A hardfacing alloy material

A technology of alloy material and hard surface, applied in the direction of welding/cutting medium/material, welding equipment, welding medium, etc., can solve the problems of insufficient economy, high content of precious metal elements, increased cost, etc., to reduce pollution and improve weldability And good impact resistance, hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

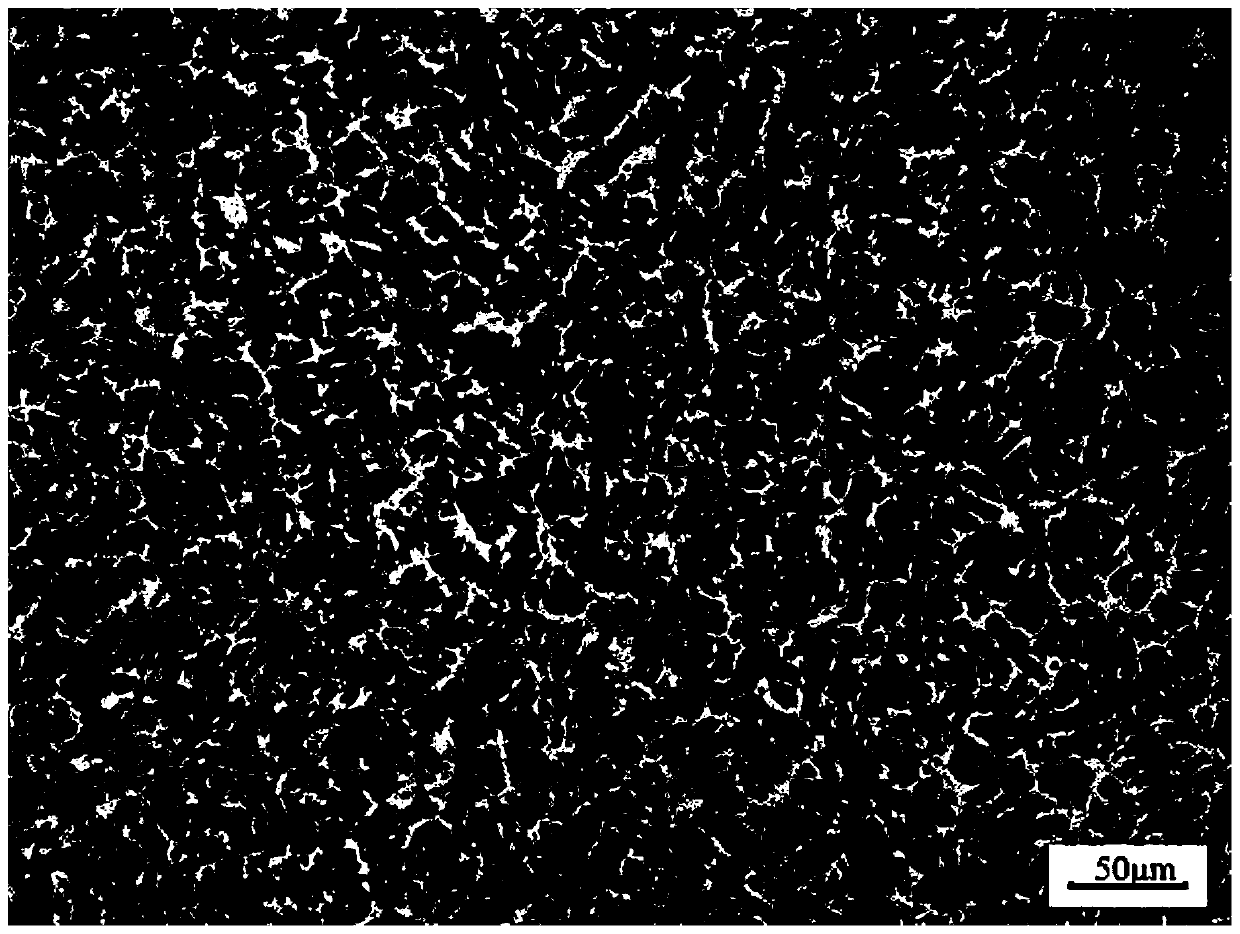

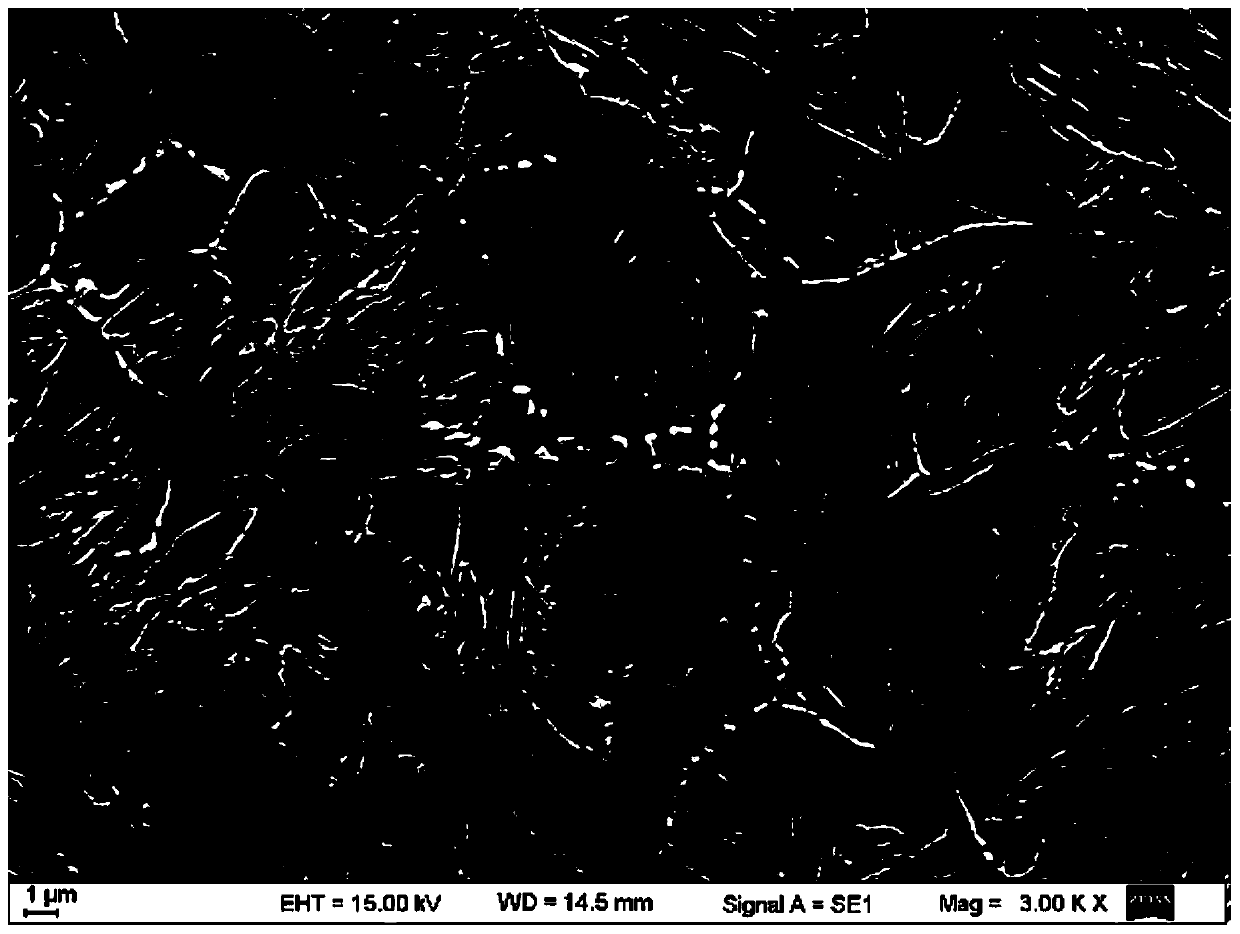

Embodiment 1

[0044] The mass percentages of the constituent elements of the hardfacing alloy material in this embodiment are: Nb: 1.0Wt%, Ni: 1.0Wt%, C: 0.5Wt%, Si: 0.5Wt%, Mn: 1.5Wt%, Cr: 3.0Wt %, Mo: 2.0Wt%, W+V+Ti: 2.5Wt% (W: 1.0Wt%, V: 1.0Wt%, Ti: 0.5Wt%), and the balance is Fe.

[0045] The raw material composition (by mass percentage) used in the alloy material of this embodiment is: 0.8% of medium carbon ferromanganese, 4.4% of high carbon ferrochrome, 0.4% of ferrosilicon, 3.2% of ferromolybdenum, 1.0% of vanadium iron, 2.0% of tungsten iron , ferro-titanium 0.2%, high-carbon ferromanganese 1.0%, reduced iron powder 85%, niobium powder 1.0%, nickel powder 1.0%. Among them, the purity of nickel powder and niobium powder is ≥0.99, and other raw materials are used according to market standards.

[0046] Use the alloy material of this example to carry out surface overlay welding on the base material 42CrMo steel (see the following table 1 for the chemical composition) by TIG cladding,...

Embodiment 2-6

[0053] The elemental composition and welding method of the alloy materials in Examples 2-6 are the same as those in Example 1, except that the contents of nickel and niobium elements are changed.

Embodiment 7

[0078] The mass percent composition of each element of the hardfacing alloy material in this embodiment is: Nb: 2.0Wt%, Ni: 1.5Wt%, C: 0.4Wt%, Si: 0.3Wt%, Mn: 1.2Wt%, Cr: 3.5Wt%, Mo: 1.8Wt%, W+V+Ti: 2.2Wt%, the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com