Composite phase change material, preparation method of composite phase change material, energy storage slurry and energy storage floor board

A composite phase change material and floor technology, applied in heat exchange materials, chemical instruments and methods, buildings, etc., can solve the problems of low thermal conductivity, large volume change, easy leakage of phase change materials, etc., and achieve high thermal conductivity. , The effect of high energy storage density and meeting the requirements of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composite phase change material provided by the embodiment of the present invention includes an organic phase change material and an inorganic carrier, the organic phase change material is filled in the pores of the inorganic carrier, the organic phase change material is polyethylene glycol, and the inorganic carrier is expanded graphite, polyethylene glycol The mass ratio of diol to expanded graphite is 11.5:1.

[0031] The composite phase change material of the present invention uses polyethylene glycol as the phase change material, expanded graphite as the support and enhanced heat transfer material, and is negatively pressured in a constant temperature drying oven with a pressure of -0.05Mpa and a temperature of 70°C at a mass ratio of 11.5:1. The composite phase change material was prepared by adsorption for 10 minutes. Expanded graphite has a high thermal conductivity and a well-developed network pore structure. Through the capillary action of the micropores, ...

Embodiment 2

[0039] The present invention also provides an energy storage mortar, including cement, water, water reducing agent, early strength agent and the composite phase change material of Example 1, the mixture of cement, composite phase change material, water, water reducing agent and early strength agent The ratio is 1:≤0.9:0.8~1:0.005:0.02.

[0040] The energy storage mortar of the present invention is a phase change energy storage cement mortar prepared by mixing cement, water, composite phase change materials, early strength agents, and water reducing agents in a certain proportion. The variable material replaces the standard sand, and a certain proportion of water reducer and early strength agent is added to accelerate the solidification. Finally, the ratio of cement, composite phase change material, water, water reducer and early strength agent in the energy storage mortar is 1: ≤0.9:0.8~1:0.005:0.02. The energy-storage mortar of the invention is lightweight and energy-storing...

Embodiment 3

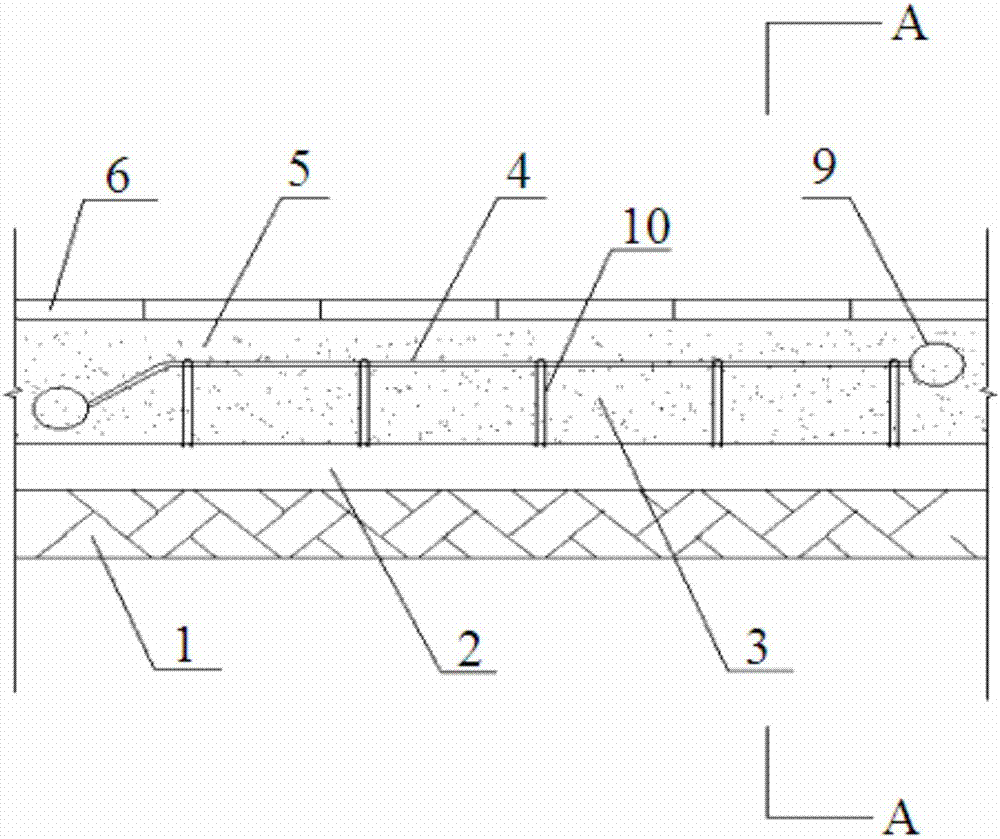

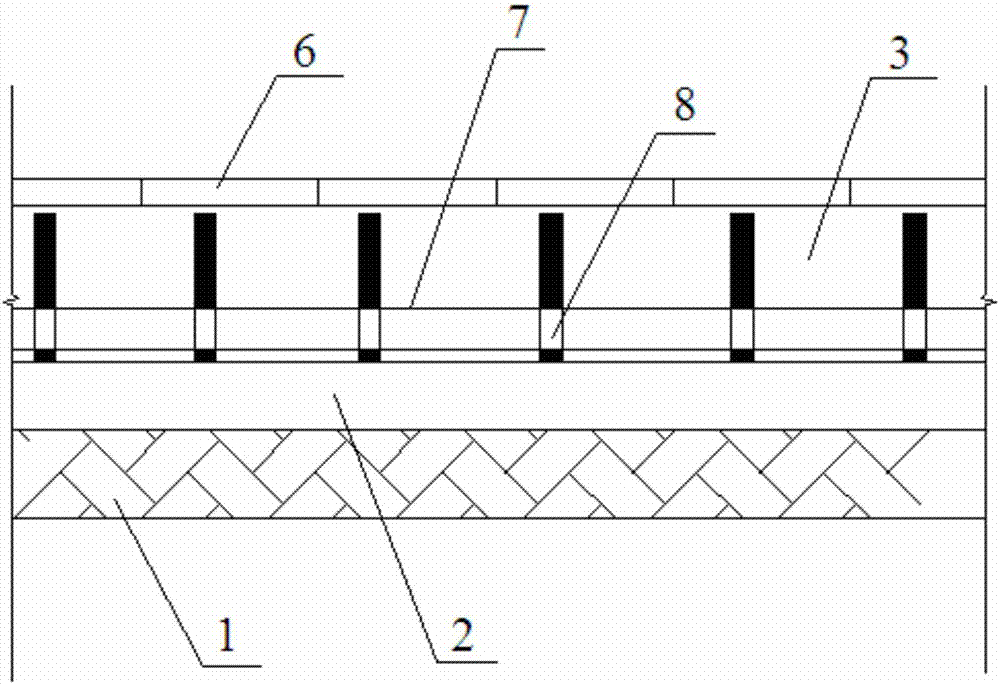

[0042] Such as figure 1 and figure 2 As shown, the present invention also provides an energy storage floor, comprising a concrete layer 1, a thermal insulation board 2, an energy storage mortar layer 3, a capillary network 4, a leveling layer 5 and a floor layer 6 laid sequentially from bottom to top, and the energy storage mortar Layer 3 is composed of the energy-storage mortar of the second embodiment.

[0043]The energy-storage floor of the invention is an energy-storage floor that applies energy-storage mortar to a terminal device of a building heating system after natural curing. The popularization and application of the energy storage floor and its heating system of the present invention in solar energy, air source heat pump, ground source heat pump heating systems or passive solar buildings can reduce building energy consumption and improve indoor thermal environment stability and comfort. Effect. The energy storage mortar layer is combined with the capillary networ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com