A kind of high toughness polylactic acid composite material for environment-friendly tableware and preparation method thereof

A technology of composite materials and polylactic acid, which is applied in the field of high-toughness polylactic acid composite materials and its preparation, can solve the problems of poor impact strength of composite materials, unsuitable for environmental protection tableware, and no obvious modification of heat resistance, so as to improve the strength , Improve processing performance, improve the effect of interfacial bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

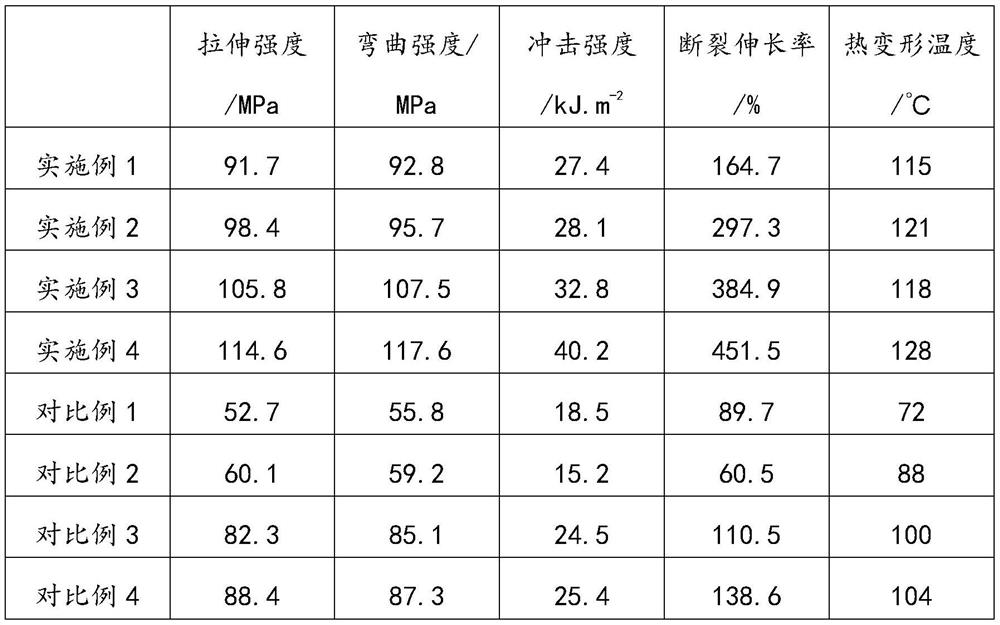

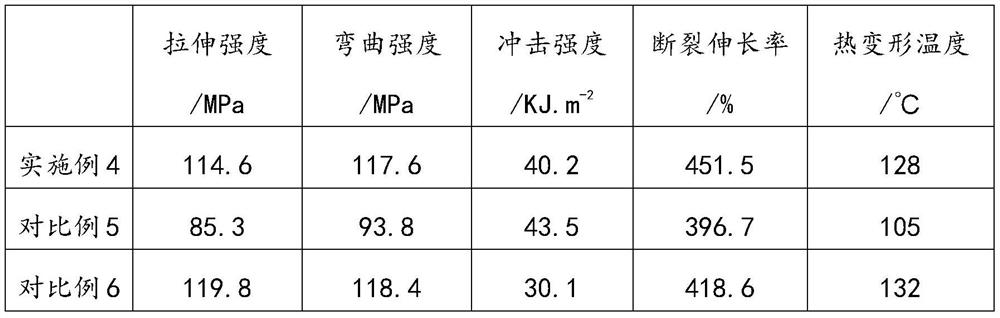

Examples

Embodiment 1

[0031]A high-toughness polylactic acid composite material for environment-friendly tableware is composed of the following raw materials in parts by weight: 40 parts of modified polylactic acid, 60 parts of adipic acid-modified vegetable fibers, 1 part of sodium rosin, 15 parts of PEG-4000 parts, 0.8 parts of magnesium aluminum silicate and 2 parts of N,N,-ethylene bis-stearamide, and its preparation method comprises the following steps:

[0032] Add the weighed modified polylactic acid, adipic acid modified plant fiber and PEG-4000 into the high-speed mixer and stir evenly. After adding sodium rosin, stir for 0.5-1h, then add magnesium aluminum silicate and N, N,-ethylene bis-stearamide, stir for 10-15min, then add the uniformly stirred mixture into a twin-screw extruder for melting and blending, extrusion, drawing, and granulation to obtain environmentally friendly tableware high-toughness polylactic acid composite. Wherein, the extrusion temperature of the twin-screw extrud...

Embodiment 2

[0038] A high-toughness polylactic acid composite material for environment-friendly tableware is composed of the following raw materials in parts by weight: 65 parts of modified polylactic acid, 35 parts of adipic acid-modified vegetable fibers, 0.5 parts of sodium rosin, 8 parts of PEG-6000 parts, 0.5 parts of magnesium aluminum silicate and 5 parts of polyethylene wax, the preparation method is the same as that in Example 1, with specific reference to Example 1, the difference is that PEG-4000 is replaced by PEG-6000, N,N,-ethylene The base bis-stearamide (i.e. lubricant) was replaced with polyethylene wax.

[0039] The preparation method of above-mentioned modified polylactic acid comprises the following concrete steps:

[0040] (1) Add 100 parts of silicon dioxide powder to 400 parts of toluene, heat to 60°C, stir evenly, then add 1.8 parts of vinyltrimethoxysilane, slowly heat up to 110°C, and stir for 3-4 hours to prepare a surface Modified silica;

[0041] (2) The abo...

Embodiment 3

[0044] A high-toughness polylactic acid composite material for environment-friendly tableware is composed of the following raw materials in parts by weight: 50 parts of modified polylactic acid, 50 parts of adipic acid modified plant fibers, 0.8 parts of sodium rosin, 50 parts of PEG-4000 parts, 5 parts of PEG-8000, 0.7 parts of magnesium aluminum silicate and 4 parts of glycerol trihydroxystearate, the preparation method is the same as that in Example 1, specifically referring to Example 1, the difference is that PEG-4000 is replaced by PEG -4000 and PEG-8000, N,N,-ethylene bis-stearamide (ie lubricant) was replaced with glycerol trihydroxystearate.

[0045] The preparation method of above-mentioned modified polylactic acid comprises the following concrete steps:

[0046] (1) Add 100 parts of silicon dioxide powder to 400 parts of toluene, heat to 60°C, stir evenly, then add 1.2 parts of vinyltrimethoxysilane, slowly heat up to 110°C, and stir for 3-4 hours to prepare a surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com