A bio-based thermoplastic elastomer material and a preparation method thereof

A thermoplastic elastomer and bio-based technology, applied in the field of bio-based thermoplastic elastomer materials and their preparation, can solve the problems of low strength and difficulty in continuous production, and achieve high strength, low cost and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

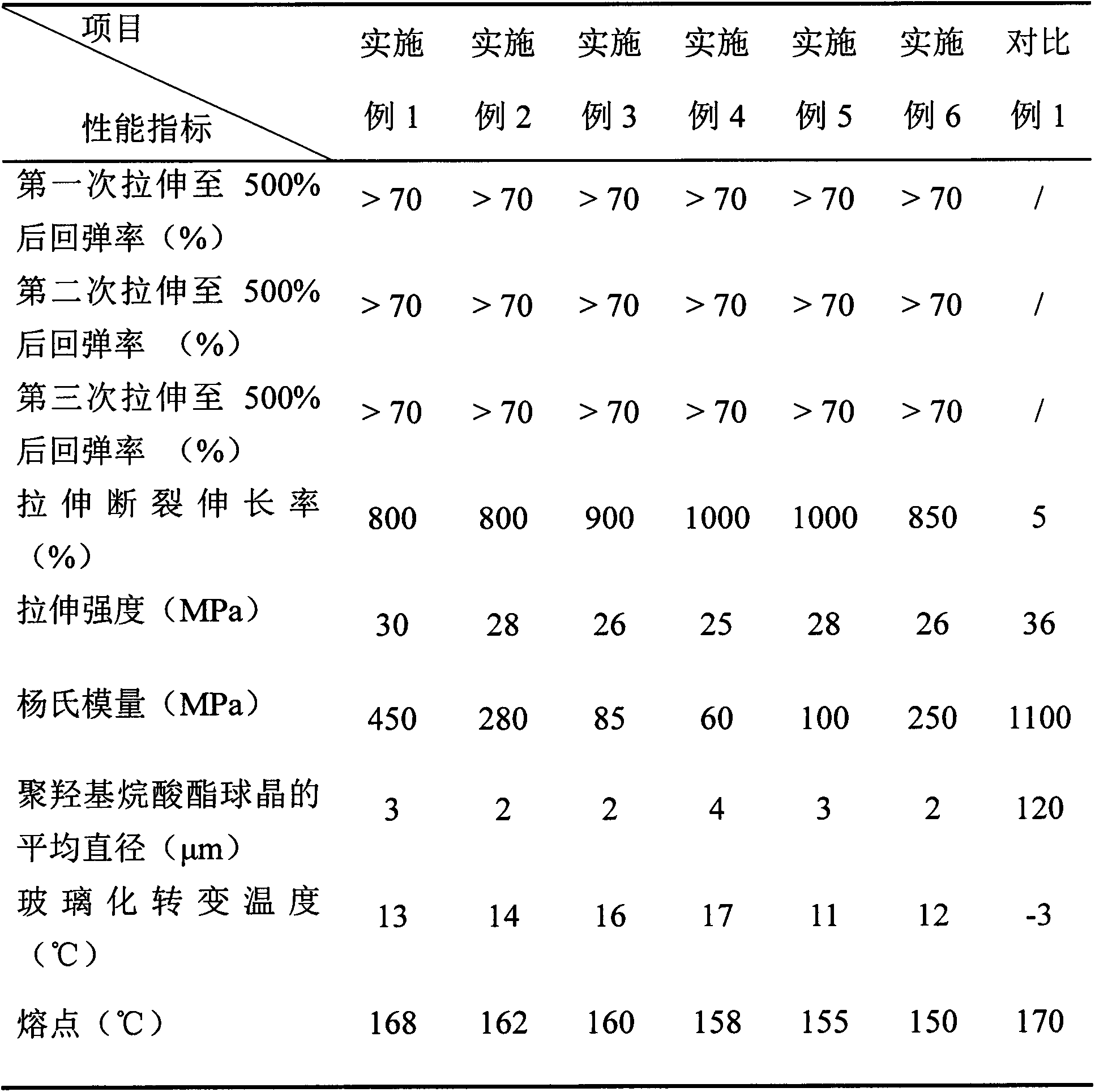

[0021] 42kg of 3-hydroxybutyrate homopolymer, 28kg of 3-hydroxybutyrate-4-hydroxybutyrate copolymer with 4-hydroxybutyrate monomer molar content of 28%, and 90% of vinyl acetate monomer by weight Ethylene-vinyl acetate random copolymer 30kg, behenic acid amide 0.35kg are premixed uniformly in a high-speed mixer (720 rev / min, 5 minutes), and then the above-mentioned premix is added to a parallel twin-screw extruder to melt Blend extrusion to obtain bio-based thermoplastic elastomer material. The temperatures of the twin-screw extruder from the feeding section to the die section were 30°C, 150°C, 155°C, 160°C, and 165°C, respectively, and the screw speed was 100 rpm. The bio-based thermoplastic elastomer material was pressed into a sheet by a flat vulcanizer for testing of tensile properties, resilience, spherulite morphology and thermal properties. The test results are listed in Table 1.

Embodiment 2

[0023] 30kg of 3-hydroxybutyrate homopolymer, 20kg of 3-hydroxybutyrate-4-hydroxybutyrate copolymer with 28% molar content of 4-hydroxybutyrate monomer, and 90% of vinyl acetate monomer by weight Ethylene-vinyl acetate random copolymer 50kg, behenic acid amide 0.25kg are premixed uniformly in a high-speed mixer (720 rev / min, 5 minutes), then the above-mentioned premix is added to a parallel twin-screw extruder to melt Blend extrusion to obtain bio-based thermoplastic elastomer material. The temperatures of the twin-screw extruder from the feeding section to the die section were 30°C, 150°C, 155°C, 160°C, and 165°C, respectively, and the screw speed was 120 rpm. The bio-based thermoplastic elastomer material was pressed into a sheet by a flat vulcanizer for testing of tensile properties, resilience, spherulite morphology and thermal properties. The test results are listed in Table 1.

Embodiment 3

[0025] 28kg of 3-hydroxybutyrate homopolymer, 20kg of 3-hydroxybutyrate-4-hydroxybutyrate copolymer with 28% molar content of 4-hydroxybutyrate monomer, and 90% of vinyl acetate monomer by weight Ethylene-vinyl acetate random copolymer 110kg, behenic acid amide 0.25kg are premixed uniformly in a high-speed mixer (720 rev / min, 5 minutes), then the above-mentioned premix is added to a parallel twin-screw extruder to melt Blend extrusion to obtain bio-based thermoplastic elastomer material. The temperatures of the twin-screw extruder from the feeding section to the die section were 30°C, 150°C, 155°C, 160°C, and 165°C, respectively, and the screw speed was 150 rpm. The bio-based thermoplastic elastomer material was pressed into a sheet by a flat vulcanizer for testing of tensile properties, resilience, spherulite morphology and thermal properties. The test results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com