Preparation method and application of nano-particle dispersed and modified insulating paperboard based on surface modification

A nanoparticle and surface modification technology, applied in the direction of insulators, organic insulators, fiber dispersant addition, etc., can solve the problems of poor dispersion of insulating cardboard nanoparticles, reduce the space charge induced electric field, homogenize the electric field distribution, improve shock The effect of field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Specific Embodiment 1: In this embodiment, a method for preparing insulating paperboard based on surface-modified nanoparticle dispersion and modification is implemented according to the following steps:

[0029] 1. Beating: according to the mass volume ratio of 460g:5L, soak the dry pulp in distilled water for 4-6 hours, then tear it into several small pieces, pour it into the beater together with the distilled water used for soaking, and add distilled water Beating after being constant to 23L, then measuring the degree of beating of the pulp by the Schober-Rigler method, when it reaches 40 ° SR, stop beating, and the resulting slurry is drained to obtain a pulp block;

[0030] Two, dissociation: put above-mentioned pulp block and distilled water into standard disintegrating machine by mass volume ratio 20g:2000ml and carry out wet dissociation, obtain wet pulp;

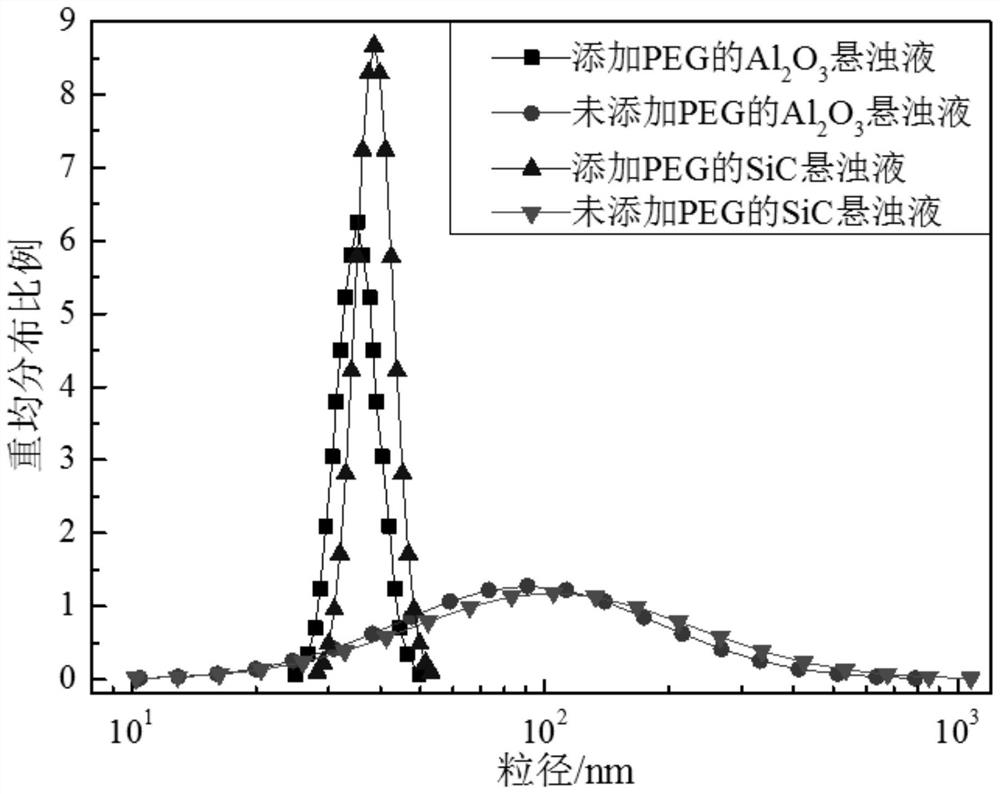

[0031] 3. Nanoparticle surface modification: Add the dispersant to distilled water and mix evenly before a...

specific Embodiment approach 2

[0041] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the size of tearing into small pieces in step 1 is (20-30) mm×(20-30) mm. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0042] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the rotational speed of beating in step 1 is 1500-2000 r / min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com