Patents

Literature

43results about How to "Reduce electric field distortion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Differential D-dot voltage sensor

ActiveCN103235170AReduce volumeWill not affect the input sideCurrent/voltage measurementElectrical conductorSmart grid

The invention discloses a differential D-dot voltage sensor, which comprises a measuring module, an electrode plate, a signal modulation module and a collection transmission module, wherein the measuring module is provided with a first input end and a second input end, the electrode plate is provided with a first electrode and a second electrode, the measuring module is a differential amplification module, the differential amplification module is used for measuring the differential voltage between conducting layers, the sensor is not in grounding contact and is also not in direct contact with a tested conductor, and the output is floating potential difference, so the sensor can reduce the size of an insulation structure. Because the differential structure carries out non-contact measurement on the same potential, no direct energy transmission exists between the tested conductor and the sensor, and the influence cannot be generated on the input side when the sensor generates fault such as insulation breakthrough or output short circuit. The differential D-dot voltage sensor can solve the non-contact electrodeless voltage measurement problem of an intelligent electric network and can be used for 10kV to 35kV voltage measurement.

Owner:CHONGQING UNIV

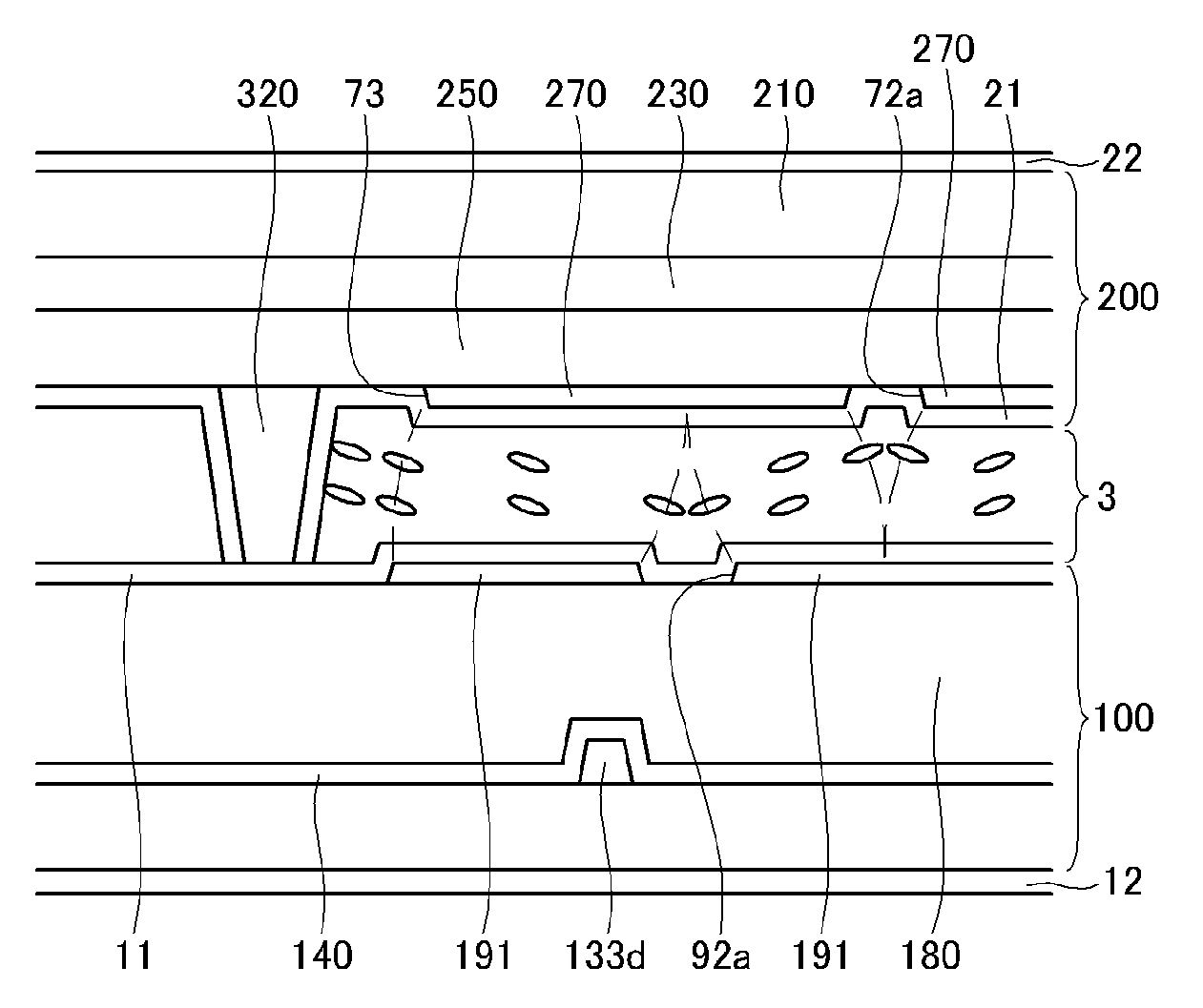

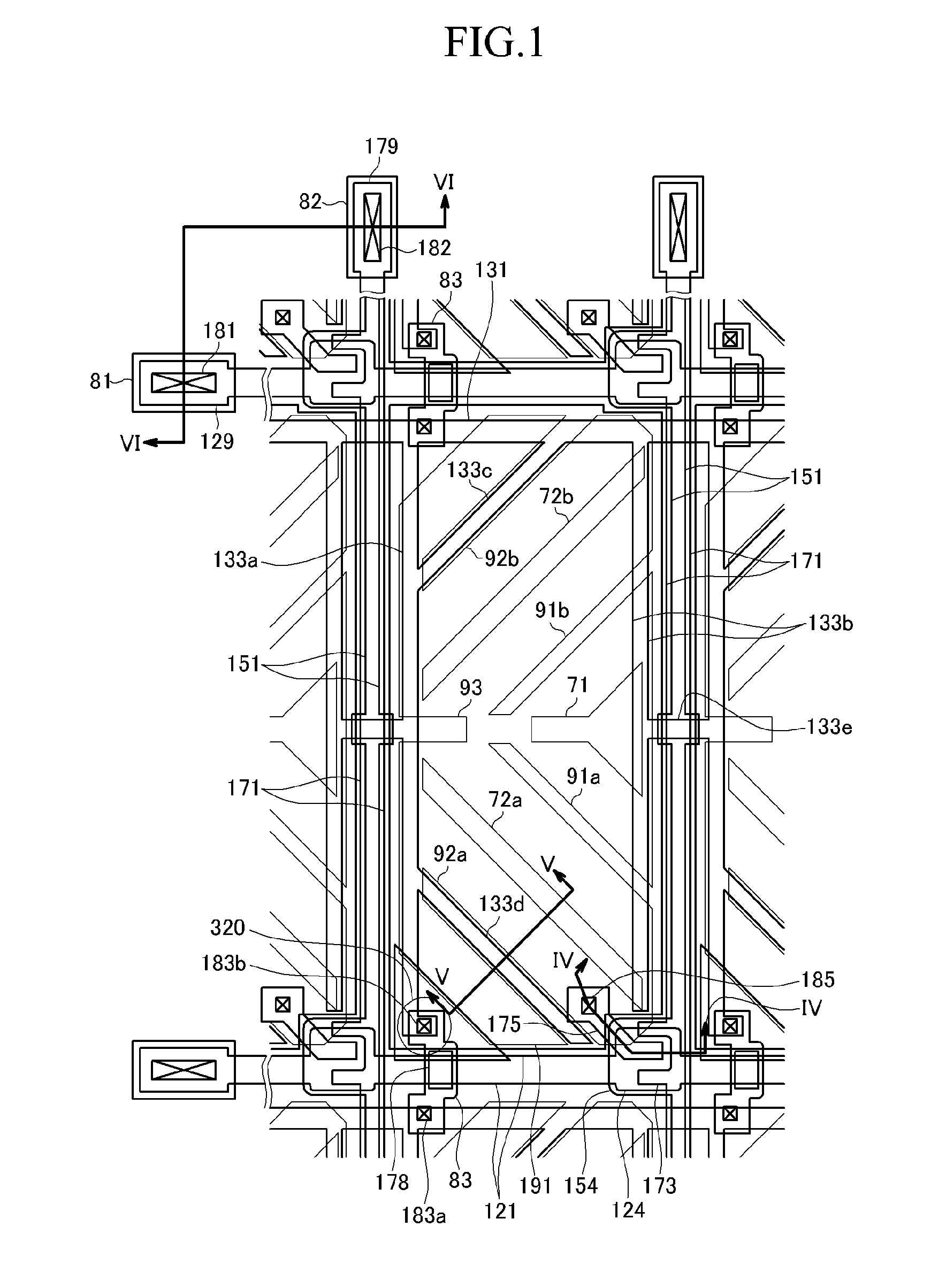

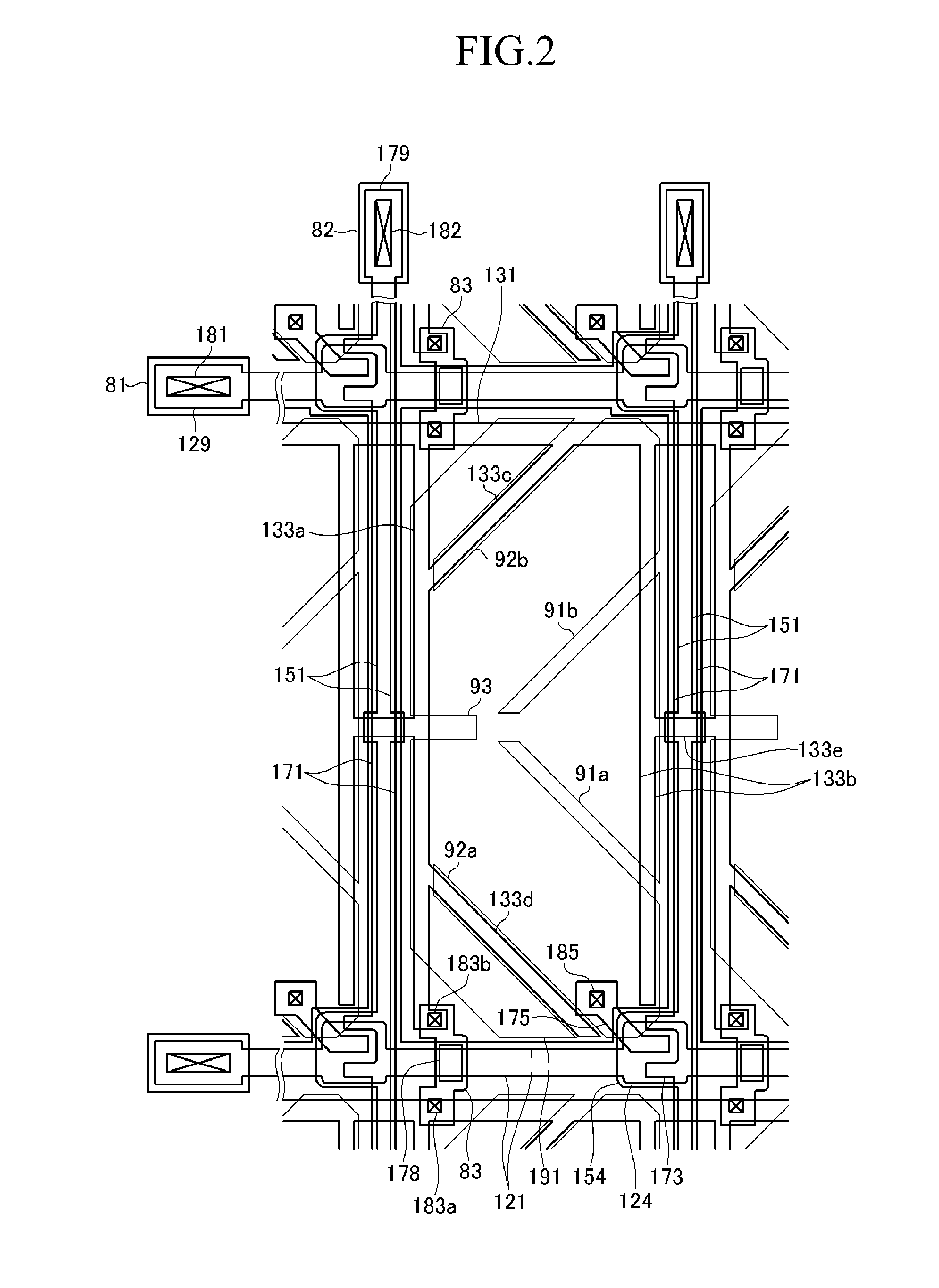

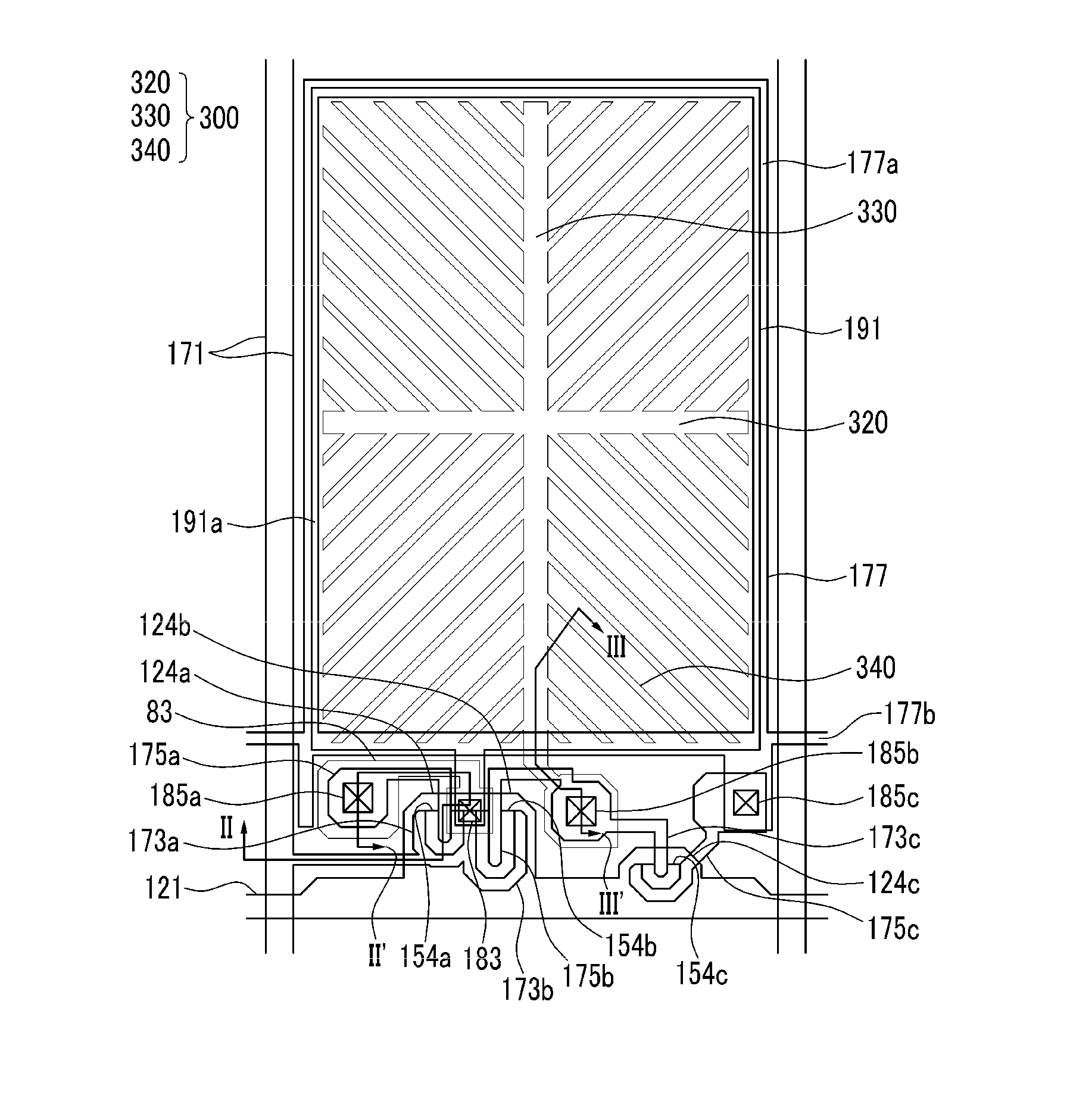

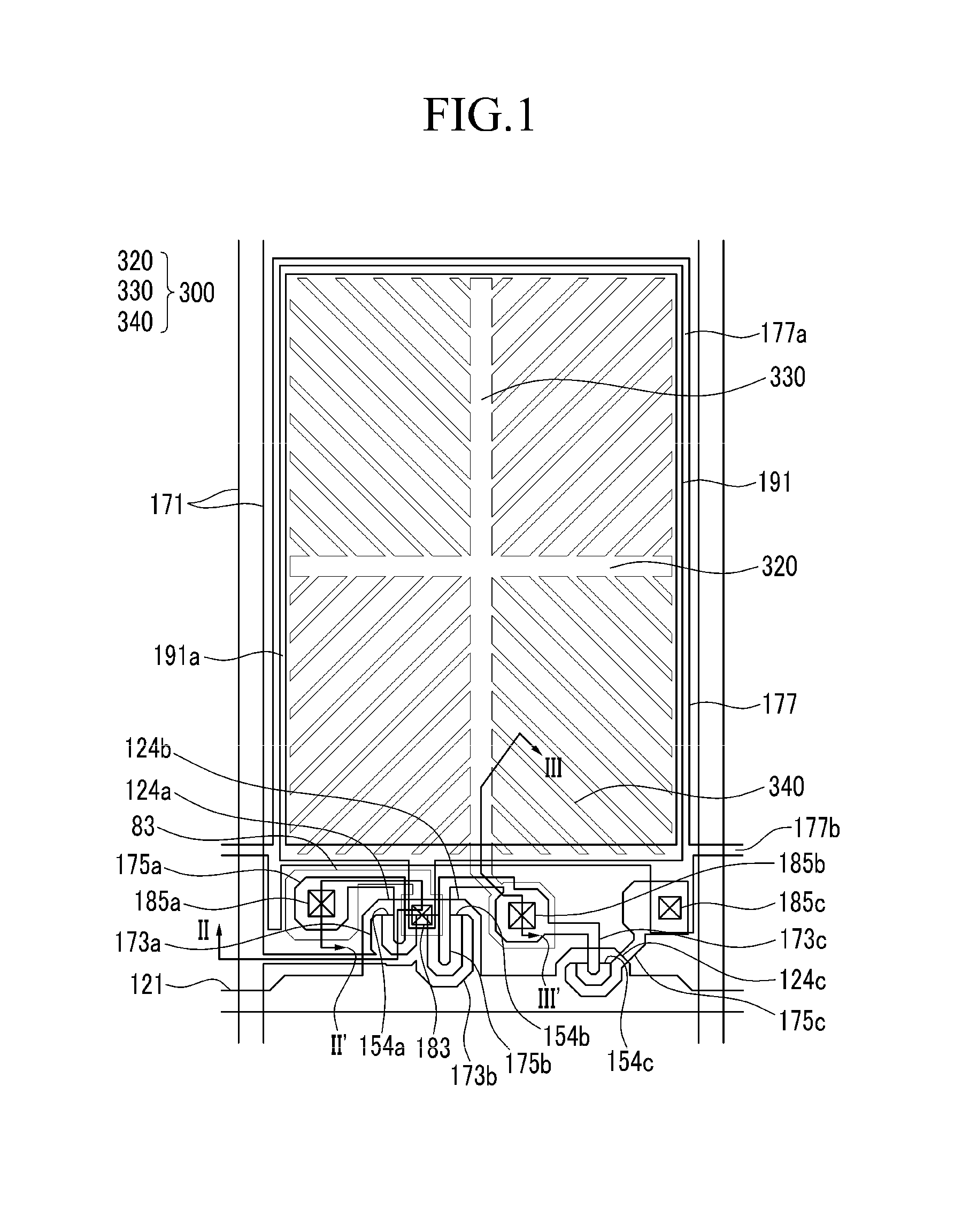

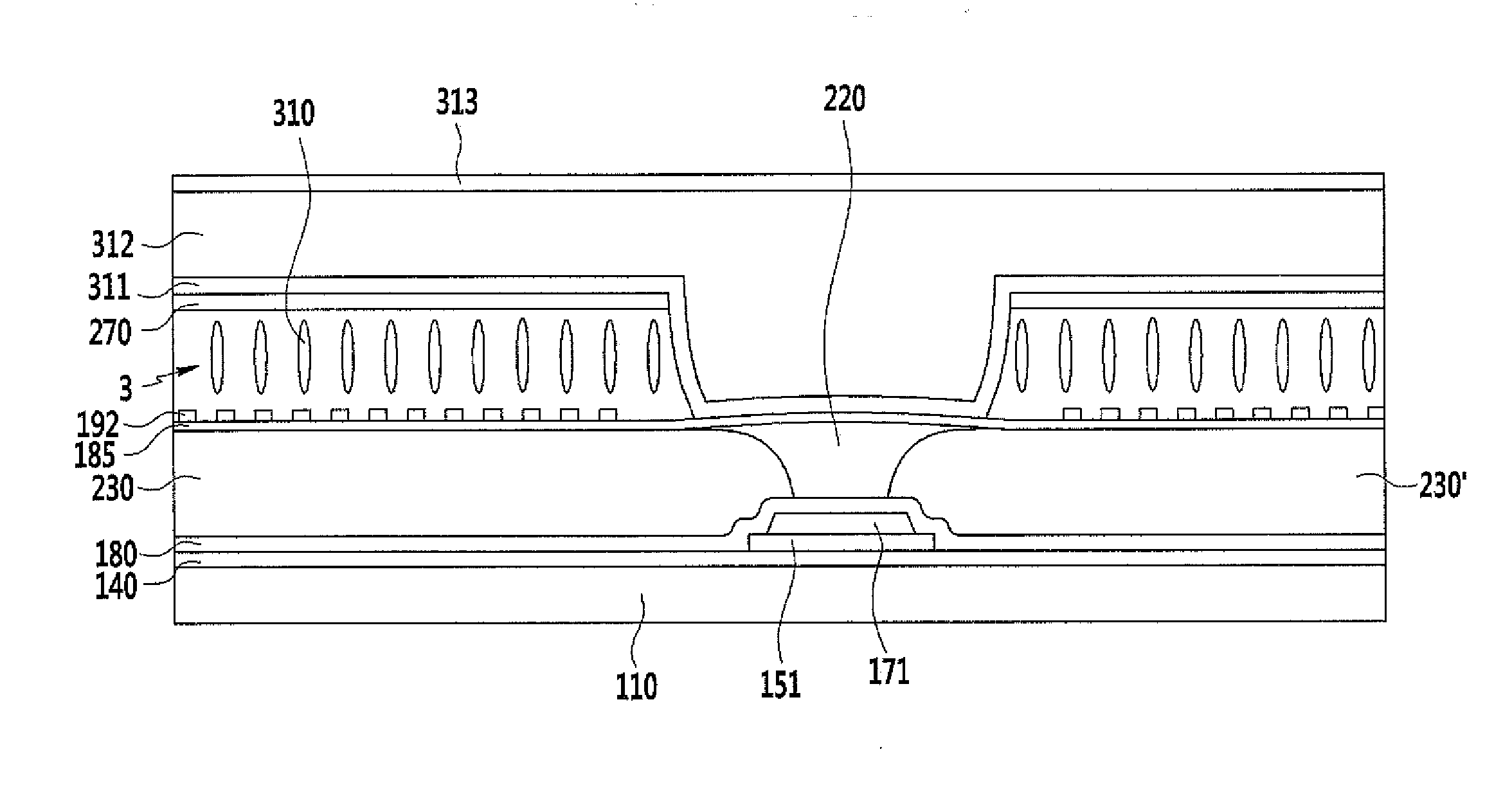

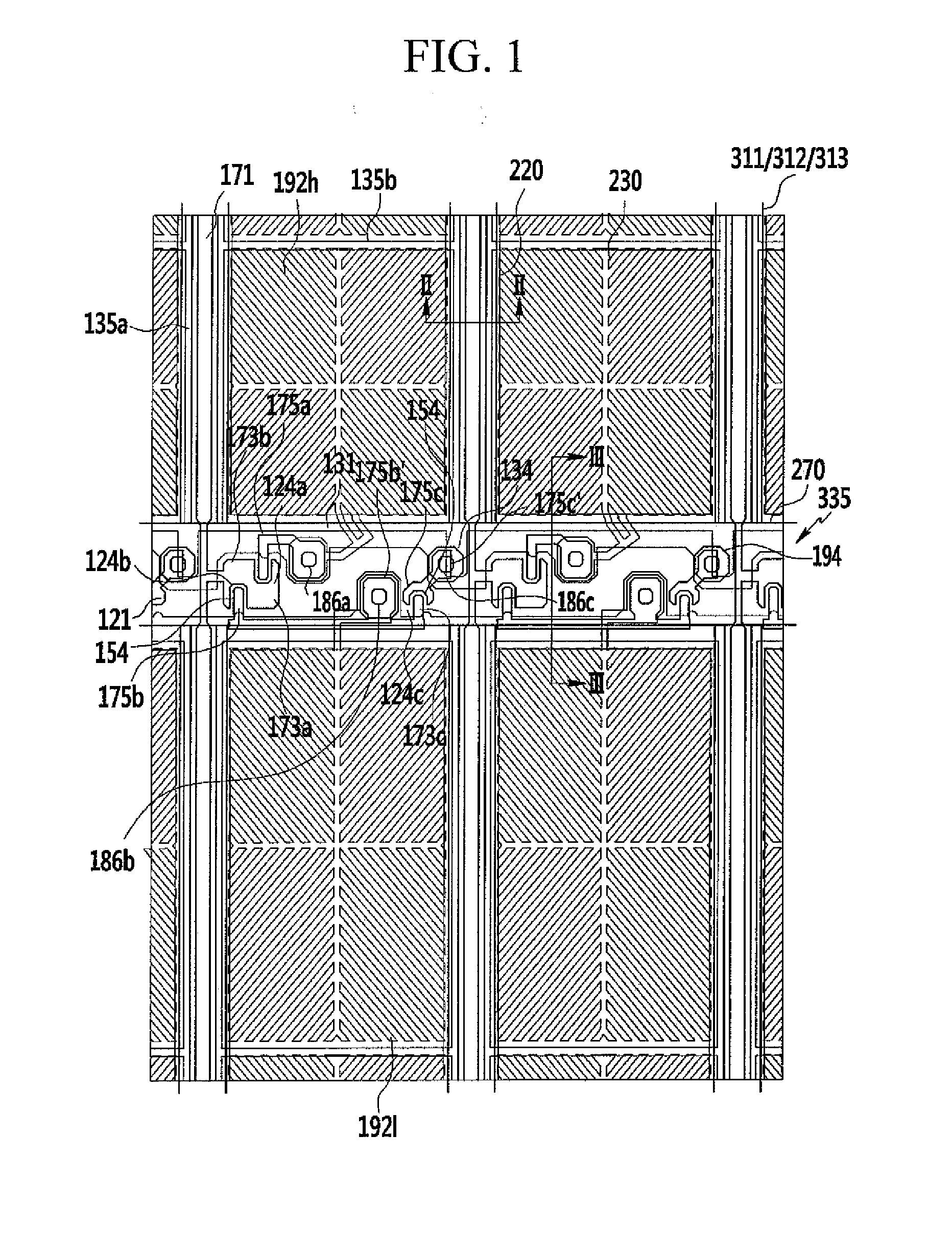

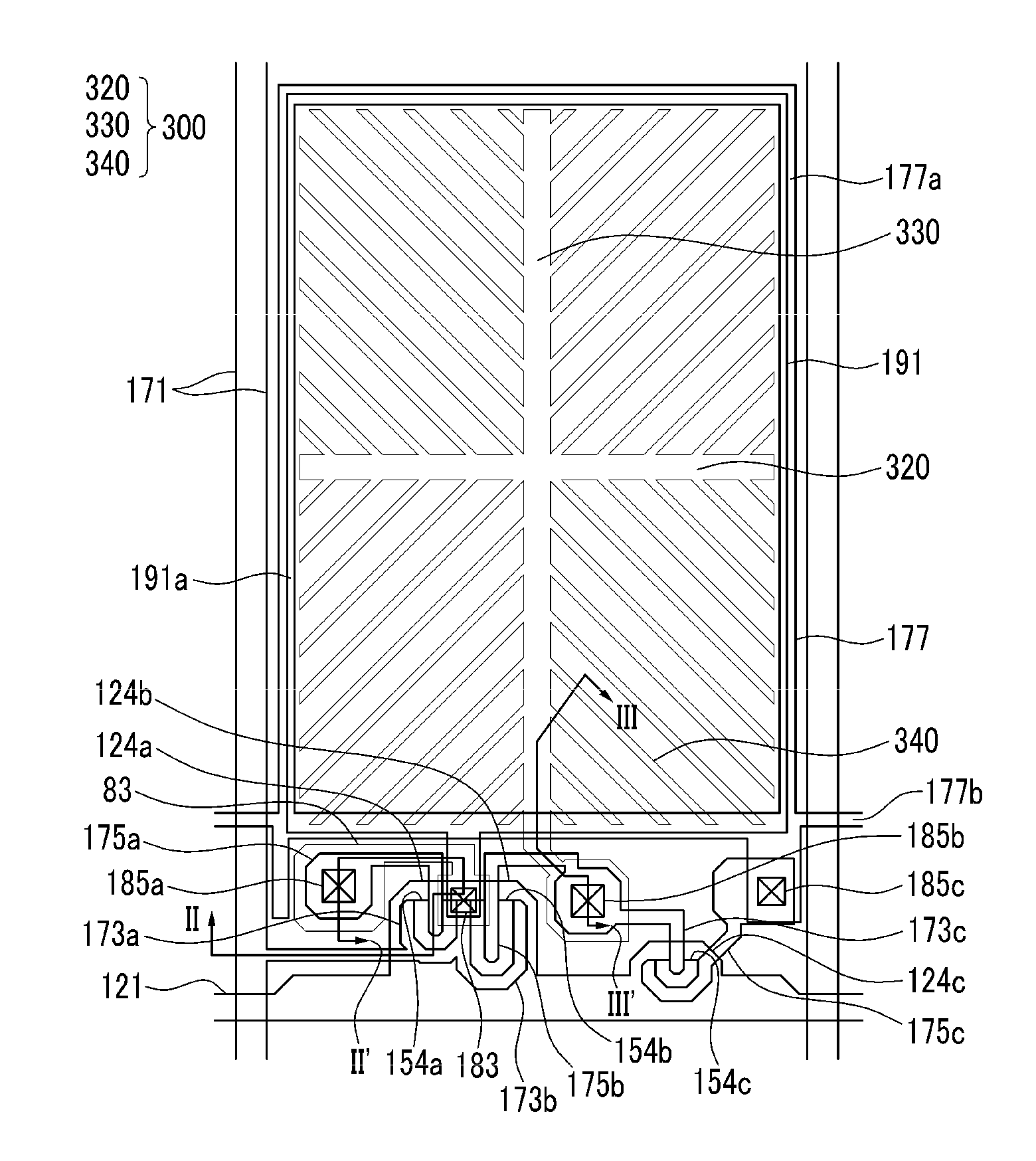

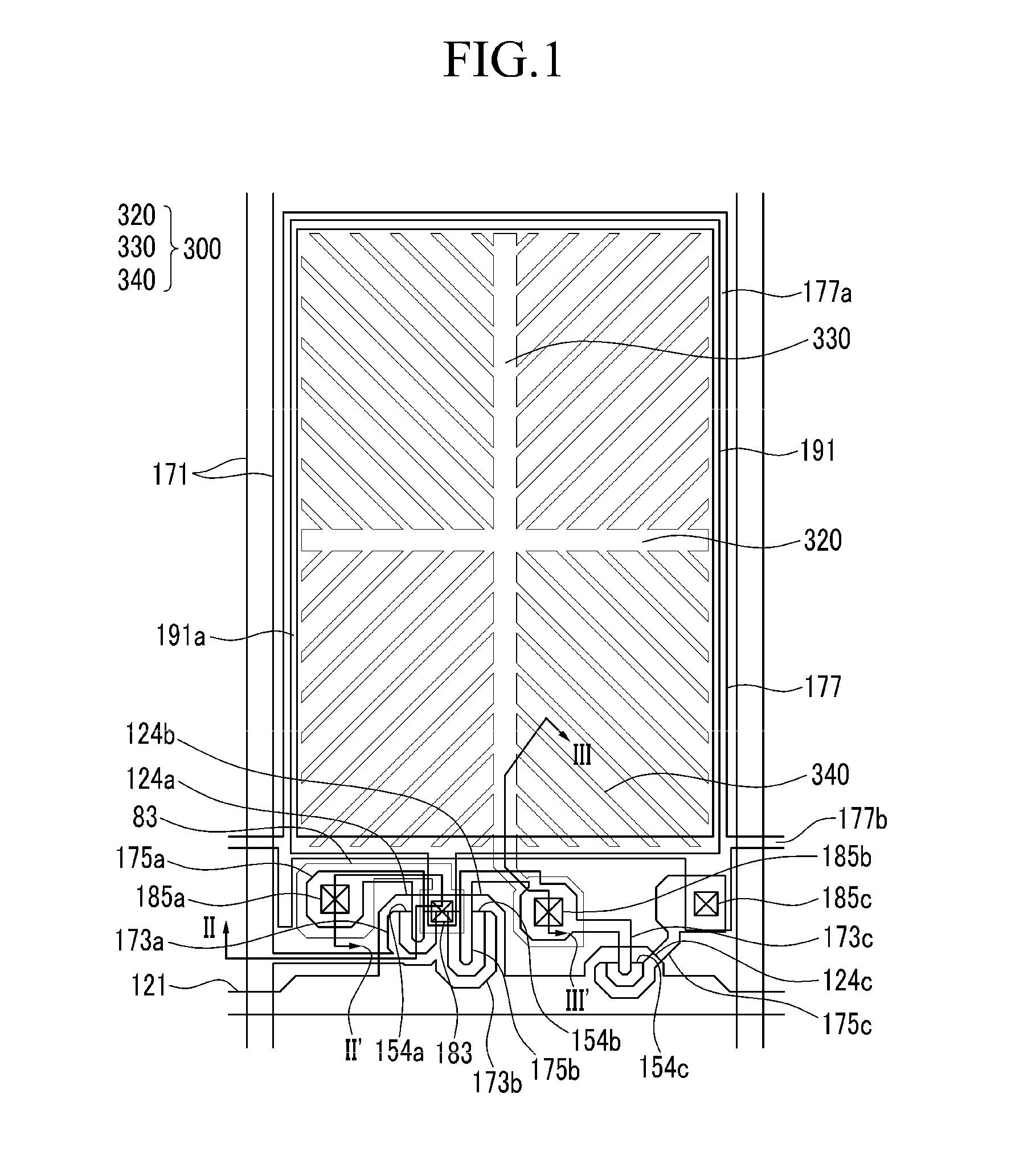

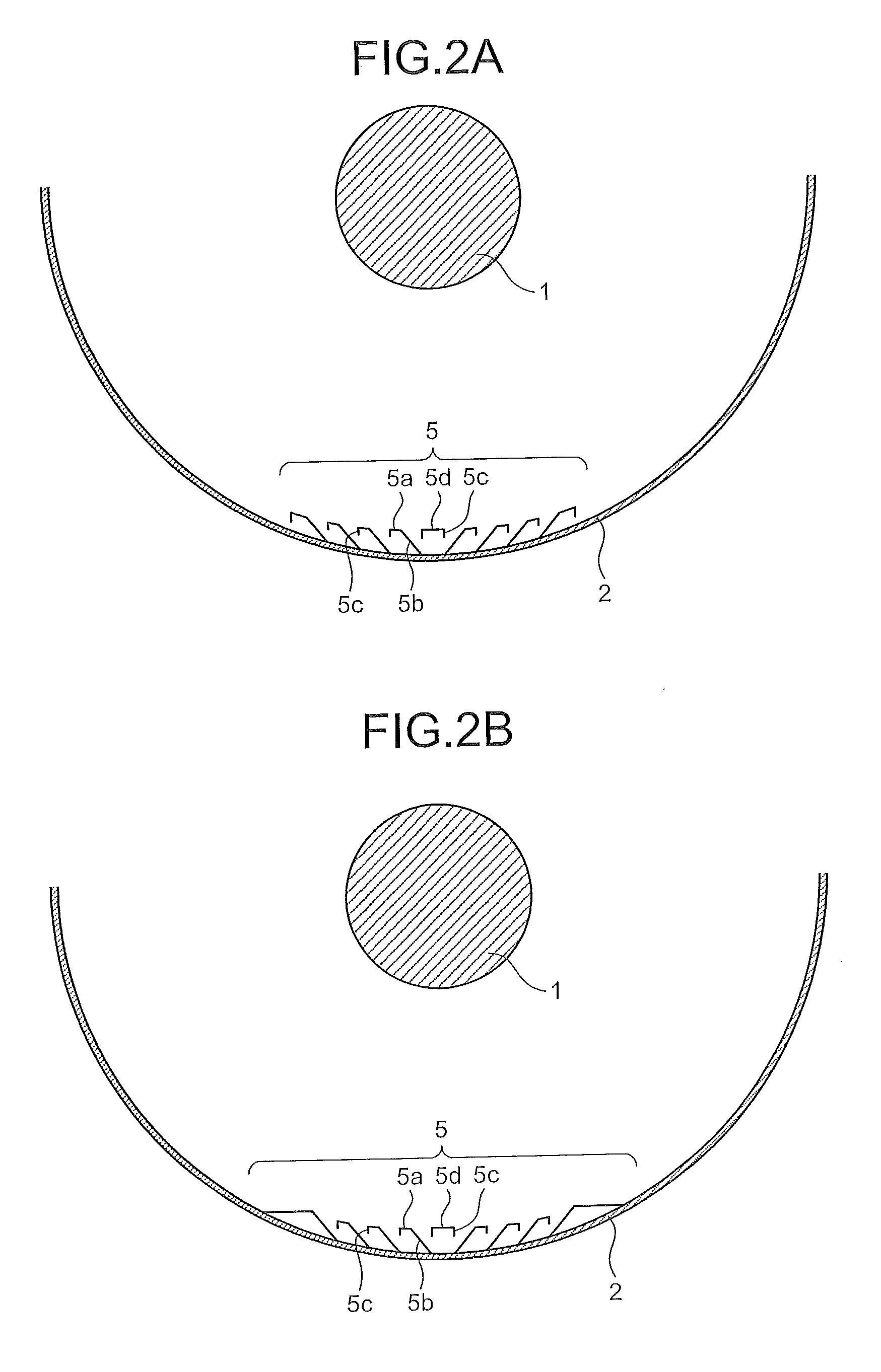

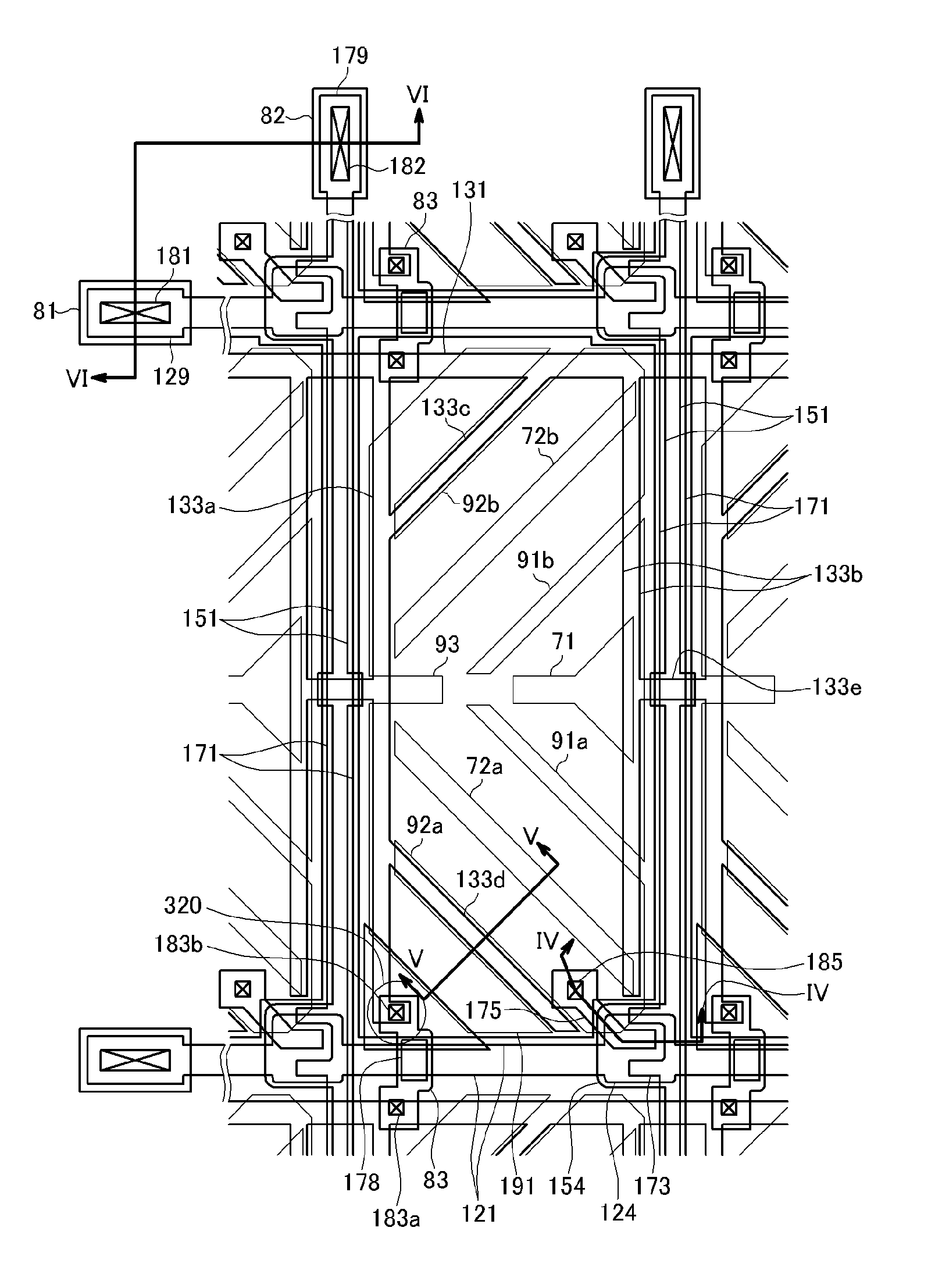

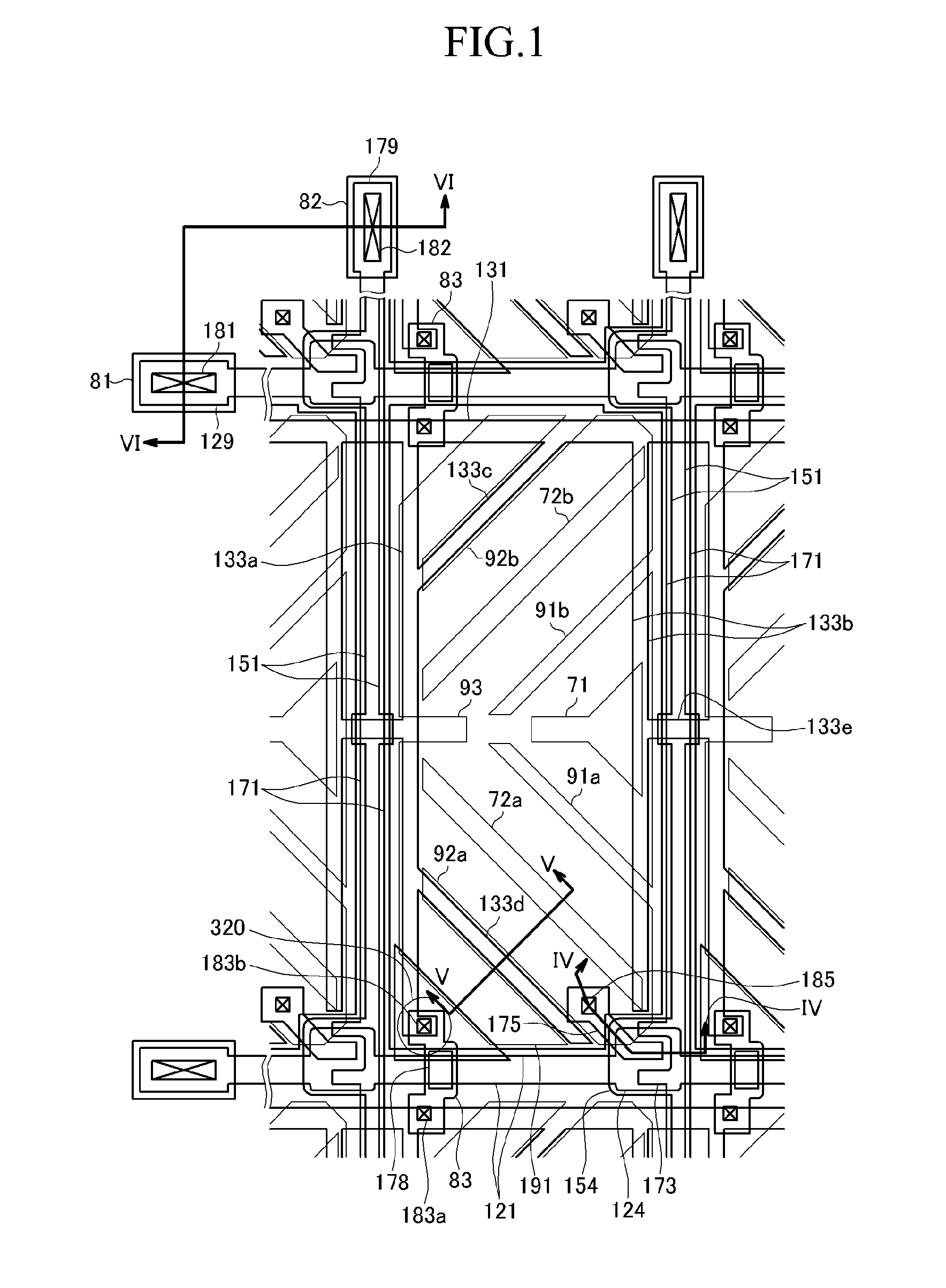

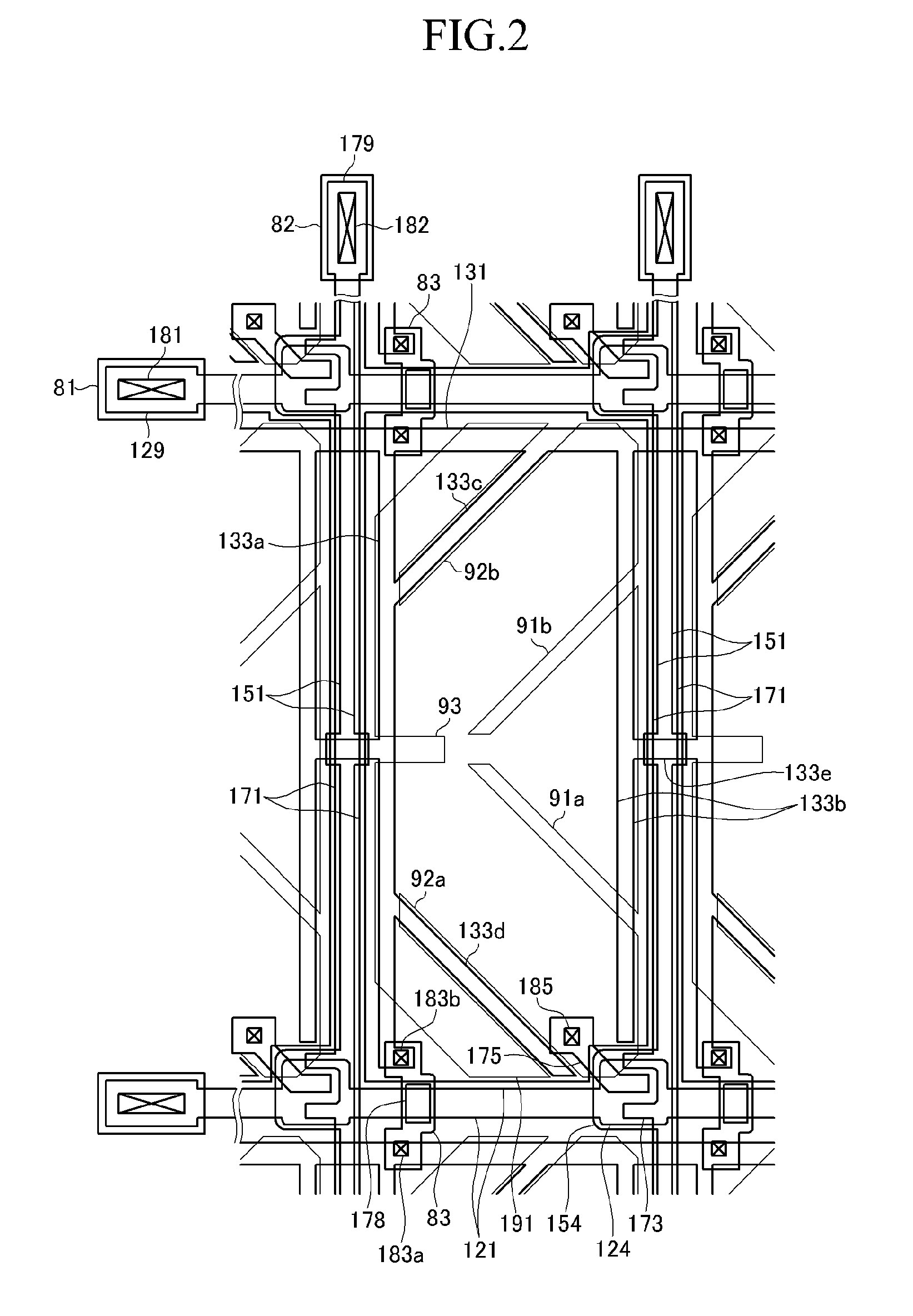

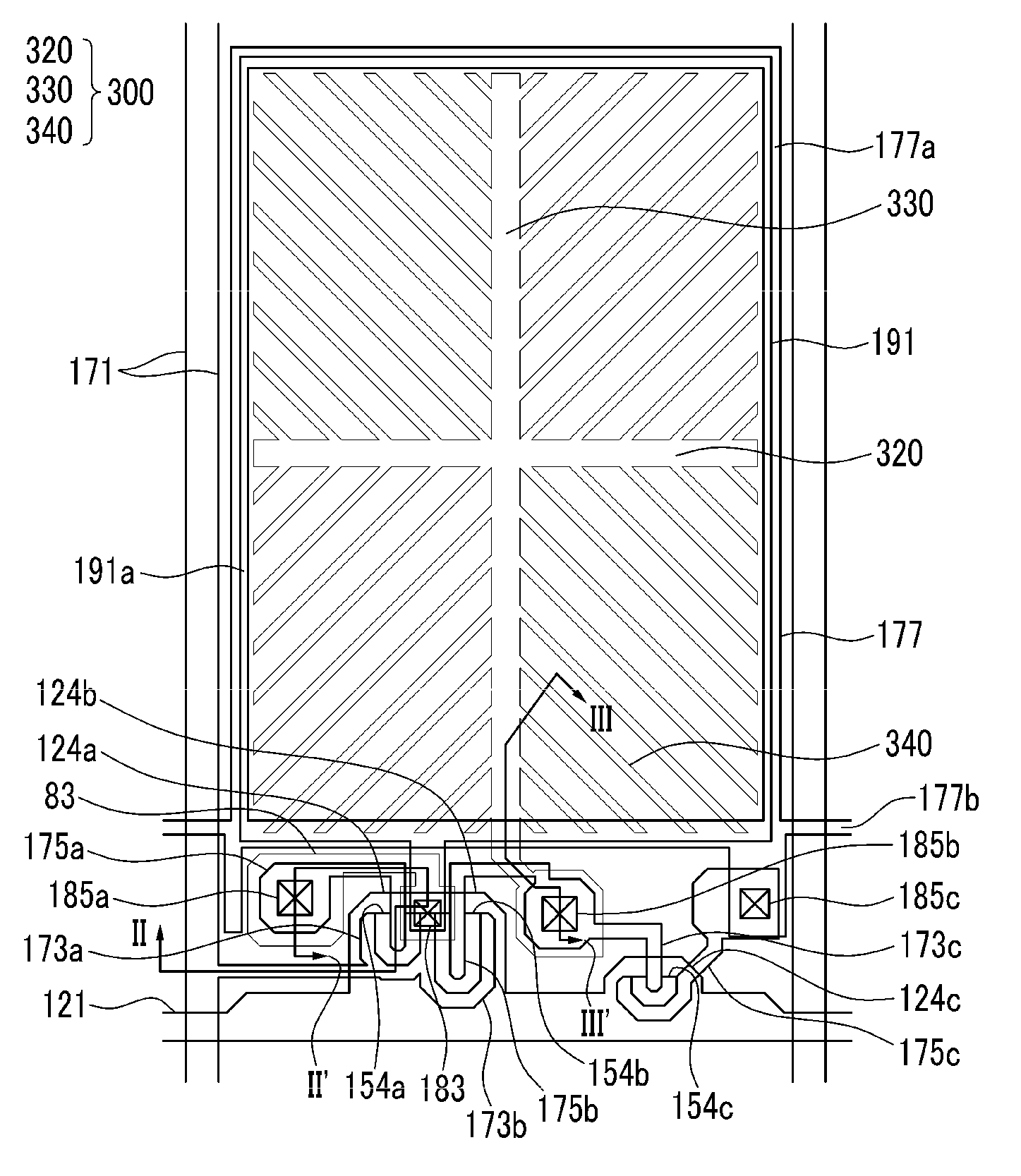

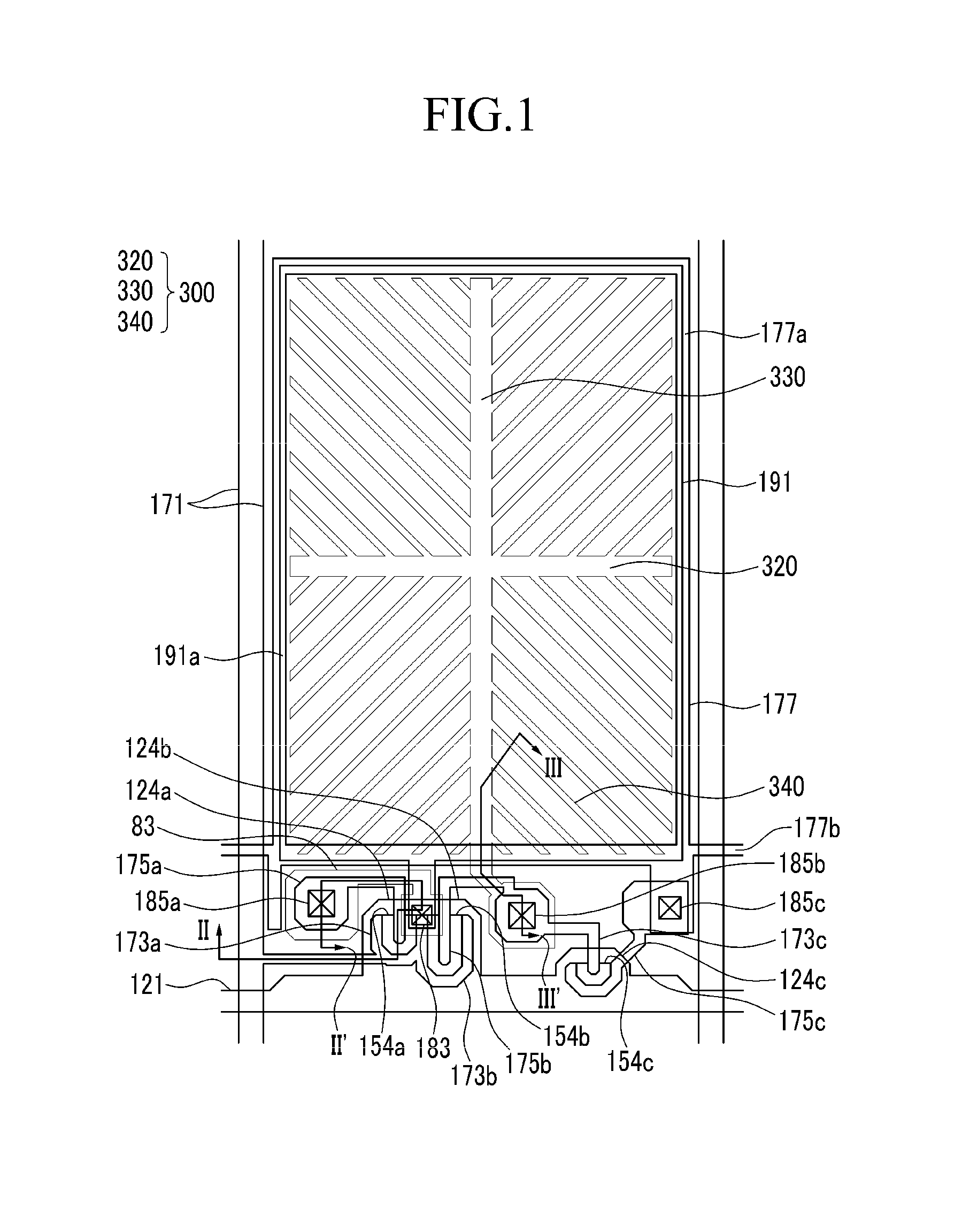

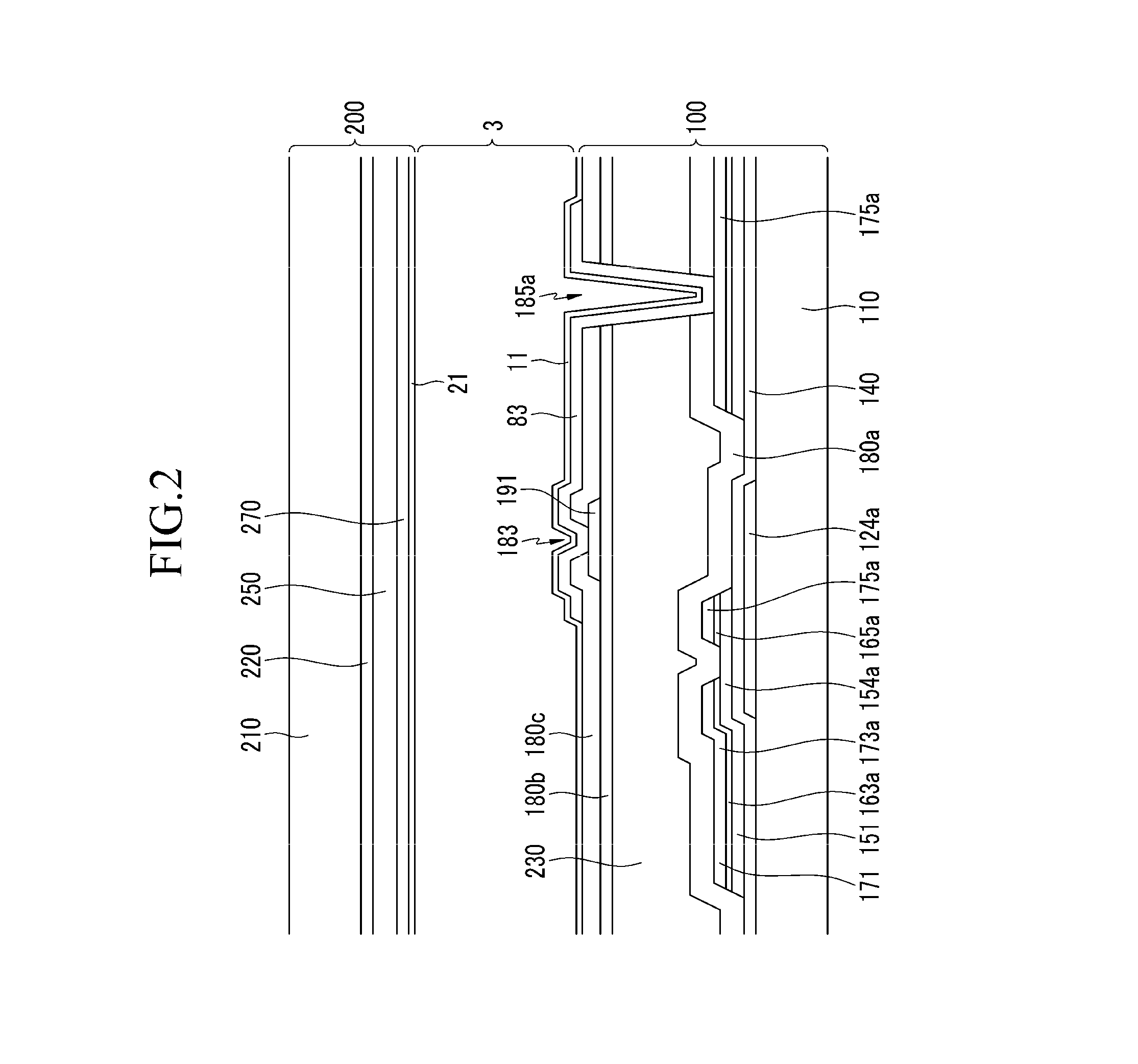

Liquid crystal display

InactiveUS20070200995A1Reduce textureReduce electric field distortionNon-linear opticsLaddersLiquid-crystal displayLiquid crystal

A liquid crystal display includes a first substrate, a first field generating electrode arranged on the first substrate and including first and second cutouts, and a second substrate facing the first substrate. A second field generating electrode is arranged on the second substrate and includes a third cutout, and a liquid crystal layer is interposed between the first and second field generating electrodes. A column spacer is interposed between the first and second substrates and is disposed in the first cutout region.

Owner:SAMSUNG DISPLAY CO LTD

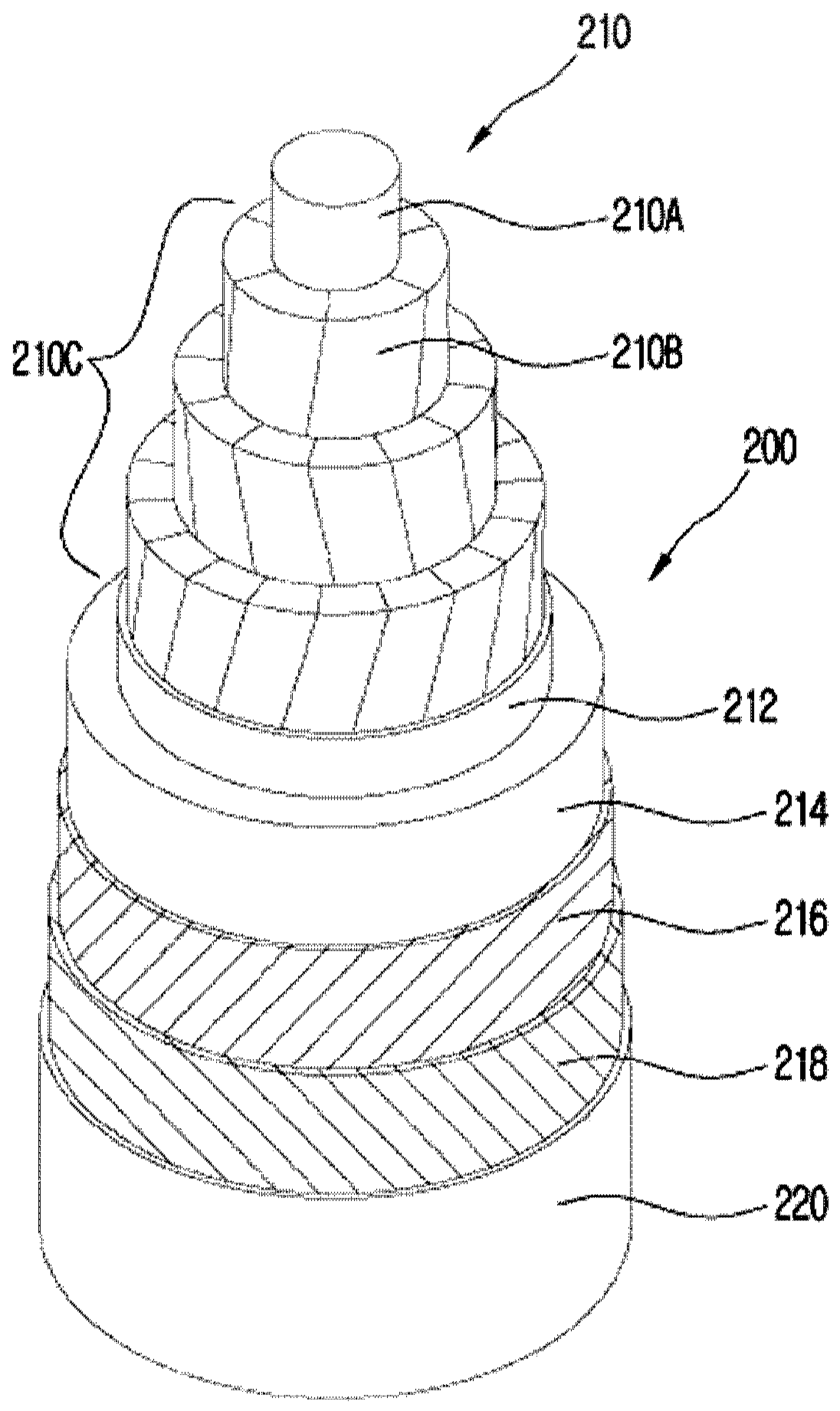

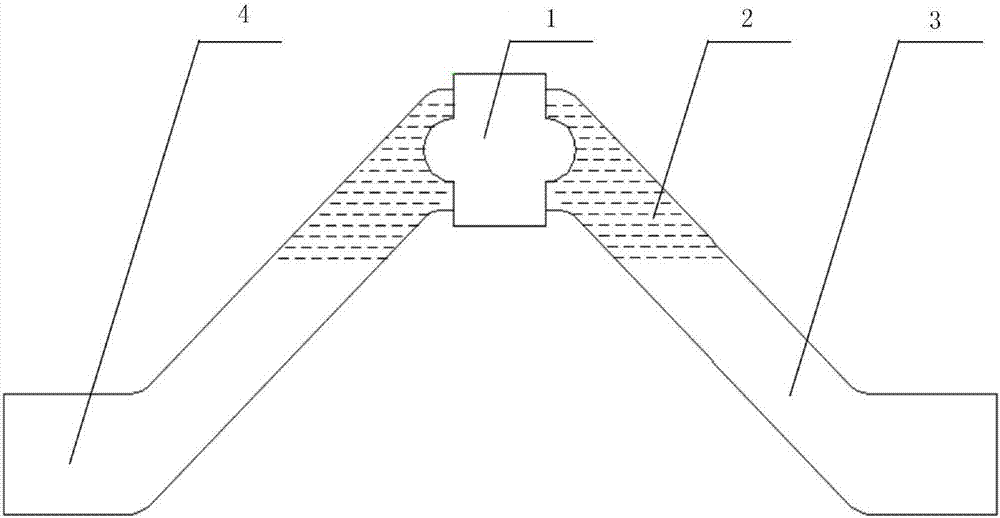

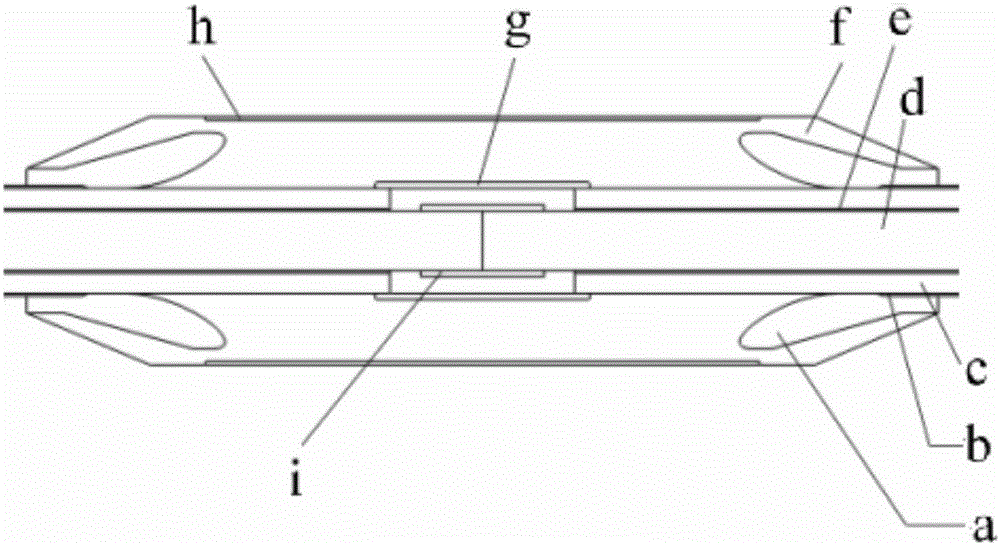

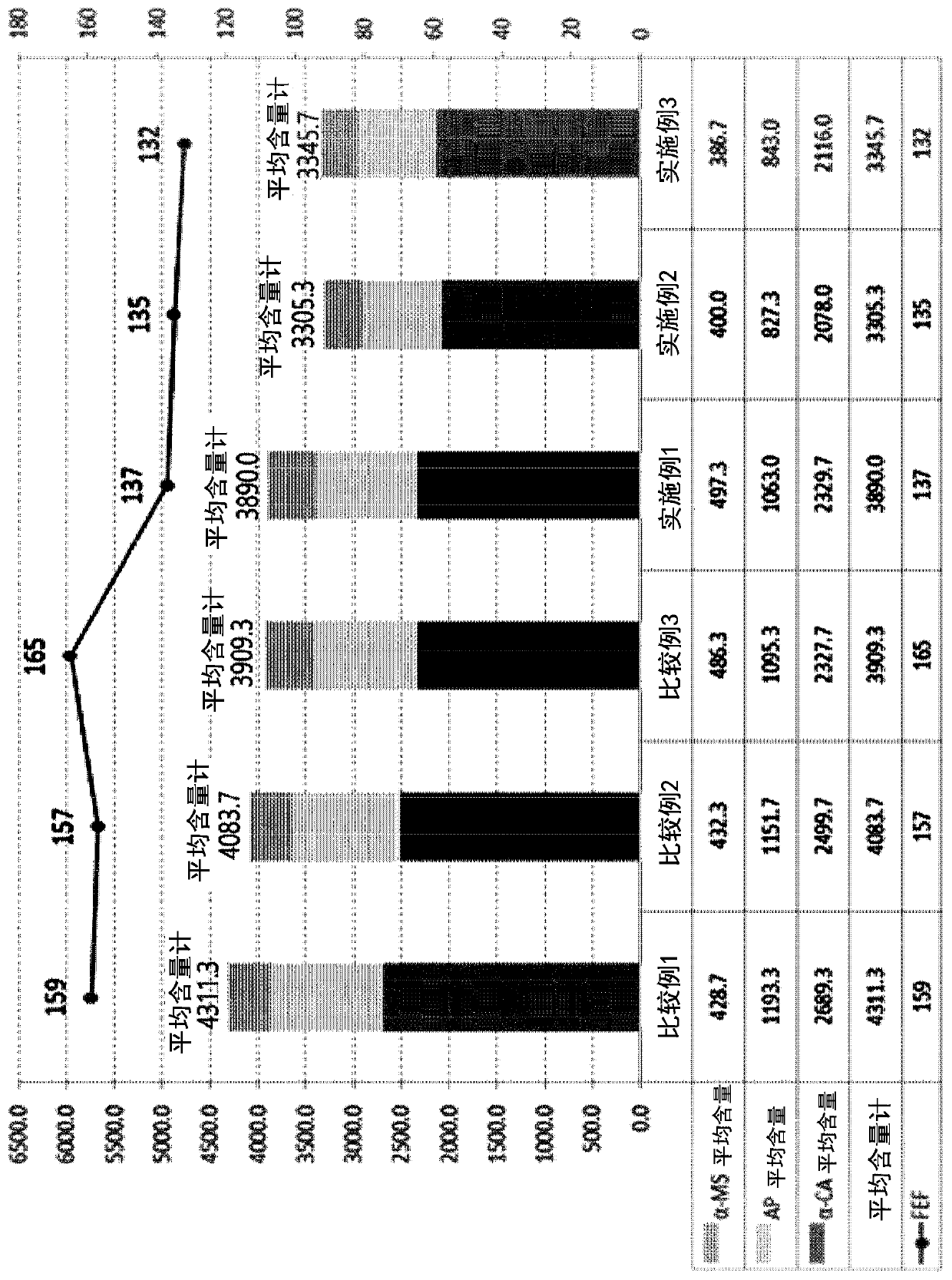

Stress control body for plastic insulation high-voltage and direct-current cable connector

InactiveCN103259240AImprove DC breakdown strengthReduce interfacial space chargeCable junctionsHigh-voltage direct currentElectric field distortion

The invention discloses a stress control body for a plastic insulation high-voltage and direct-current cable connector, and relates to the stress control body for the cable connector. The stress control body for the plastic insulating high-voltage and direct-current cable connector aims at solving the problems that an existing plastic insulation direct current cable prefabricated connector structure hardly meets the requirement for connecting a plastic insulation high-voltage and direct-current cable prefabricated connector with the voltage over 160 kilovolts, and at present a mature plastic insulation direct current cable prefabricated connector design scheme does not exist. The stress control body for the plastic insulating high-voltage and direct-current cable connector is a stress control body for a cross linked polyethylene insulated high-voltage and direct-current cable connector with the voltage between 160kV and 500kV, and is composed of a high-voltage shielding layer, a strengthening insulator, a stress cone and an outer shielding layer, and two side end ports of the strengthening insulator are in a trapezoid shape. According to the stress control body, electric field distortion inside the prefabricated connector can be effectively reduced, the diameter of the prefabricate connector is reduced, the prefabricated connector is convenient to install, the heat dissipation property of the prefabricated connector is improved, and the stress control body can be applied to designing the plastic insulation high-voltage and direct-current cable with the voltage over 160 kilovolts.

Owner:HARBIN UNIV OF SCI & TECH

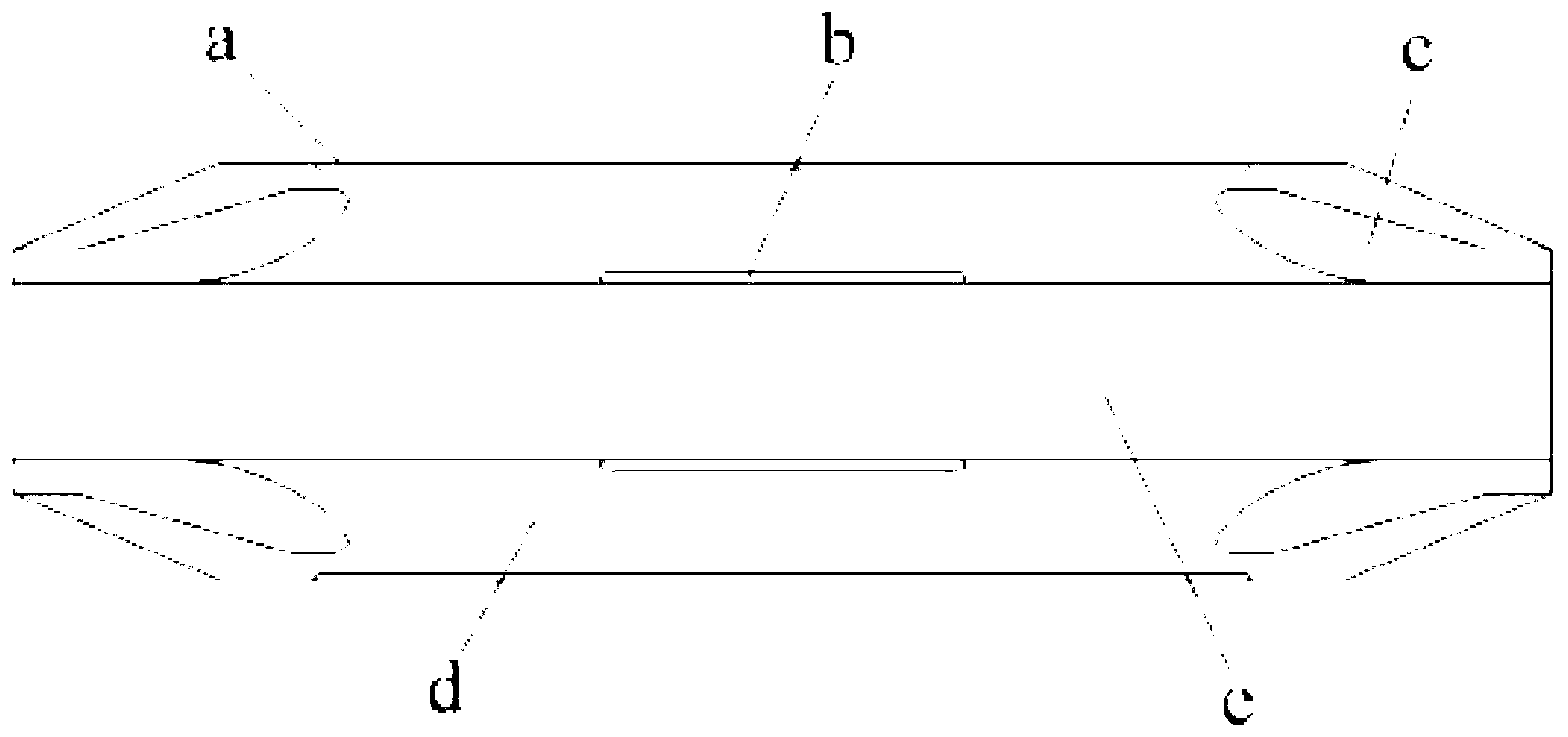

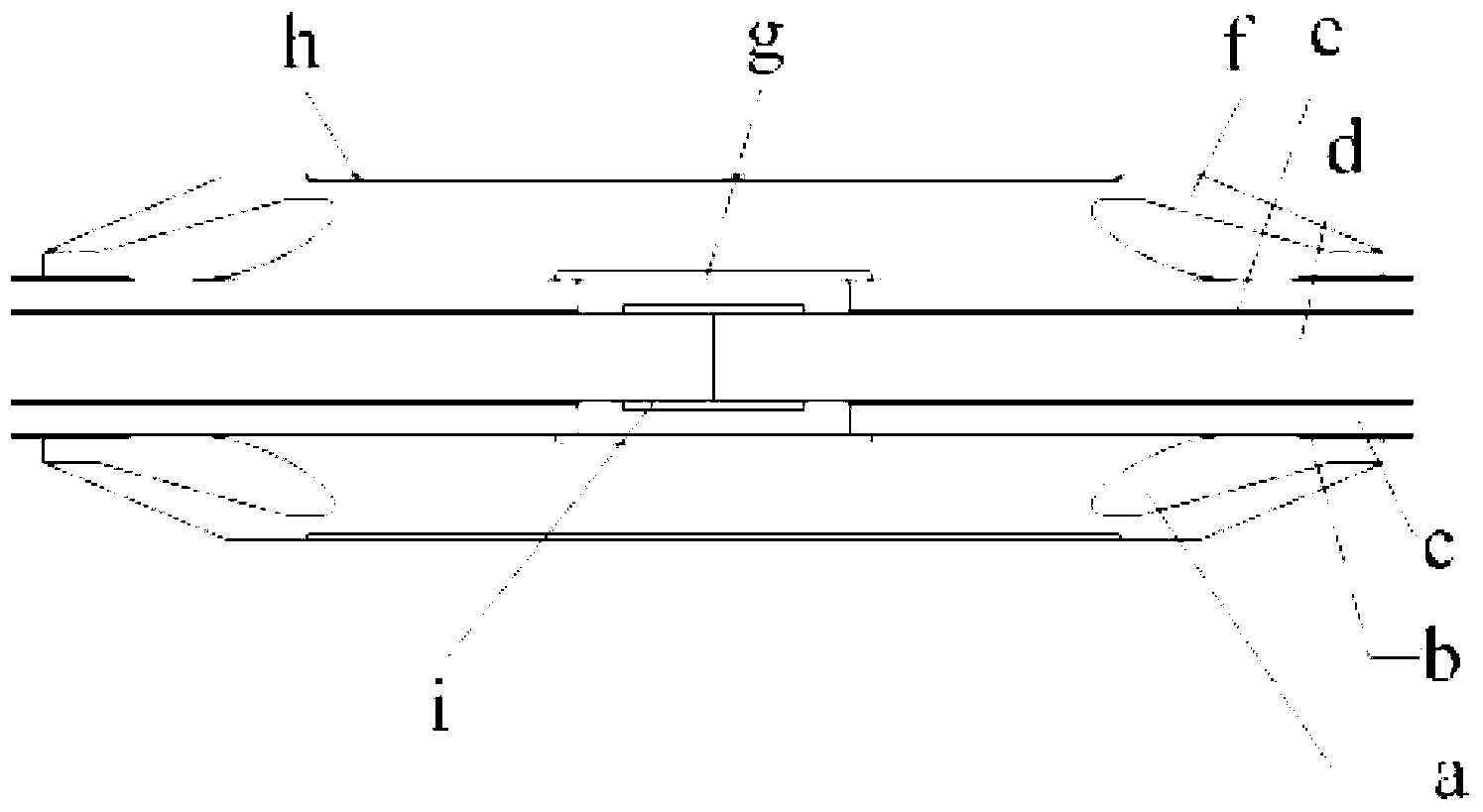

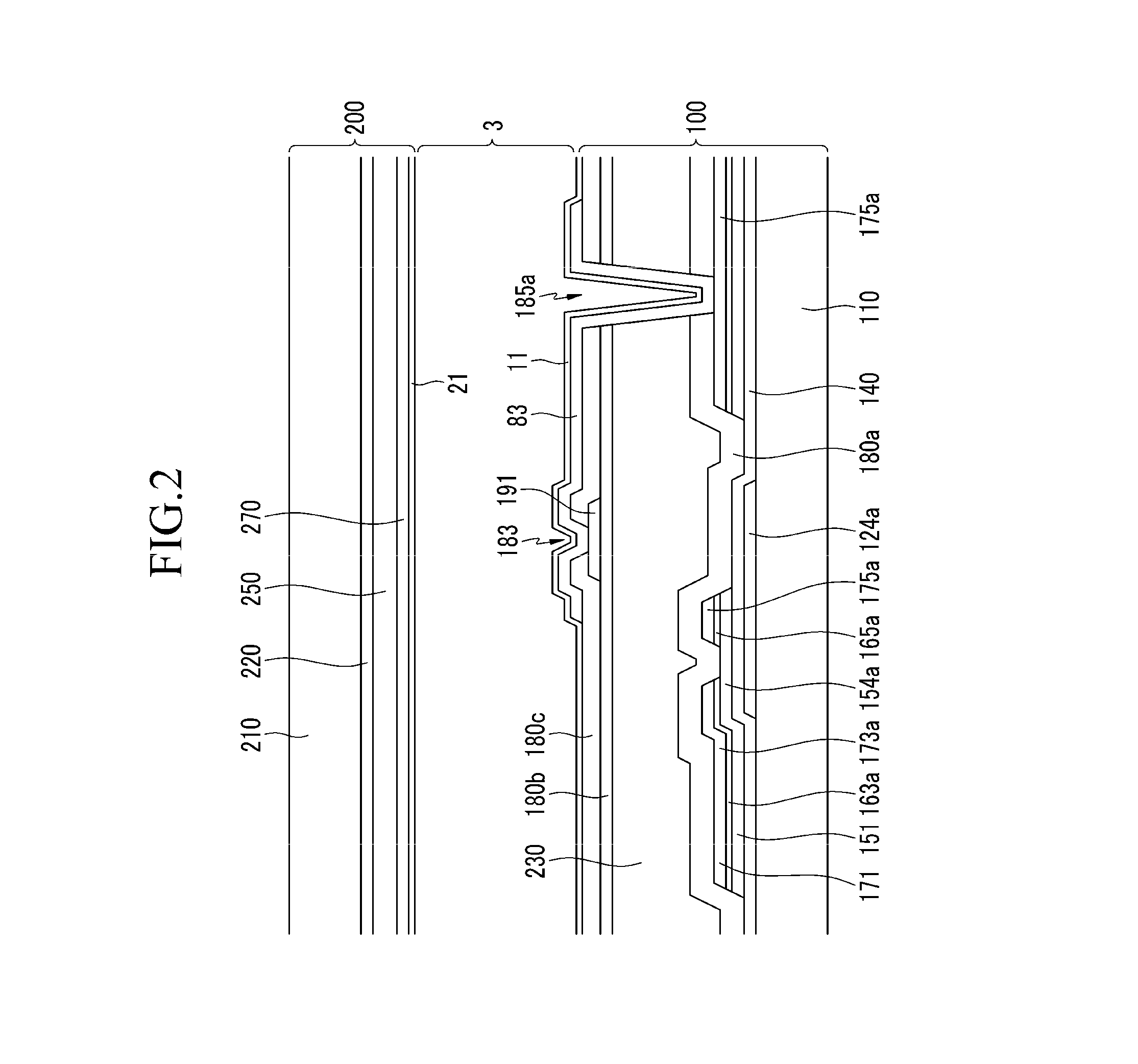

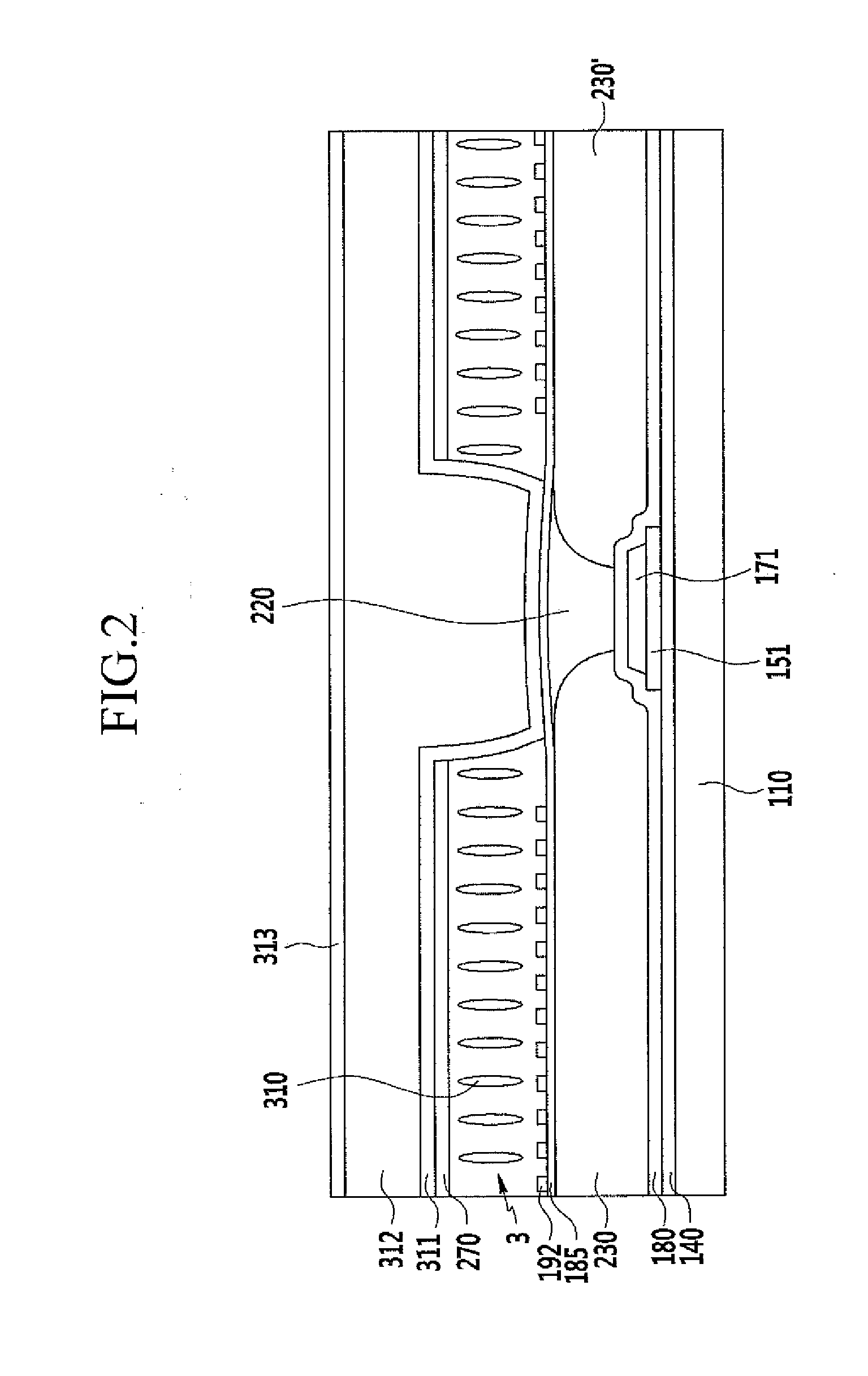

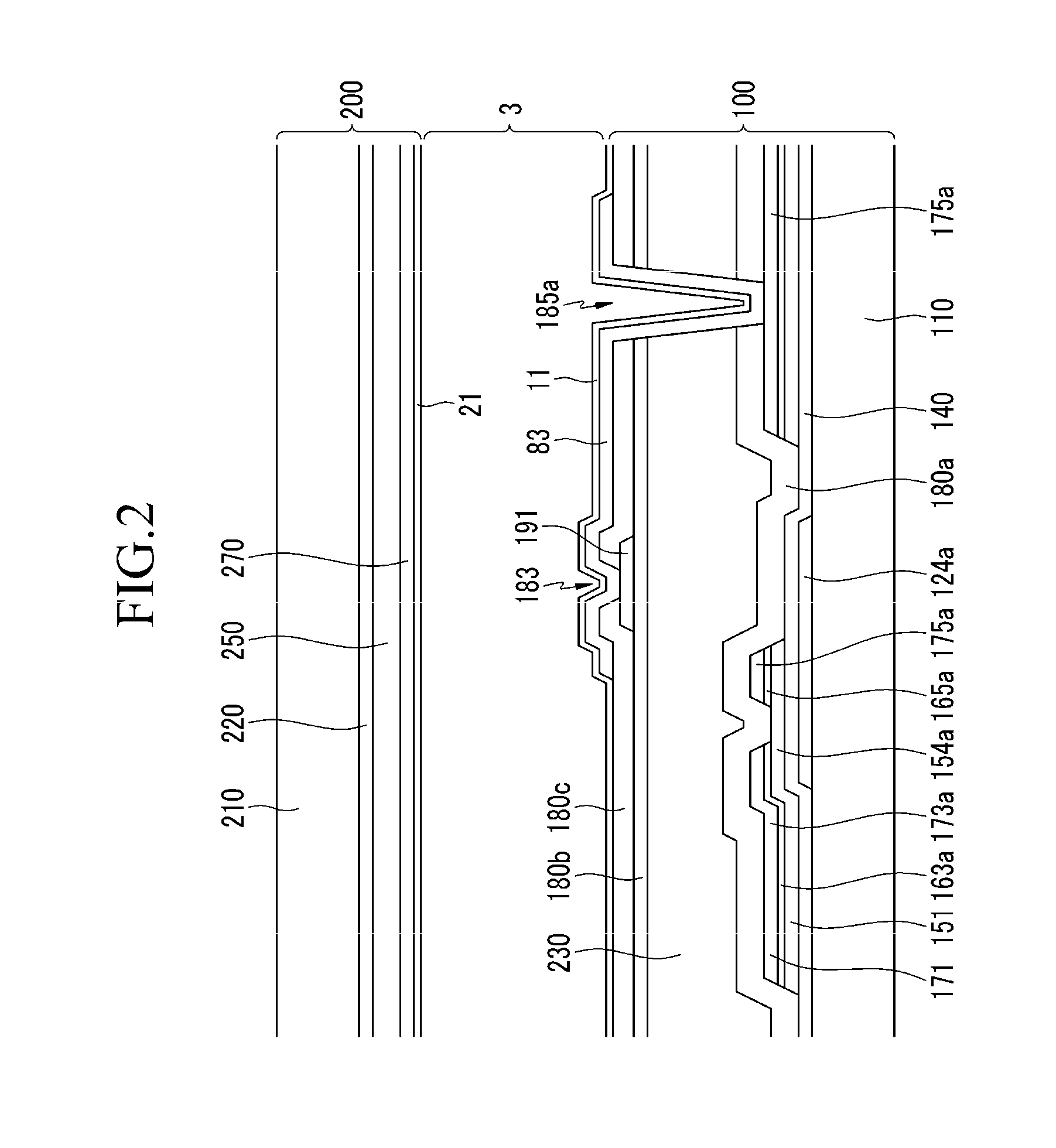

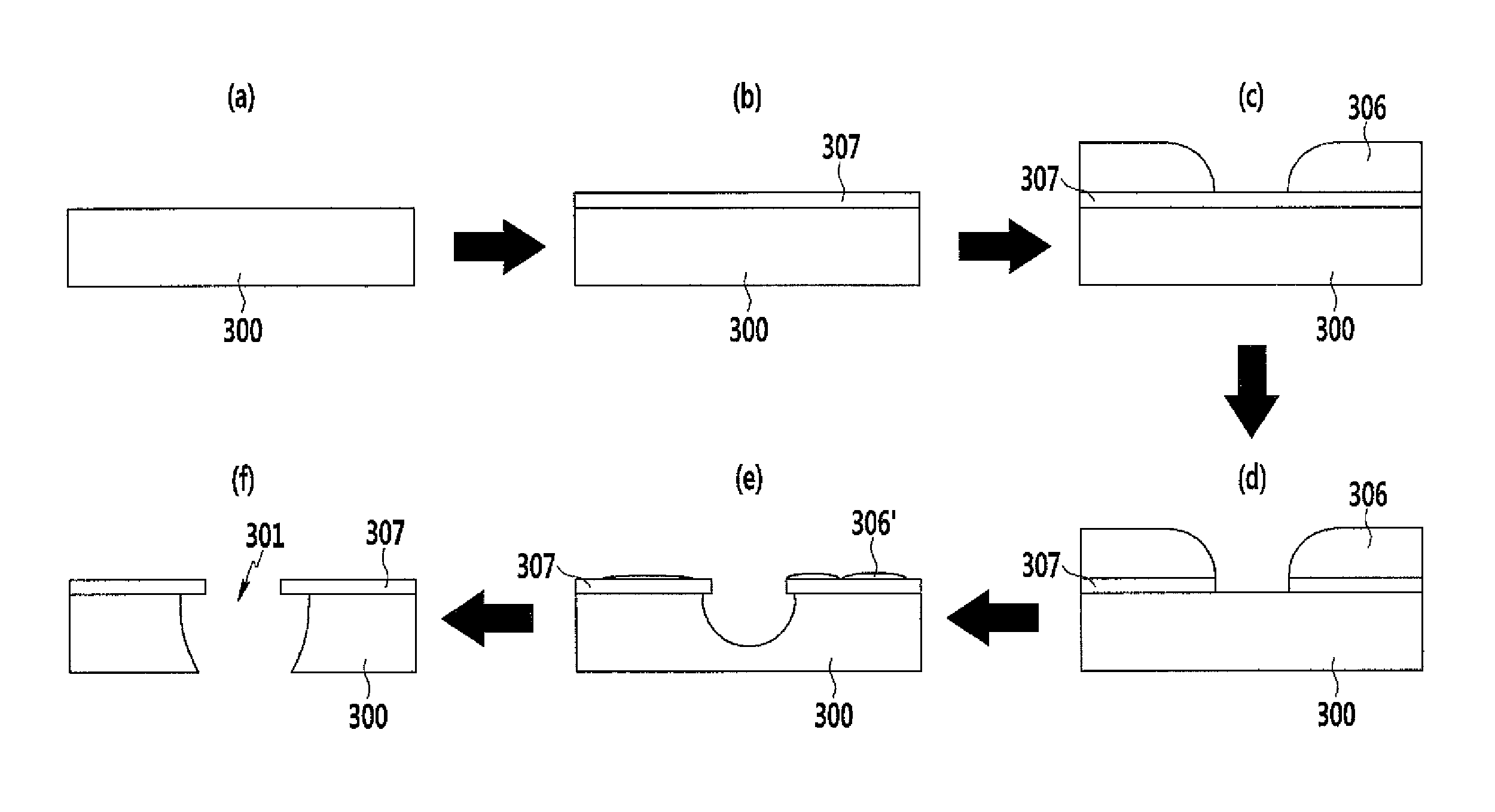

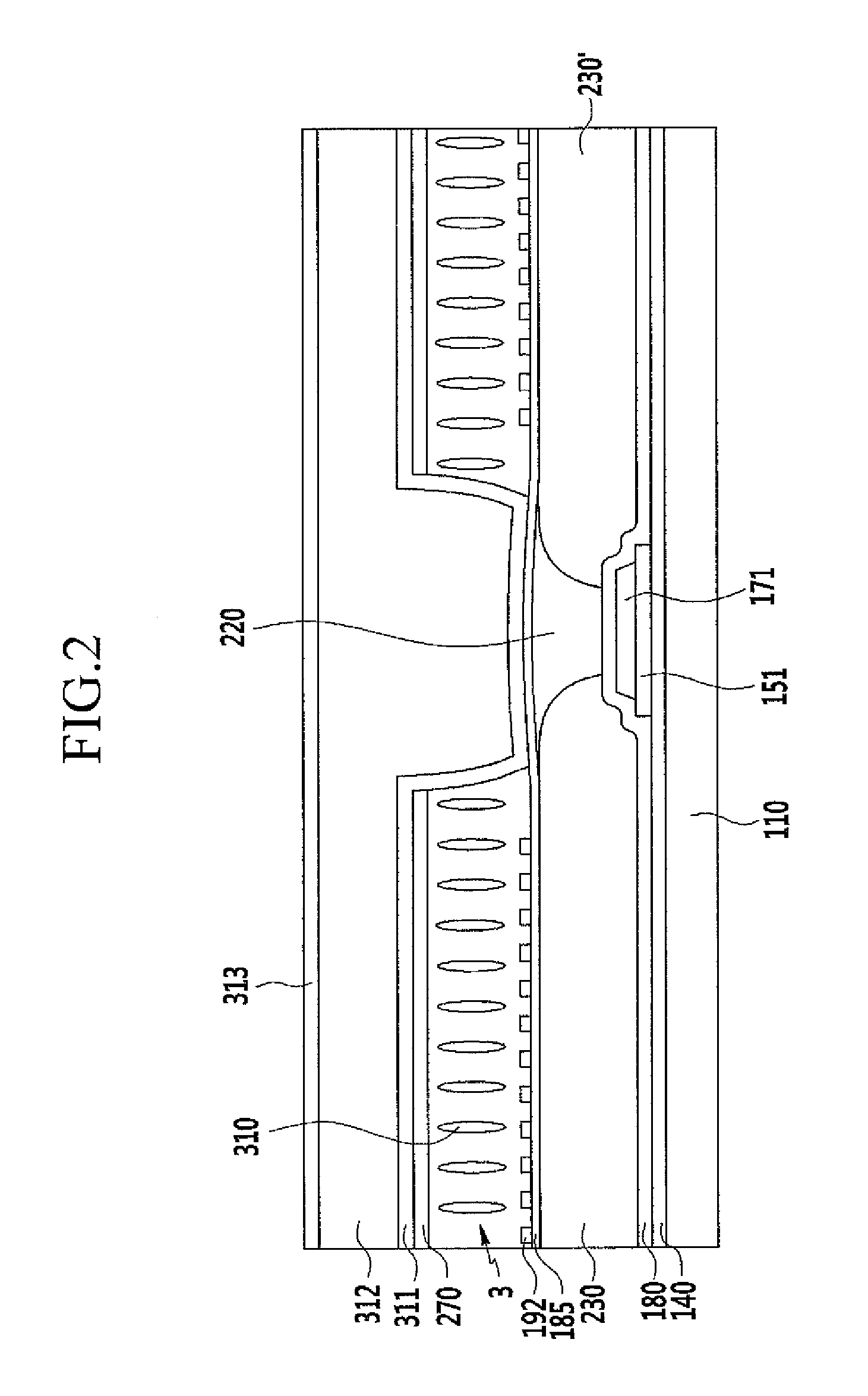

Liquid crystal display and manufacturing method thereof

ActiveUS20120300148A1Reduce distortionImprove response speedStatic indicating devicesVessels or leading-in conductors manufactureEngineeringLiquid crystal molecule

A liquid crystal display and a manufacturing method are provided. A liquid crystal display according to an exemplary embodiment of the present invention includes: a first substrate; a second substrate facing the first substrate; a liquid crystal layer interposed between the first substrate and the second substrate, and including liquid crystal molecules; a first electrode positioned on the first substrate; an insulating layer positioned on the first electrode; a second electrode positioned on the insulating layer; and a third electrode positioned on the second substrate, wherein the second electrode includes a plurality of branches and a slit between neighboring ones of the branches, and a width of the slit is more than about two times to less than about five times a width of its corresponding branches.

Owner:SAMSUNG DISPLAY CO LTD

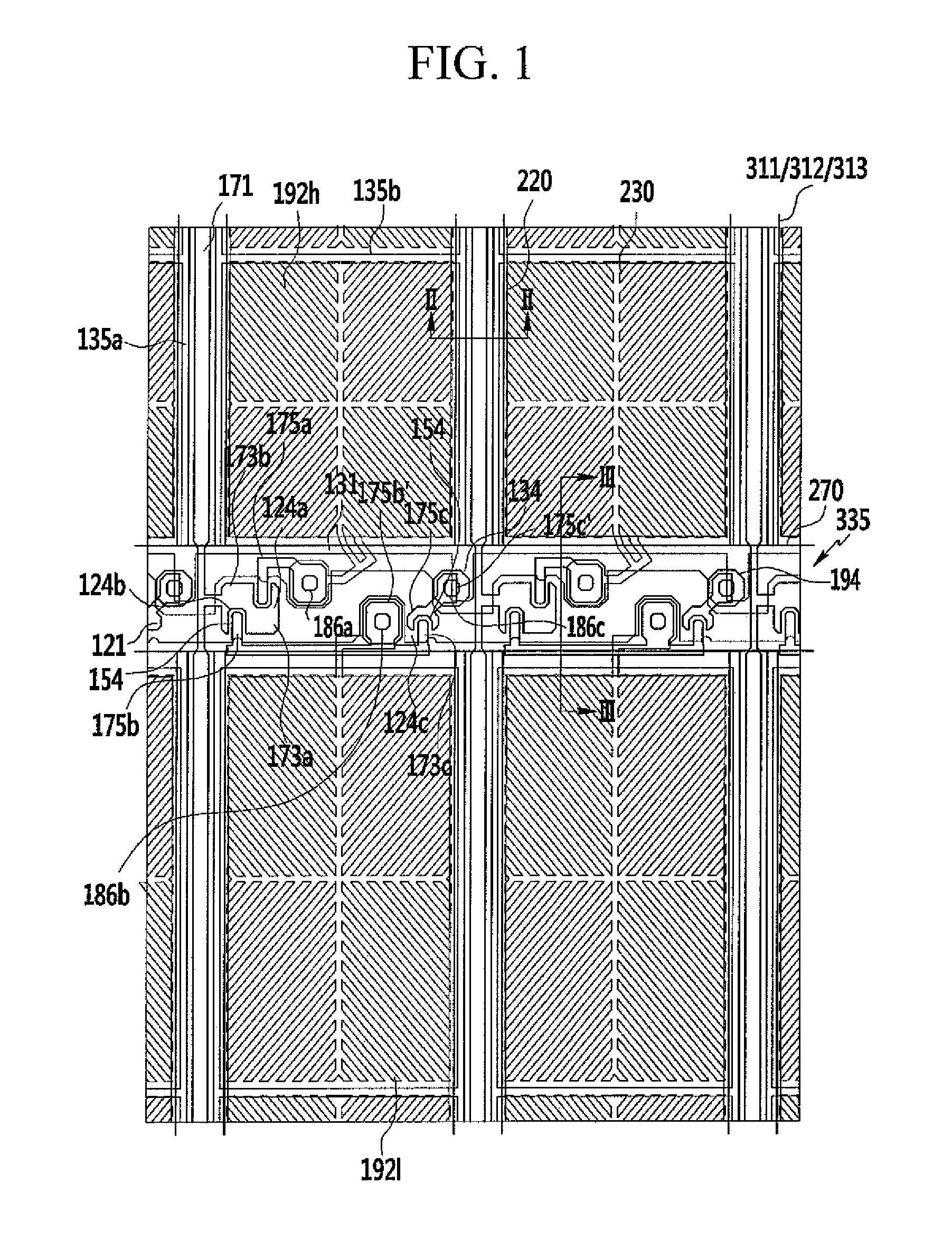

Liquid crystal display and manufacturing method thereof

InactiveUS20140104533A1Increase the aperture ratioReduce electric field distortionSemiconductor/solid-state device manufacturingNon-linear opticsResistLiquid-crystal display

A manufacturing method of a liquid crystal display includes forming a sacrificial layer on a liquid crystal panel, forming an etch stop layer on the sacrificial layer, forming a photo resist pattern on the etch stop layer, completing the etch stop layer using the photo resist pattern as a mask, ashing the photo resist pattern and the sacrificial layer by using the completed etch stop layer as a mask, forming a microcavity by removing a portion of the sacrificial layer and forming a liquid crystal layer in the microcavity.

Owner:SAMSUNG DISPLAY CO LTD

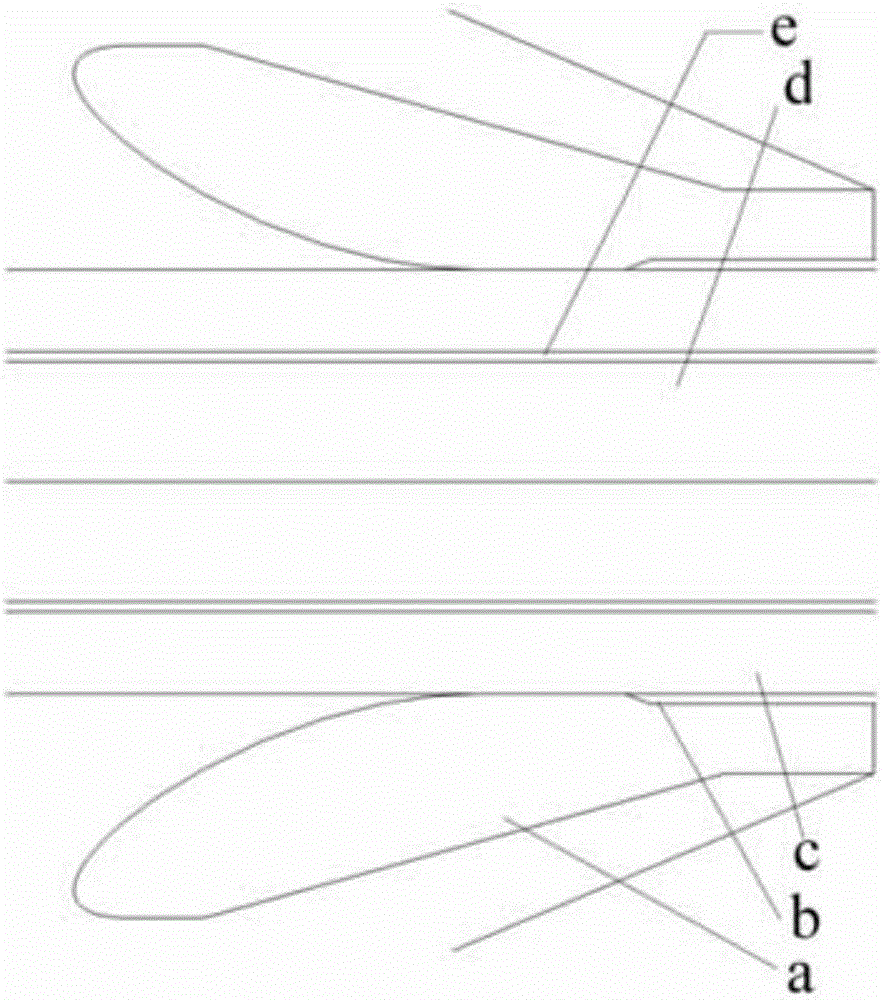

Stress control body for plastic insulation high-voltage and direct-current cable terminal

InactiveCN103259239AReduce interfacial space chargeExcellent homogenizing electric field distributionCable fittingsElectric fieldElectricity

The invention relates to a stress control body for a plastic insulation high-voltage and direct-current cable terminal. The stress control body for the plastic insulation high-voltage and direct-current cable terminal aims at solving the problems that electric fields in an existing plastic insulation high-voltage and direct-current cable terminal are distributed unreasonably, and a qualified plastic insulation high-voltage and direct-current cable terminal with the voltage more than 160kV does not exist. The stress control body for the plastic insulation high-voltage and direct-current cable terminal is composed of a strengthening insulator and a stress cone, wherein the stress cone is arranged on one side end port of the strengthening insulator, the stress cone is in a horn shape, the curve of the inner conical surface of the stress cone is a tri-bezier curve, and the other side end port of the strengthening insulator is in a trapezoid shape. After the diameter of the stress control body for the plastic insulation high-voltage and direct-current cable terminal is expanded, the stress control body for the plastic insulation high-voltage and direct-current cable terminal is installed on the end portion of a cable. The stress control body for the plastic insulation high-voltage and direct-current cable terminal is applied to the electricity field.

Owner:HARBIN UNIV OF SCI & TECH

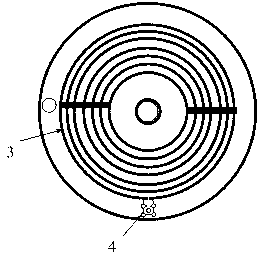

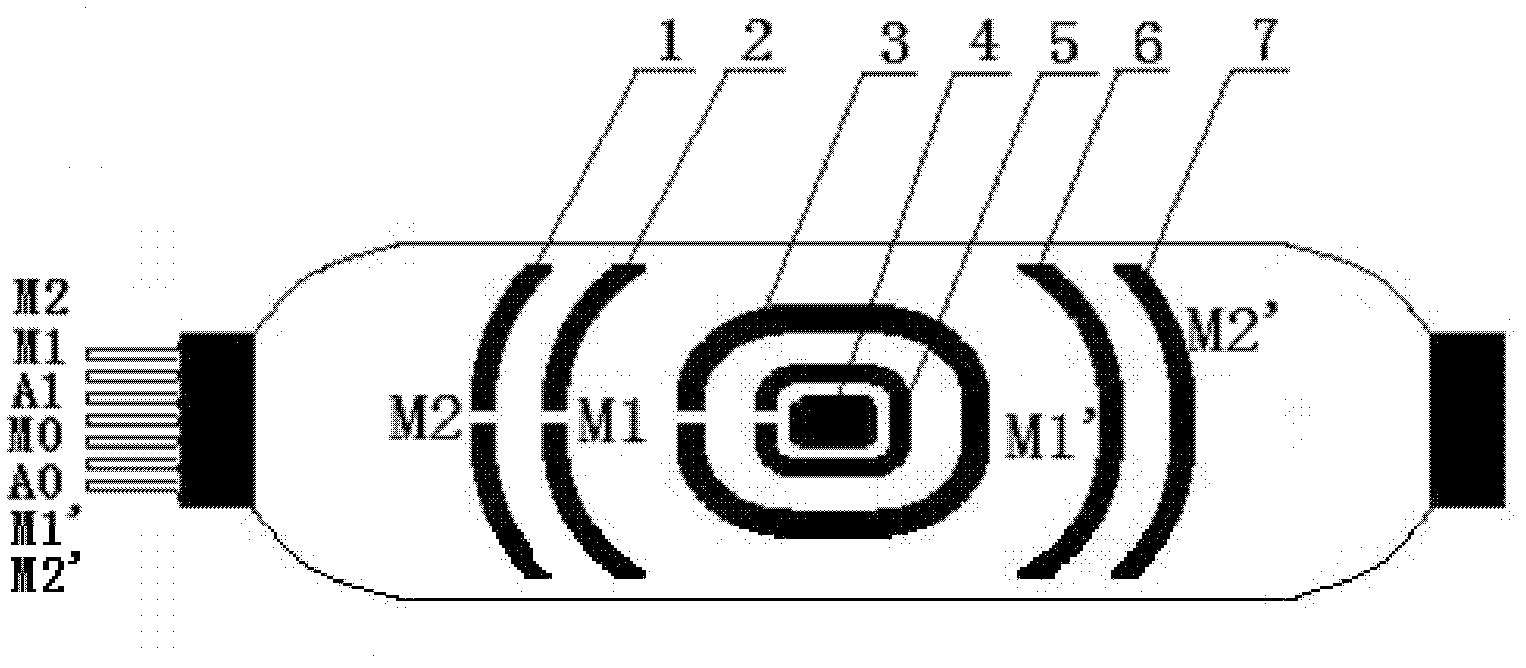

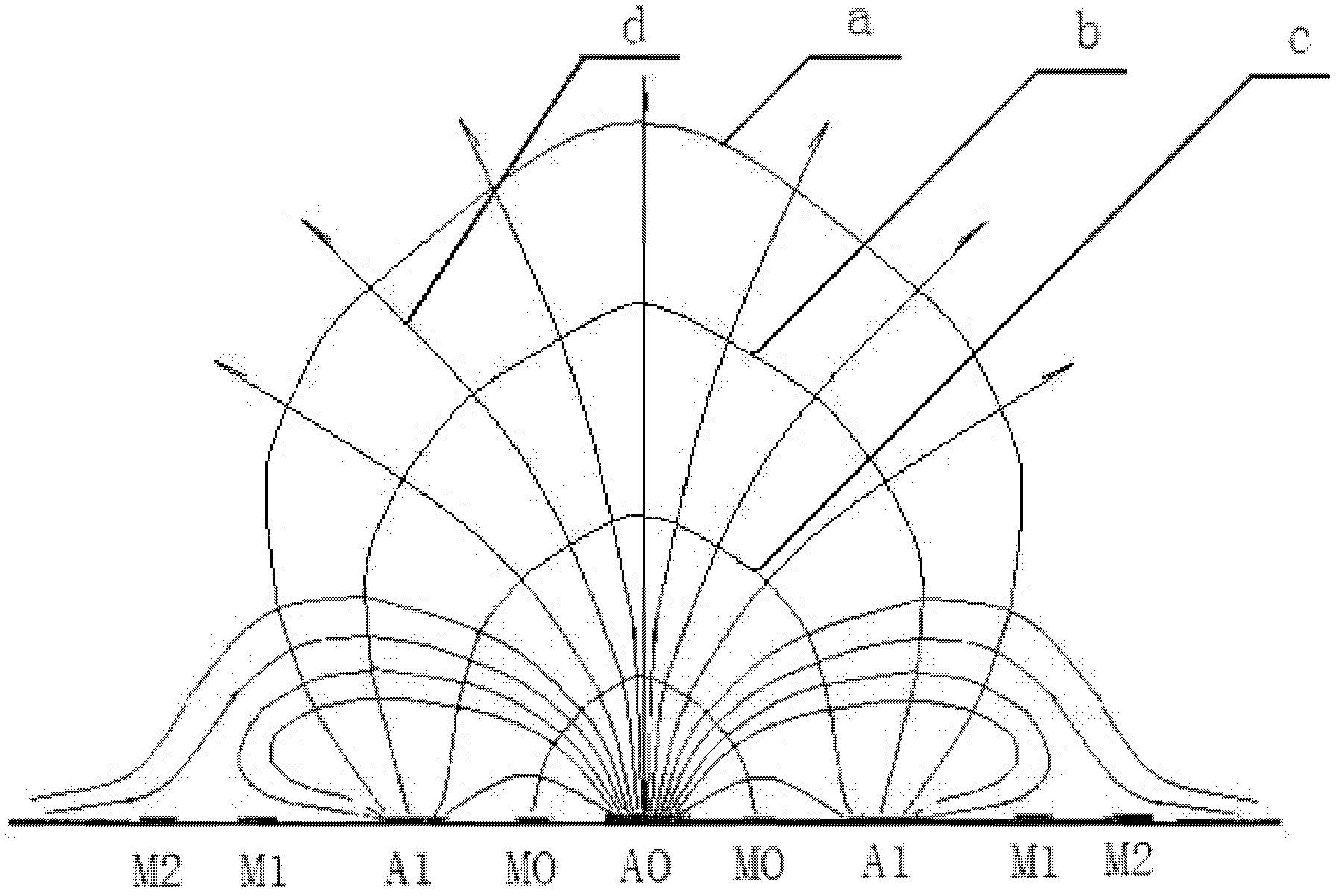

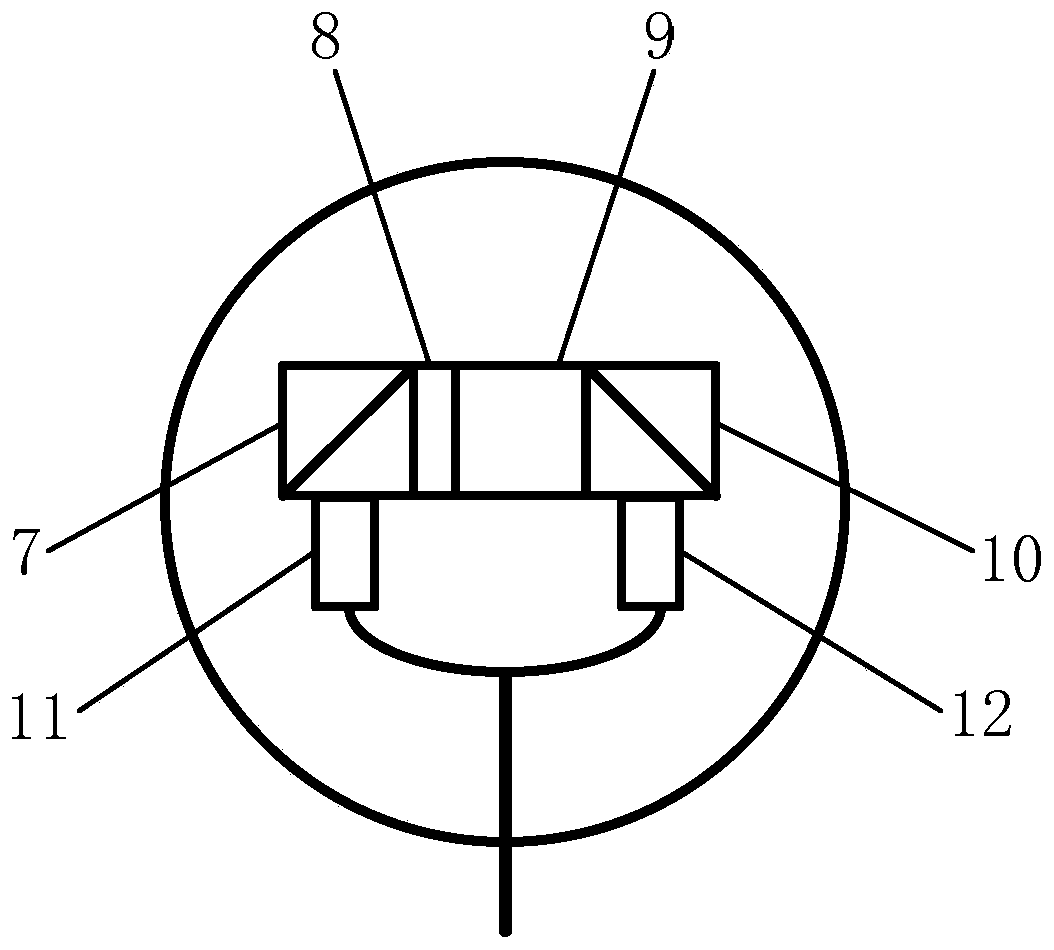

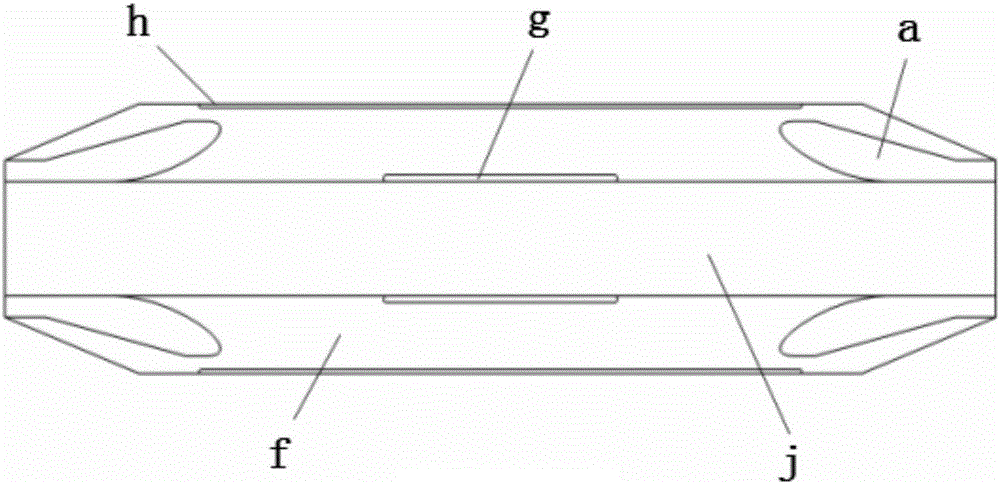

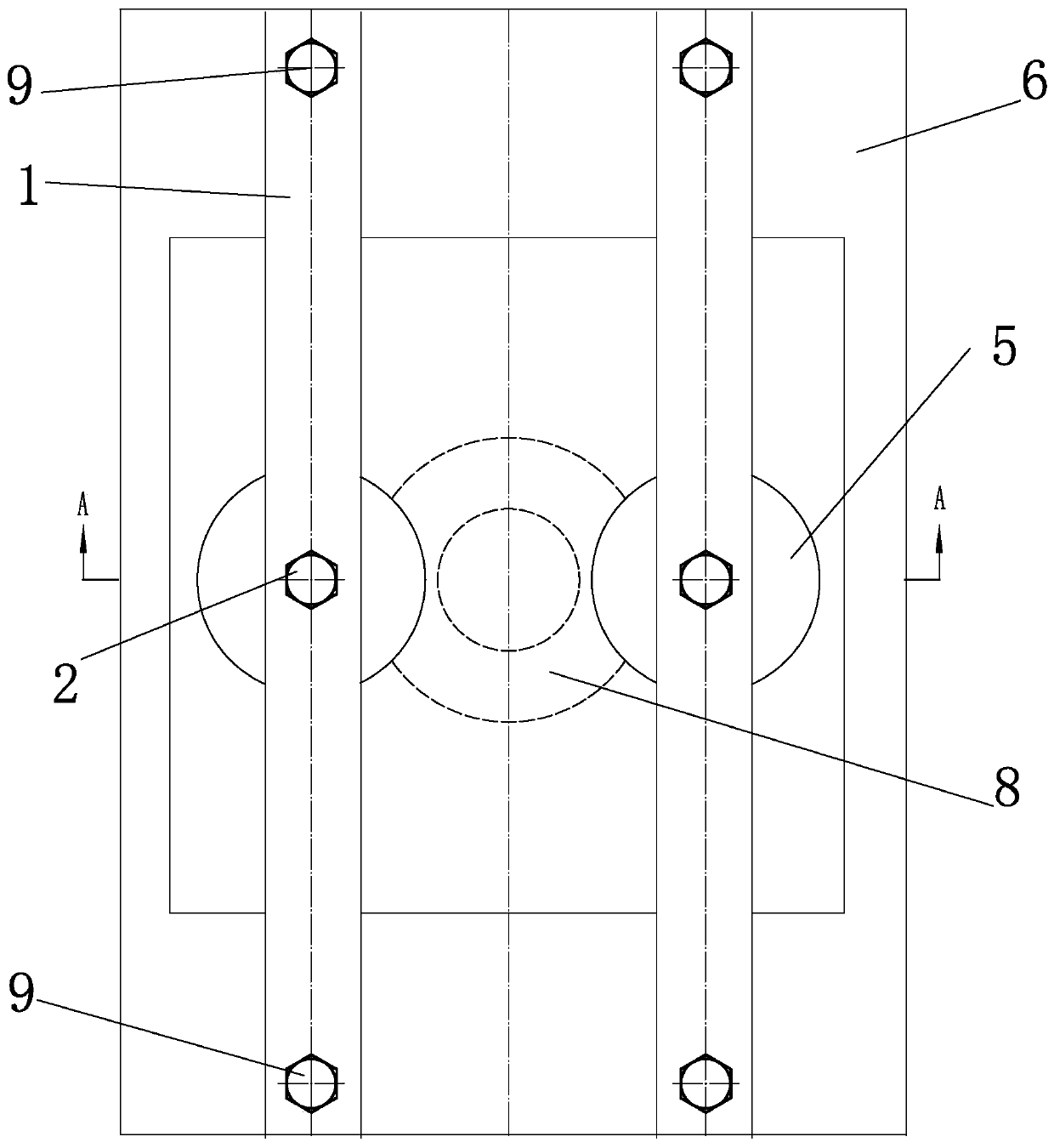

Polar plate of micro-disc type focused logging device

The invention discloses a polar plate of a micro-disc type focused logging device. The polar plate comprises the polar plate and polar plate electrodes arranged on the plate surface of the polar plate, wherein the polar plate is in the shape of a rectangle, the two ends of the polar plate are in circular arc-shaped structures, and the polar plate electrodes comprise a main electrode A0 at the center of the plate surface of the polar plate, as well as an annular electrode M0 and an annular electrode A1 which are sequentially distributed on the periphery of the main electrode A0 from inside to outside; and two groups of semi-circular electrodes, namely a monitor electrode M1 and a monitor electrode M1', as well as monitor electrode M2 and a monitor electrode M2', are symmetrically distributed on the two sides of the annular electrode A1, the electrode distances from the monitor electrode M1, the monitor electrode M2', the monitor electrode M2 and the monitor electrode M1' to the main electrode A0 are equal, and after signals acquired by the two groups of the monitor electrodes are synthesized by a transformer, the two groups of the monitor electrodes controls the main current measurement. Since the electrodes of the novel polar plate are the two groups of the semi-circular type electrode structures and the overall dimension and the shape of the polar plate are further changed, the novel polar plate has the advantages of stable electric field, a large measurement dynamic range, high measurement precision, good layering capability and the like.

Owner:西安威盛电子科技股份有限公司

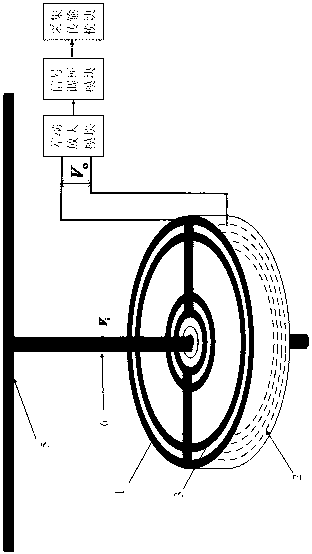

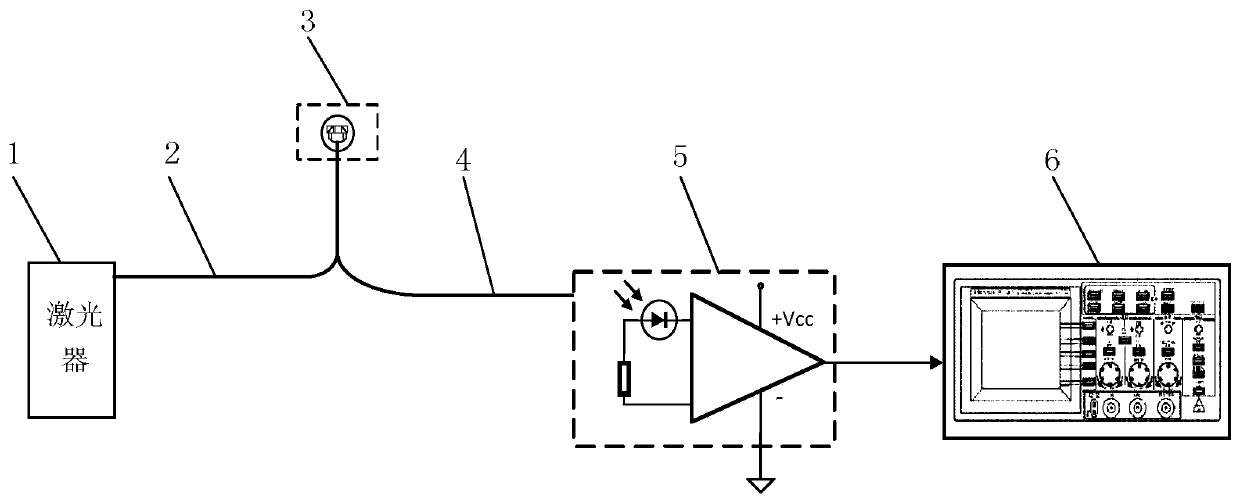

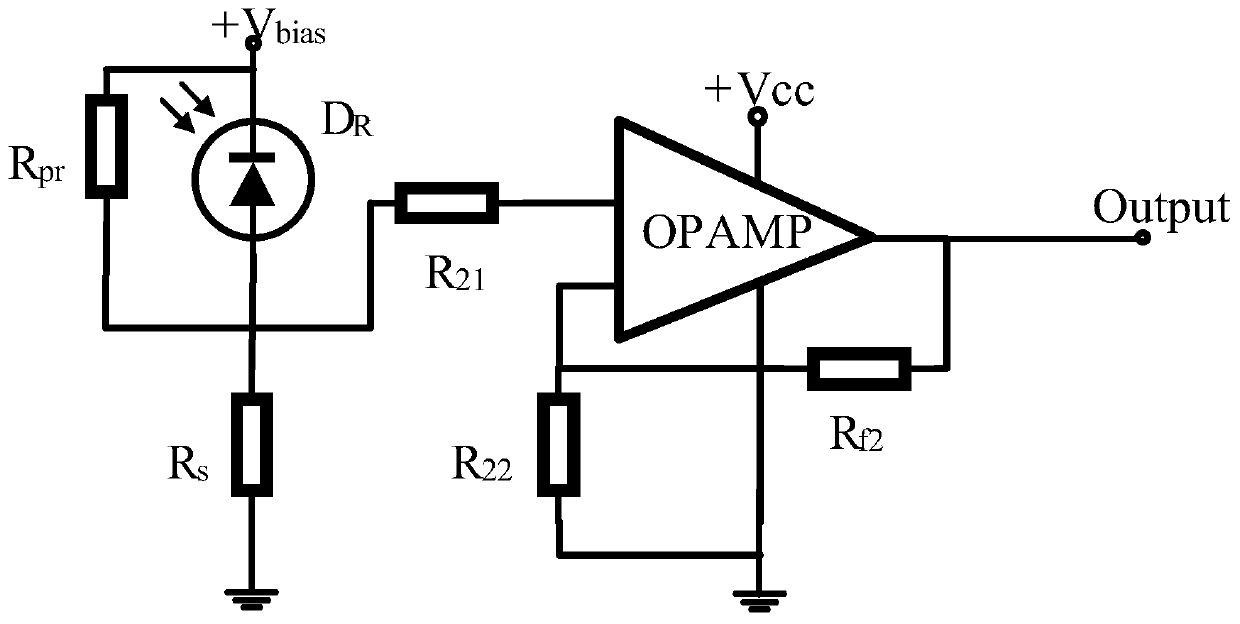

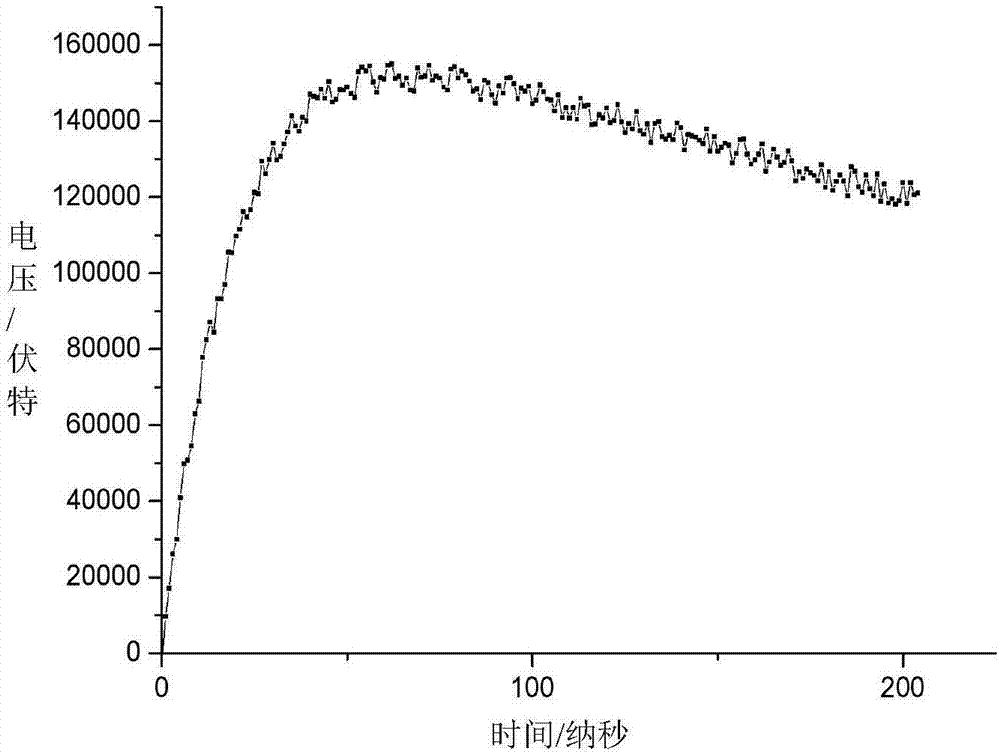

Transient strong electric field measuring system for long air gap discharging

InactiveCN110007156ASmall distortionLow immunity to electromagnetic interferenceElectromagentic field characteristicsElectrical field strengthPolarization-maintaining optical fiber

The invention discloses a transient strong electric field measuring system for long air gap discharging. The transient strong electric field measuring system comprises a laser device used for emittinga stable monochromatic linear polarization laser, a polarization maintaining optical fiber used for transmitting the monochromatic linear polarization laser and maintaining a polarization state of the monochromatic linear polarization laser, an integrated optical device used for modulating the monochromatic linear polarization laser in the transient strong electric field environment, and a photoelectric detector used for collecting and processing modulated laser signals to obtain to-be-measured applied electric field strength. The transient strong electric field measuring system has the measuring properties of strong electric field measuring range, low distorsion, anti-electromagnetic interference, high-frequency band and high stability, and has the advantages of small size, high measuring precision and the like, and the practical demand for quantitative measuring of the space electric field in the long air gap discharging process is met.

Owner:STATE GRID CORP OF CHINA +3

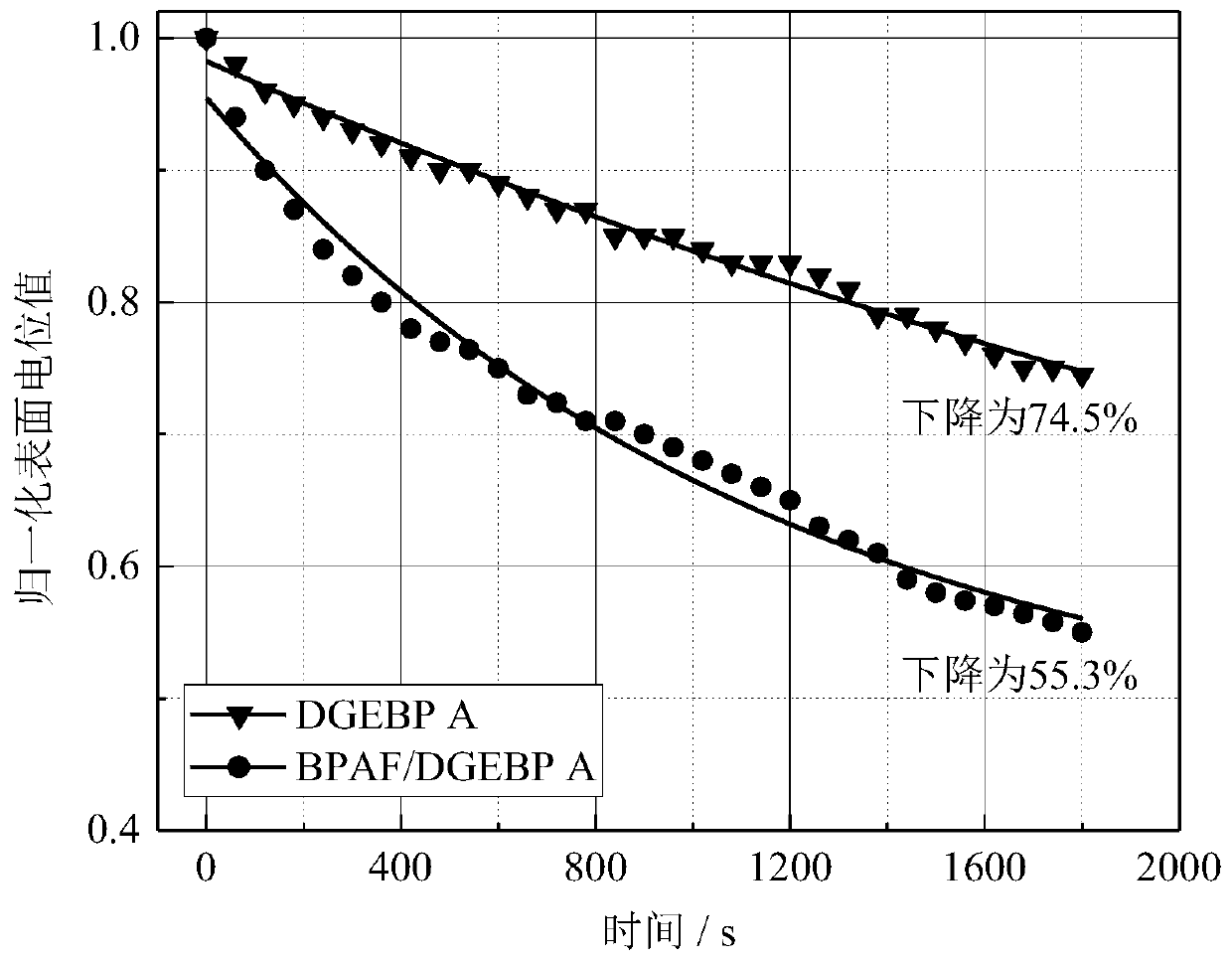

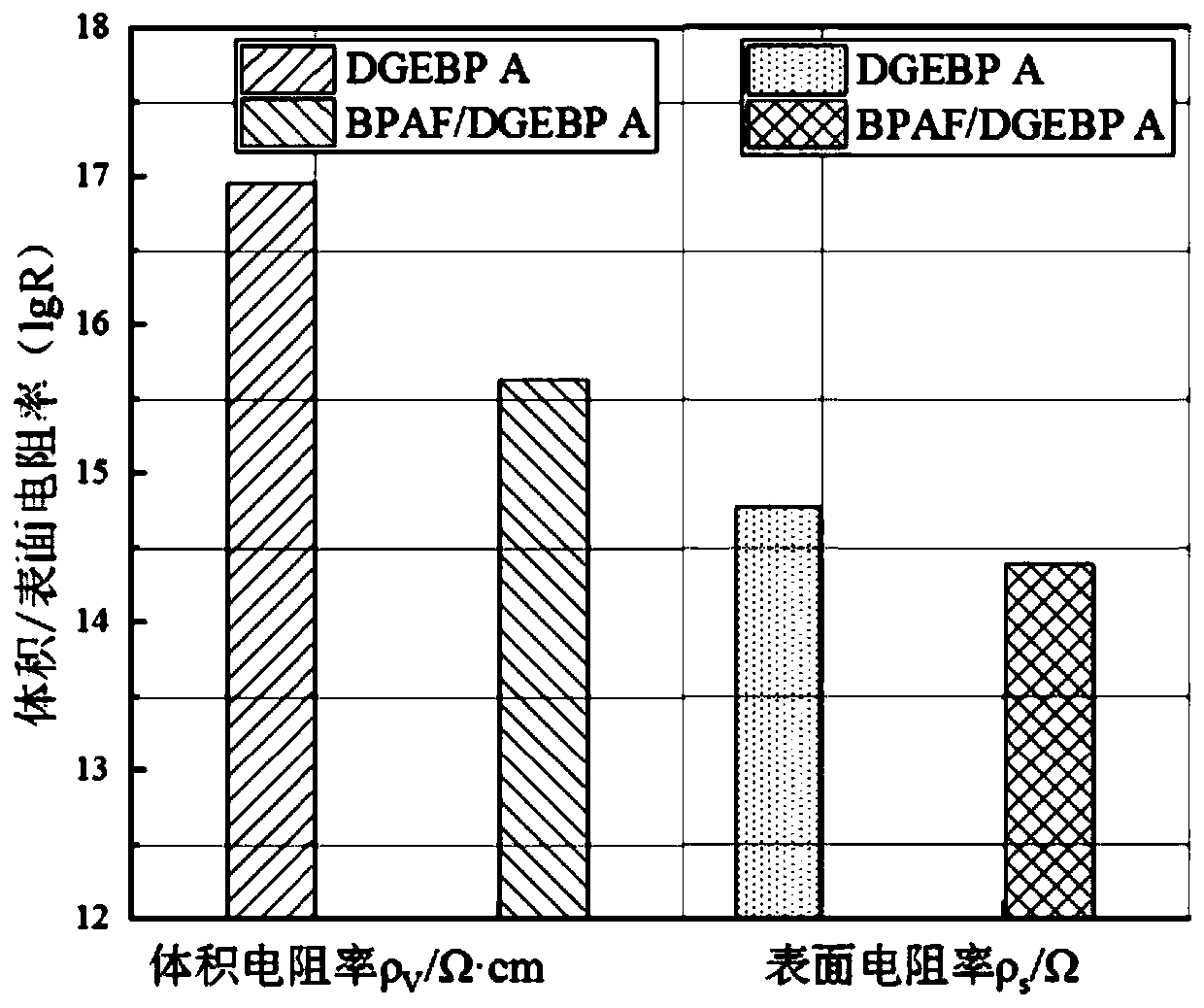

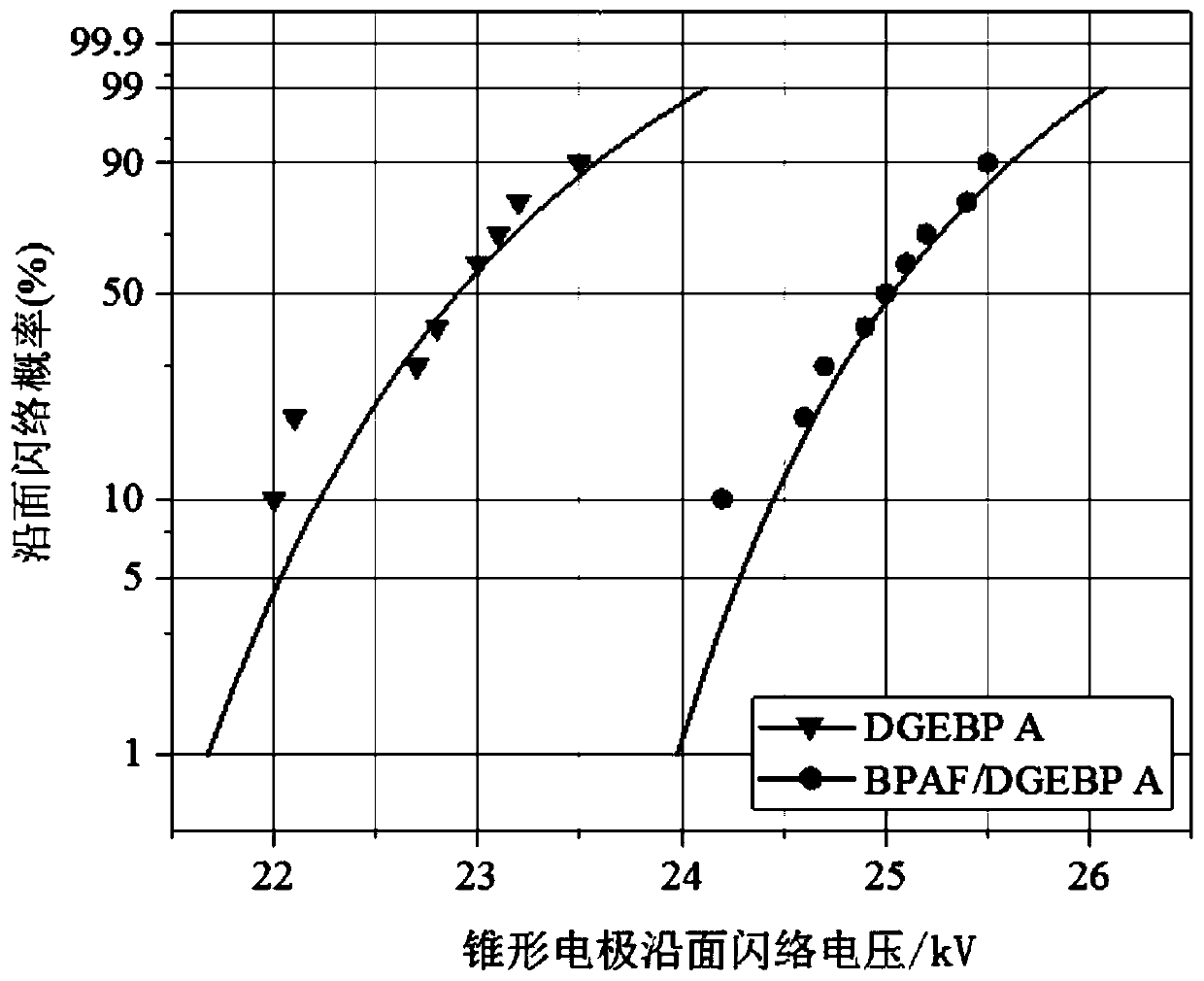

Organic fluorine-modified epoxy resin for improving flashover voltage along surface, as well as preparation method and application thereof

ActiveCN109942793AReduced volume/surface resistivityIncrease the flashover voltage along the surfacePolymer sciencePtru catalyst

Owner:HEFEI UNIV OF TECH

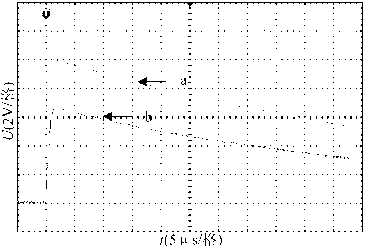

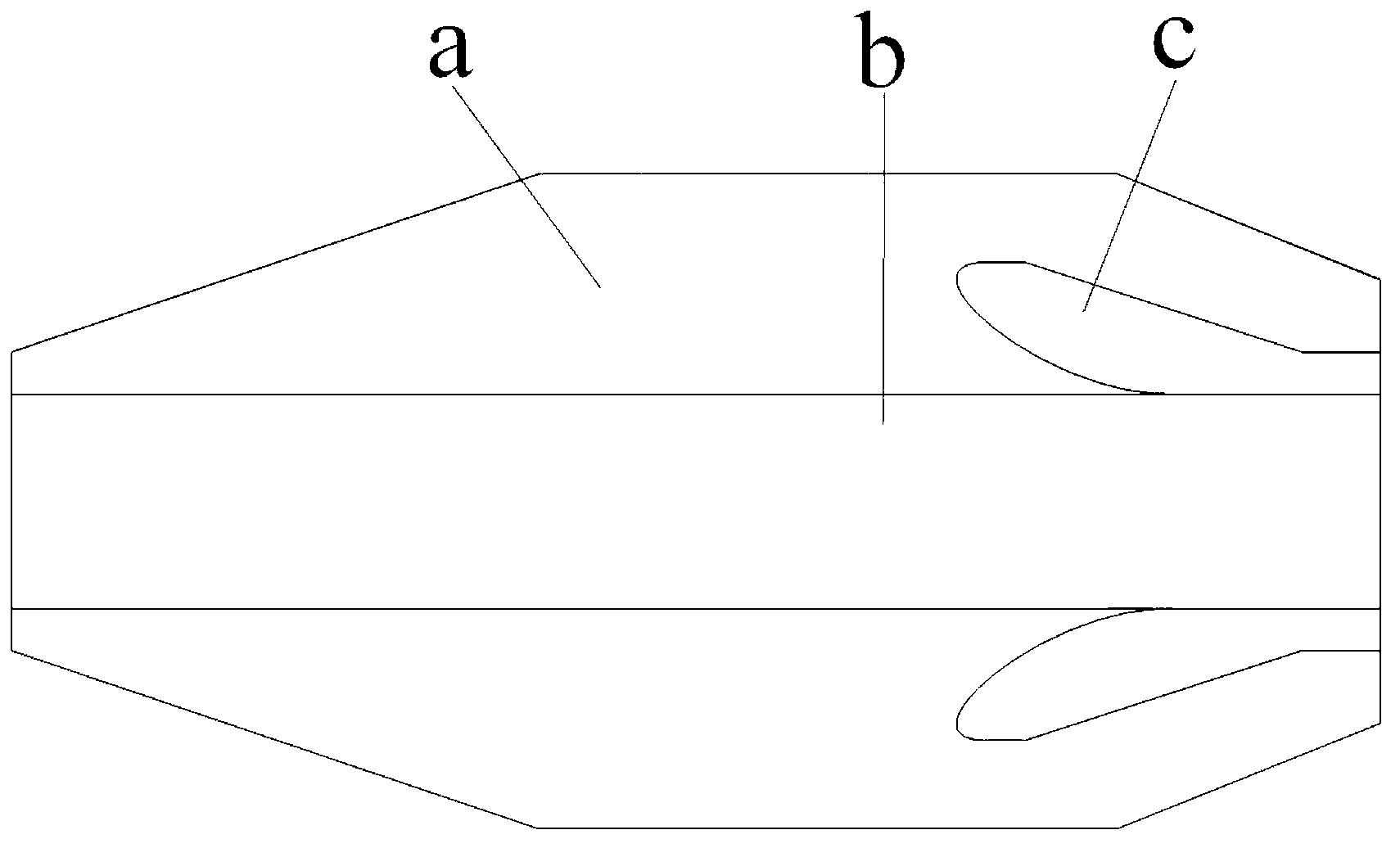

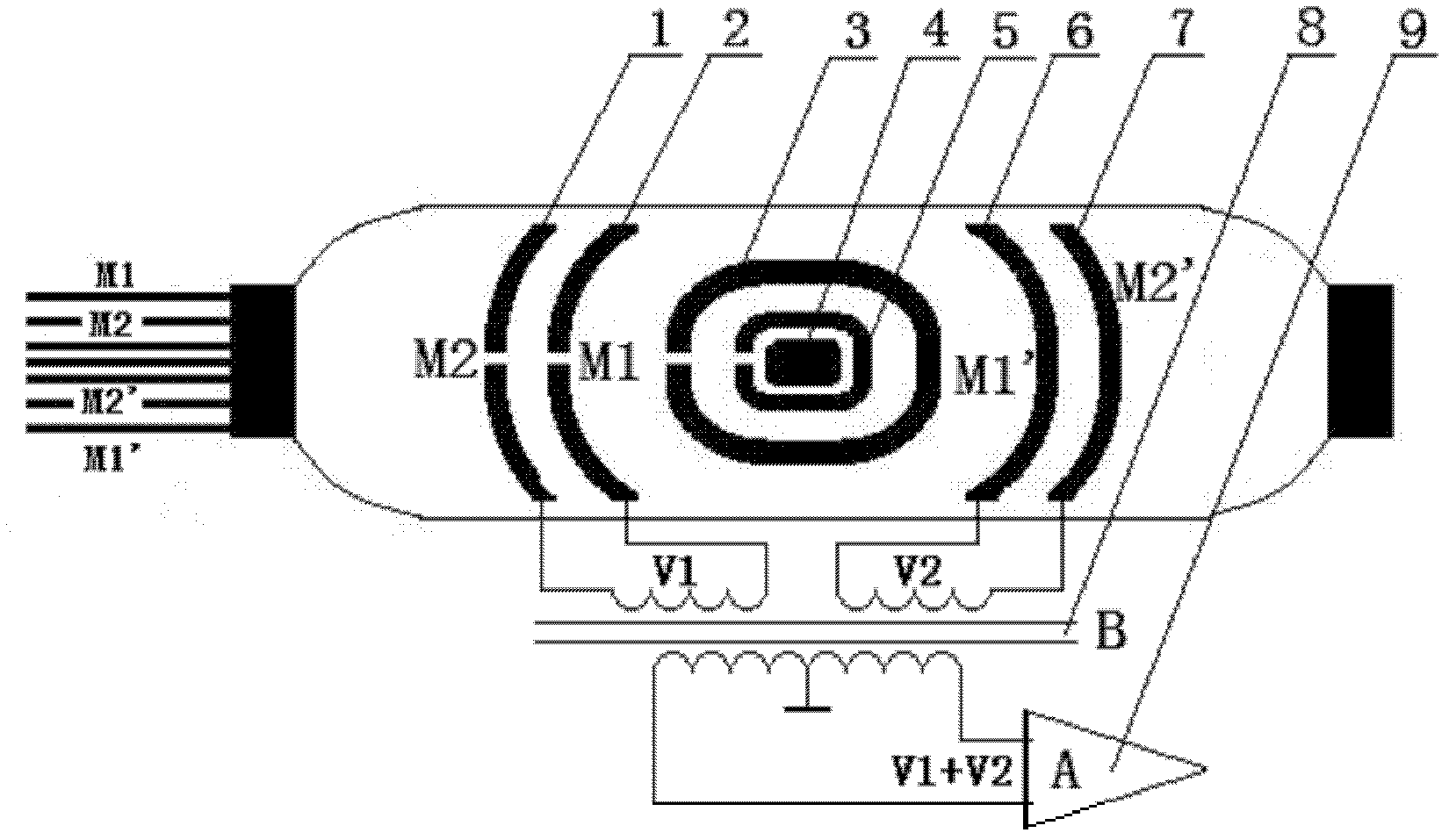

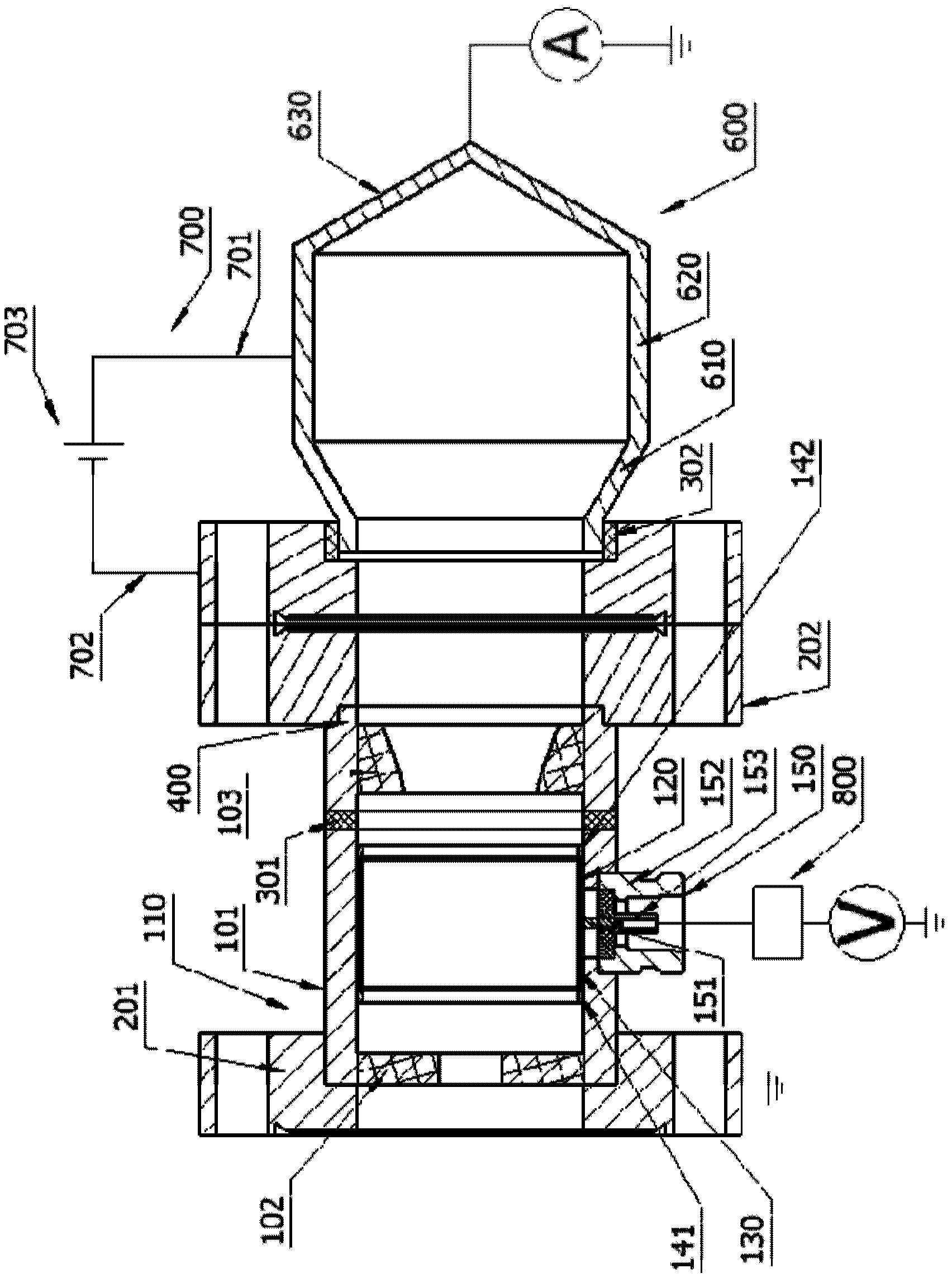

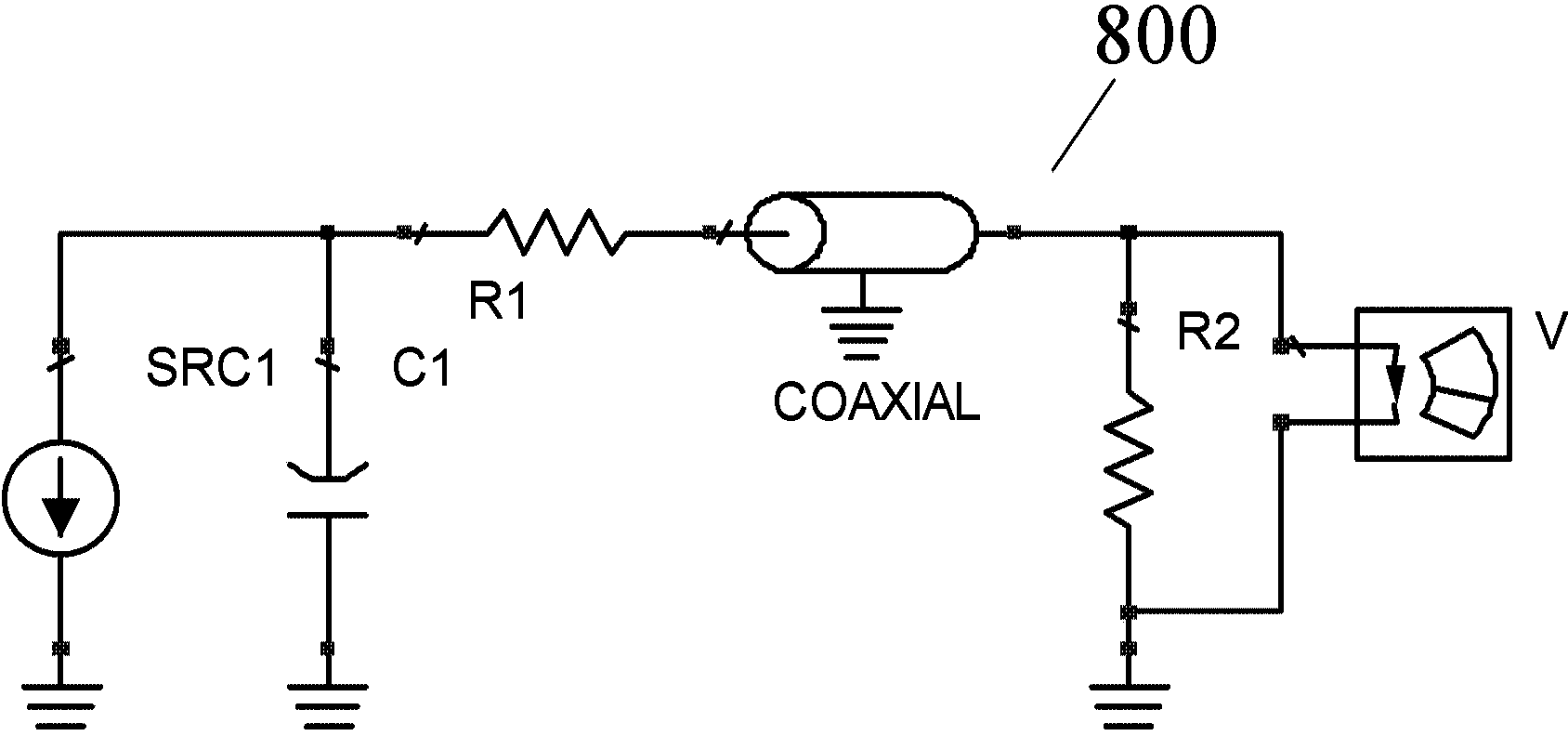

Electronic beam axial velocity measurement system

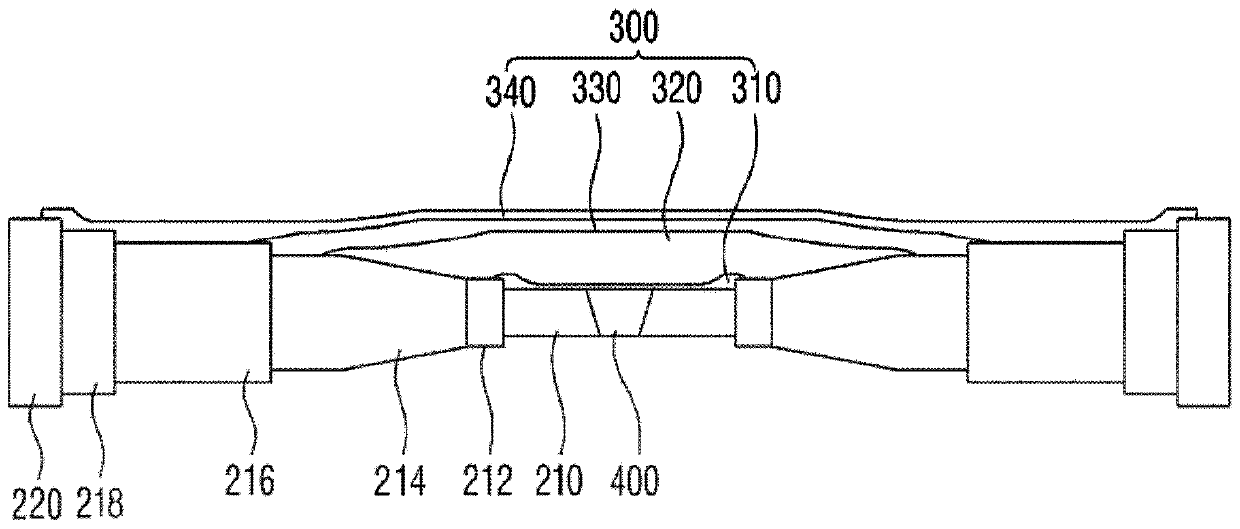

InactiveCN103794449APrevent escapeReduce electric field distortionElectric discharge tubesMeasurement deviceMeasurement precision

The invention provides an electron beam axial velocity measurement system which comprises a capacitive probe device, a collector cavity structure, a voltage integral and transmission circuit, a voltage measurement device and a current measurement device. The capacitive probe device comprises a main cavity structure and an electron beam induction ring; the collector cavity structure is communicated with the main cavity structure and is in a shape of a spindle with a large middle and two small ends; the front end of the voltage integral and transmission circuit is electrically connected to the electron beam induction ring and used for converting inductive charge generated when electron beams penetrate through a capacitive probe into voltage signals; the voltage measurement device is electrically connected to the rear end of the a voltage integral and transmission circuit; the current measurement device is electrically connected to the collector cavity structure. By means of the electron beam axial velocity measurement system, influence of stray electrons during measurement is reduced, and measurement precision of electron beam axial velocity is increased.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

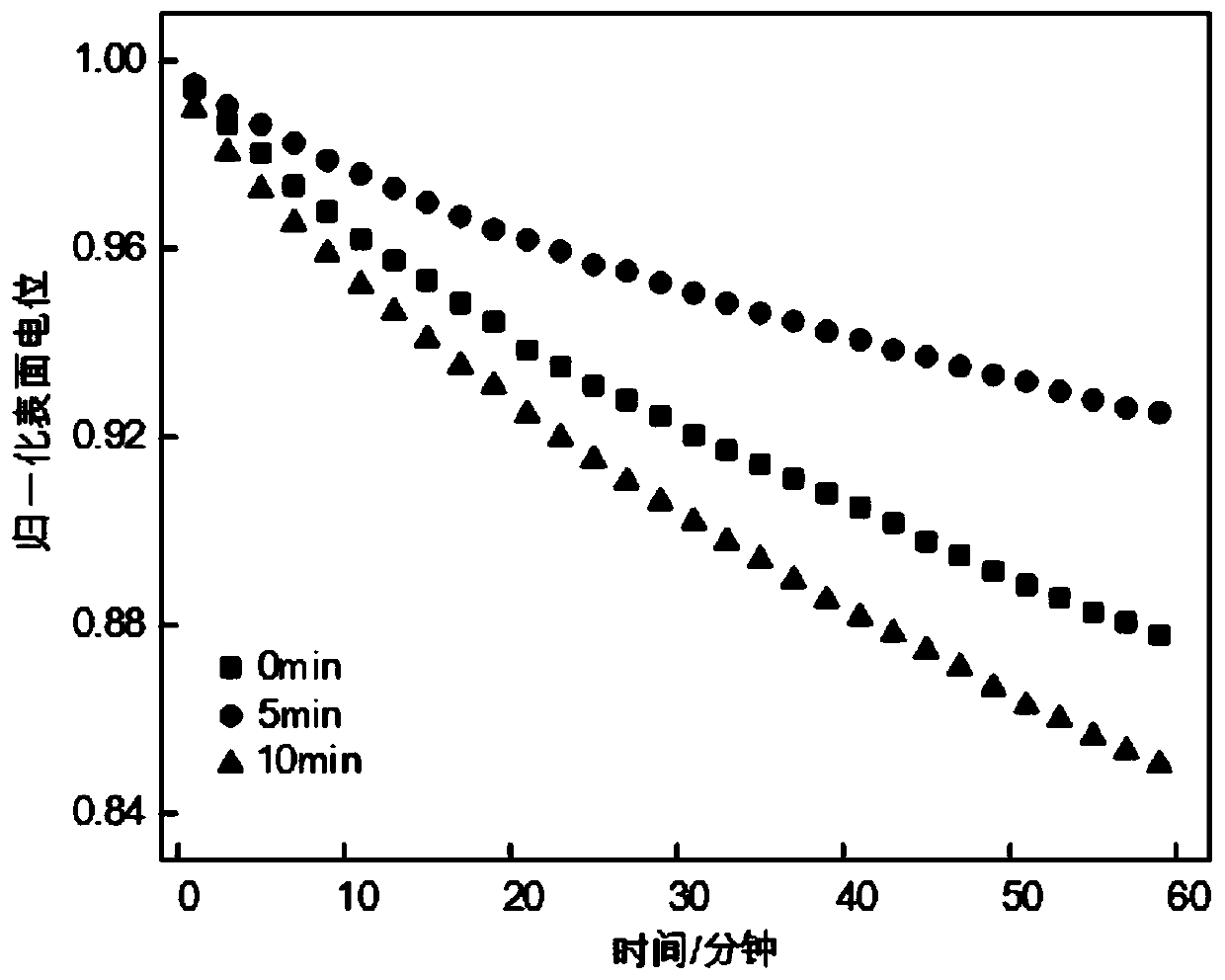

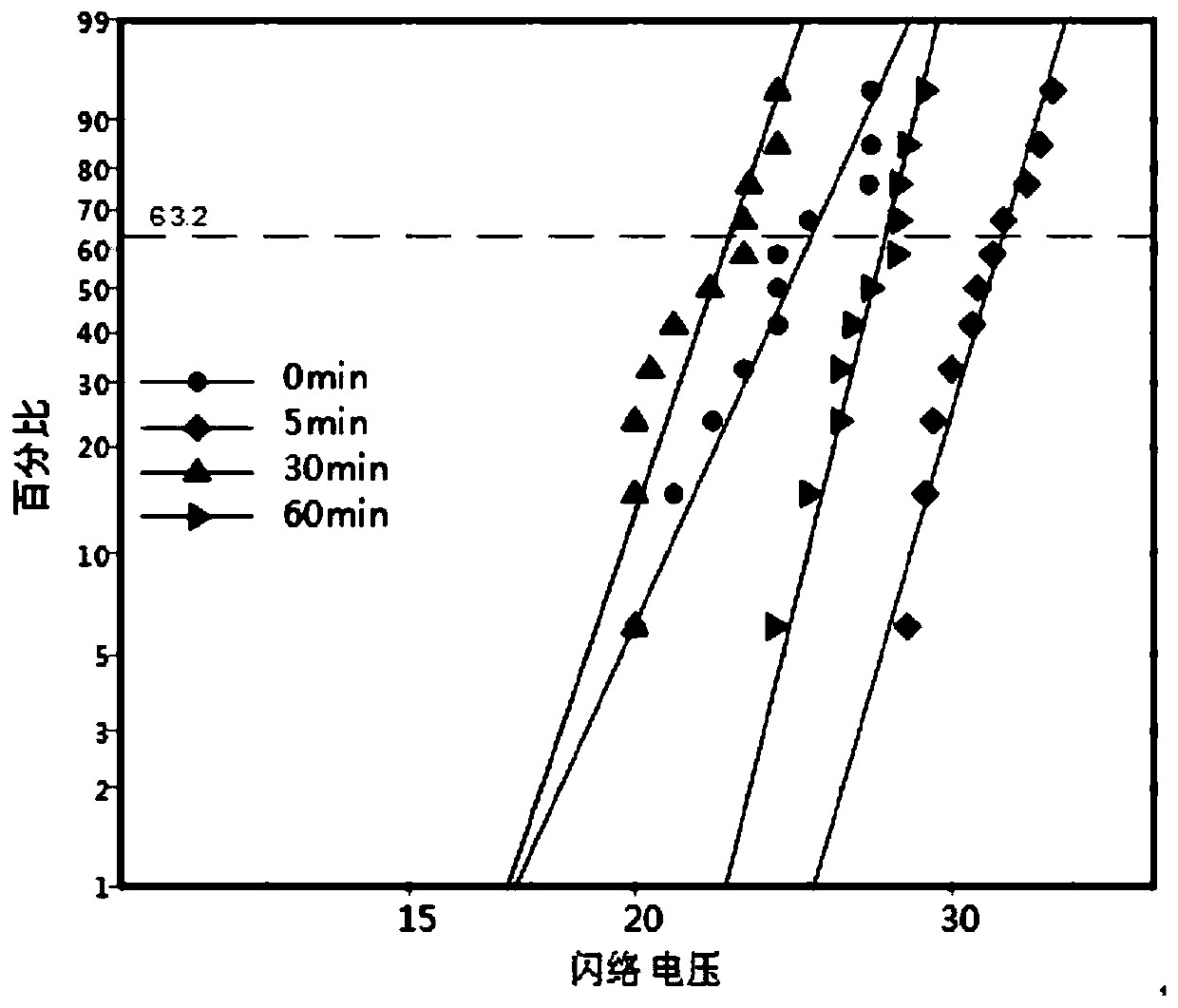

Processing method for improving insulator flashover voltage through atmospheric pressure plasma jet method

InactiveCN110853848AIncrease the flashover voltageImprove surface conductanceInsulatorsPlasma jetElectrical conductor

The invention discloses a processing method for improving insulator flashover voltage through an atmospheric pressure plasma jet method. The method comprises steps of ionizing tetraethyl orthosilicateTEOS mixed gas in a plasma jet pipe to obtain plasmas; the plasmas are sprayed to a surface of a direct-current basin-type insulator to form surface deposition of 500nm-2mu m to obtain a high-voltagedirect-current basin-type insulator with different conductivities, specifically, a quartz glass tube is used as a jet tube body, a hollow or solid conductor tube is used as a plasma guide tube and aninternal high-voltage electrode, and a copper foil is attached to a tail end of an outer side of the jet tube; the TEOS liquid filled with the precursor is heated; one path of 150-250sccm argon is introduced into a gas washing bottle, the precursor TEOS molecules are brought into a jet pipe, the precursor TEOS molecules are fully mixed with the other path of 5-7slm argon, the mixture is introduced into the jet pipe, and the plasmas are formed through ionization. The method is advantaged in that a mechanical arm is adopted to clamp the jet pipe, the jet pipe is controlled to spray the plasmasperpendicular to a surface of an insulating material and move parallel to a surface of the insulating material, and a modified object is subjected to plasma treatment.

Owner:TIANJIN UNIV +1

Liquid crystal display and manufacturing method thereof

ActiveUS20140287646A1Reduce electric field distortionImprove response speedStatic indicating devicesVessels or leading-in conductors manufactureCrystallographyDisplay device

A liquid crystal display and a manufacturing method are provided. A liquid crystal display according to an exemplary embodiment of the present invention includes: a first substrate; a second substrate facing the first substrate; a liquid crystal layer interposed between the first substrate and the second substrate, and including liquid crystal molecules; a first electrode positioned on the first substrate; an insulating layer positioned on the first electrode; a second electrode positioned on the insulating layer; and a third electrode positioned on the second substrate, wherein the second electrode includes a plurality of branches and a slit between neighboring ones of the branches, and a width of the slit is more than about two times to less than about five times a width of its corresponding branches.

Owner:SAMSUNG DISPLAY CO LTD

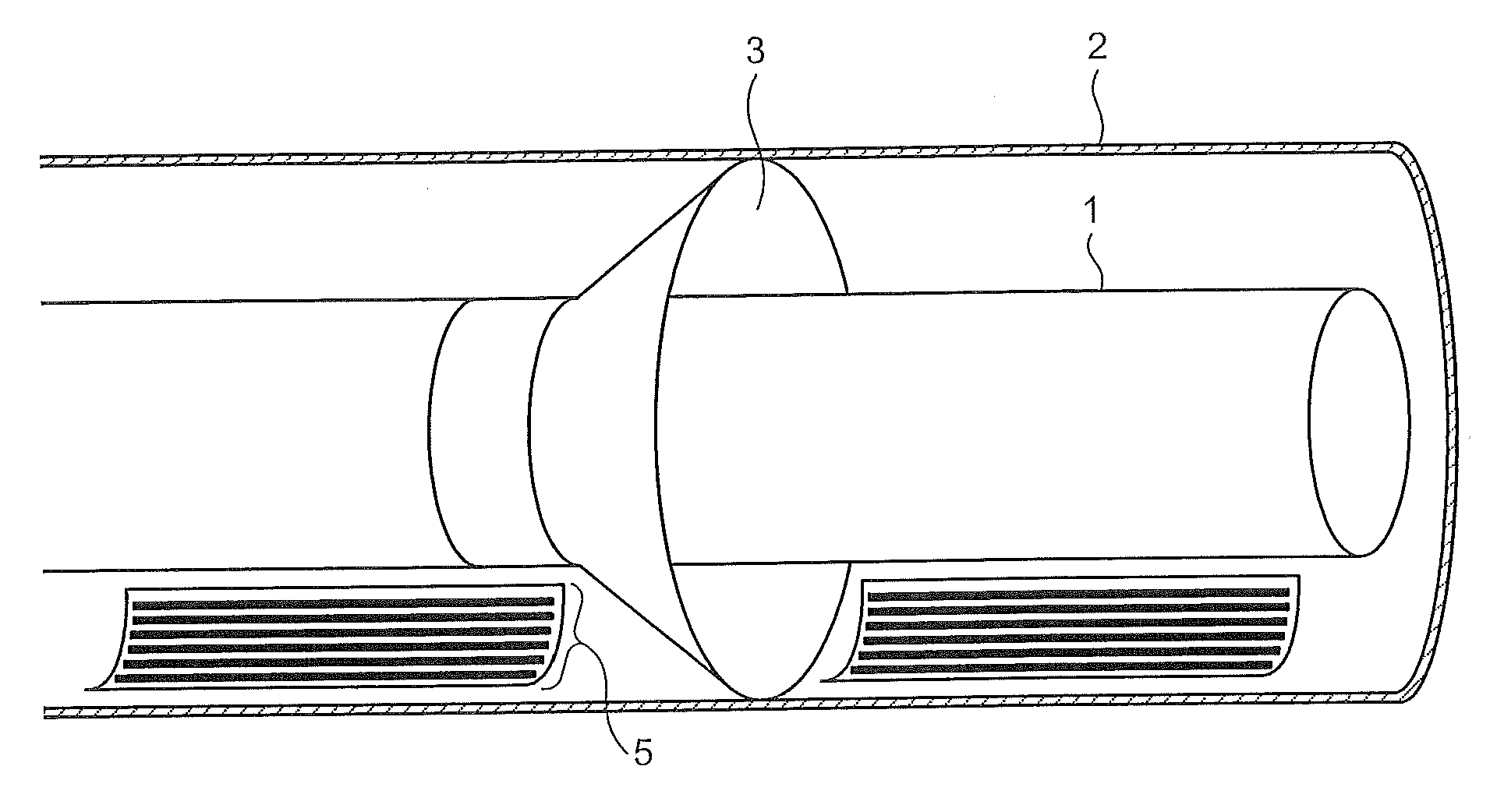

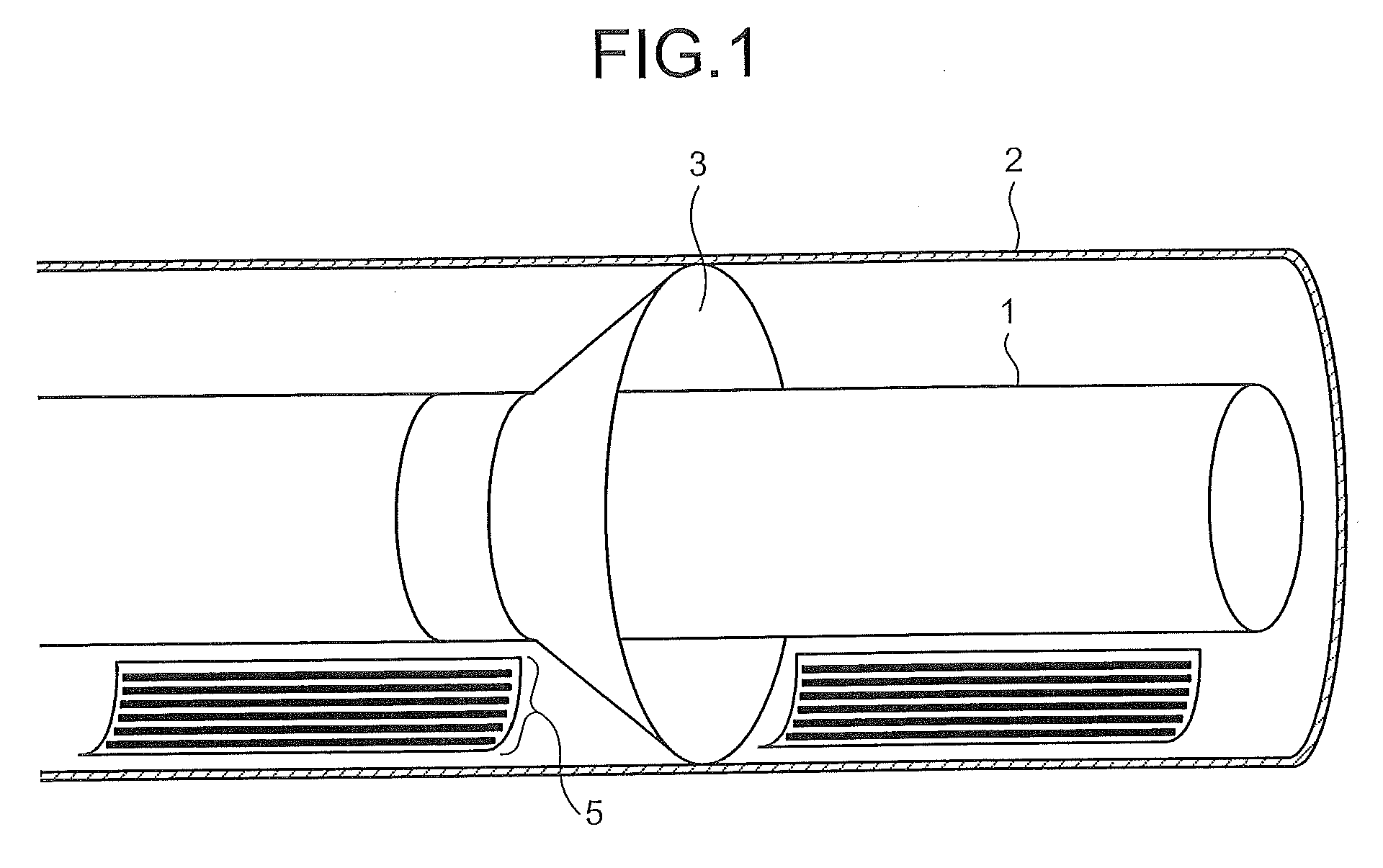

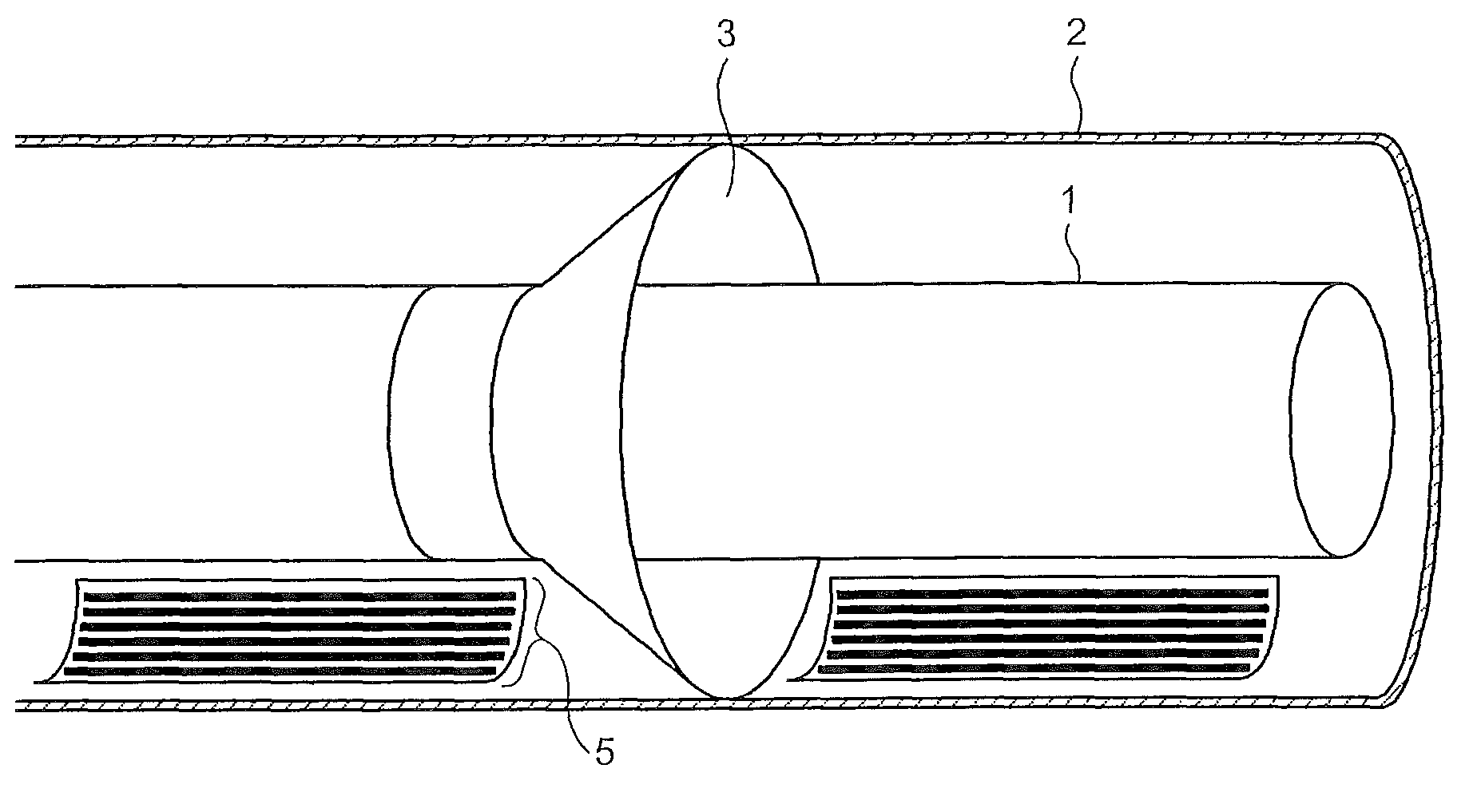

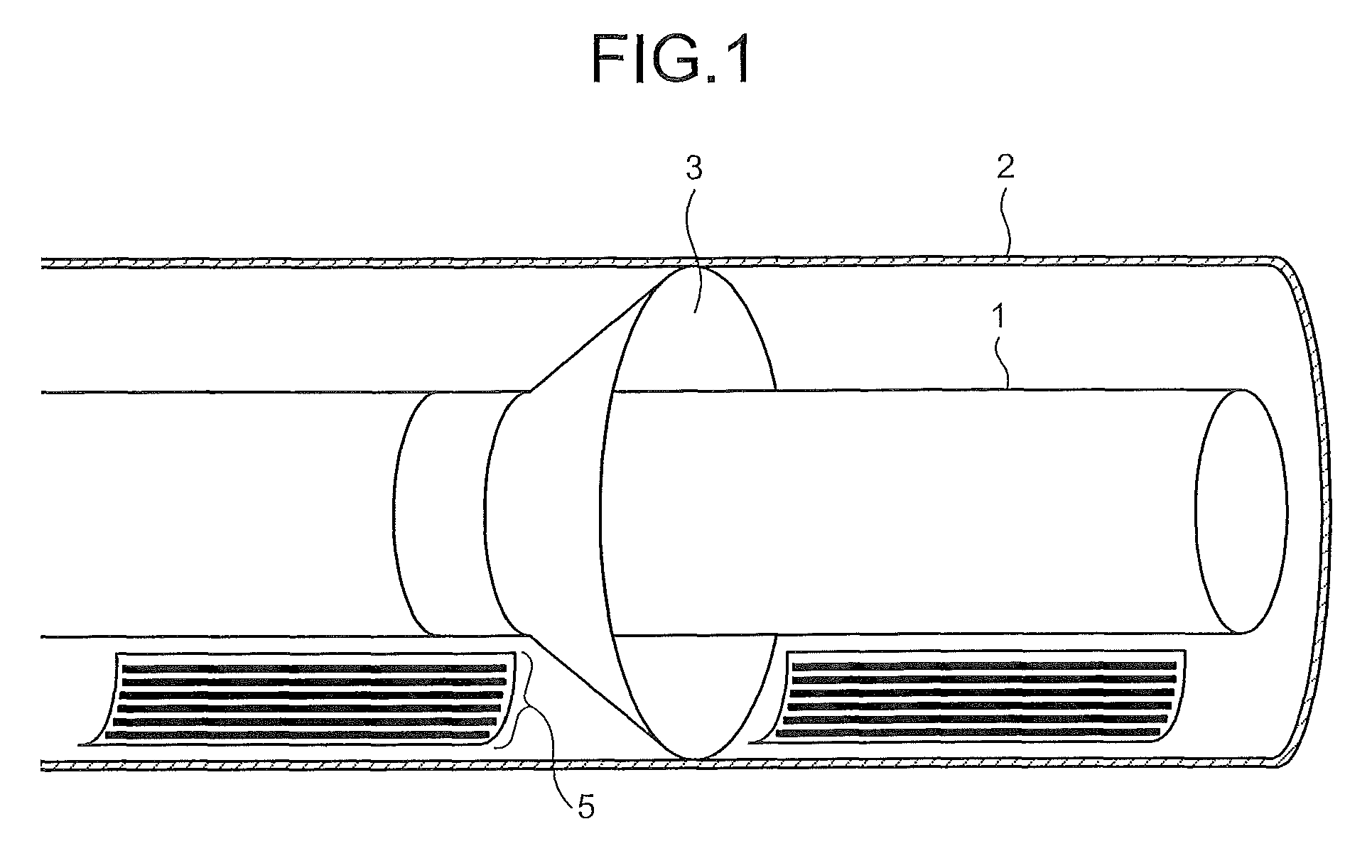

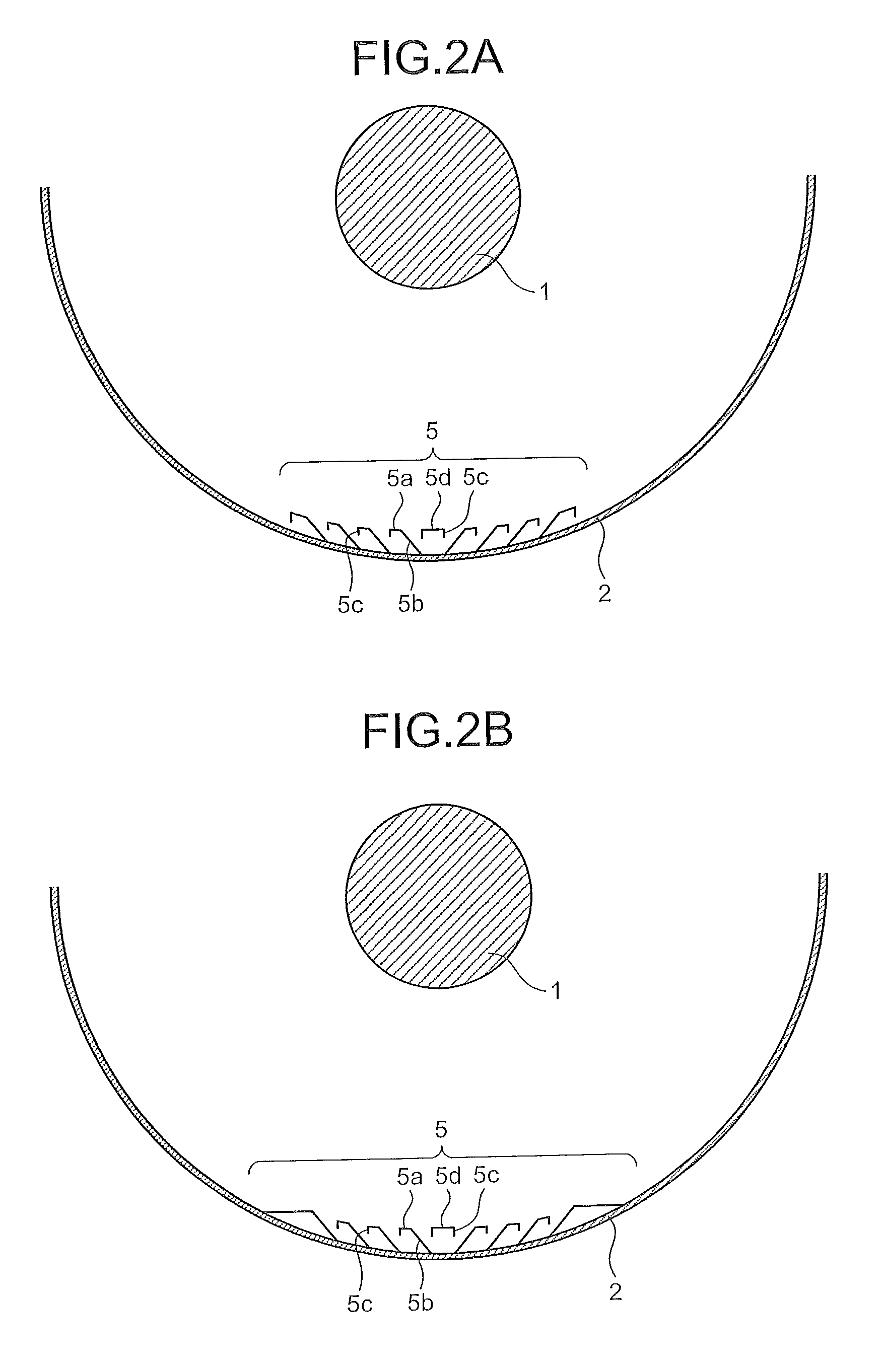

Fluid-insulated electrical apparatus

ActiveUS20100206615A1Solve problemsReduce electric field distortionNon-enclosed substationsBus-bar/wiring layoutsElectrical conductorMetal

A fluid-insulated electrical apparatus includes a grounded tank which is an airtight metal vessel filled with an insulating fluid. A conductor to which a high voltage is applied is disposed in the grounded tank. A metal plate that is press-processed to have an inclined portion and a groove between adjacent head top portions is fixed to and electrically connected to an inner wall of the grounded tank.

Owner:NEXGEN CONTROL SYST LLC

High-frequency transformer, and packaging method and application thereof

PendingCN113823506AReduce electric field distortionReduce partial dischargeTransformers/inductances coils/windings/connectionsFixed transformers or mutual inductancesTransformerEngineering

The invention belongs to the technical field of transformer packaging, and particularly relates to a high-frequency transformer, and a packaging method and an application thereof. The packaging method comprises the following steps: placing high-frequency transformer accessories in a mold, filling the mold with a packaging material, curing, demolding, cooling to a room temperature, and carrying out temperature treatment, wherein the temperature treatment is carried out in any one of the following modes: mode 1: cooling to -30 to -20 DEG C and keeping for 1-24 hours, heating to -10 to 10 DEG C and keeping for 1-24 hours, and heating to 80 to 120 DEG C and keeping for 1-72 hours; mode 2: cooling to -30 to -20 DEG C, keeping for 1-24 hours, heating to 80-120 DEG C, and keeping for 1-72 hours; mode 3: raising the temperature to 80-120 DEG C, and keeping the temperature for 1-72 hours; and mode 4: heating to 80-120 DEG C, keeping for 1-72 hours, cooling to -30--20 DEG C, and keeping for 1-24 hours. According to the packaging method provided by the invention, after curing is completed, temperature treatment is carried out so that an internal stress of the high-frequency transformer can be redistributed, electric field distortion caused by stress concentration is reduced, partial discharge is reduced, and the packaging method is suitable for packaging of the high-frequency transformer.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Liquid crystal display and manufacturing method thereof

InactiveUS9140939B2Increase the aperture ratioReduce electric field distortionNon-linear opticsResistLiquid-crystal display

A manufacturing method of a liquid crystal display includes forming a sacrificial layer on a liquid crystal panel, forming an etch stop layer on the sacrificial layer, forming a photo resist pattern on the etch stop layer, completing the etch stop layer using the photo resist pattern as a mask, ashing the photo resist pattern and the sacrificial layer by using the completed etch stop layer as a mask, forming a microcavity by removing a portion of the sacrificial layer and forming a liquid crystal layer in the microcavity.

Owner:SAMSUNG DISPLAY CO LTD

Fluid-insulated electrical apparatus

ActiveUS8173896B2Reduce electric field distortionElectric field is enhancedNon-enclosed substationsBus-bar/wiring layoutsElectrical conductorElectrical devices

Owner:NEXGEN CONTROL SYST LLC

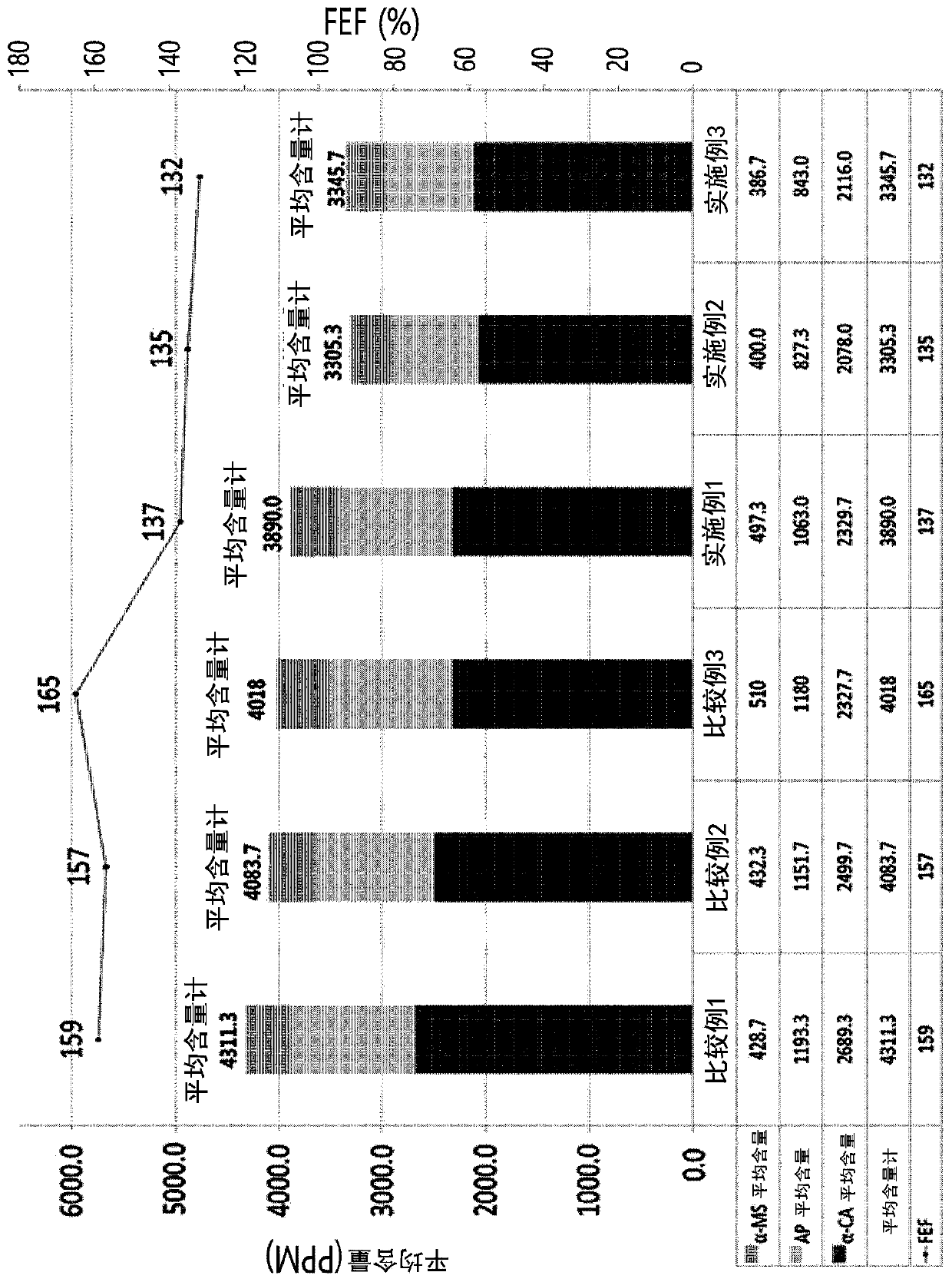

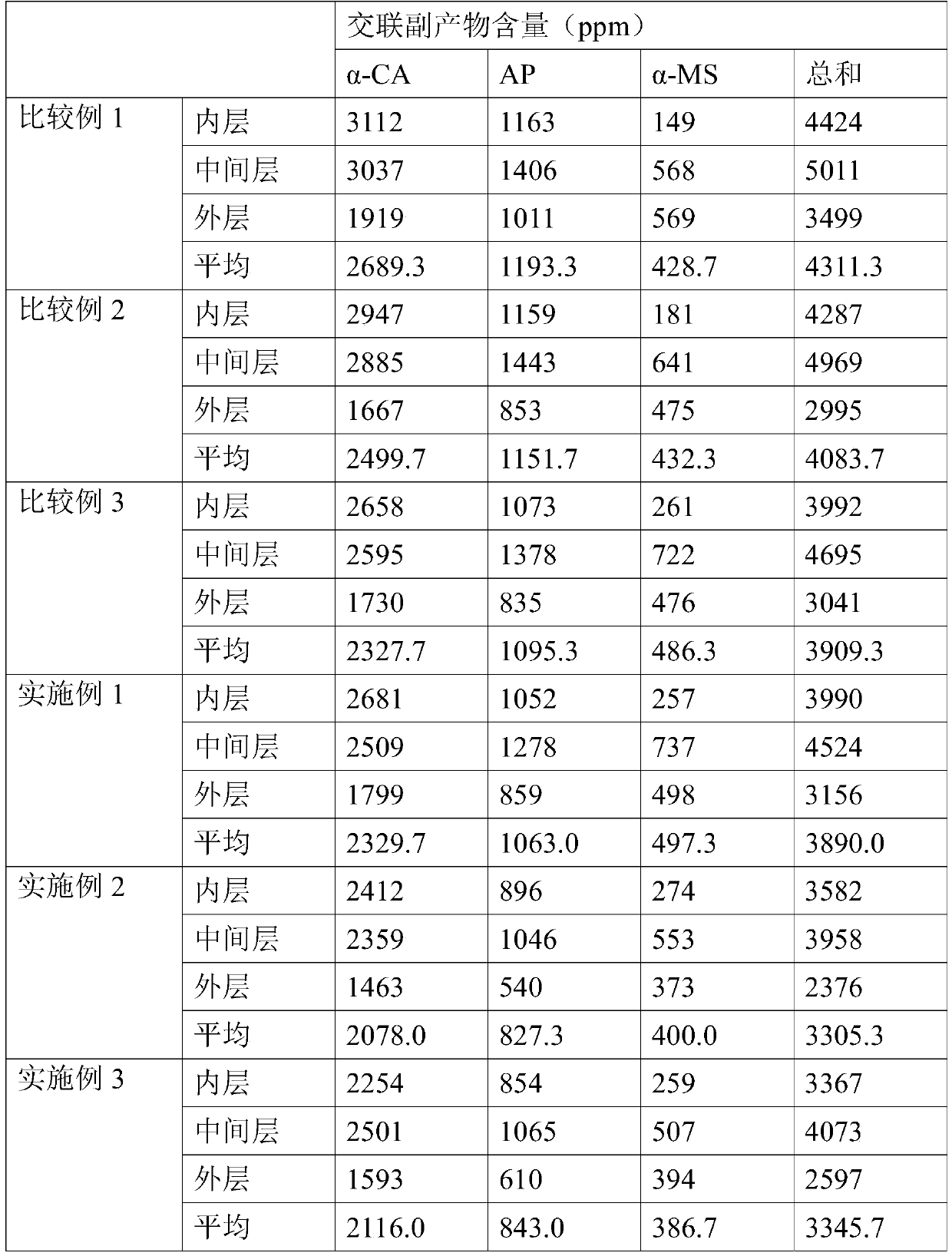

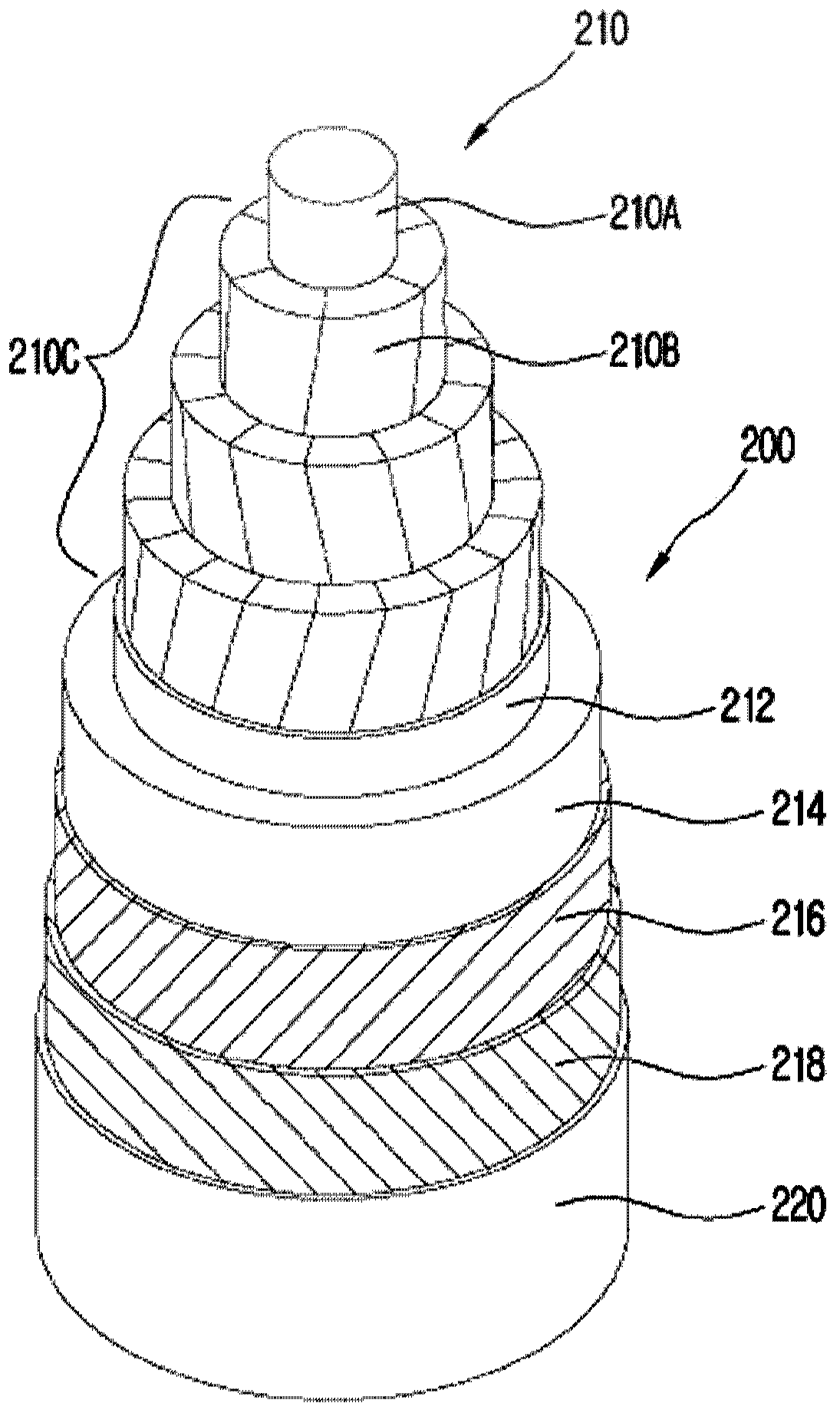

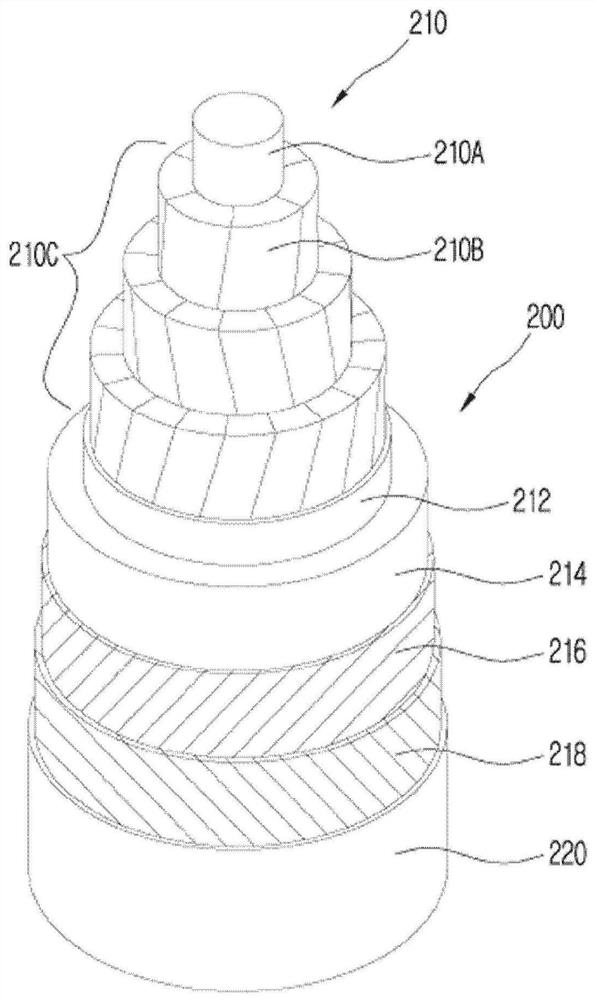

Ultra-high voltage direct current power cable

ActiveCN110692112AThe content is precisely controlledReduce electric field distortionPlastic/resin/waxes insulatorsPower cables with screens/conductive layersComputational physicsElectric field distortion

The present invention relates to an ultra-high voltage direct current power cable. Specifically, the present invention relates to an ultra-high voltage direct current power cable enabling the simultaneous prevention or minimization of electric field distortion, DC dielectric strength degradation and impulse breakdown strength degradation caused by the accumulation of space charge in an insulator.

Owner:LG CABLE LTD (KR)

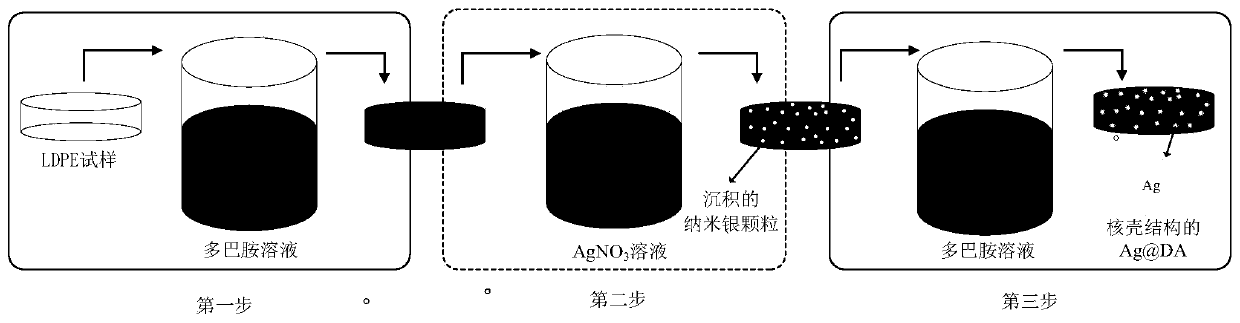

Insulating material structure and production method thereof

ActiveCN110253995AStrong adhesionStrong reductionSynthetic resin layered productsMetal layered productsPolymer insulationOptoelectronics

The invention discloses an insulating material structure and a production method thereof. The insulating material structure is used as an insulating medium of electrical equipment in high-voltage direct-current transmission, and comprises a polymer base layer, wherein a first polydopamine layer, a nano-silver layer and a second polydopamine layer are sequentially arranged on the surface of the polymer base layer from inside out, the nano-silver layer comprises a plurality of nano-silver particles, the range of the particle size RA<g> of the nano-silver particles is as follows: 0<RA<g><100 nm. The insulating material structure can effectively inhibit injection and accumulation of space charges in a polymer insulating medium under high voltage and direct current, reduces electric field distortion, caused by a space-charge effect, in an insulating material, improves the breakdown performance of the insulating material, and thus prolongs the service life of the electrical equipment, achievement is simple, the practicability is high, the safety is high, equipment needed in a production method of the material is simple and easy to obtain, treatment conditions needed in the production method of the material are simple and easy to achieve, and the repeatability is high.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

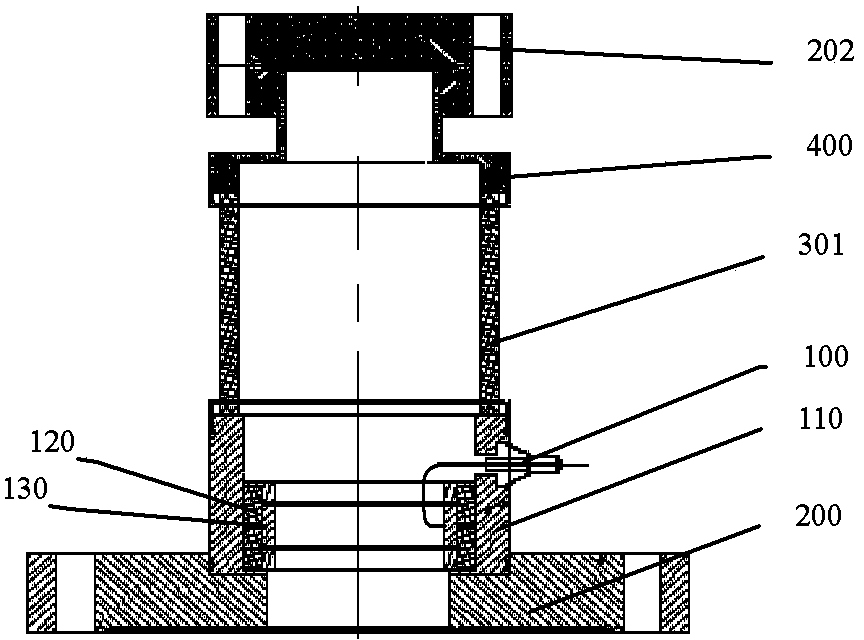

Conical insulator with VFTO suppression function

PendingCN107393662AGuaranteed reliabilityReduce electric field distortionInsulatorsElectric power equipmentEngineering

The invention relates to the technical field of electric power equipment, in particular to a conical insulator with a VFTO suppression function. The conical insulator includes a center insert, an insulation area, a creepage area and a fixed flange, wherein the center insert is arranged at the top end of a hollow cone, and the end, close to the center insert, of the cone is provided with the insulation area, and the area except the insulation area is the creepage area; the bottom of the creepage area is connected with the fixed flange. When an external VFTO acts on the surface of the insulator, the resistivity of nonlinear packing in the local area of the creepage area decreases rapidly under the action of transient high voltage provided by the VFTO, so that charges accumulated on the surface of the insulator are dissipated in the propagation direction of the creepage area and the fixed flange, and therefore charge accumulation which is formed on the surface of the conical insulator by the VFTO is inhibited; therefore, the reliability of the insulator is maintained, electric field distortion on the surface of the insulator is reduced, and the stability of running of GIS equipment is improved.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

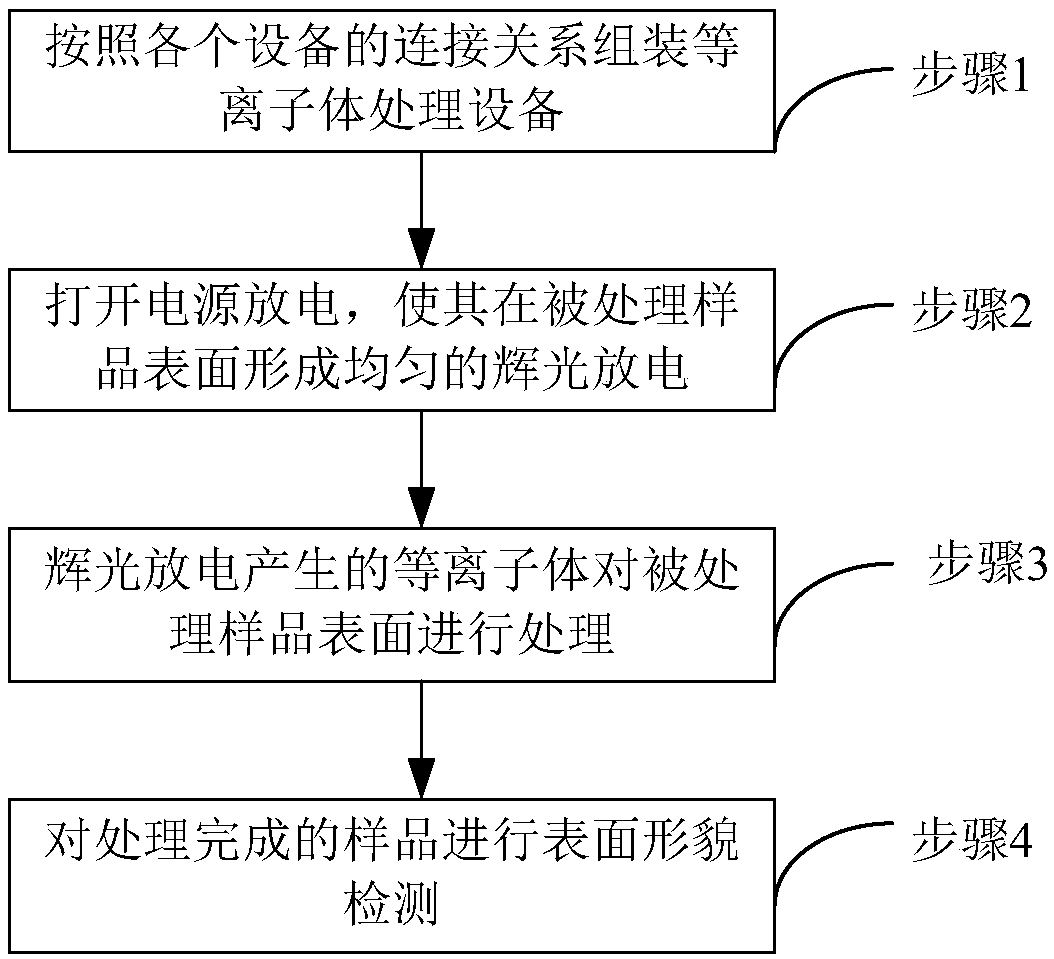

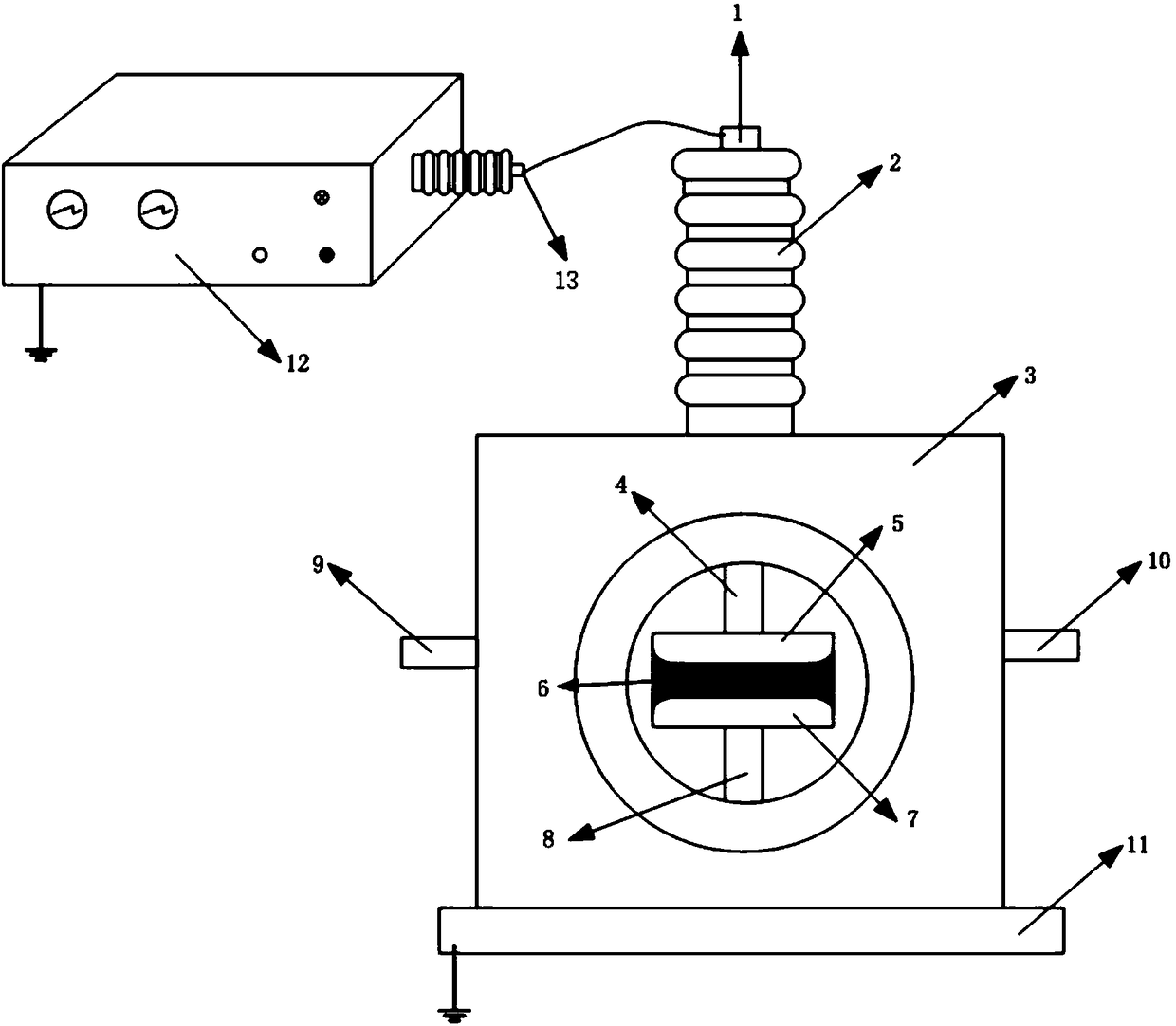

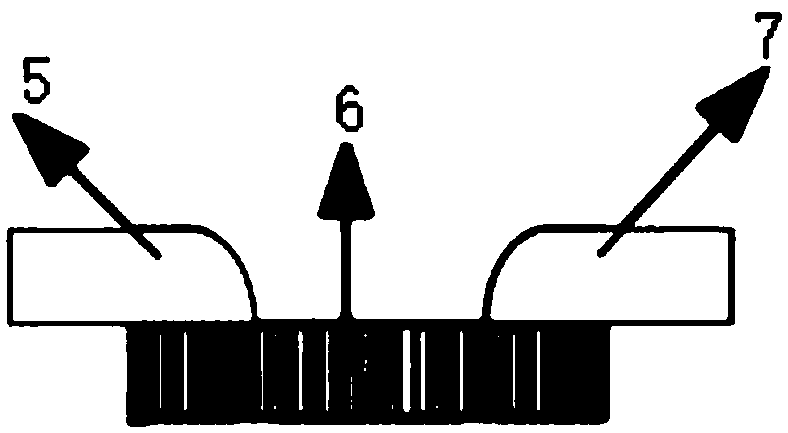

Device and method for treating micro-stacking structure insulating material surfaces by discharge plasma

The invention discloses a device for treating micro-stacking structure insulating material surfaces by discharge plasma. The device is characterized in that one end of a high-voltage leading electrodeis connected with a pulse power supply through a power supply high-voltage output terminal, the other end of the high-voltage leading electrode is connected with a high-voltage electrode through a high-voltage conducting rod, a grounding electrode is arranged under the high-voltage electrode, connected with a base through a grounding conducting rod and grounded, and a treated test sample is fixedbetween the high-voltage electrode and the grounding electrode and fitted closely with the high-voltage electrode and the grounding electrode in a gapless manner. The invention further discloses a method for treating the micro-stacking structure insulating material surfaces by the discharge plasma. The method includes the steps: 1 treating the device according to connecting assembly of equipment;2 placing the treated test sample and fixing the treated test sample between the high-voltage electrode and the grounding electrode in the gapless manner; 3 turning on the pulse power supply to formuniform glow discharge; 4 eroding the surface of the treated test sample by low-temperature plasma generated by glow discharge.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

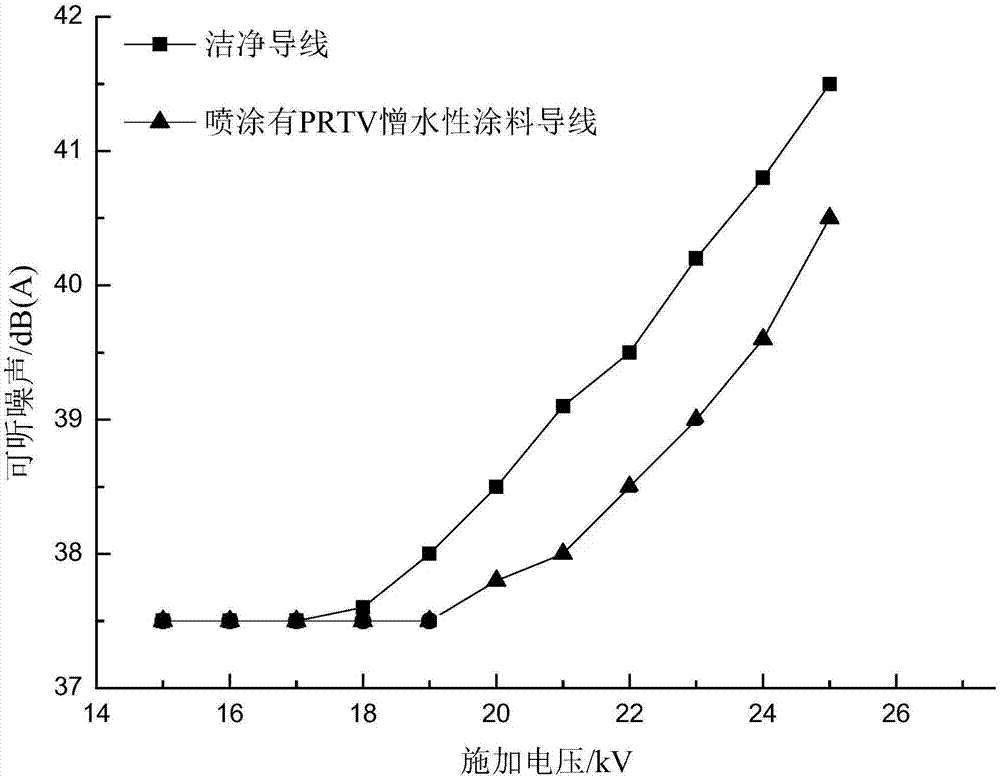

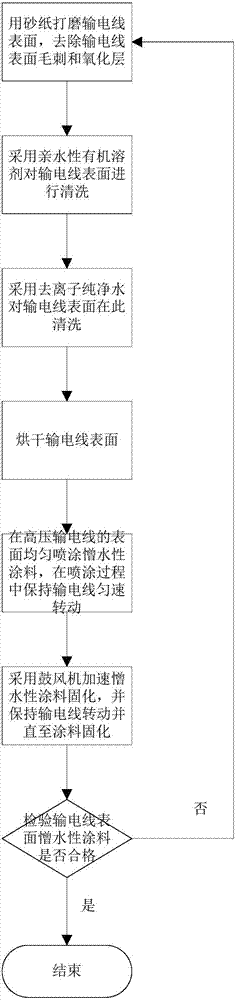

Noise lowering treatment method for corona audible noise of high-voltage power transmission line

InactiveCN107961964AReduces corona audible noiseReduce electric field distortionPretreated surfacesCleaning using toolsEngineeringElectric field distortion

The invention provides a noise lowering treatment method for a corona audible noise of a high-voltage power transmission line. The noise lowering treatment method for the corona audible noise of the high-voltage power transmission line comprises the following steps that S1, the surface of the high-voltage power transmission line is cleaned; S2, the surface of the high-voltage power transmission line is evenly coated with hydrophobic paint. By the adoption of the noise lowering treatment method for the corona audible noise of the high-voltage power transmission line, accumulation of water dropsand dirt on the surface of the power transmission line can be effectively reduced, so that the electric field distortion on the surface of a wire is reduced, so that the corona starting voltage of the high-voltage power transmission line is improved, and then the corona audible noise of the high-voltage power transmission line during severe weather can be lowered.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

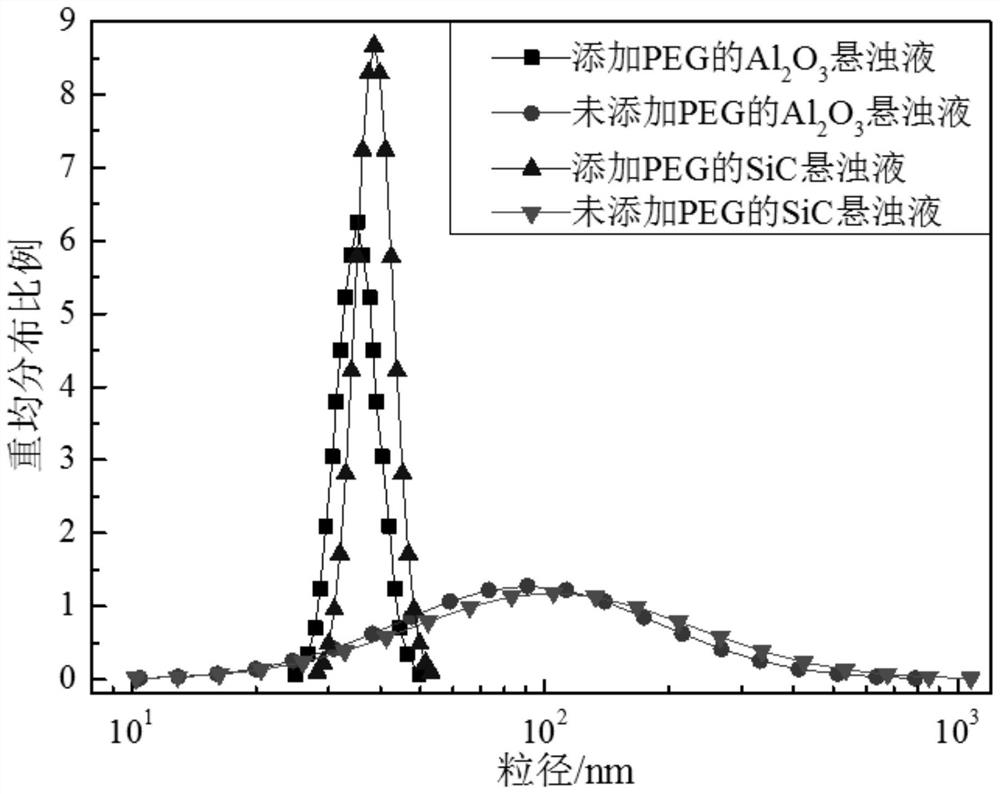

Preparation method and application of nano-particle dispersed and modified insulating paperboard based on surface modification

InactiveCN114086418AEvenly dispersedReduce spacingNatural cellulose pulp/paperPlastic/resin/waxes insulatorsCapacitanceNanoparticle

The invention discloses a preparation method and application of a nano-particle dispersed and modified insulating paperboard based on surface modification, belongs to the technical field of insulating paperboards of transformers, and aims to solve the problem of poor nanoparticle dispersion of insulating paperboards prepared by existing methods. The method comprises the following steps of: 1, pulping; 2, dissociation; 3, modifying the surfaces of nano-particles; 4, manufacturing and forming; 5, squeezing; and 6, drying. The material is used as a material of a capacitor core of a capacitor bushing for a converter transformer. According to the nano-particle dispersed and modified insulating paperboard based on surface modification prepared by the invention, nano-particles on the surface are uniformly dispersed, and the distance between adjacent nano-particles is reduced along with the increase of the nano-doping proportion; and the uniformly dispersed nano-particles improve the insulation resistance of the insulating paperboard, effectively improve the breakdown field strength of the insulating paperboard, improve the operation reliability of the transformer and prolong the service life of the transformer. The insulating paperboard is used as a material of a capacitor core of a capacitor bushing for a converter transformer.

Owner:STATE GRID HEILONGJIANG ELECTRIC POWER CO LTD ELECTRIC POWER RES INST +1

Liquid crystal display

InactiveUS7705941B2Reduce textureReduce electric field distortionNon-linear opticsLaddersLiquid-crystal displayLiquid crystal

A liquid crystal display includes a first substrate, a first field generating electrode arranged on the first substrate and including first and second cutouts, and a second substrate facing the first substrate. A second field generating electrode is arranged on the second substrate and includes a third cutout, and a liquid crystal layer is interposed between the first and second field generating electrodes. A column spacer is interposed between the first and second substrates and is disposed in the first cutout region.

Owner:SAMSUNG DISPLAY CO LTD

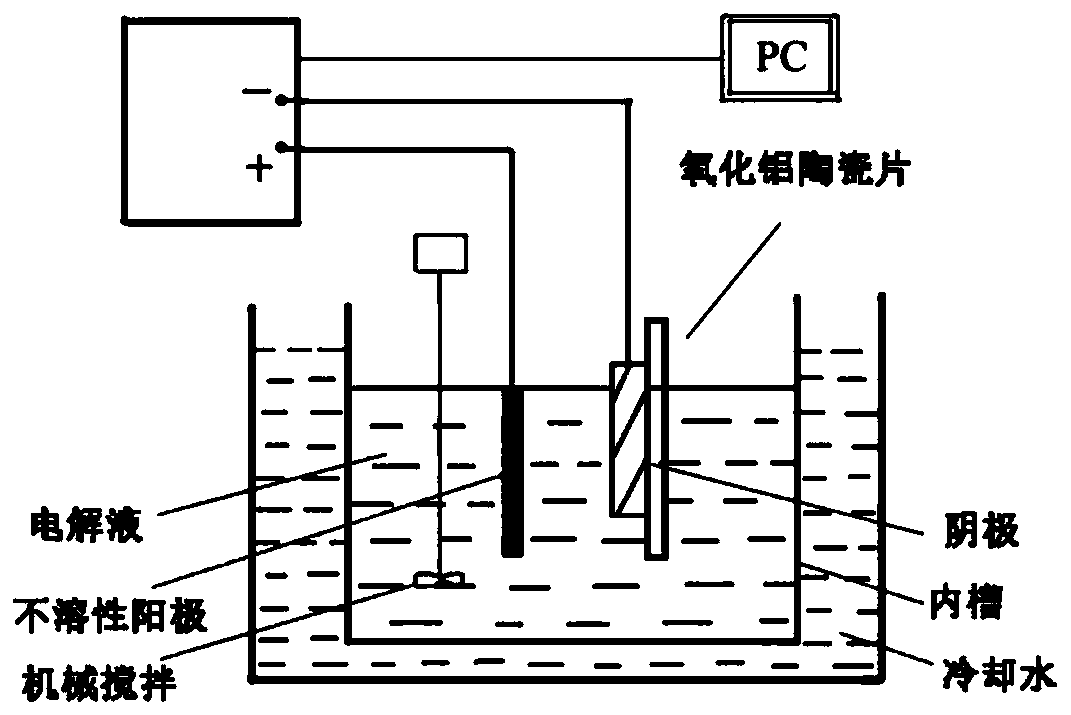

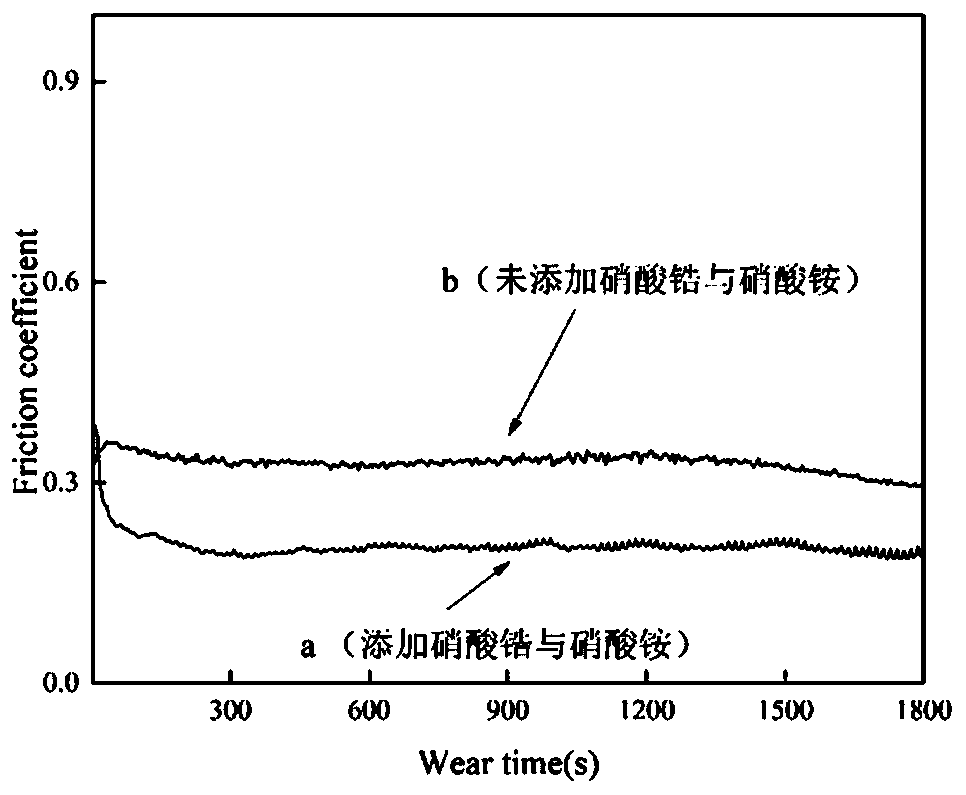

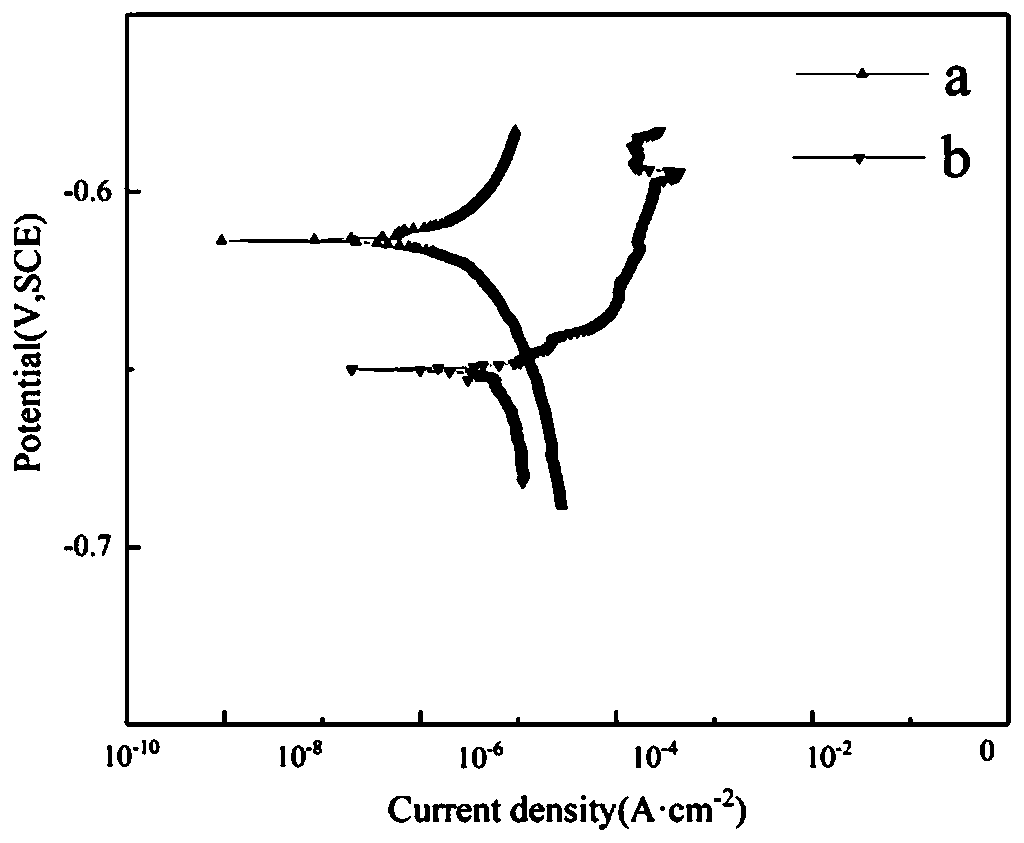

aluminum alloy surface 3 c 4 -al 2 o 3 -zro 2 Preparation method of wear-resistant composite coating

ActiveCN108441912BHigh bonding strengthSimple deposition processElectrolytic coatingsWear resistantElectrolyte

The invention discloses a preparation method of an Al3C4-Al2O3-ZrO2 wear-resistant composite coating on the surface of aluminum alloy. According to the preparation method, an electrolytic tank of a single-groove structure is adopted, and a mixed solution prepared from zirconium nitrate, urea, formamide and glycerin is used as an electrolyte. The cathode side is covered with an aluminum oxide ceramic sheet with the size similar to the size of a workpiece so that a non-conducting shielding effect can be achieved in the discharging process, electric field distortion caused by the edge effect around the cathode is reduced, and discharging of the cathode is more uniform. A direct-current voltage or a pulse voltage is applied to the electrolytic tank, so that a continuous and uniform air film israpidly formed on the surface of the cathode, continuous plasma micro-arc discharging can be caused on the surface of the aluminum alloy, and accordingly, the stable, uniform and hard ceramic coatingis formed on the surface of the aluminum alloy. By adoption of the preparation method, the wear-resistant and corrosion-resistant coating with high hardness, a small friction coefficient and a low wear rate can be prepared on the surface of the aluminum alloy, and thus, the application of the aluminum alloy in the fields of traffic, energy and the like is effectively widened.

Owner:NANJING UNIV OF SCI & TECH

Liquid crystal display and manufacturing method thereof

ActiveUS8780306B2Reduce electric field distortionImprove response speedStatic indicating devicesVessels or leading-in conductors manufactureEngineeringLiquid crystal molecule

A liquid crystal display and a manufacturing method are provided. A liquid crystal display according to an exemplary embodiment of the present invention includes: a first substrate; a second substrate facing the first substrate; a liquid crystal layer interposed between the first substrate and the second substrate, and including liquid crystal molecules; a first electrode positioned on the first substrate; an insulating layer positioned on the first electrode; a second electrode positioned on the insulating layer; and a third electrode positioned on the second substrate, wherein the second electrode includes a plurality of branches and a slit between neighboring ones of the branches, and a width of the slit is more than about two times to less than about five times a width of its corresponding branches.

Owner:SAMSUNG DISPLAY CO LTD

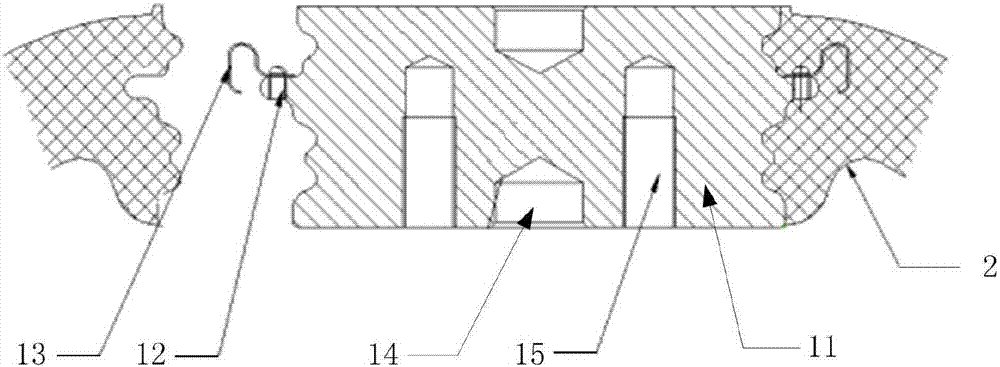

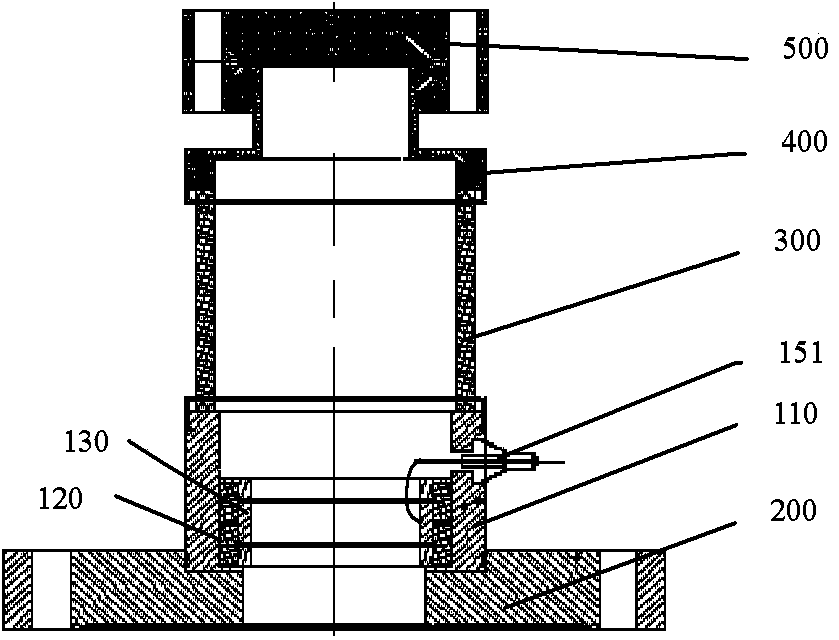

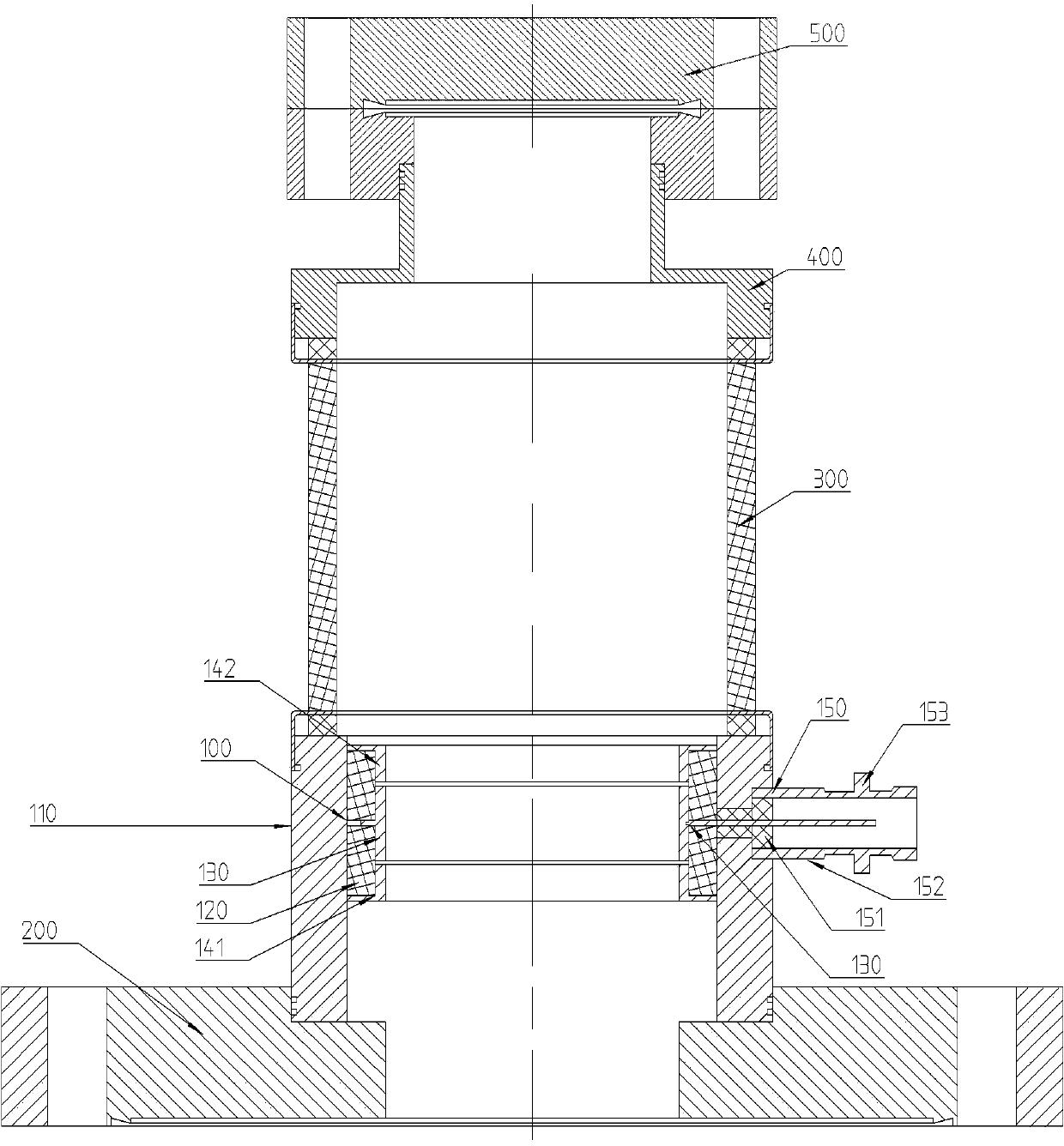

Capacitive probe device with function of reducing electric field distortion

InactiveCN103808990AReduce electric field distortion functionReduce electric field distortionElectrical measurement instrument detailsElectrical testingMetallic materialsElectric field distortion

The invention provides a capacitive probe device with the function of reducing electric field distortion. The capacitive probe device comprises a cylindrical vacuum cavity structure, an insulating ceramic barrel fixed to the inner side of the vacuum cavity structure, an annular electron beam induction ring which is made of a metal conducting material and is fixed to the middle of the inner side of the insulating ceramic barrel, annular electric field improving rings which are made of a metal conducting material, fixed to the upper portion and the lower portion of the inner side of the insulating ceramic barrel, insulated from the electron beam induction ring, and equipotential with the vacuum cavity structure, and a lead adapting assembly which is used for leading an induction signal of the electron beam induction ring out of the vacuum cavity structure. In the capacitive probe device, the electric field improving rings which are insulated from the electron beam induction ring are arranged on both sides of the electron beam induction ring, thereby greatly reducing the electric field distortion on the edges of both sides of the electron beam induction ring, and making an electron field more uniform.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

A stress control body for plastic insulating high-voltage DC cable joints

InactiveCN103259240BImprove DC breakdown strengthReduce interfacial space chargeCable junctionsHigh-voltage direct currentElectric field distortion

The invention discloses a stress control body for a plastic insulation high-voltage and direct-current cable connector, and relates to the stress control body for the cable connector. The stress control body for the plastic insulating high-voltage and direct-current cable connector aims at solving the problems that an existing plastic insulation direct current cable prefabricated connector structure hardly meets the requirement for connecting a plastic insulation high-voltage and direct-current cable prefabricated connector with the voltage over 160 kilovolts, and at present a mature plastic insulation direct current cable prefabricated connector design scheme does not exist. The stress control body for the plastic insulating high-voltage and direct-current cable connector is a stress control body for a cross linked polyethylene insulated high-voltage and direct-current cable connector with the voltage between 160kV and 500kV, and is composed of a high-voltage shielding layer, a strengthening insulator, a stress cone and an outer shielding layer, and two side end ports of the strengthening insulator are in a trapezoid shape. According to the stress control body, electric field distortion inside the prefabricated connector can be effectively reduced, the diameter of the prefabricate connector is reduced, the prefabricated connector is convenient to install, the heat dissipation property of the prefabricated connector is improved, and the stress control body can be applied to designing the plastic insulation high-voltage and direct-current cable with the voltage over 160 kilovolts.

Owner:HARBIN UNIV OF SCI & TECH

Intermediate connection system for ultra-high-voltage direct current power cable

ActiveCN110709946AThe content is precisely controlledReduce electric field distortionPlastic/resin/waxes insulatorsPower cables with screens/conductive layersImpulse breakdown strengthPower cable

The present invention relates to an intermediate connection system for an ultra-high-voltage direct current power cable. Particularly, the present invention relates to an intermediate connection system for an ultra-high-voltage direct current power cable, capable of simultaneously preventing or minimizing electric field distortion, deterioration of a direct current dielectric strength, and deterioration of an impulse breakdown strength, which are caused by accumulation of space charges within an insulating layer of a cable and within an insulating material of an intermediate connection part.

Owner:LG CABLE LTD (KR)

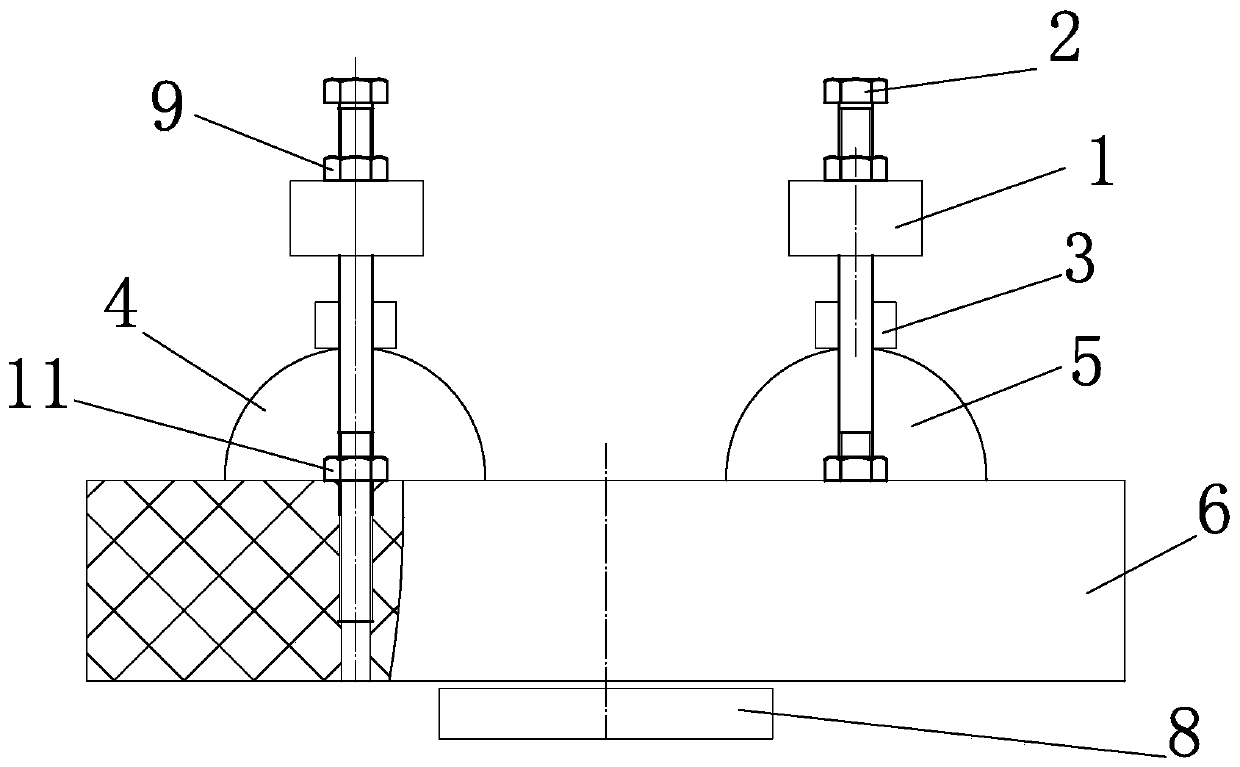

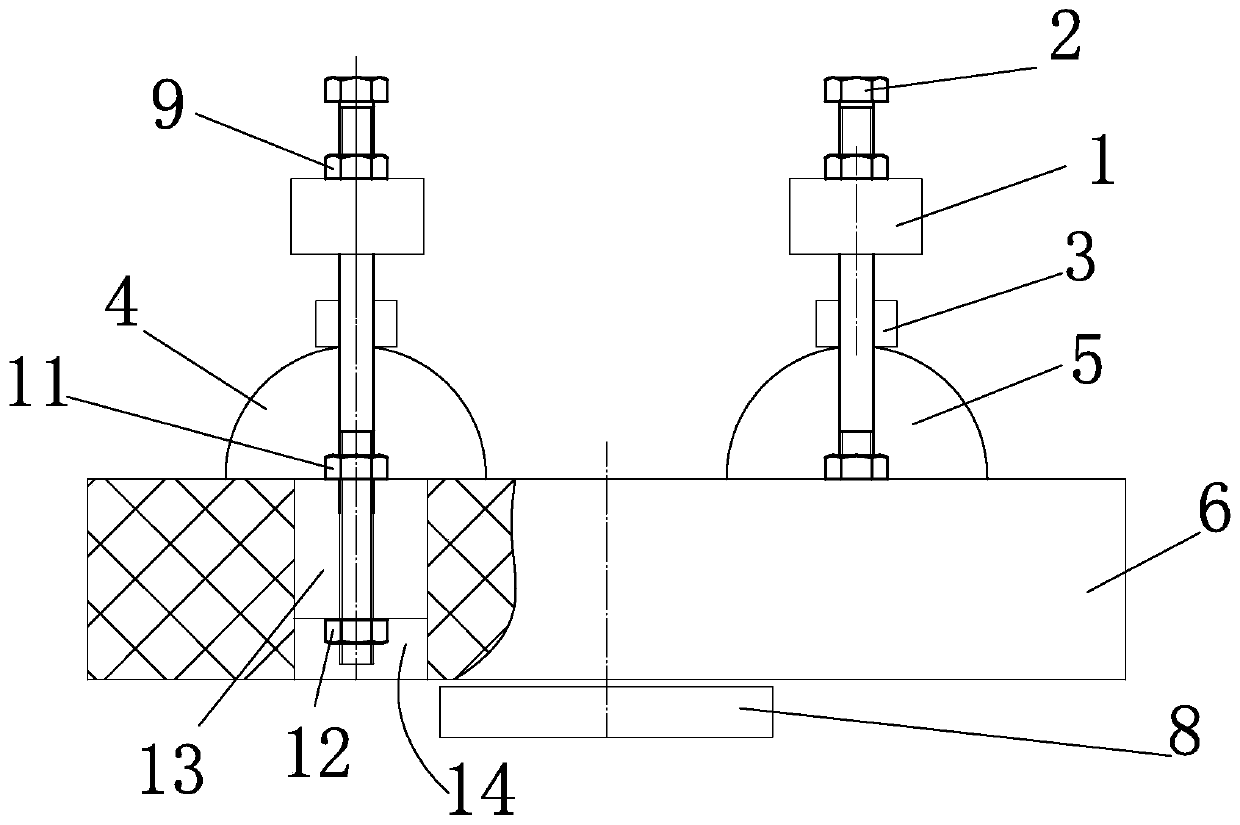

A Planar Electrode Structure Suitable for Surface Flashover in Vacuum

ActiveCN107703429BLittle effect of electric fieldSimple structureTesting vessel constructionPlanar electrodeHigh voltage electrode

The invention discloses a planar electrode structure suitable for vacuum surface flashover, including an insulating fastener, a high voltage electrode, a ground electrode, an insulating bracket and aninsulator to be measured. A groove is arranged in the middle of the upper part of the insulating bracket, and the insulator to be measured and the groove are matched. The high voltage electrode and the ground electrode are in surface contact with the insulator to be measured. The high voltage electrode and the upper part of the ground electrode are connected with a pressing mechanism, and the clamping mechanism keeps the close contact with the insulator to be measured. The pressing mechanism includes the insulating fastener, an electrode fixing bolt I and a fixing bolt I. The electrode fixingbolt I is connected with the insulating fastener. The fixing bolt I is matched with the electrode fixing bolt I. The insulating fastener is connected with the insulating bracket at the lower part through a support piece. The planar electrode structure has the advantages of simple structure, good discharge stability, small influence of the gap electric field of the vacuum surface flashover, reduction in the discharge dispersion of the vacuum surface flashover, high reliability, strong operability, long service life, and small influence of the electrode fixing and the insulating support structure on the gap electric field.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Extra High Voltage DC Power Cable

ActiveCN110692112BThe content is precisely controlledReduce electric field distortionPlastic/resin/waxes insulatorsPower cables with screens/conductive layersPower cableUltra high voltage

The invention relates to an ultra-high voltage direct current power cable. Specifically, the present invention relates to an ultra-high voltage direct current power cable capable of simultaneously preventing or minimizing electric field distortion and loss of direct current dielectric strength due to space charge accumulation in an insulator. Reduction and reduction of pulse damage intensity.

Owner:LG CABLE LTD (KR)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com