Insulating medium capable of improving vacuum surface flashover voltage and preparation method of insulating medium

A surface flashover and insulating medium technology, applied to insulators, organic insulators, circuits, etc., to achieve the effects of low process difficulty, improved pulse and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

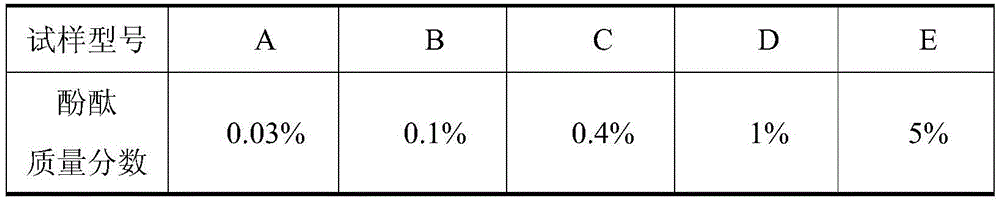

[0030] Embodiment 1: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 60° C., and the time is 12 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 135°C, and rotate at 60 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 30 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 130°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

Embodiment 2

[0031] Embodiment 2: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 50° C., and the time is 12 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 125°C, and rotate at 60 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 50 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 150°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

Embodiment 3

[0032] Embodiment 3: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 80° C., and the time is 11 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 145°C, and rotate at 40 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 40 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 140°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

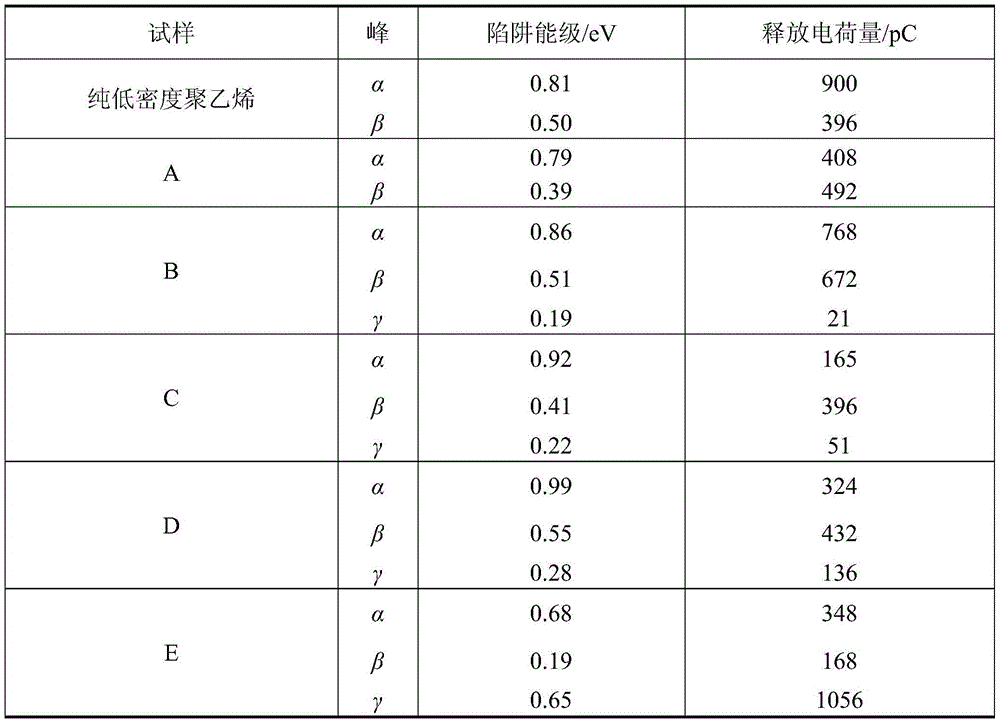

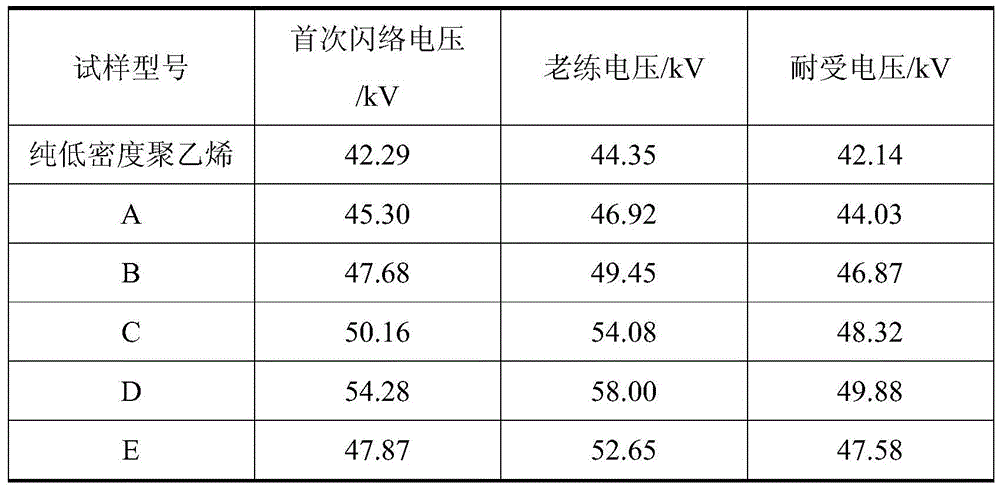

[0033] Take the round sample prepared in Example 1 as an example:

[0034] Table 2 shows the crystallinity and spherulite size of pure LDPE samples and different types of LDPE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com