A kind of insulating medium and preparation method thereof for improving vacuum surface flashover voltage

An insulating medium and flashover technology applied to insulators, organic insulators, circuits, etc., to achieve low process difficulty, high reliability, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 60° C., and the time is 12 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 135°C, and rotate at 60 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 30 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 130°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

Embodiment 2

[0031] Embodiment 2: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 50° C., and the time is 12 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 125°C, and rotate at 60 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 50 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 150°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

Embodiment 3

[0032] Embodiment 3: First, put the weighed raw materials (low-density polyethylene and phenolphthalein powder) into an oven for drying, the temperature is set at 80° C., and the time is 11 hours; after drying, put the low-density polyethylene into Heat and stir in a torque rheometer until it reaches a molten state, set the temperature at 145°C, and rotate at 40 rpm; after the low-density polyethylene is melted, add phenolphthalein powder, melt and blend for 40 minutes, and then extrude the low-density polyethylene composite material After the material is cooled, the low-density polyethylene composite material is hot-pressed in a flat vulcanizer at a temperature of 140°C to form a sample plate with a thickness of 5mm; the sample plate is machined to prepare A circular sample with a diameter of 25 mm.

[0033] Take the round sample prepared in Example 1 as an example:

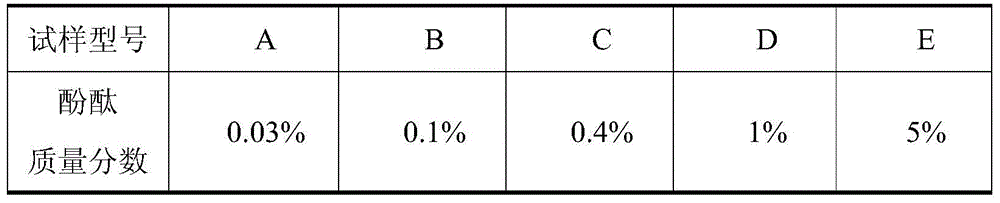

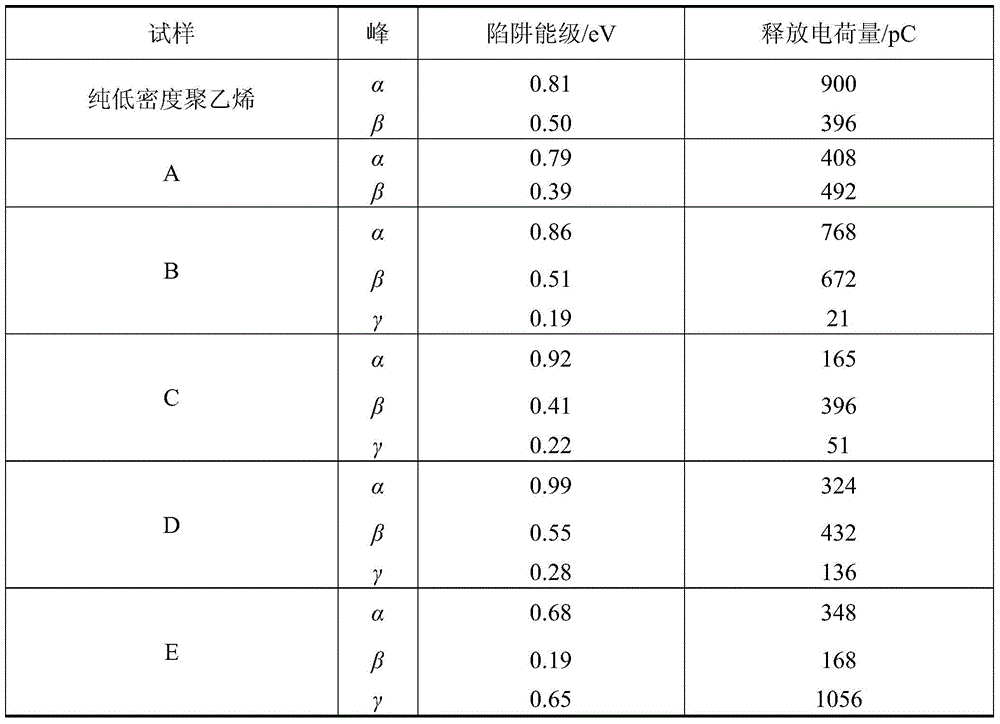

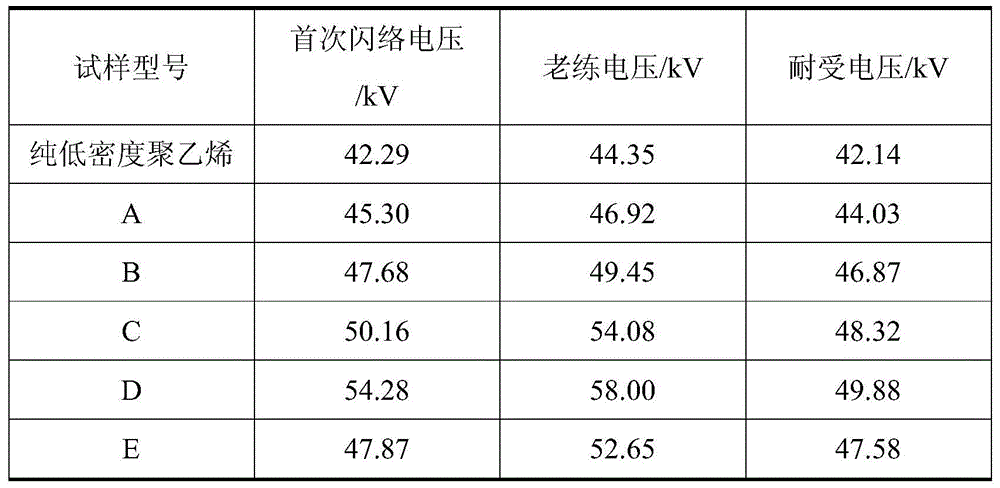

[0034] Table 2 shows the crystallinity and spherulite size of pure LDPE samples and different types of LDPE ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com