Method for improving vacuum surface flashover performance of solid insulating medium

A technology of surface flashover and solid insulation, which is applied to insulators, electrical components, circuits, etc., can solve the problems of complex processes, expensive raw materials, and is not suitable for large-scale application in industrial production, and achieves simple process, process safety, and improved flash The effect of network voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

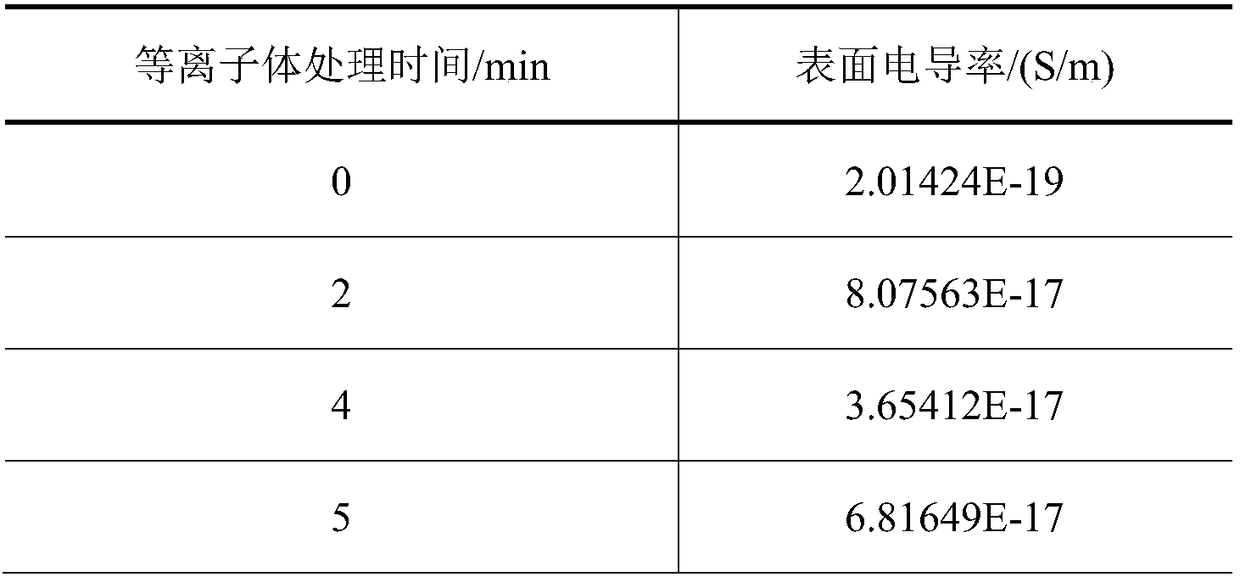

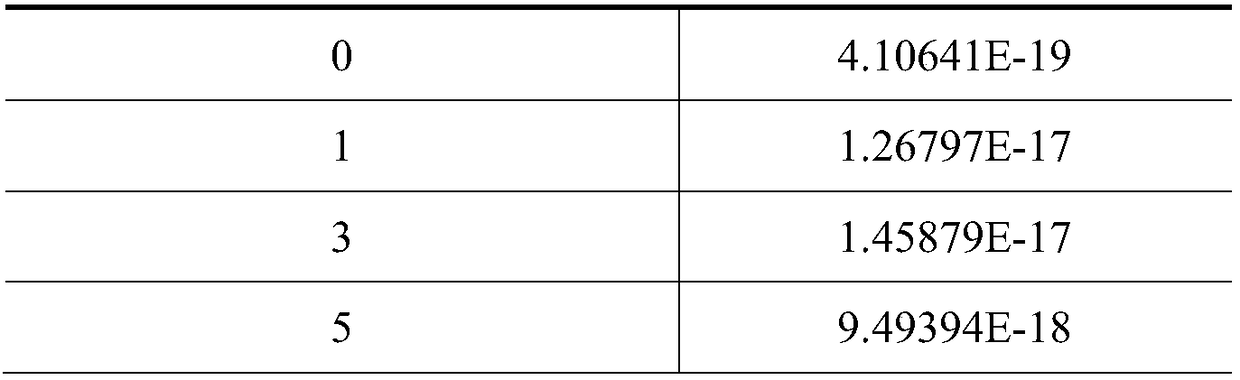

[0025] The invention provides a method for improving the vacuum surface flashover performance of a solid insulating medium. The epoxy resin and its aluminum oxide micron The photodischarge plasma treatment instrument performs air plasma treatment on it. The invention carries out surface modification treatment on the epoxy resin and its micro-composite material through air plasma treatment, and the method can change the surface conductivity and trap distribution of the insulating material, thereby adjusting or improving the vacuum surface flashover characteristic of the material. The method has the advantages of simple process, safe process and environmental friendliness, and can be widely applied to the surface treatment of solid insulating dielectric materials in the field of high-voltage insulating technology.

[0026] The present invention is a method for improving the vacuum surface flashover performance of a solid insulating medium, comprising the following steps:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com