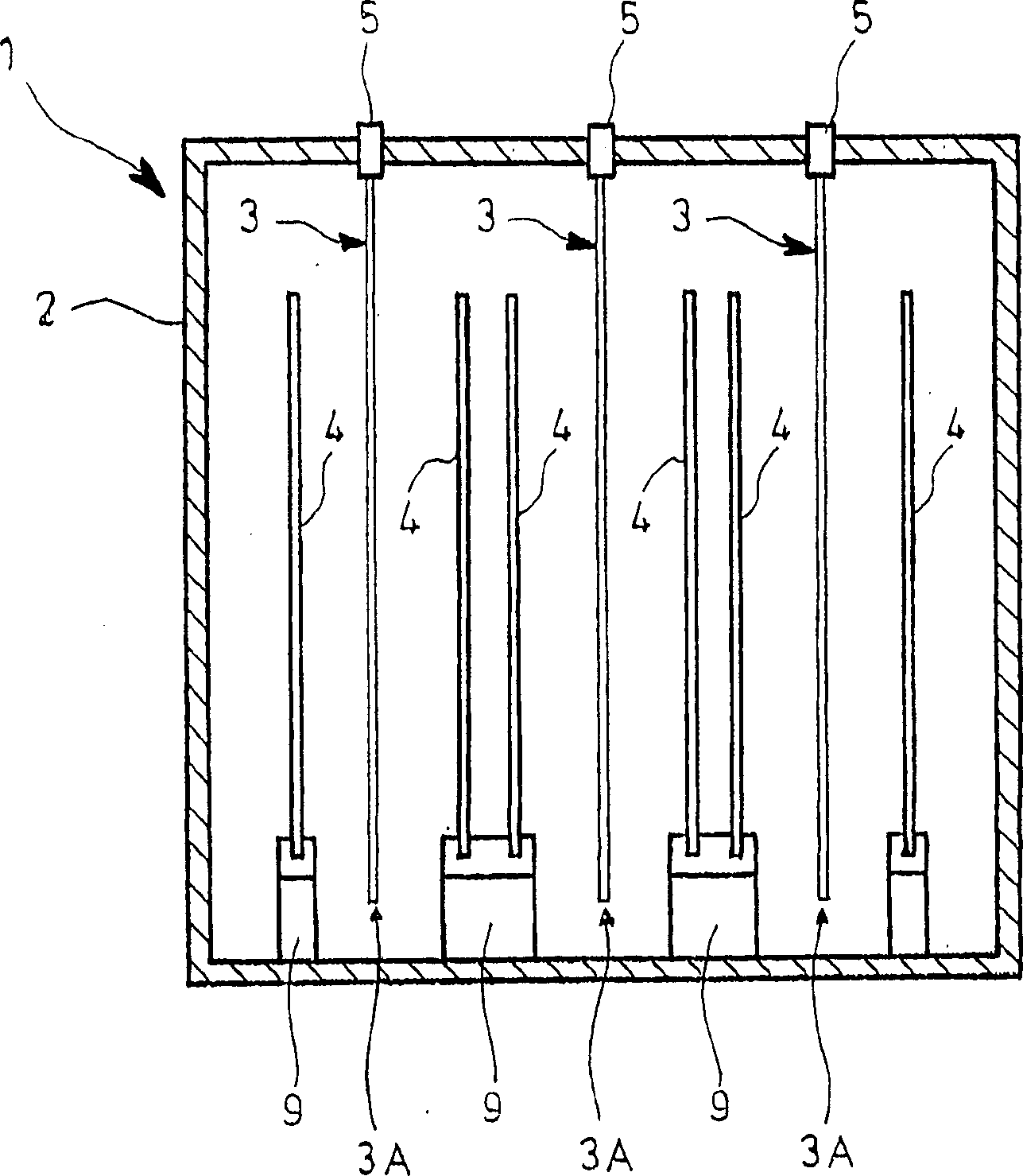

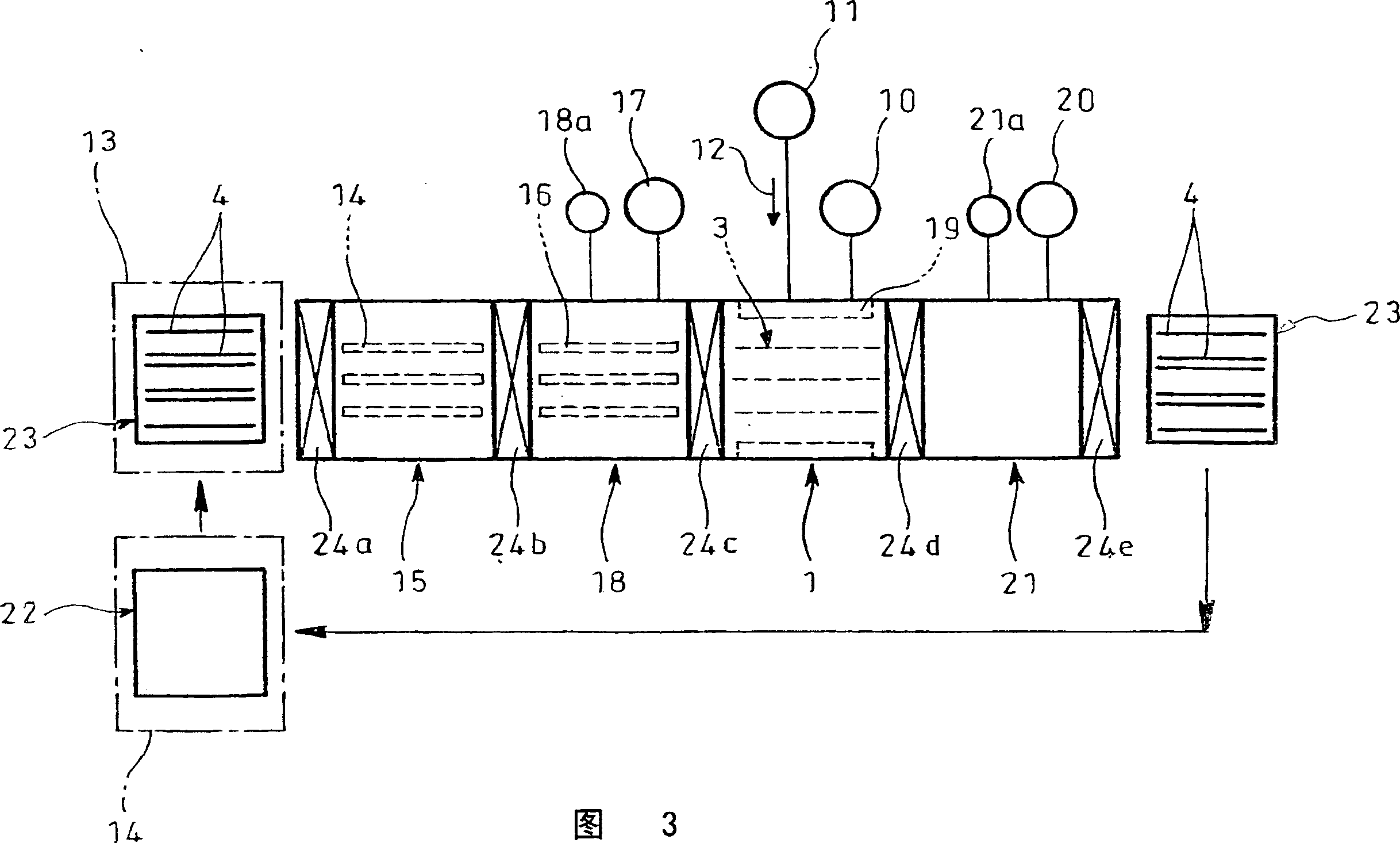

[0050] Embodiments of the present invention will be described below with reference to the drawings.

[0051] Figure 6 ~ Figure 11 An example of the present invention is shown. In the figure, with Figure 3~ Figure 5 Parts using the same reference numerals represent the same parts, and its basic structure is the same as that shown in Fig. 3- Figure 5 The same goes for the prior art shown. However, this embodiment is characterized in that, as Figure 6 ~ Figure 11 As shown, on the transport trolley 23, a partition wall plate 37 formed with an opening 36 larger than the substrate 4 and facing the inductive coupling type electrode 3 is erected, and a partition wall plate 37 away from the inductive coupling type electrode 3 is provided. On one side, a photo frame-shaped substrate holder 38 on which the substrate 4 is mounted is disposed such that the substrate 4 is disposed substantially in the center of the opening 36 of the partition wall plate 37 and the outer periphery of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com