Polypropylene foam material with bimodal distribution and preparation method thereof

A foamed material, bimodal distribution technology, applied in the field of polymer porous materials, can solve the problems of complex process, large limitations, low controllability, etc., and achieves low preparation cost, no damage to equipment, and good controllability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The above-mentioned preparation method of the polypropylene foam material with bimodal distribution, comprises the following steps:

[0036] Step 1. Composite porous inorganic particles and matrix resin to obtain a composite material. If the polypropylene foam material with bimodal distribution contains additives, after selecting the additives, add the additives, porous inorganic particles and matrix resin together Compounding, the matrix resin can also be replaced by the matrix resin modified by additives;

[0037]The composite material can be a sheet or a particle. In the composite material, the mass percentage of the porous inorganic particles is 0.05%-10%. When the mass percentage of the porous inorganic particles is less than 0.05%, the number of nucleation points is too small. % is not conducive to the dispersion of porous inorganic particles, and is prone to agglomeration in the matrix resin; the mass percentage of additives is within 2%;

[0038] The compoundin...

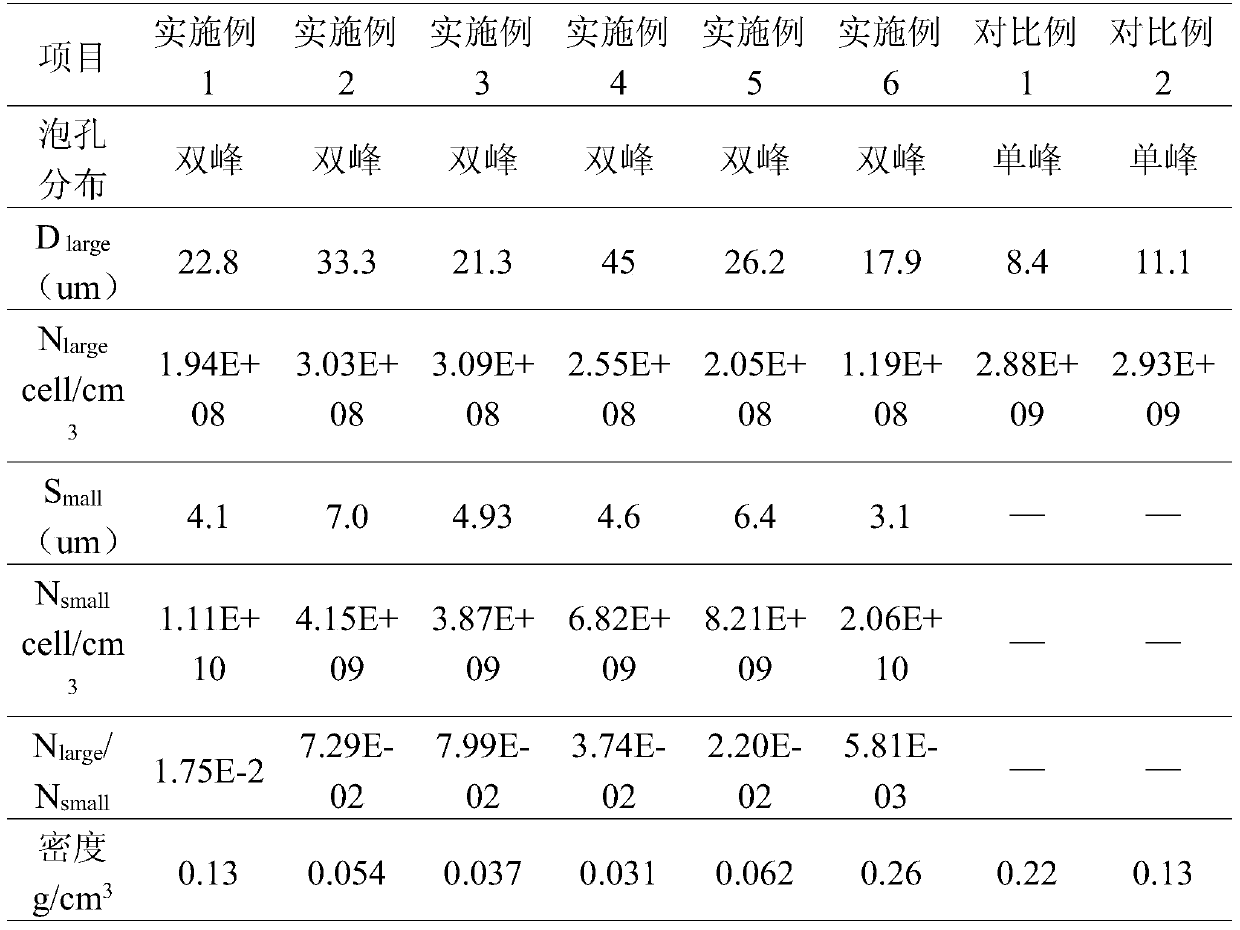

Embodiment 1

[0055] First, isotactic polypropylene (Tm=167°C, MFR=3.3g / 10min), activated carbon powder (particle size 200nm, specific surface 1300m 2 / g, pore diameter 1.2nm, 3wt%) and antioxidant (B215, 0.2wt%) after melt extruding granulation in twin-screw extruder, make polypropylene sheet in flat vulcanizer; Propylene sheet, carbon dioxide and dispersant water whose volume is 5% of the volume of the autoclave are added into the autoclave for saturation, the saturation pressure is 15MPa, the saturation temperature is 160°C, the saturation time is 1h, and the pressure relief rate is 45MPa / s The pressure of the autoclave was released to obtain a polypropylene foam with a bimodal distribution.

[0056] The polypropylene foam material obtained in embodiment 1 is characterized by a scanning electron microscope, and the results are as follows: figure 1 As shown in b, it can be seen that the polypropylene foam material of Example 1 is a bimodal cell structure, and by comparing with Comparativ...

Embodiment 2

[0059] Atactic polypropylene (Tm=145°C, MFR=9g / 10min), A-type silica gel (particle size 38um, specific surface 600m 2 / g, pore size 2nm, 0.8wt%) and antioxidant (B215, 0.2wt%) melt extrusion granulation in twin-screw extruder, make polypropylene sheet in flat vulcanizer; Propylene sheet, carbon dioxide and 15% dispersant water of the volume of the autoclave are added into the autoclave for saturation. The saturation pressure is 4.5MPa, the saturation temperature is 153°C, and the saturation time is 1.5h. The pressure rate releases the pressure of the autoclave to obtain a polypropylene foam with a bimodal distribution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com