Condensate drainage with maintenance interface

A technology of condensate and discharge, applied in steam traps, transportation and packaging, machinery and equipment, etc., can solve the problem of time-consuming and expensive replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

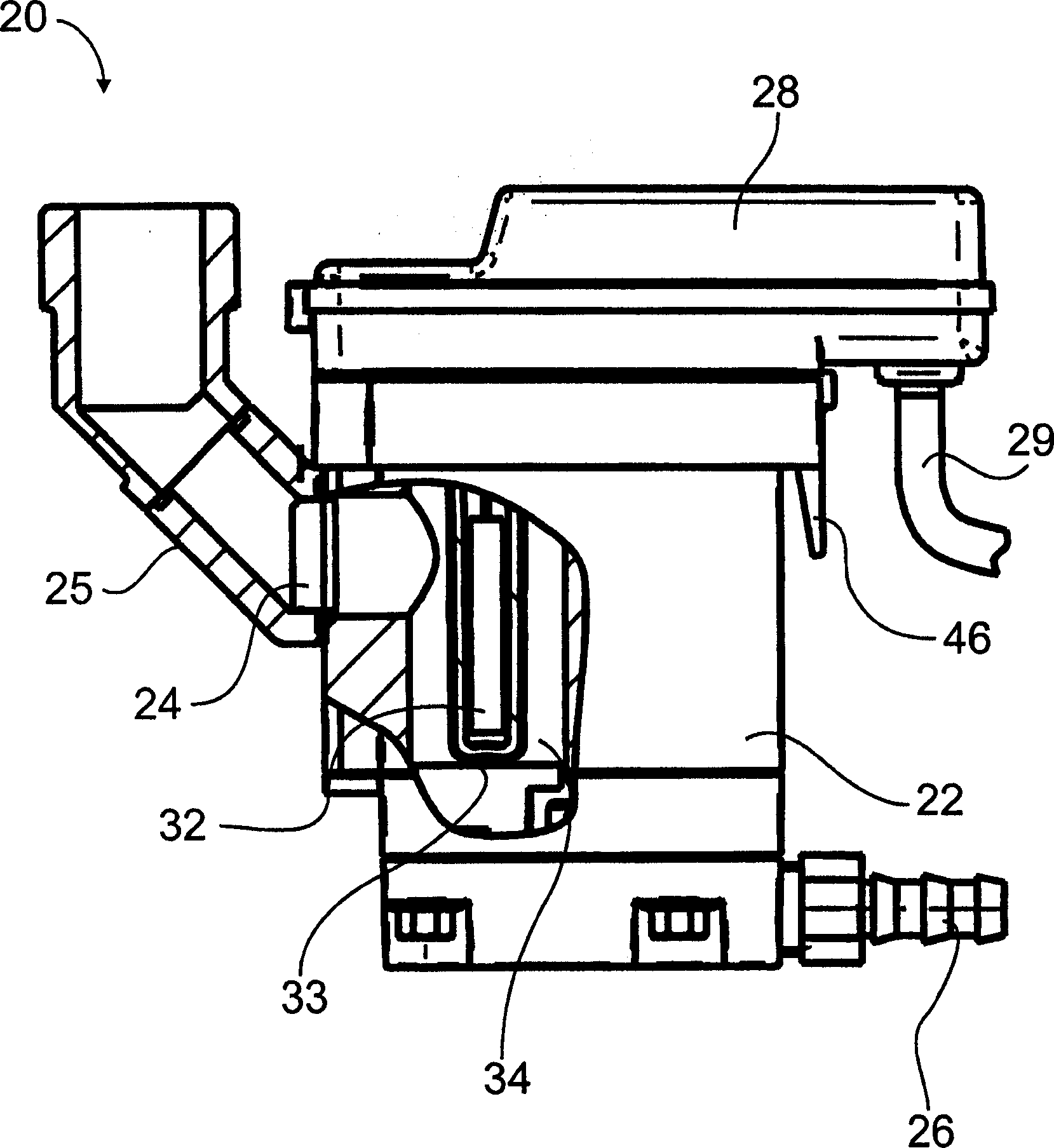

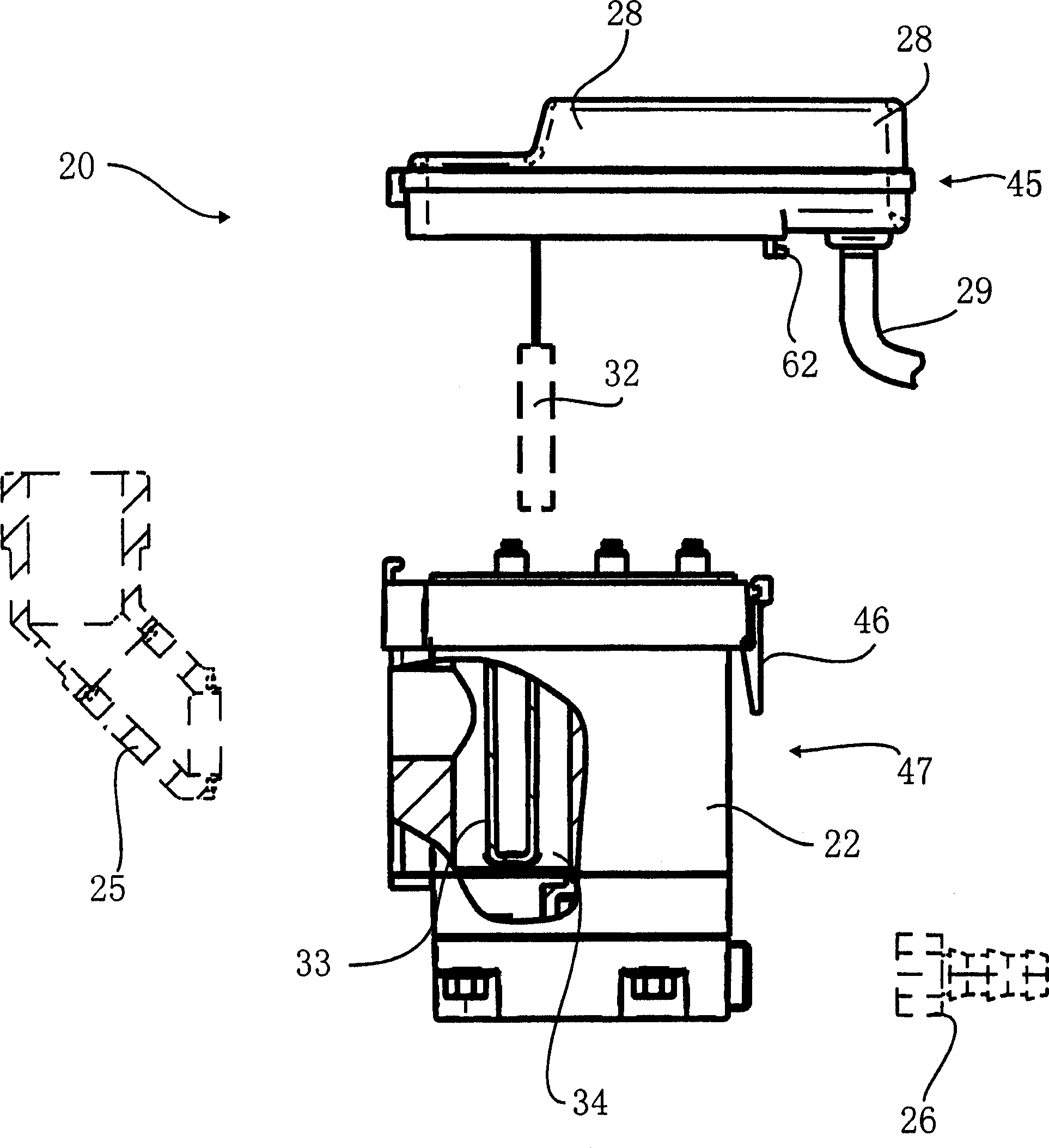

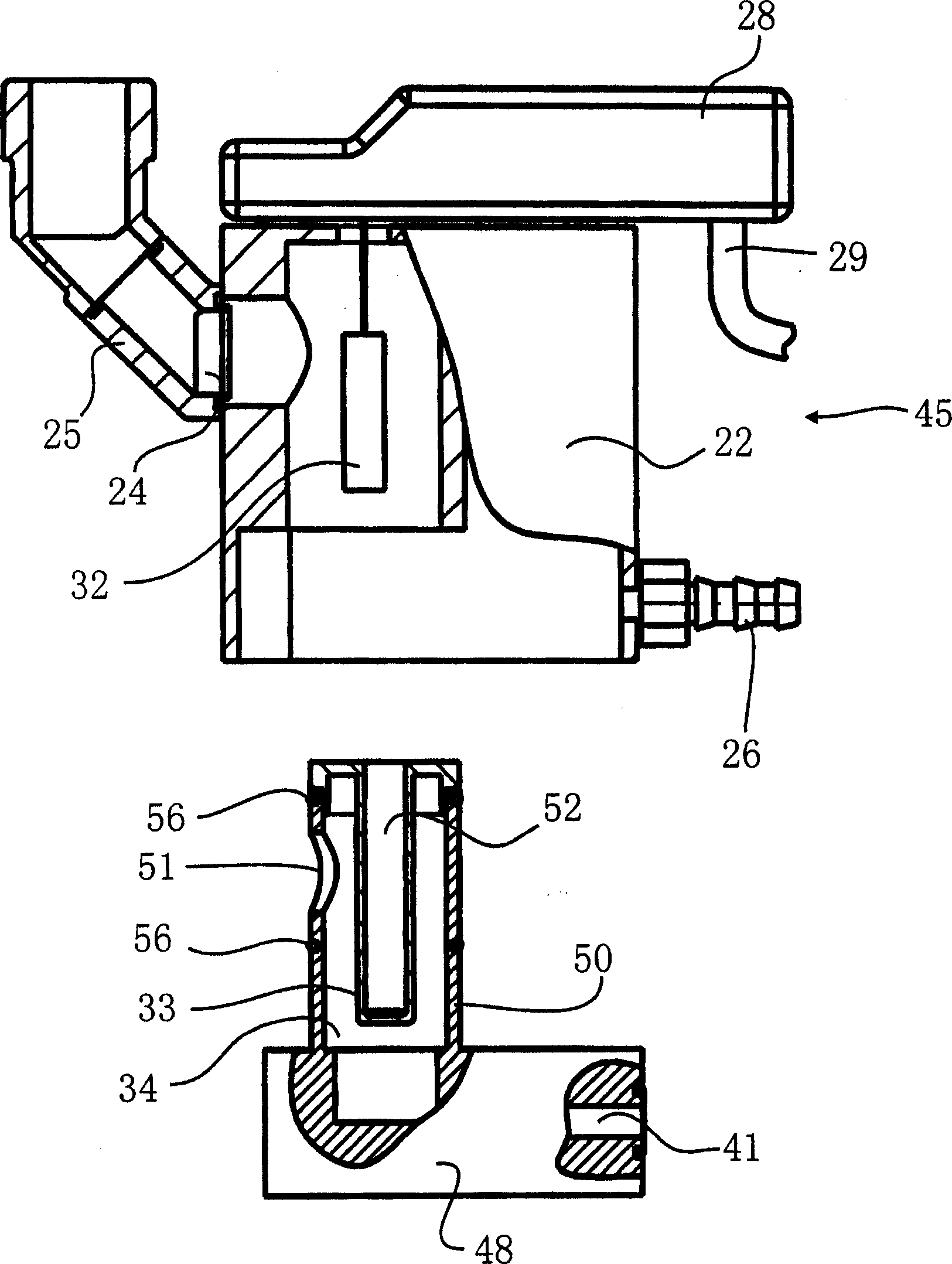

[0026] Each figure shows the air filter water drainer 20 of the present invention. It has a housing 22 with a compressed air connection 24 for connection to a pressurized gas line, in particular a compressed air line 25, and an outlet 26 for discharging condensed water to the outside .

[0027] An electronic unit 28 is connected to the housing 22 . The electronics unit 28 includes a power connection 29 for connection to a power source. Also, the electronics unit 28 is connected to a level indicator 32 which in this embodiment comprises several capacitive sensors. Each of these sensors is connected to the electronic unit 28 by wires. In this way, the condensate level in this container can be recorded by capacitive electronics without any parts subject to wear.

[0028] The level indicator 32 protrudes from above into a collection chamber 34 in which condensed water is deposited and collected via a compressed air connection, which is also connected to the collection chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com