Polypropylene macromolecular stiffening nucleating agent as well as preparation method and application thereof

A technology for polypropylene and macromolecules, which is applied in the field of polypropylene macromolecular stiffening and nucleating agents and its preparation. It can solve the problems of poor compatibility and dispersibility, and accelerate the formation of α-crystal form, and achieve good dispersibility and accelerated crystallization. rate, effect of reducing spherulite size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Mix 0.2 parts of dicumyl peroxide, 20 parts of 4-vinylbiphenyl, and 0.1 part of sodium phosphate evenly, and melt and mix them together with 100 parts of polypropylene on an internal mixer at 190°C for 10 minutes. The rotation speed of the internal mixer is 80r / min, after cooling, a polypropylene macromolecular stiffening nucleating agent is obtained, which is denoted as A1.

[0037] After uniformly mixing 0.1 part of A1 and 100 parts of polypropylene, it was fed into an extruder at 190°C to melt, extrude and granulate to obtain stiffened polypropylene, which was designated as B1.

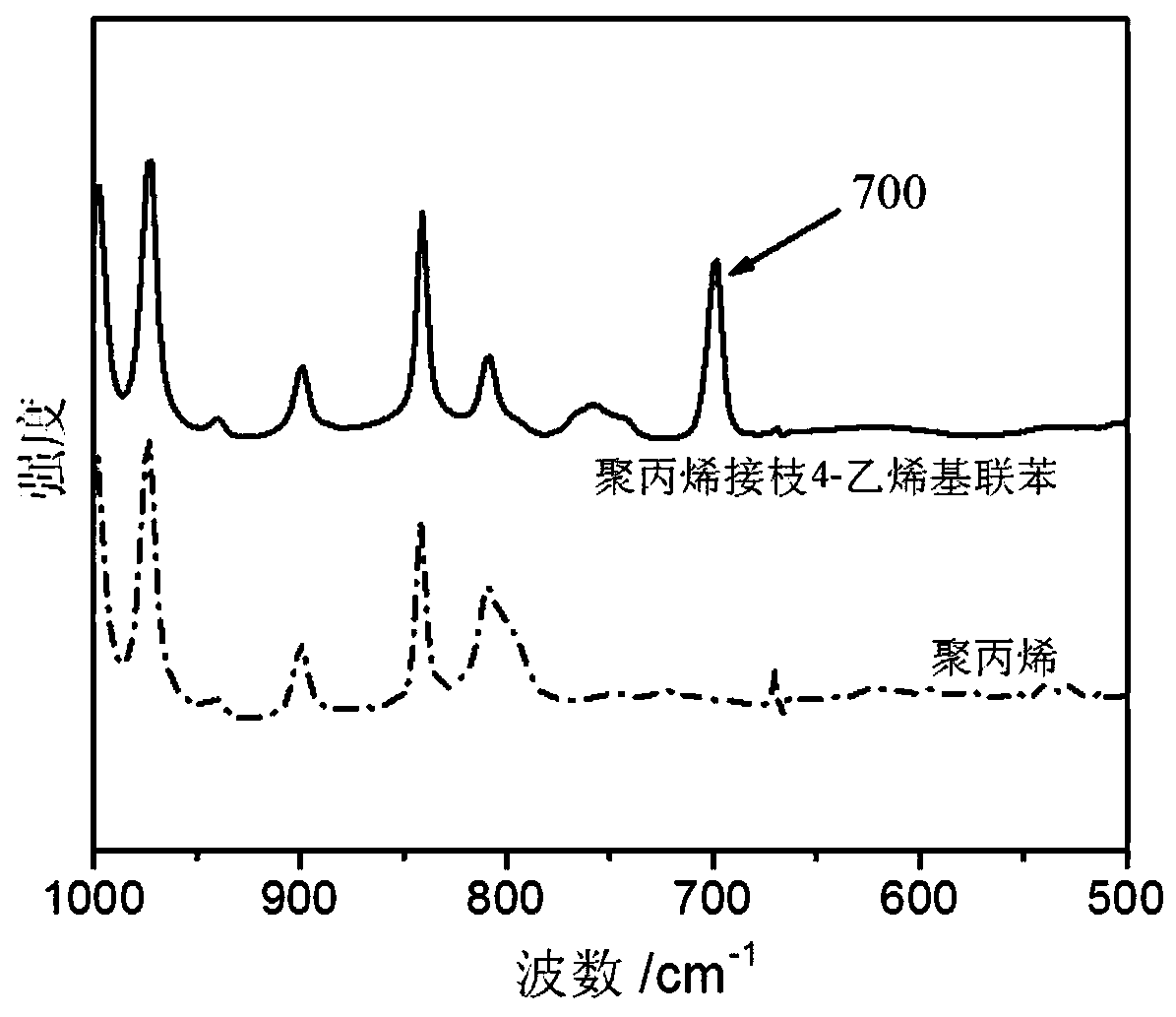

[0038] Infrared test method: A1 is first extracted with acetone, unreacted 4-vinyl biphenyl and blended sodium phosphate are extracted and removed, and after drying, infrared test is carried out to obtain figure 1 Infrared spectrum of polypropylene grafted with 4-vinylbiphenyl shown in .

[0039] Grafting rate calculation method: After blending different proportions of polypropylene and 4-...

Embodiment 2

[0041] Mix 0.2 parts of dicumyl peroxide, 10 parts of 4-vinyl biphenyl, and 0.1 parts of sodium phosphate evenly, and melt and mix them together with 100 parts of polypropylene on an internal mixer at 190°C for 10 minutes. The rotation speed of the internal mixer is 80r / min, after cooling, a polypropylene macromolecular stiffening nucleating agent is obtained, which is denoted as A2.

[0042] After mixing 0.03 parts of A2 and 100 parts of polypropylene evenly, put them into an extruder at 190°C to melt, extrude and granulate to obtain stiffened polypropylene, which is designated as B2.

Embodiment 3

[0044] After mixing 0.1 part of A2 and 100 parts of polypropylene evenly, they were fed into an extruder at 190°C to melt, extrude and granulate to obtain modified polypropylene, which was designated as B3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com