A kind of antistatic, friction-resistant and wear-resistant polyoxymethylene material and preparation method thereof

A polyoxymethylene material and friction-resistant technology, which is applied in the field of polyoxymethylene materials and its preparation, can solve the problems of the decline in the mechanical properties of polyoxymethylene and reduce the friction coefficient of polyoxymethylene, and achieve excellent antistatic performance, good ion conductivity, and good anti-static properties. The effect of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Step (1): Dry polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide and polytetrafluoroethylene in vacuum at 80°C for 24 hours:

[0064] Step (2): Add 3kg of dried polyoxymethylene, 15g of tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and 300g of polytetrafluoroethylene into the extruder for melt extrusion at 180°C. The rotation speed is 50rpm, the extruded material is water-cooled, sheared and granulated, and the mixture is obtained:

[0065] Step (3) The mixture is discharged from the melt extrusion equipment, water-cooled to room temperature, and granulated to obtain polyoxymethylene material.

[0066] The mass ratio of polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and polytetrafluoroethylene in the polyoxymethylene material prepared in Example 1 is 100:0.5:10

[0067] The test results of the samples are shown in Table 1

Embodiment 2

[0069] Step (1): Dry polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide and polytetrafluoroethylene in vacuum at 80°C for 24 hours:

[0070] Step (2): Add 3kg of dried polyoxymethylene, 30g of tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and 300g of polytetrafluoroethylene into the extruder for melt extrusion at 180°C. The rotation speed is 50rpm, the extruded material is water-cooled, sheared and granulated, and the mixture is obtained:

[0071] Step (3) The mixture is discharged from the melt extrusion equipment, water-cooled to room temperature, and granulated to obtain polyoxymethylene material.

[0072] In the polyoxymethylene material prepared in Example 2, the mass ratio of polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and polytetrafluoroethylene is 100:1:10

[0073] The test results of the samples are shown in Table 1

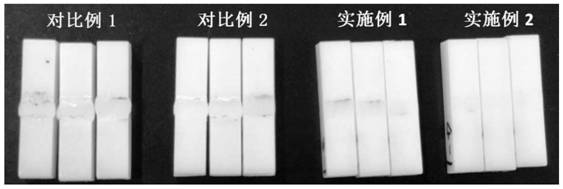

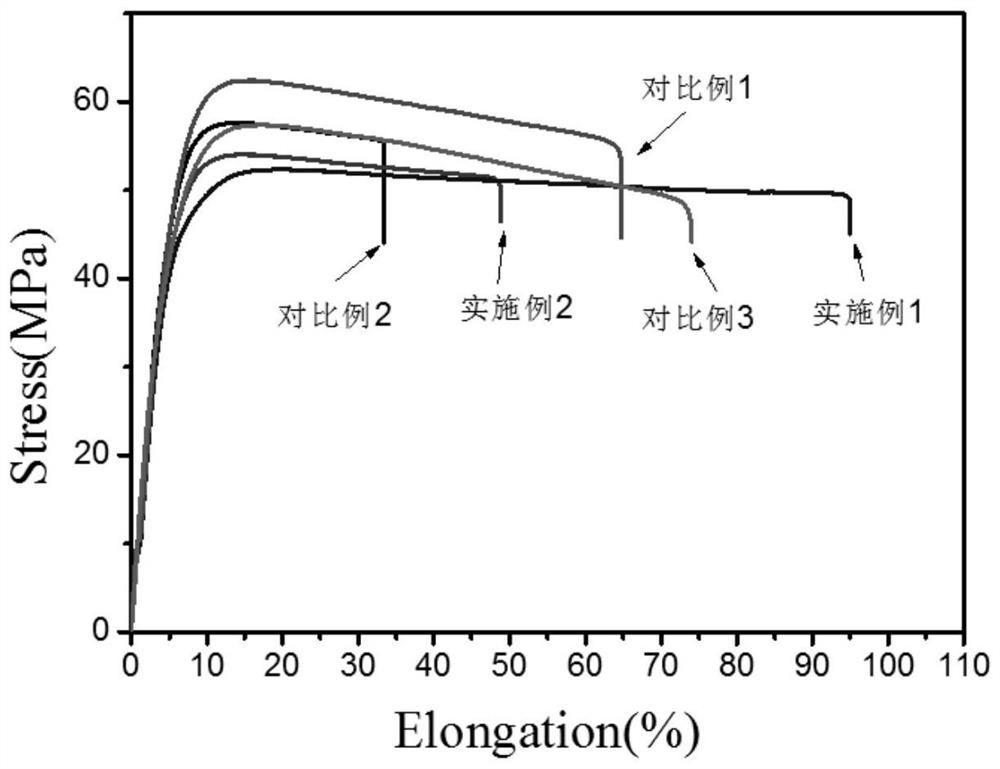

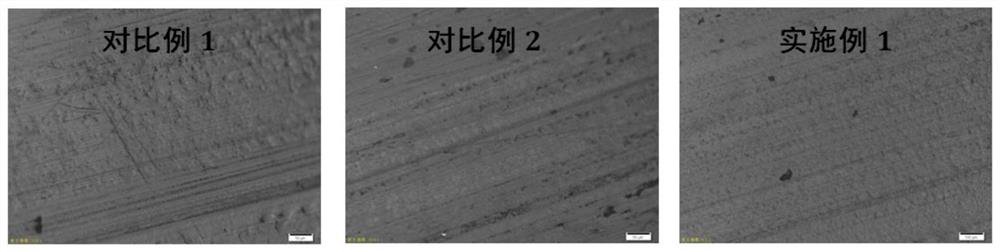

[0074] The materials prepared in Comparative Examples 1-3 and ...

Embodiment 3

[0095] Step (1): Dry polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide and polytetrafluoroethylene in vacuum at 80°C for 24 hours:

[0096] Step (2): Add 3kg of dried polyoxymethylene, 45g of tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and 300g of polytetrafluoroethylene into the extruder for melt extrusion at 180°C. The rotating speed is 50rpm, the extruded material is water-cooled, sheared and granulated to obtain a mixture;

[0097] Step (3) The mixture is discharged from the melt extrusion equipment, water-cooled to room temperature, and granulated to obtain polyoxymethylene material.

[0098]The mass ratio of polyoxymethylene, tri-n-butyloctylphosphine bis(trifluoromethanesulfonyl)imide salt and polytetrafluoroethylene in the polyoxymethylene material prepared in Example 3 is 100:1.5:10

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com