Flame-retardant and anti-impact cable

A shock-resistant and cable technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of flame retardancy, poor impact resistance, limited cable application, general performance, etc., and achieve low price, light weight, and high operating temperature high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

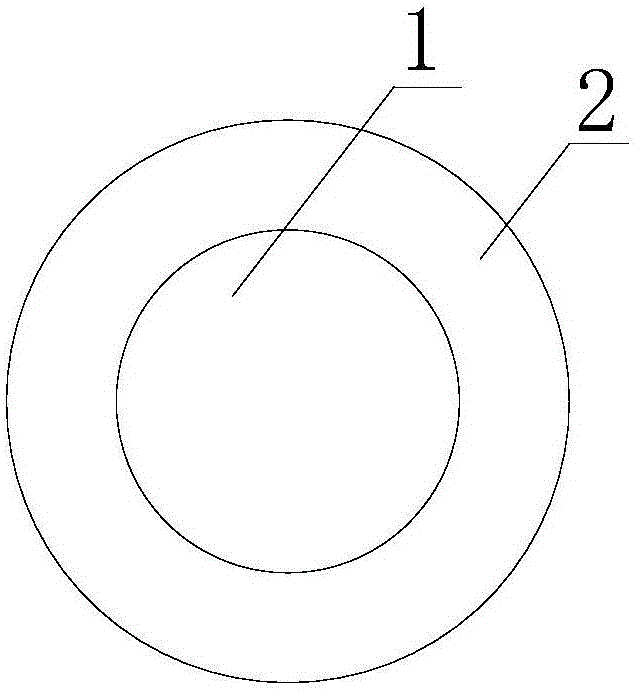

[0016] figure 1 It is a structural schematic diagram of the flame-retardant and impact-resistant cable of the present invention. refer to figure 1 , a flame-retardant and impact-resistant cable proposed by the present invention, comprising a conductor 1 covered with a sheath 2; wherein, the sheath 2 is made of polypropylene composite material, and the polypropylene The raw materials of the composite material include the following components by weight: 100 parts of polypropylene, 35 parts of EPDM rubber, 3 parts of epoxy resin, 10 parts of EPDM grafted maleic anhydride, 1,2-polybutylene 3 parts of diene, 20 parts of nano rubber powder, 6 parts of magnesium hydroxide, 6 parts of red phosphorus, 2 parts of zinc borate, 10 parts of calcium sulfate whiskers, 5 parts of cellulose whiskers, 15 parts of raw gypsum, 3 parts of calcium carbonate, 5 parts of 2,2'-methylene-bis(4,6-di-n-butylphenol)sodium phosphate, 0.5 parts of stearic acid, 2 parts of dicumyl peroxide, 3 parts of sila...

Embodiment 2

[0018] refer to figure 1 , a flame-retardant and impact-resistant cable proposed by the present invention, comprising a conductor 1 covered with a sheath 2; wherein, the sheath 2 is made of polypropylene composite material, and the polypropylene The raw materials of the composite material include the following components by weight: 100 parts of polypropylene, 20 parts of EPDM rubber, 15 parts of epoxy resin, 2 parts of EPDM grafted maleic anhydride, 1,2-polybutylene 10 parts of diene, 10 parts of nano rubber powder, 20 parts of magnesium hydroxide, 3 parts of red phosphorus, 10 parts of zinc borate, 4 parts of calcium sulfate whiskers, 12 parts of cellulose whiskers, 3 parts of raw gypsum, 15 parts of calcium carbonate, 1 part of 2,2'-methylene-bis(4,6-di-n-butylphenol)sodium phosphate, 3 parts of stearic acid, 0.5 part of dicumyl peroxide, 1 part of vinyltriethoxysilane , 2 parts of γ-chloropropyl triethoxysilane, 1 part of 3-glycidyl etheroxypropyl trimethoxysilane, 4 parts...

Embodiment 3

[0020] refer to figure 1 , a flame-retardant and impact-resistant cable proposed by the present invention, comprising a conductor 1 covered with a sheath 2; wherein, the sheath 2 is made of polypropylene composite material, and the polypropylene The raw materials of the composite material include the following components by weight: 100 parts of polypropylene, 31 parts of EPDM rubber, 7 parts of epoxy resin, 7 parts of EPDM grafted maleic anhydride, 1,2-polybutylene 6 parts of diene, 18 parts of nano rubber powder, 10 parts of magnesium hydroxide, 5 parts of red phosphorus, 5 parts of zinc borate, 10 parts of calcium sulfate whiskers, 8 parts of cellulose whiskers, 9 parts of raw gypsum, 6 parts of calcium carbonate, 4 parts of 2,2'-methylene-bis(4,6-di-n-butylphenol)sodium phosphate, 2 parts of stearic acid, 1.7 parts of dicumyl peroxide, γ-chloropropyl triethoxy 2 parts of silane, 1 part of 3-glycidyl etheroxypropyl trimethoxysilane, 3 parts of β-(3,4-epoxycyclohexyl) ethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com