Patents

Literature

169results about How to "Reduce stress load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

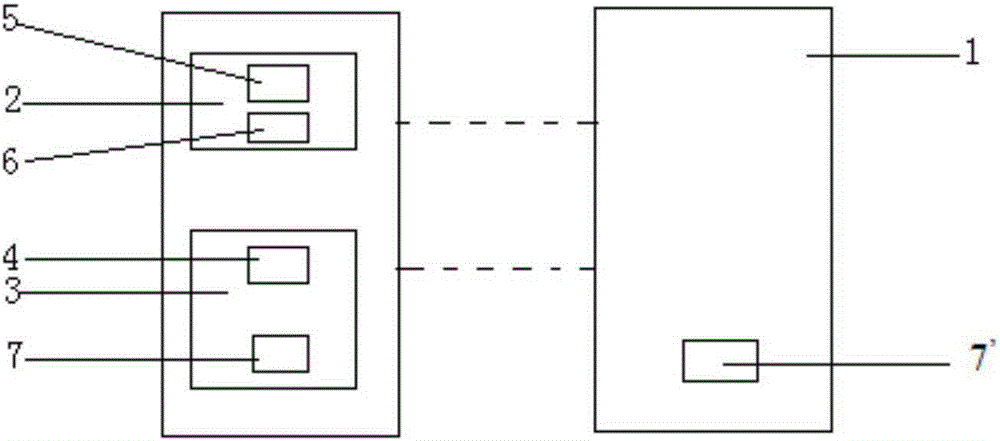

Flight region monitoring device for unmanned plane and monitoring method thereof

PendingCN105225540AAvoid exposing sensitive dataEnhance aviation safetyAircraft traffic controlUnmanned spacecraftReal-time computing

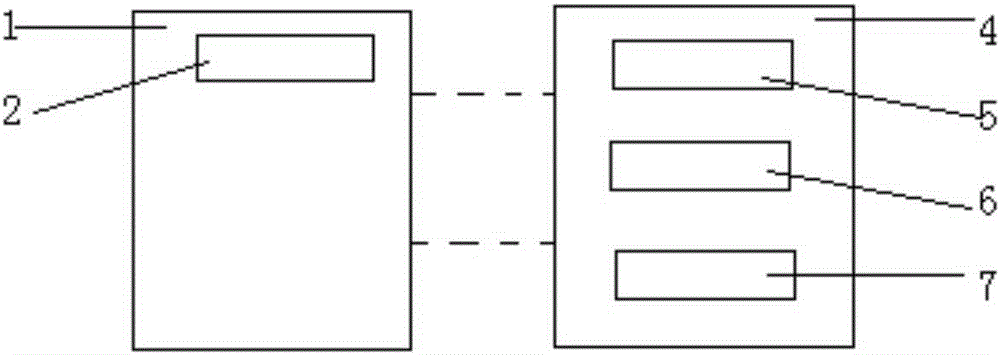

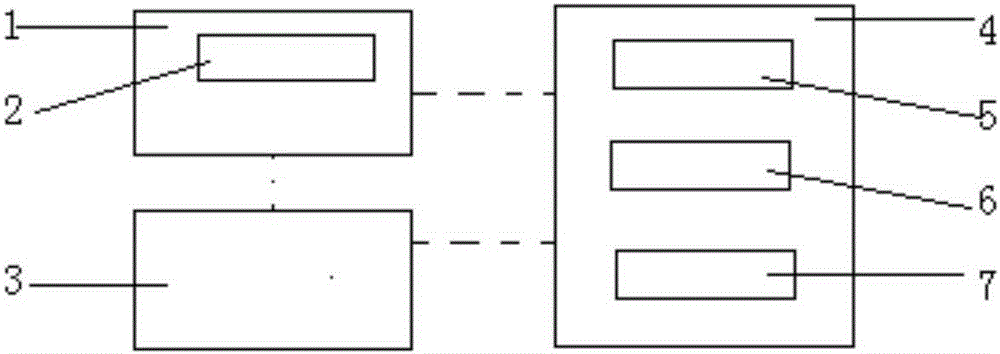

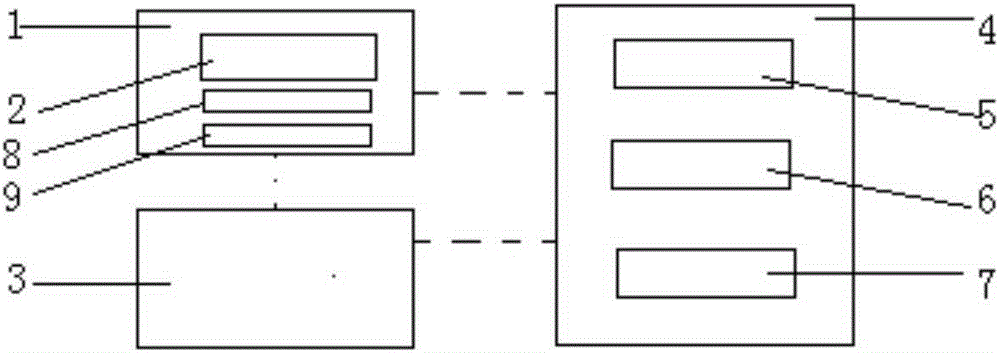

The invention provides a flight region monitoring device for an unmanned plane and a monitoring method thereof. The device comprises a flight state module (2) arranged on an unmanned plane (1) and a cloud server (4) corresponding to at least one unmanned plane (1). The flight state module (2) is used for measuring the flight state information of the unmanned plane (1) and then sending the flight state information and a uniquely corresponding identification code of the unmanned plane (1) to the cloud server (4). The unmanned plane (1) sends the predetermined route information thereof to the cloud server (4). The cloud server (4) comprises a storage module (5), a verification module (6) and a monitoring module (7). The verification module (6) verifies the received identification code. When the identification code is verified by the verification module (6), the verification module (6) verifies the received route information. Meanwhile, when the route information is verified by the verification module (6), the monitoring module (7) receives the flight state information and compares the flight state information with the route information so as to monitor the unmanned plane (1).

Owner:高域(北京)智能科技研究院有限公司

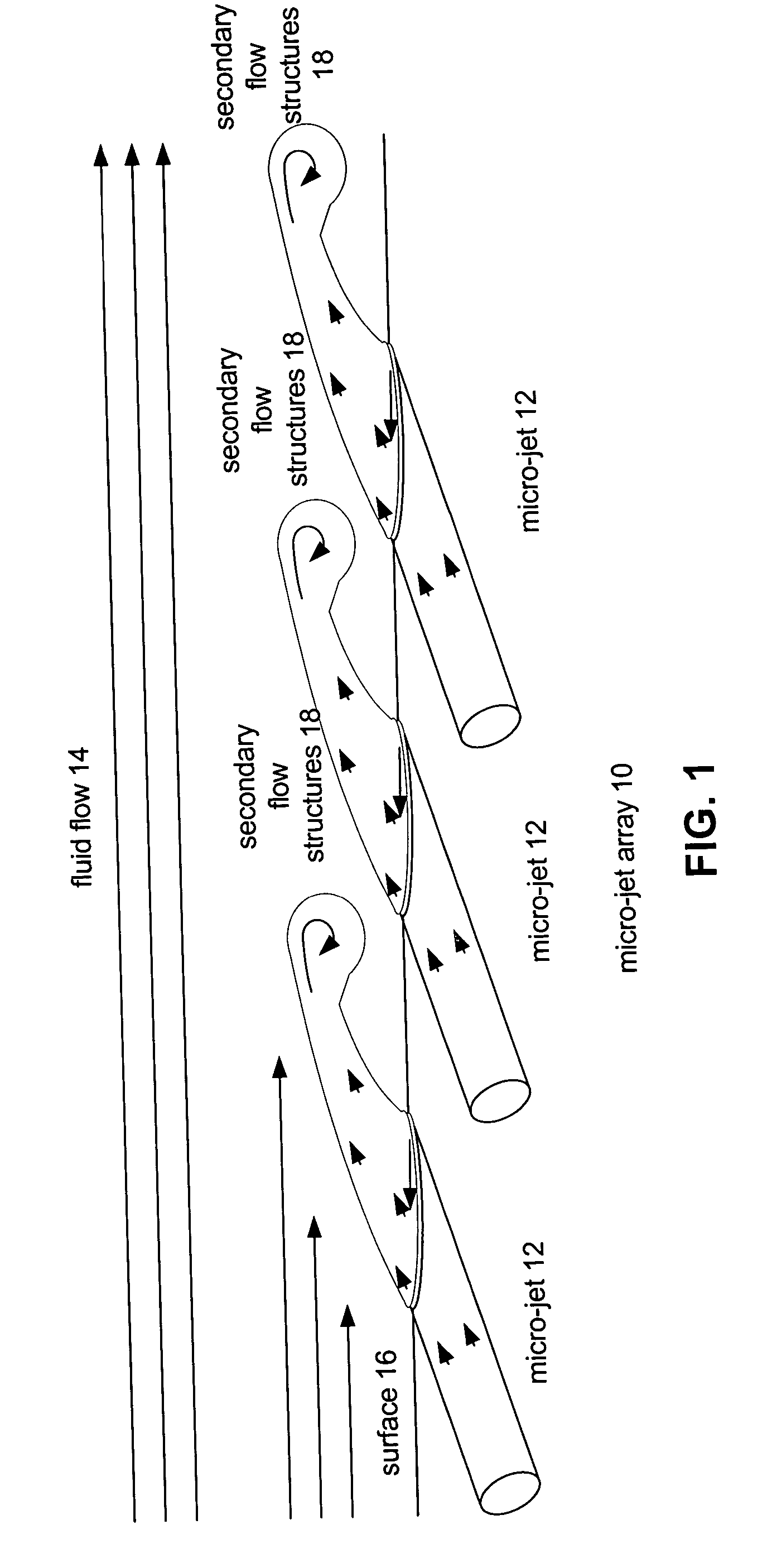

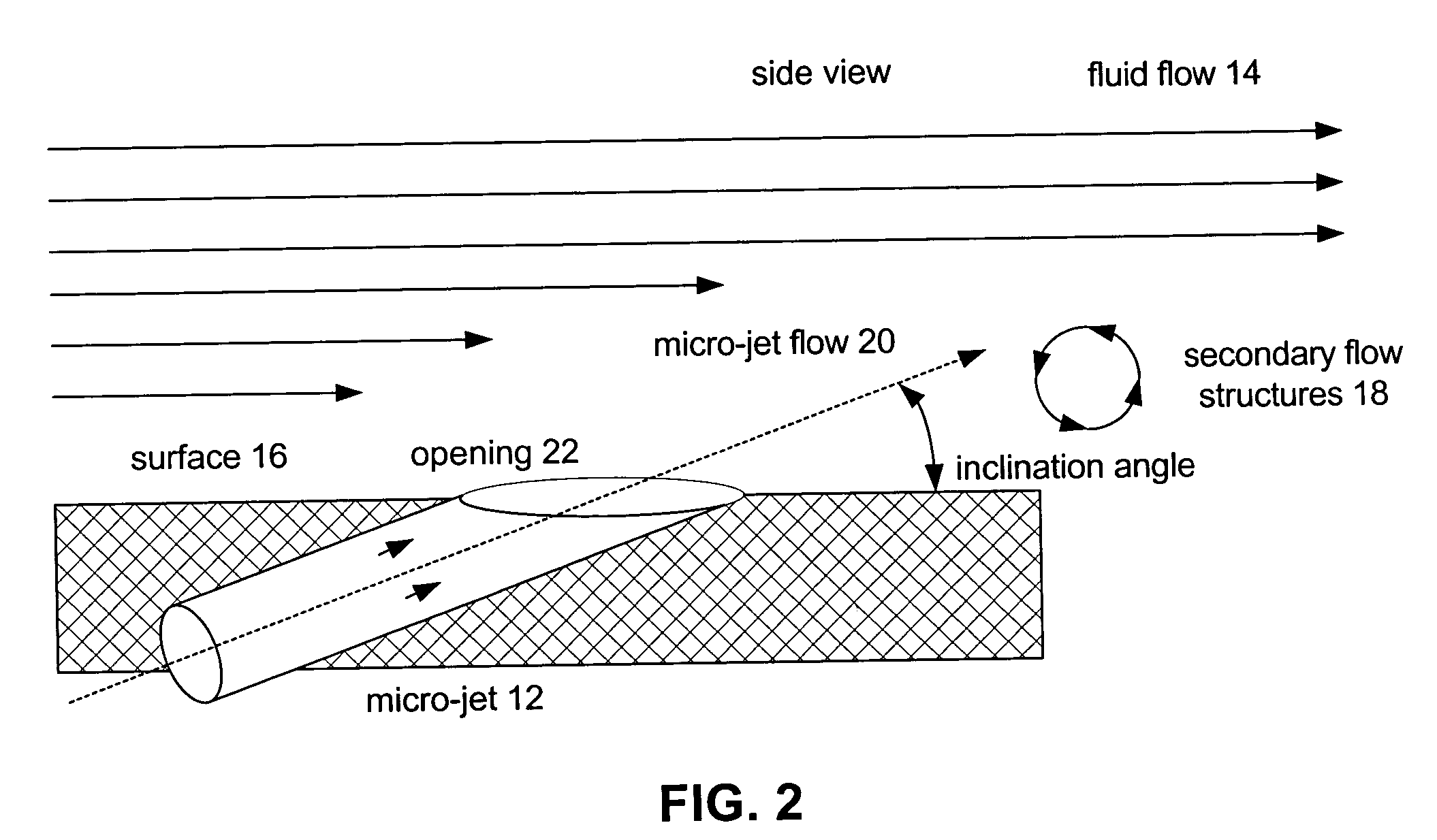

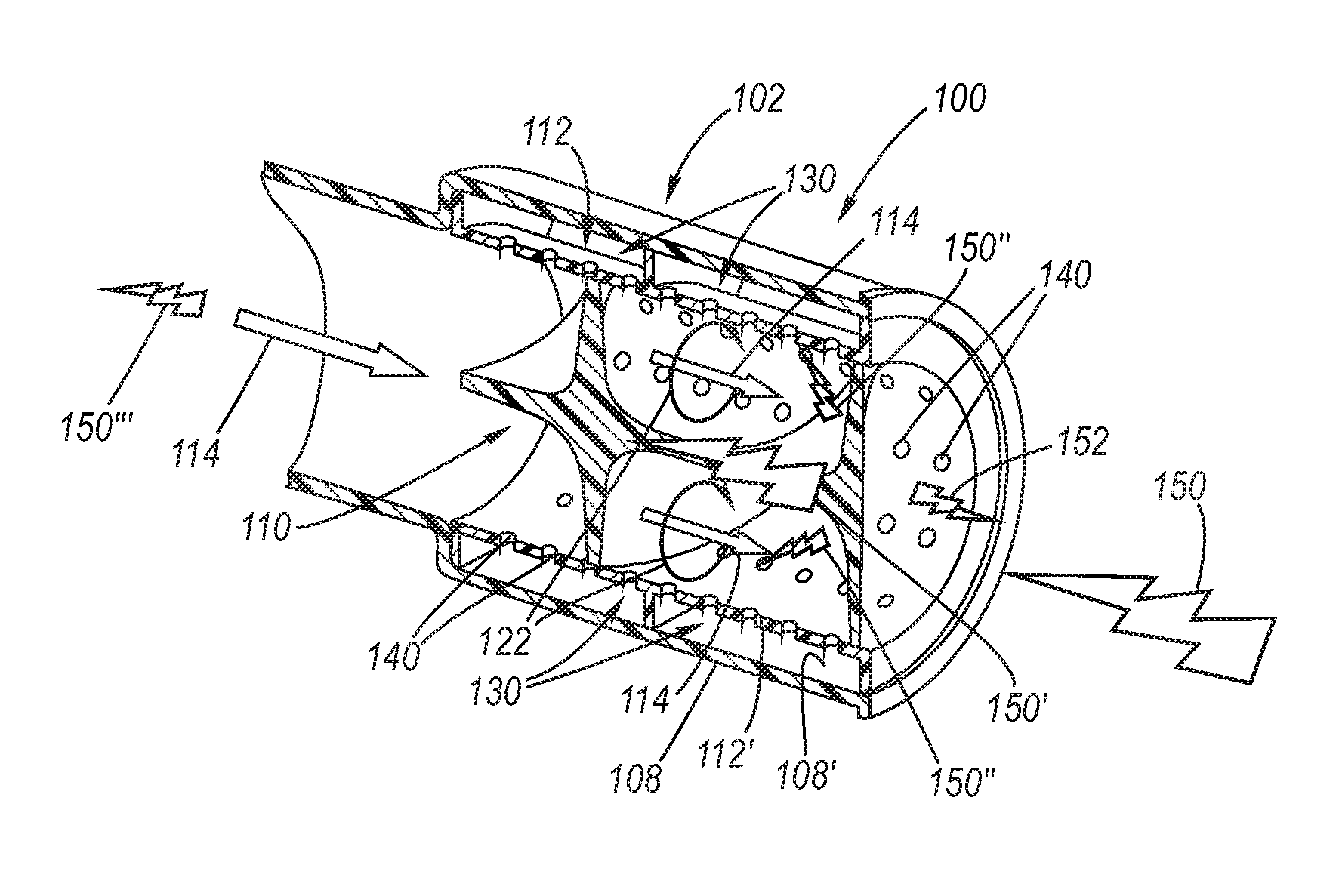

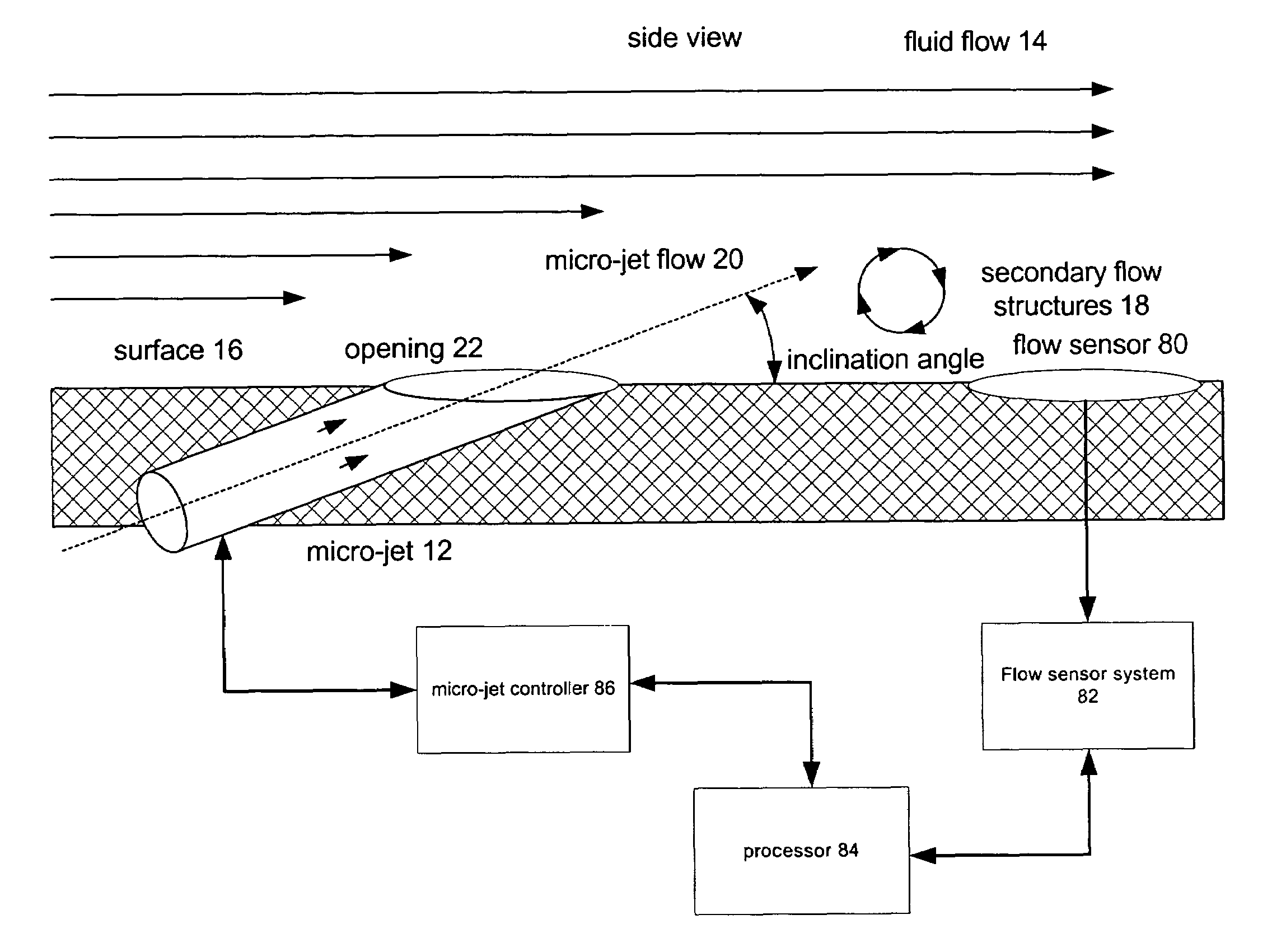

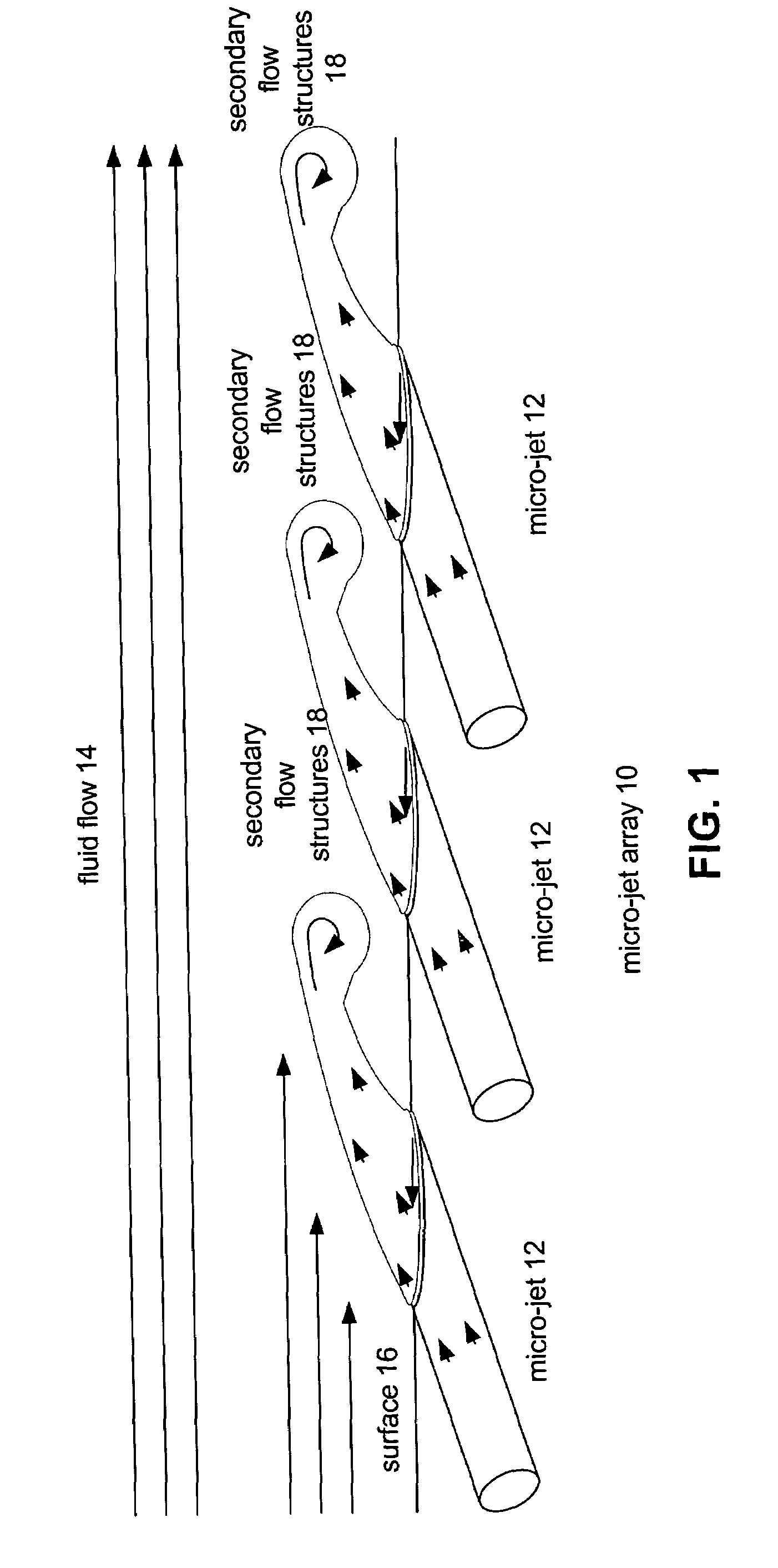

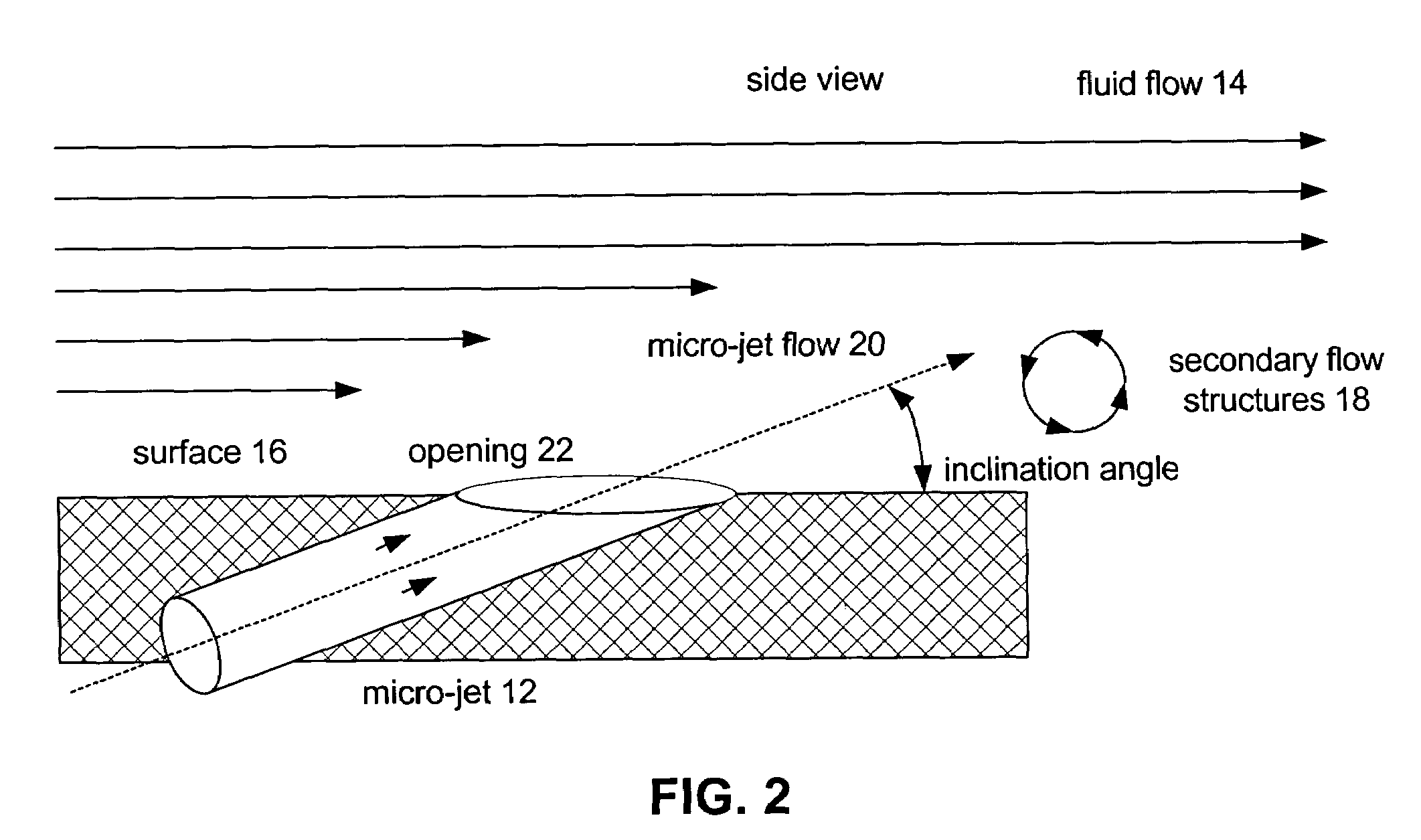

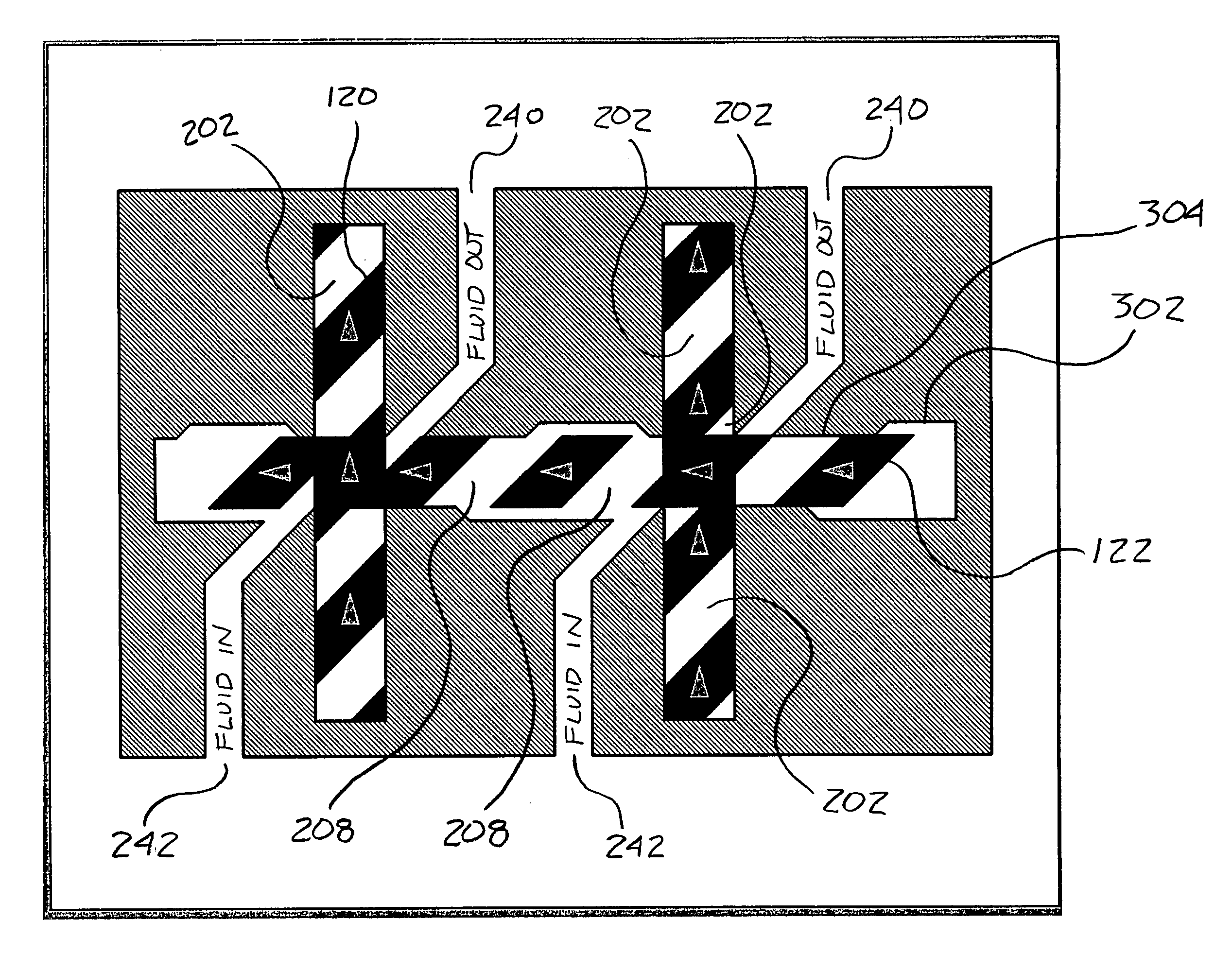

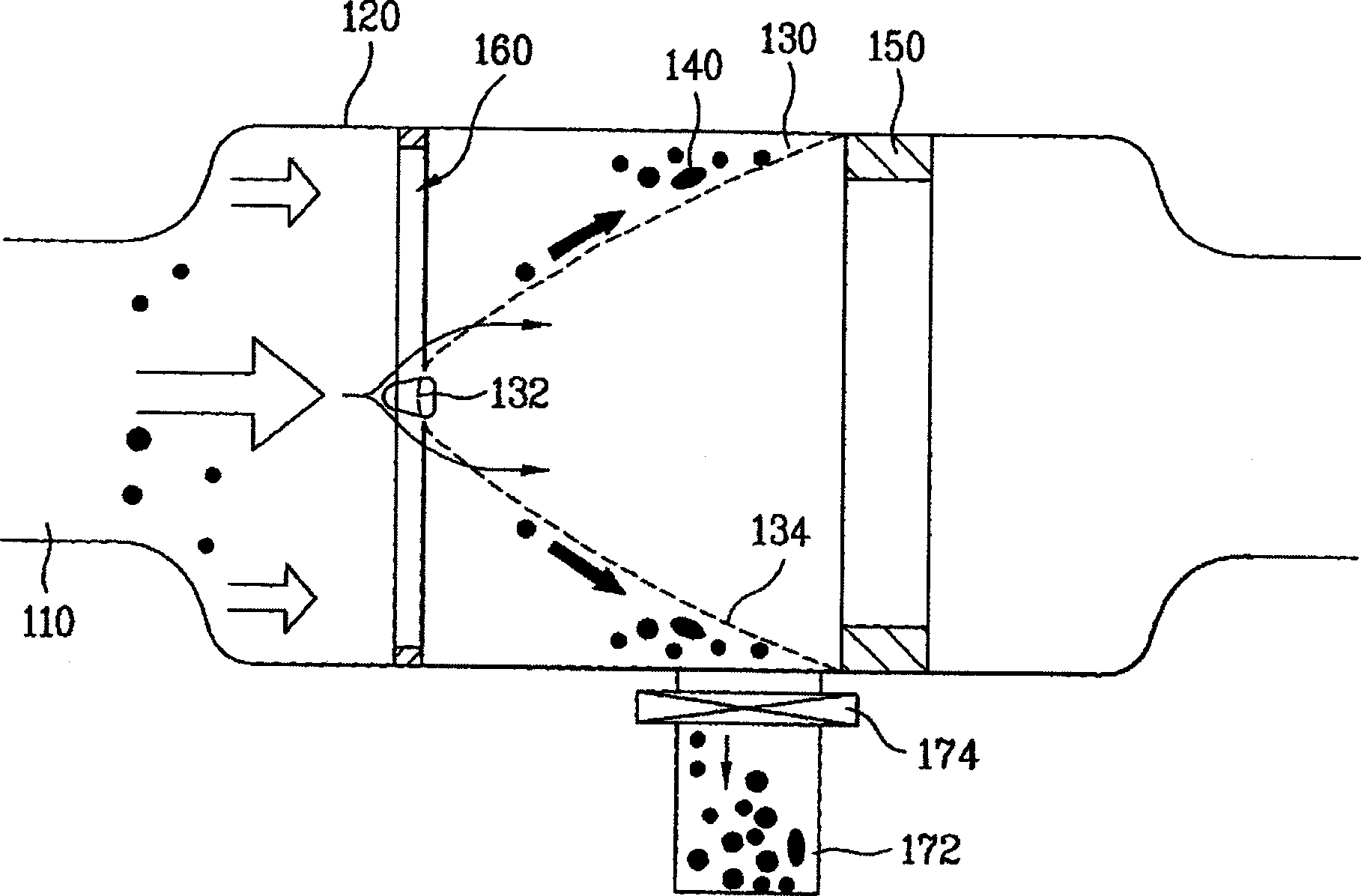

System and method to control flowfield vortices with micro-jet arrays

ActiveUS20060022092A1Reduce downstream buffetingReduce fatigueBoundary layer controlsWingsEngineeringFluid field

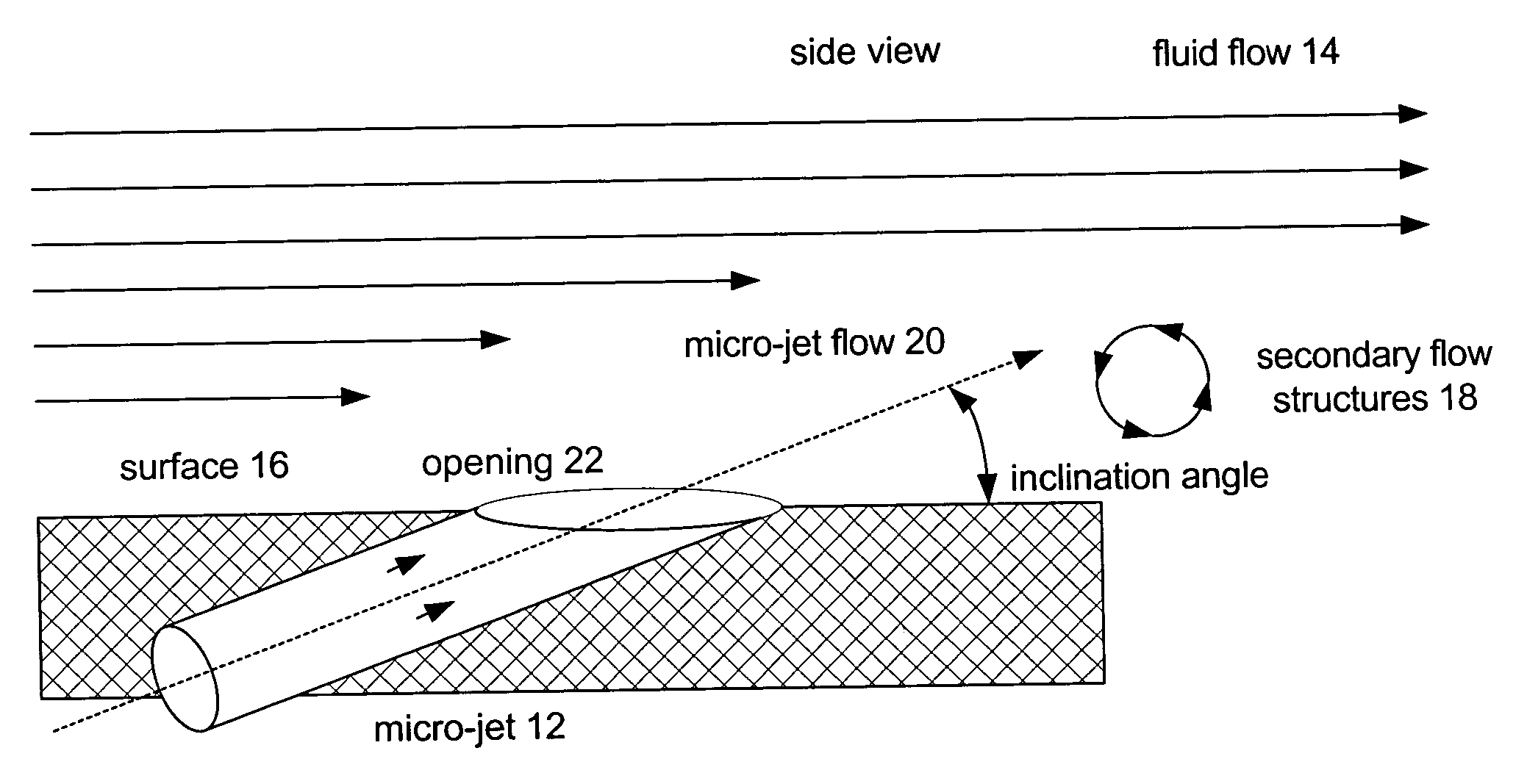

The present invention provides a system and method for actively manipulating and controlling aerodynamic or hydrodynamic flow field vortices within a fluid flow over a surface using micro-jet arrays. The system and method for actively manipulating and controlling the inception point, size and trajectory of flow field vortices within the fluid flow places micro-jet arrays on surfaces bounding the fluid flow. These micro-jet arrays are then actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

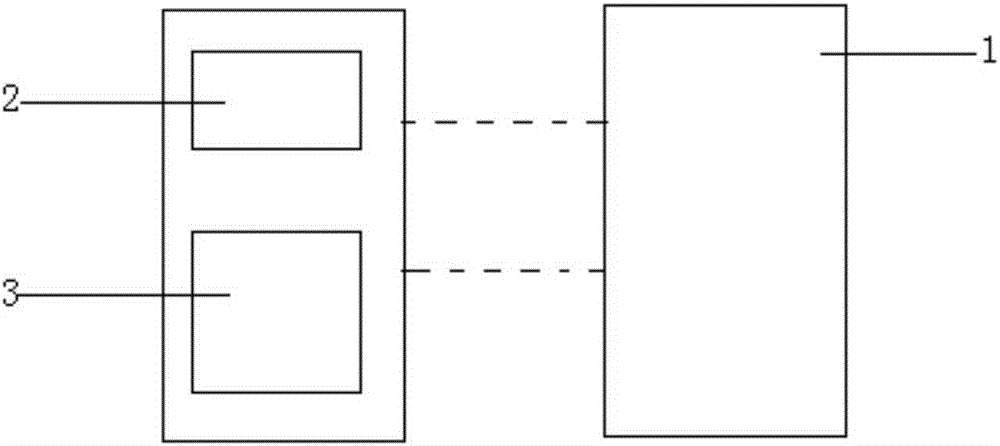

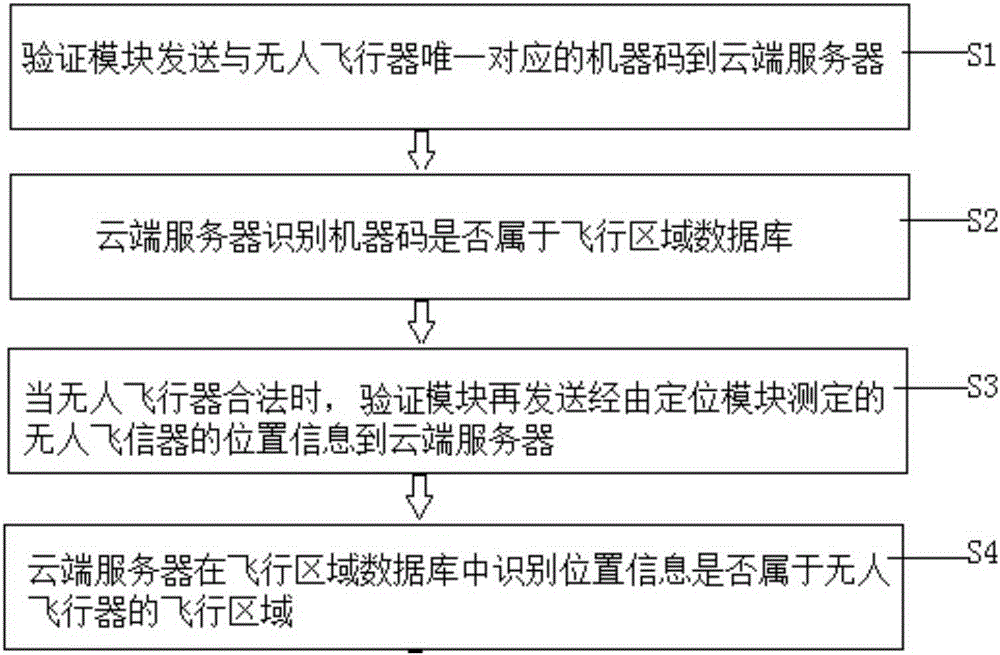

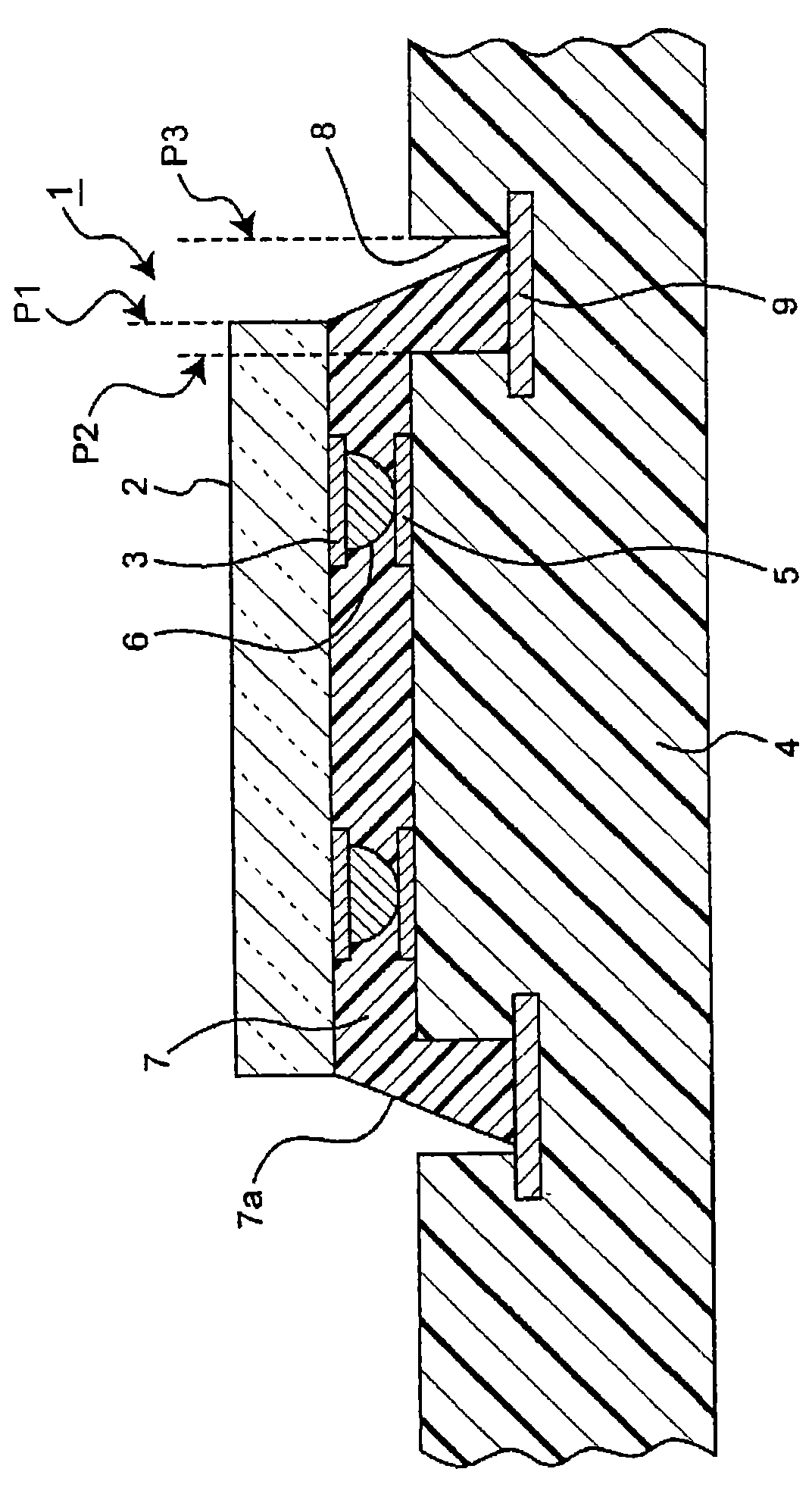

Unmanned aerial vehicle flight range verification device and verification method thereof

ActiveCN105206116AReduce stress loadAvoid exposing sensitive dataAircraft traffic controlValidation methodsUnmanned spacecraft

The invention discloses an unmanned aerial vehicle flight range verification device and a verification method thereof. The device comprises a cloud end server (1), a positioning module (2) and a verification module (3), wherein the positioning module (2) and the verification module (3) are arranged on an unmanned aerial vehicle, the cloud end server (1) comprises a flight range database, the verification module (3) sends a machine code uniquely corresponding to the unmanned aerial vehicle to the cloud end server (1), the cloud end server (1) sends a legal unmanned aerial vehicle instruction to the verification module (3) after identifying that the machine code belongs to the flight range database, the verification module (3) sends the position information, detected by the positioning module (2), of the unmanned aerial vehicle to the cloud end server (1), and the cloud end server (1) sends allowed information to the verification module (3) when the position information belongs to the flight range.

Owner:杨珊珊

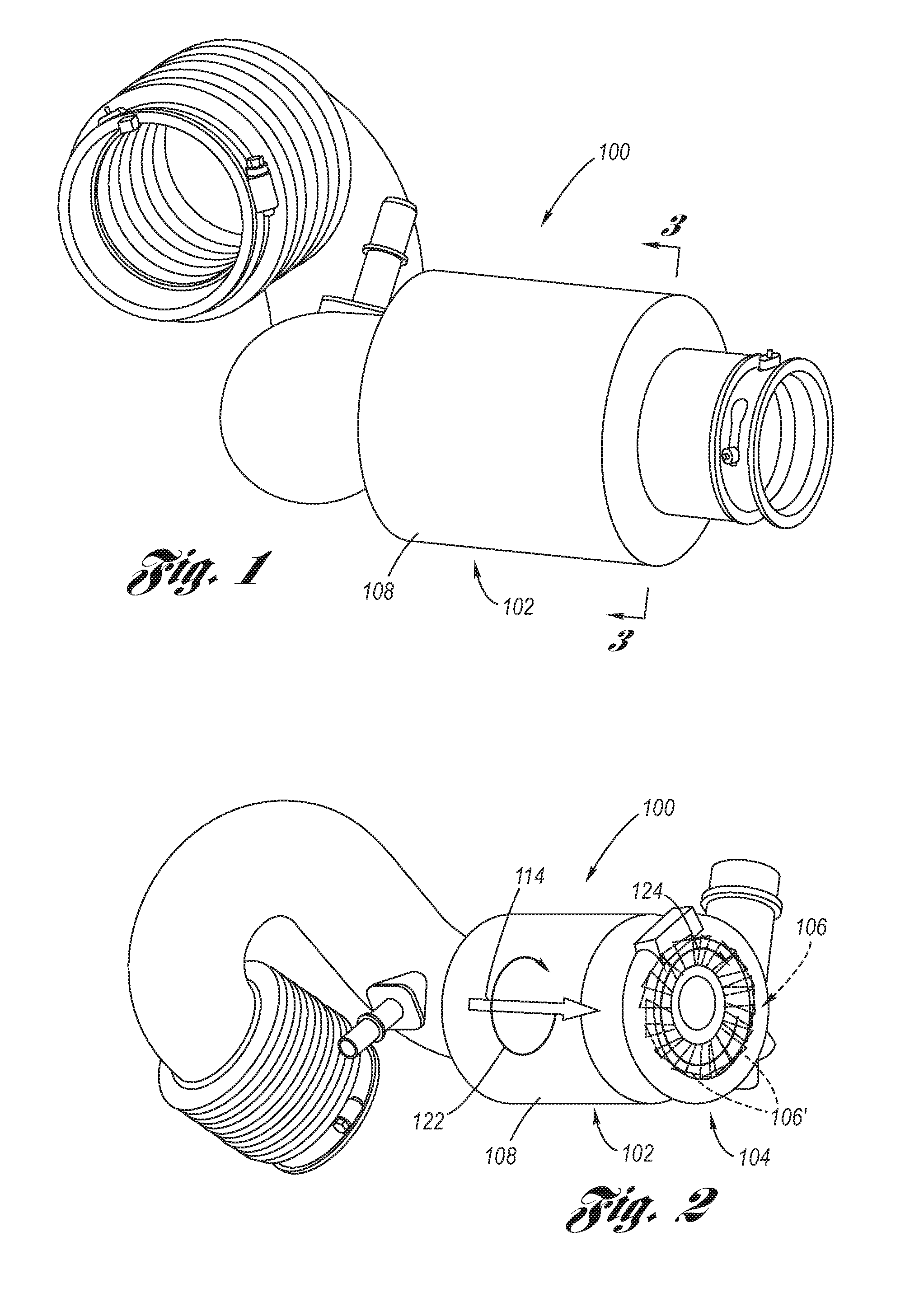

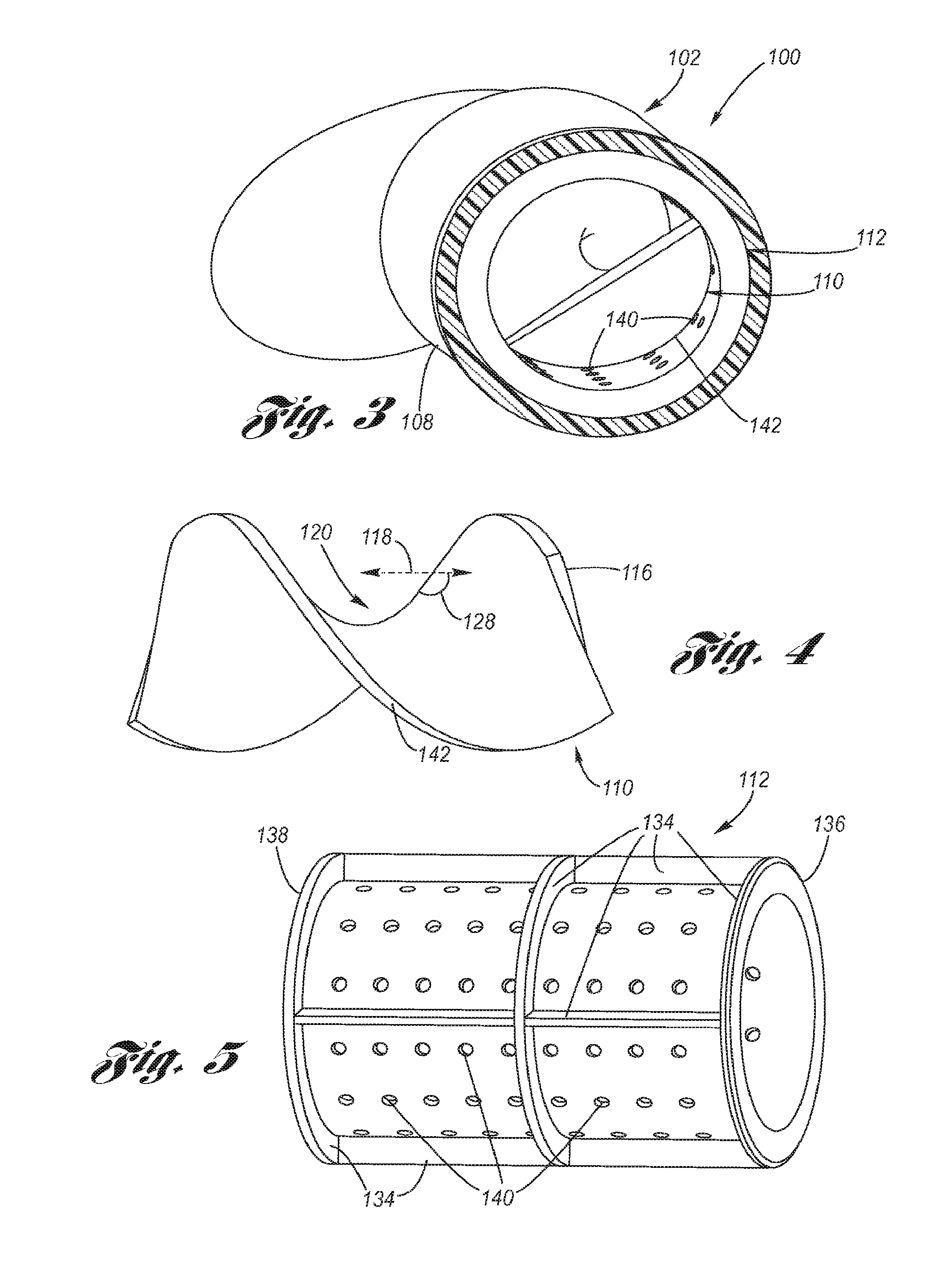

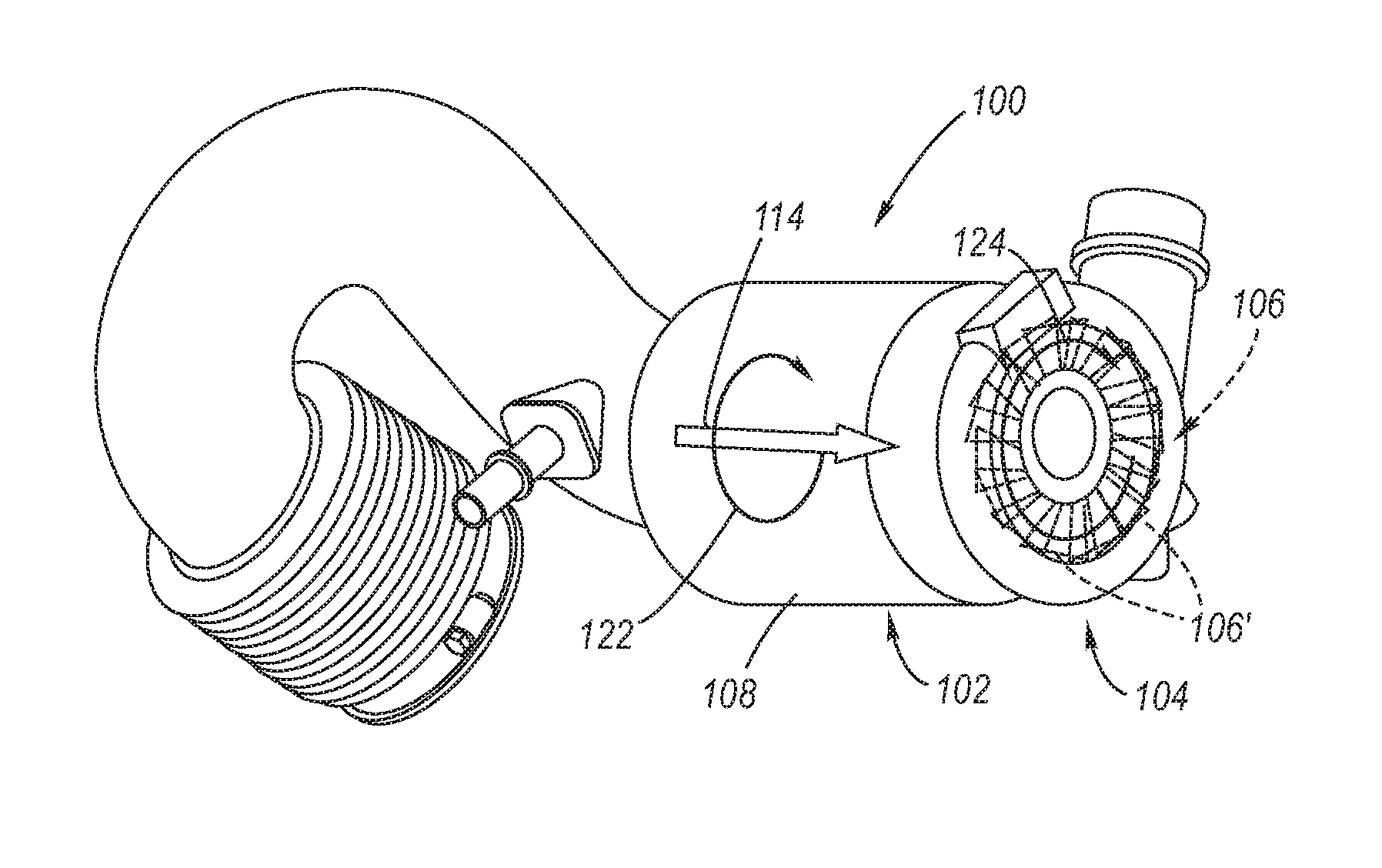

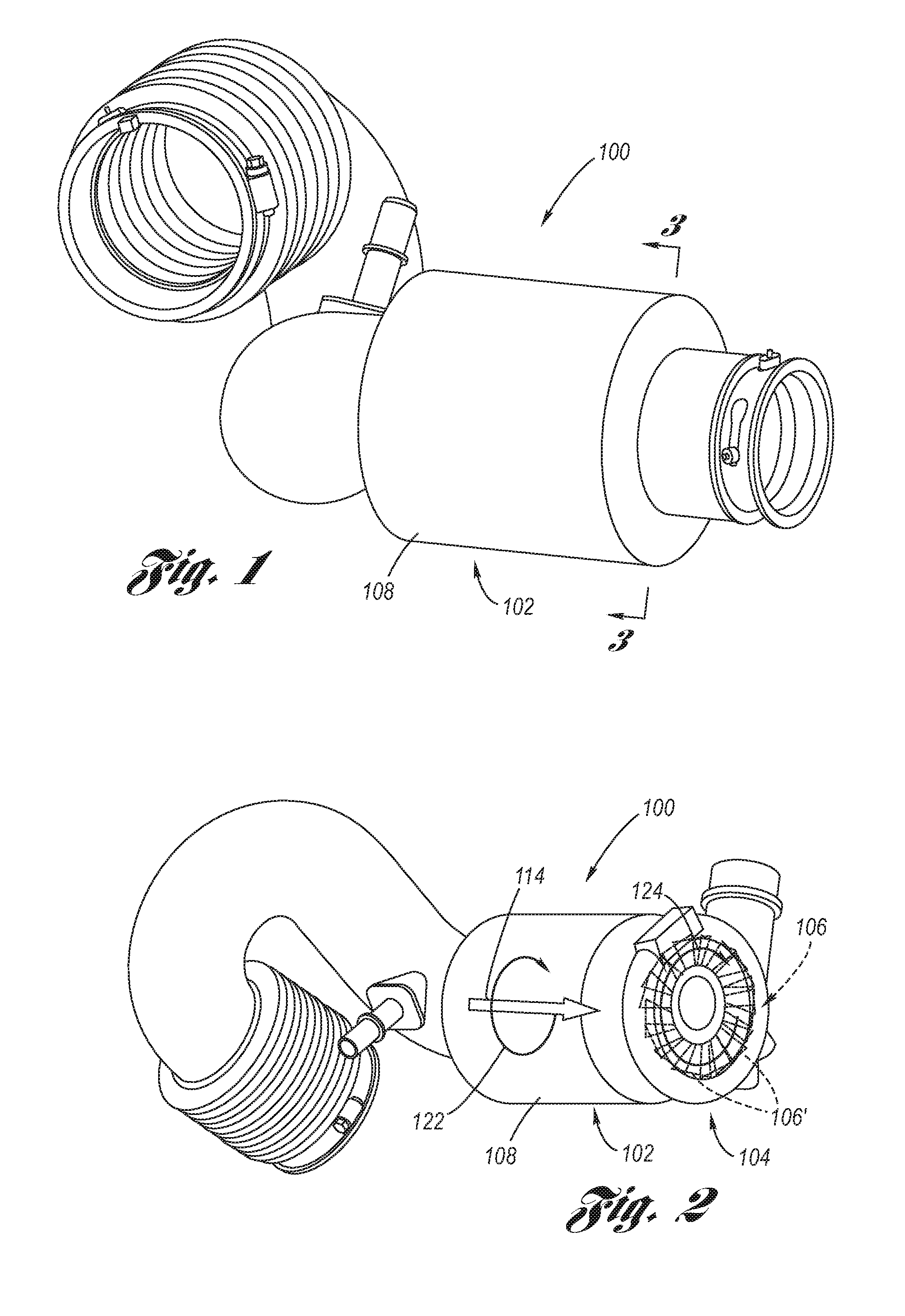

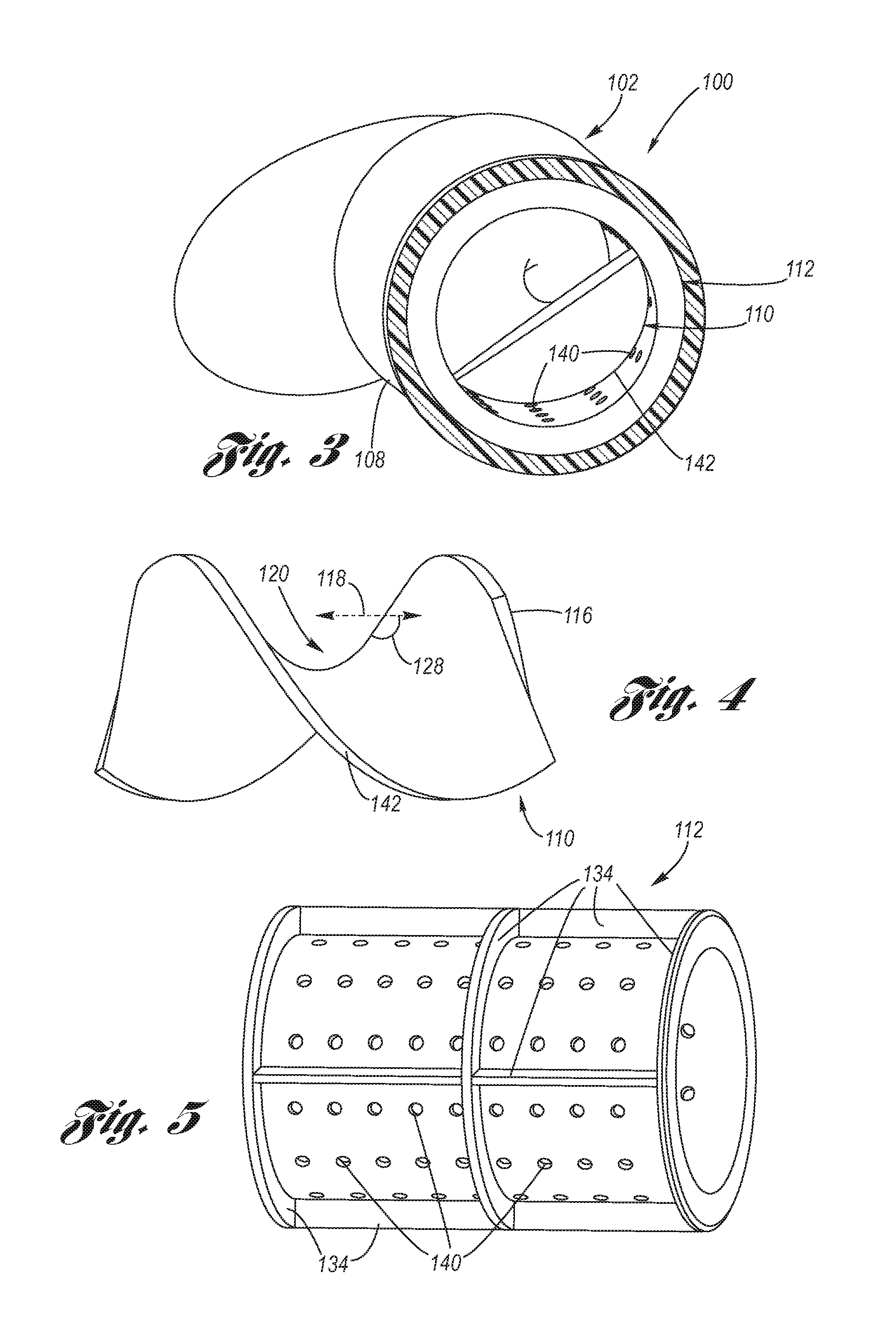

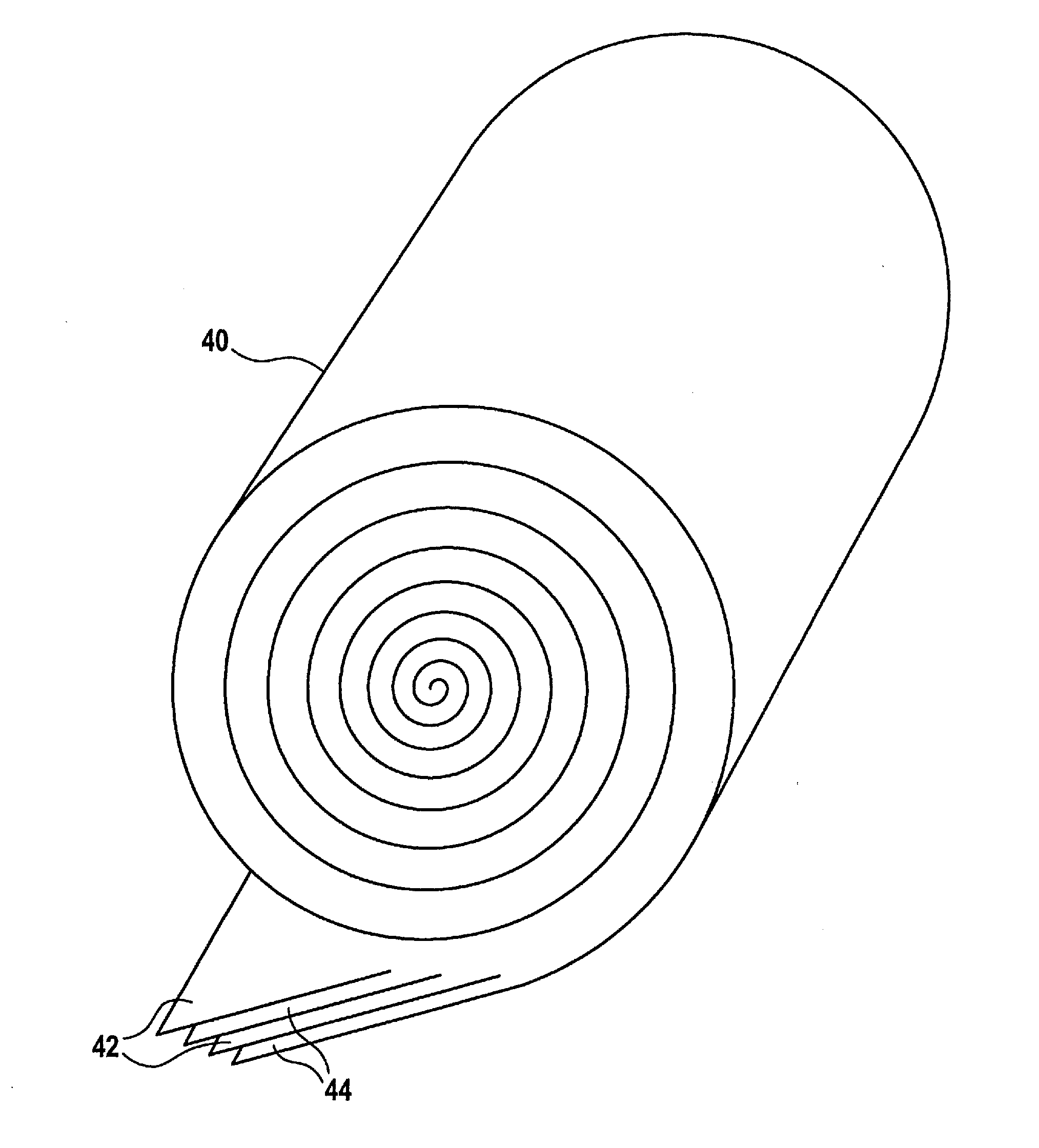

Induction system with air flow rotation and noise absorber for turbocharger applications

InactiveUS8651800B2Minimized pressure lossAssists functionalityPropellersInternal combustion piston enginesImpellerTurbine wheel

An air induction system consisting of a cylindrical main flow tube, a helical vane disposed within the main flow tube, and, preferably, a noise absorbing perforated tube disposed within the main flow tube in concentric relation to the helical vane. The twist direction of the helical vane provides air flow rotation in the same direction of rotation as the turbine wheel. The helical vane causes noise reflection and enhancement of noise attenuation by the perorated tube and its adjoining one or more acoustic cavities.

Owner:GM GLOBAL TECH OPERATIONS LLC

System and method to control flowfield vortices with micro-jet arrays

ActiveUS7510149B2Reduce downstream buffeting and fatigueReduce buffeting and fatigueBoundary layer controlsWingsEngineeringAerodynamics

The present invention provides a system and method for actively manipulating and controlling aerodynamic or hydrodynamic flow field vortices within a fluid flow over a surface using micro-jet arrays. The system and method for actively manipulating and controlling the inception point, size and trajectory of flow field vortices within the fluid flow places micro-jet arrays on surfaces bounding the fluid flow. These micro-jet arrays are then actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

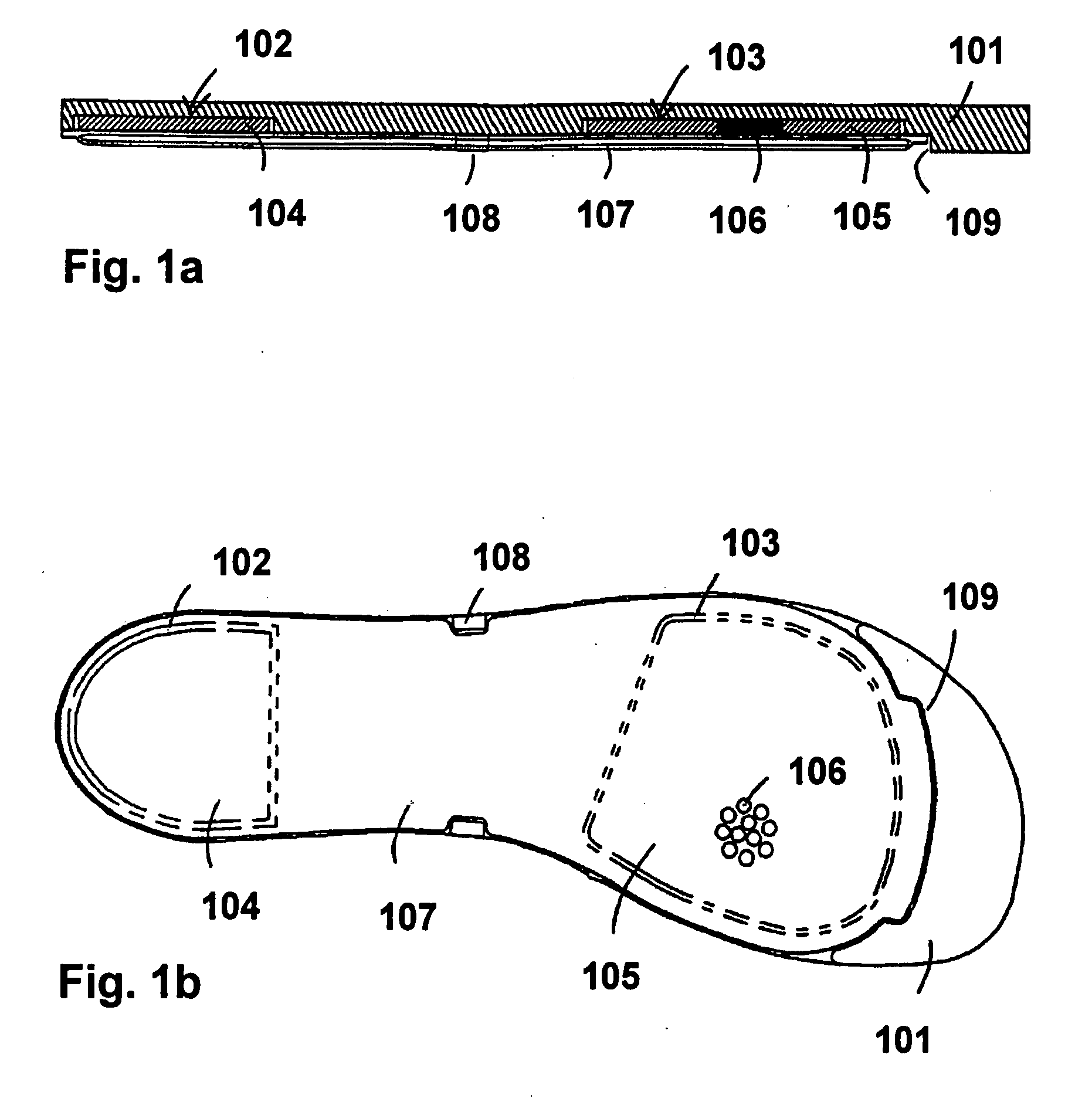

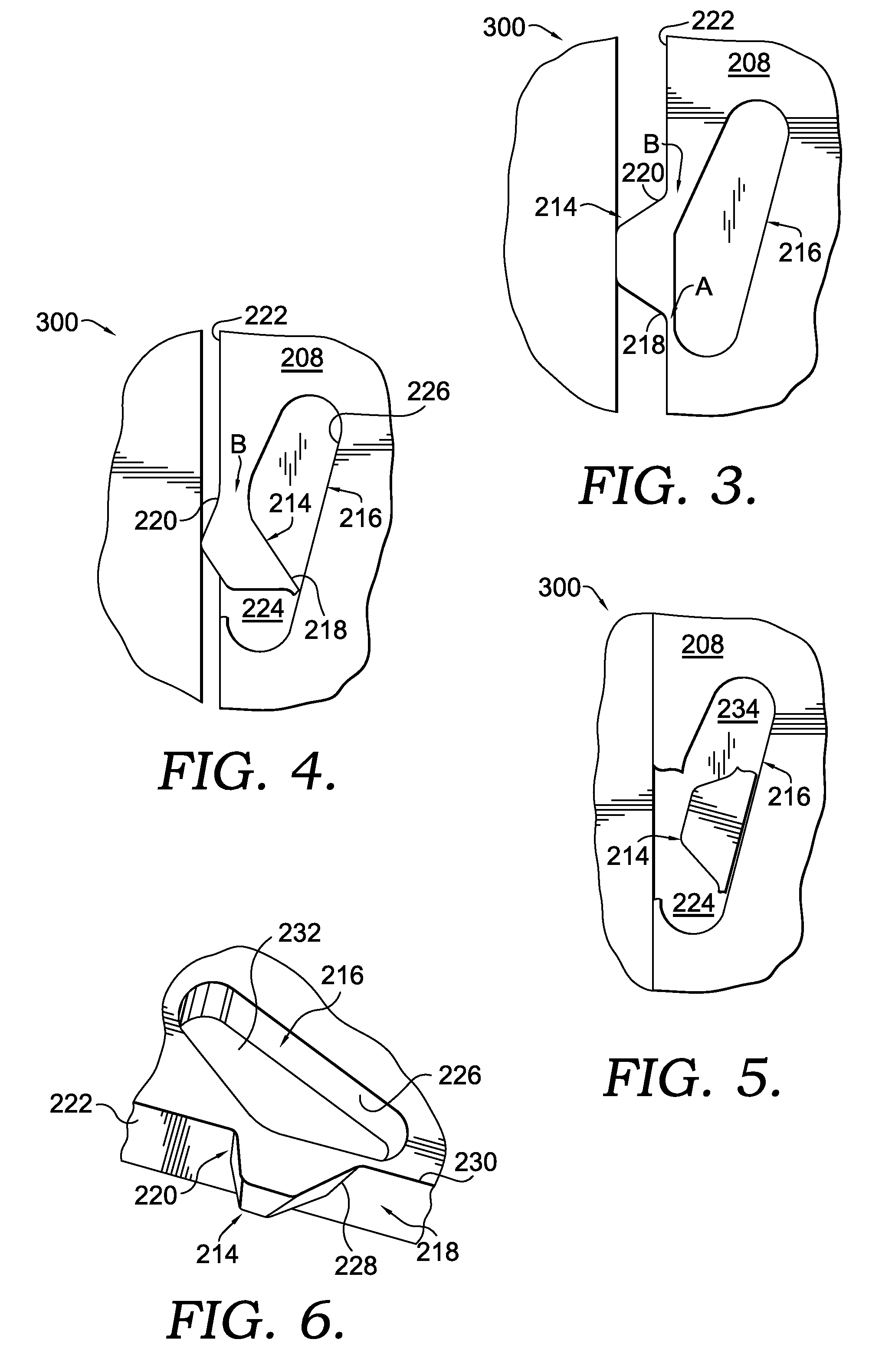

Cushioning insole adjustment kit

Insole adjustment kit, the kit comprising an upper, elastic cushioning insole layer and a lower, liquid filled insole layer under the upper layer and at least one pocket between the upper layer and the lower layer, the kit further comprising a number of inserts dimensioned for insertion into the pocket, the inserts having mutually different degrees of hardness.

Owner:VINDRIIS SOREN

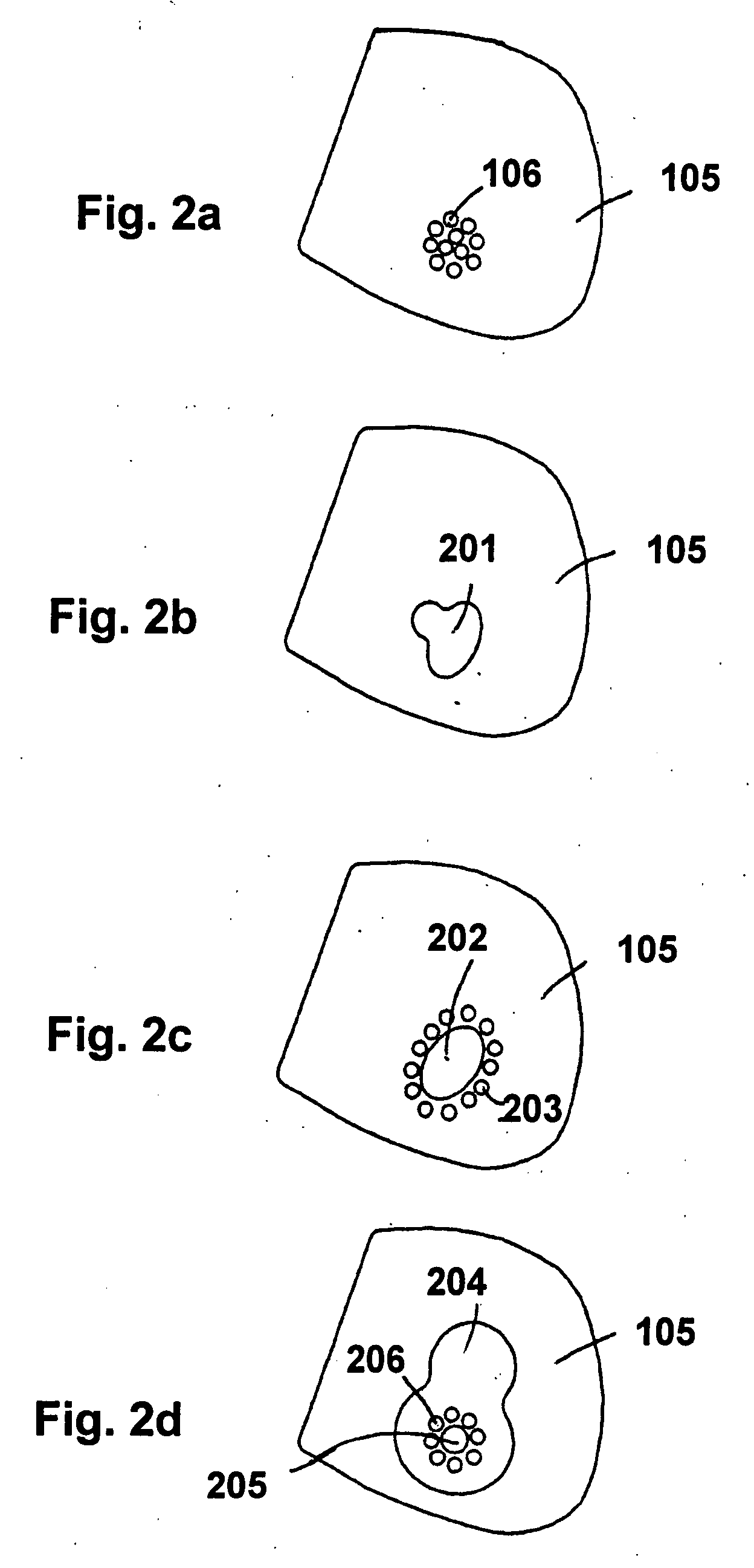

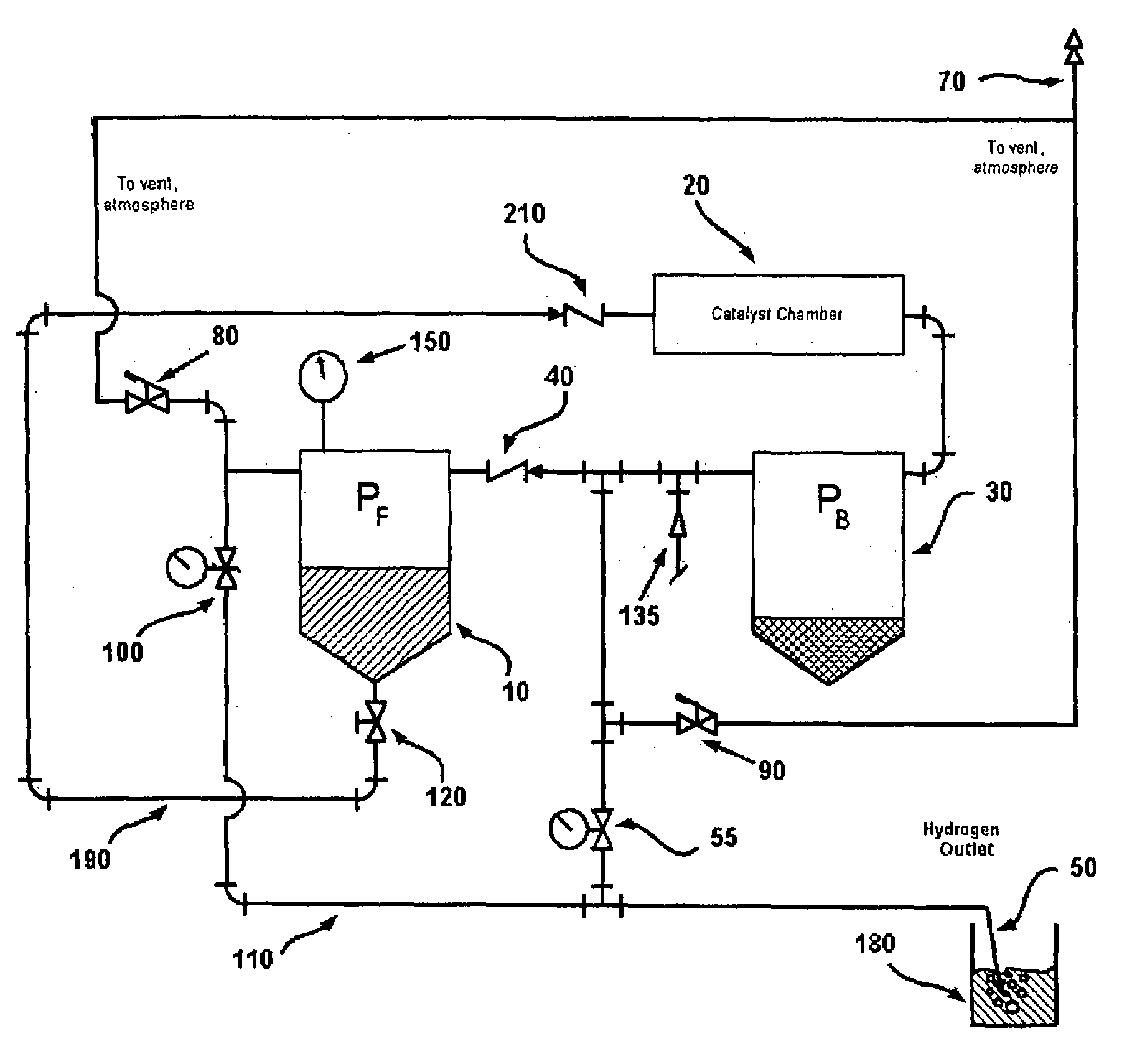

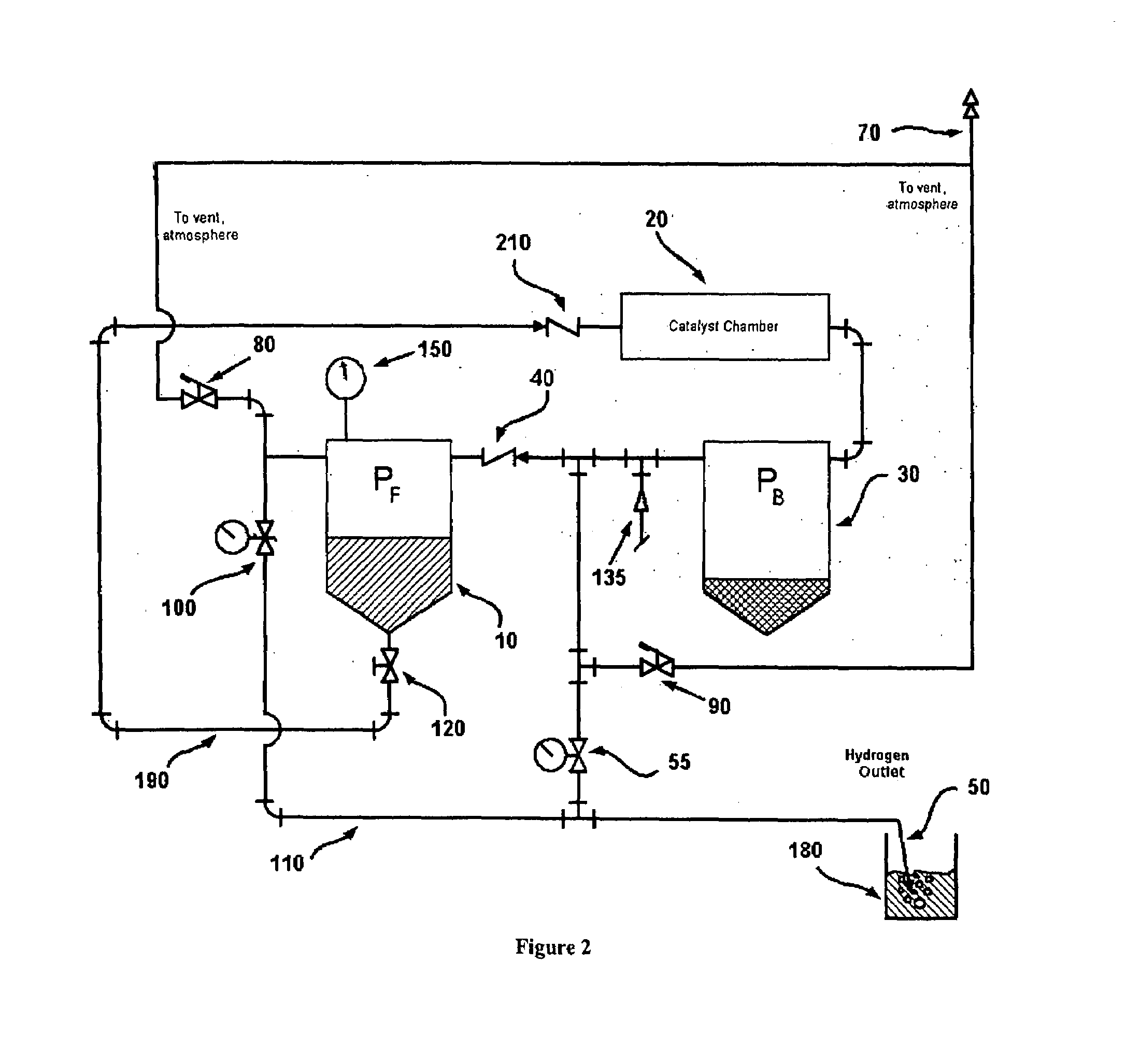

Differential pressure-driven borohydride based generator

InactiveUS7316718B2Reduce stress loadLiquid degasificationPhysical/chemical process catalystsHydrogenDifferential pressure

An arrangement for generating hydrogen gas utilizes differential pressure to transport fuel and spent fuel components without requiring an electrically powered fuel delivery pump.

Owner:SILICON VALLEY BANK

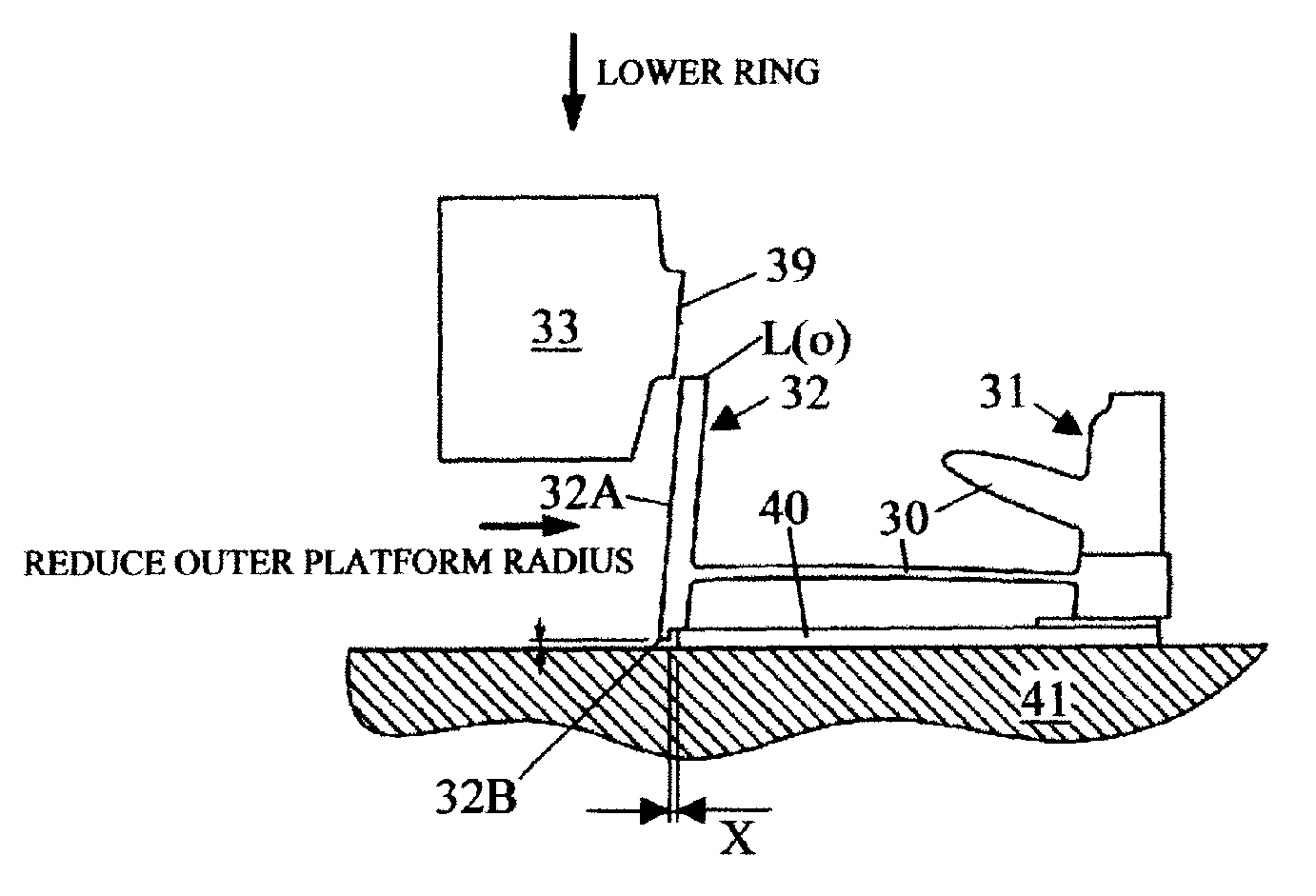

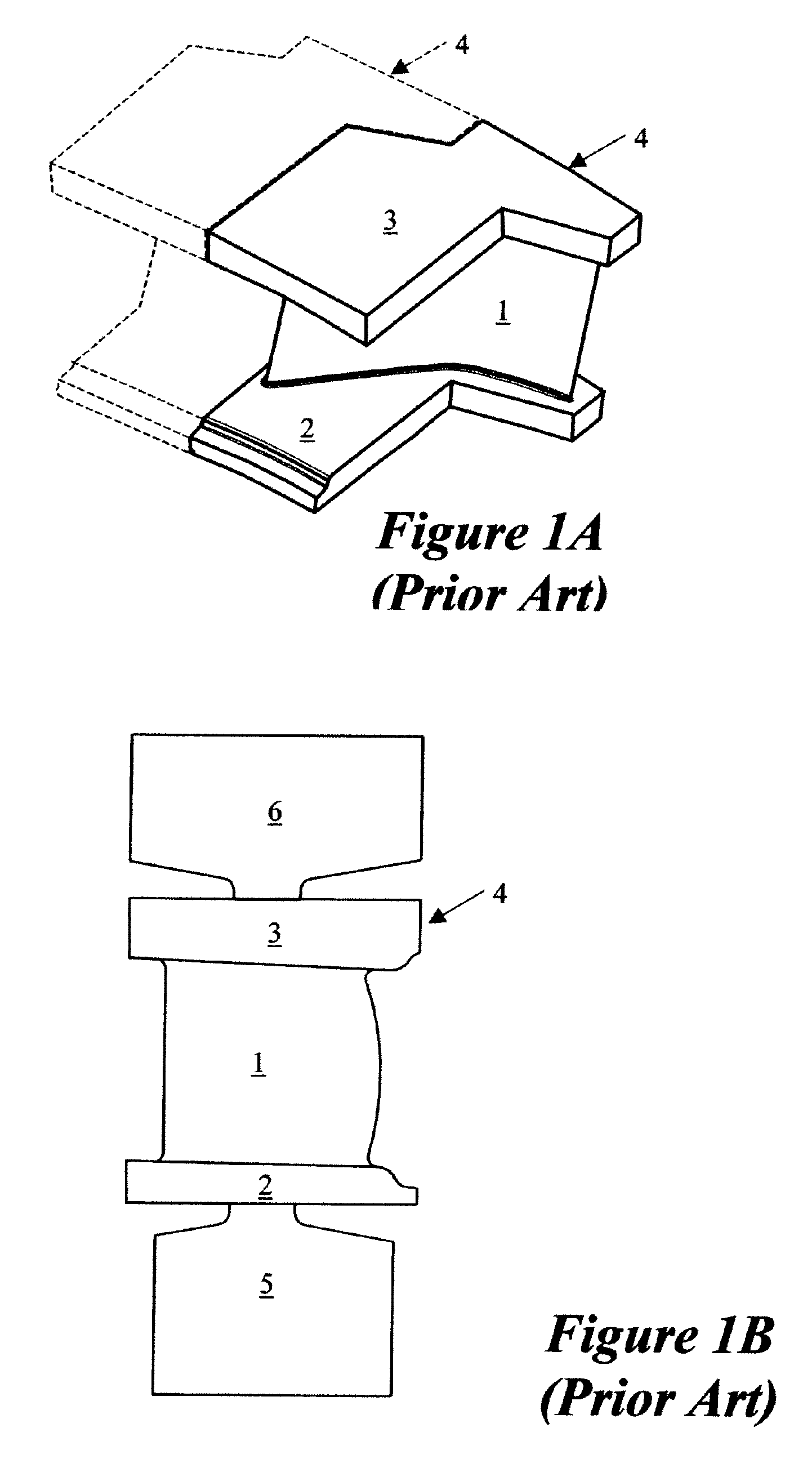

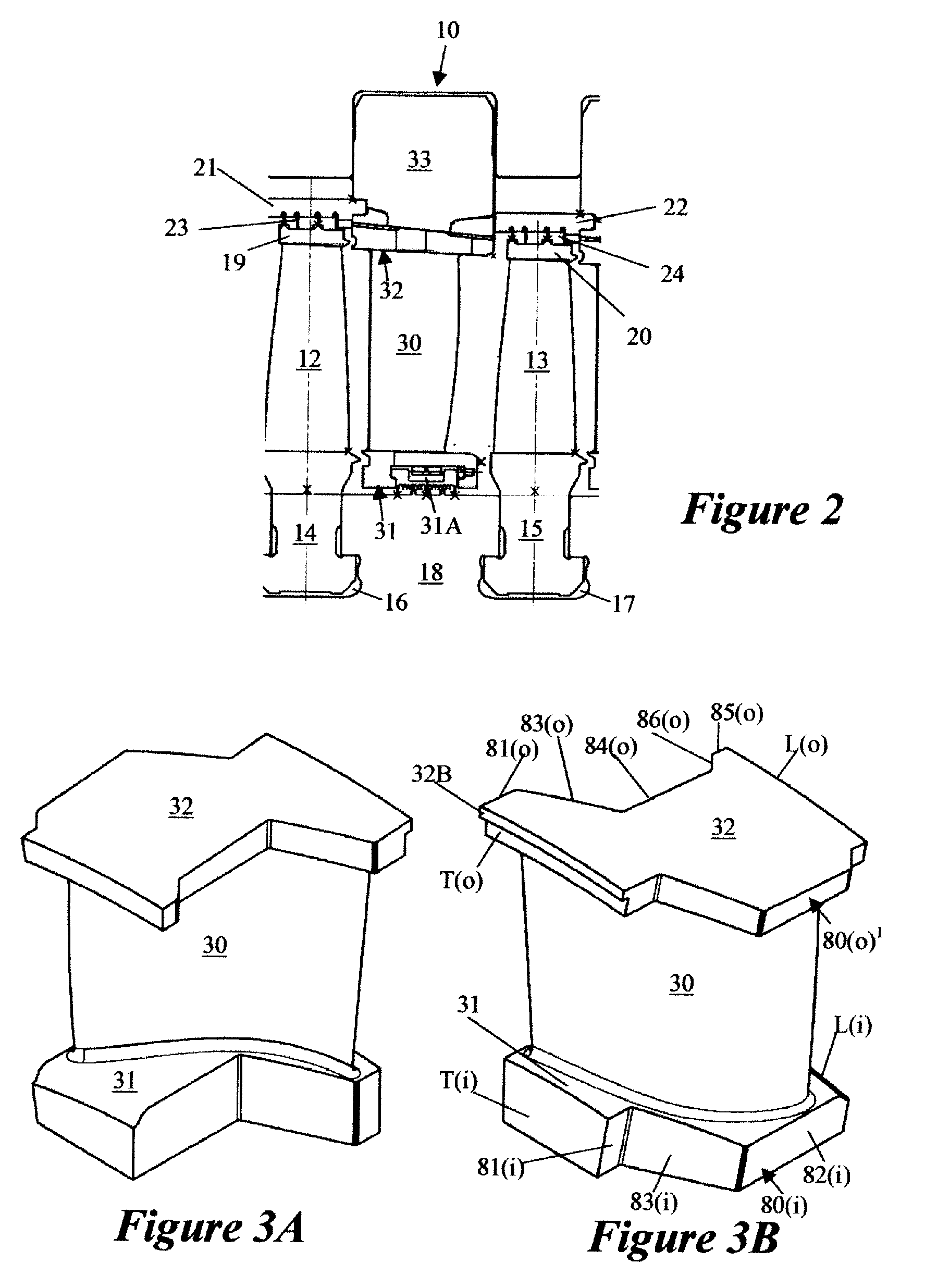

Diaphragm for Turbomachines and Method of Manufacture

ActiveUS20080170939A1Reduce weldingReduce material requirementsPropellersRotary propellersInterference fitTurbine

A turbine diaphragm includes an annulus of static blades and an outer diaphragm ring surrounding the annulus of static blades and welded to the outer platforms. Each static blade has an inner platform, an aerofoil, and an outer platform. The inner platforms serve the function of an inner diaphragm ring, thereby reducing material and manufacturing costs. Furthermore, confronting edges of the inner platforms have an interference fit with each other and the aerofoils are in a state of torsional stress between the inner and outer platforms. The latter two features improve the dynamic characteristics of the diaphragm.

Owner:GENERAL ELECTRIC TECH GMBH

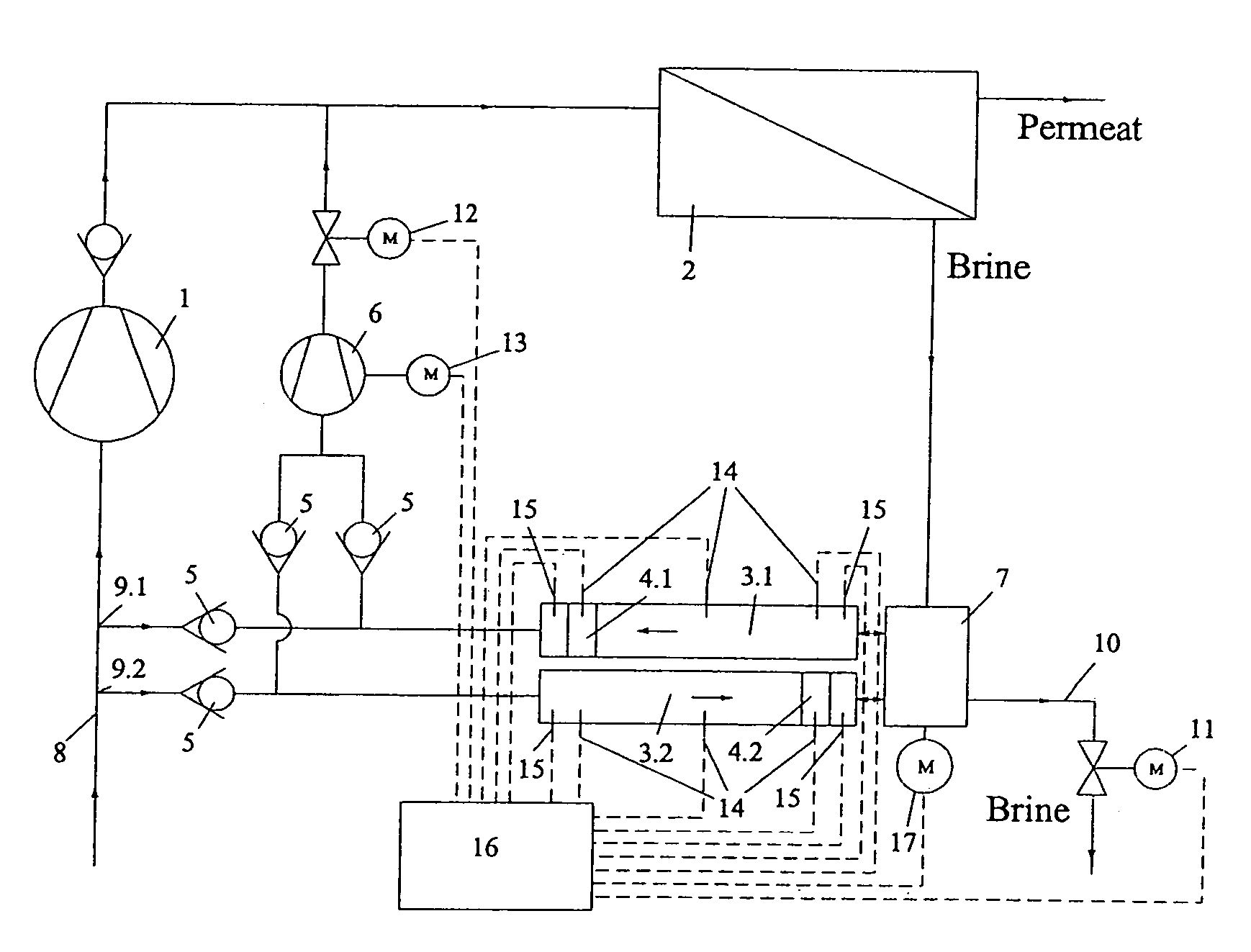

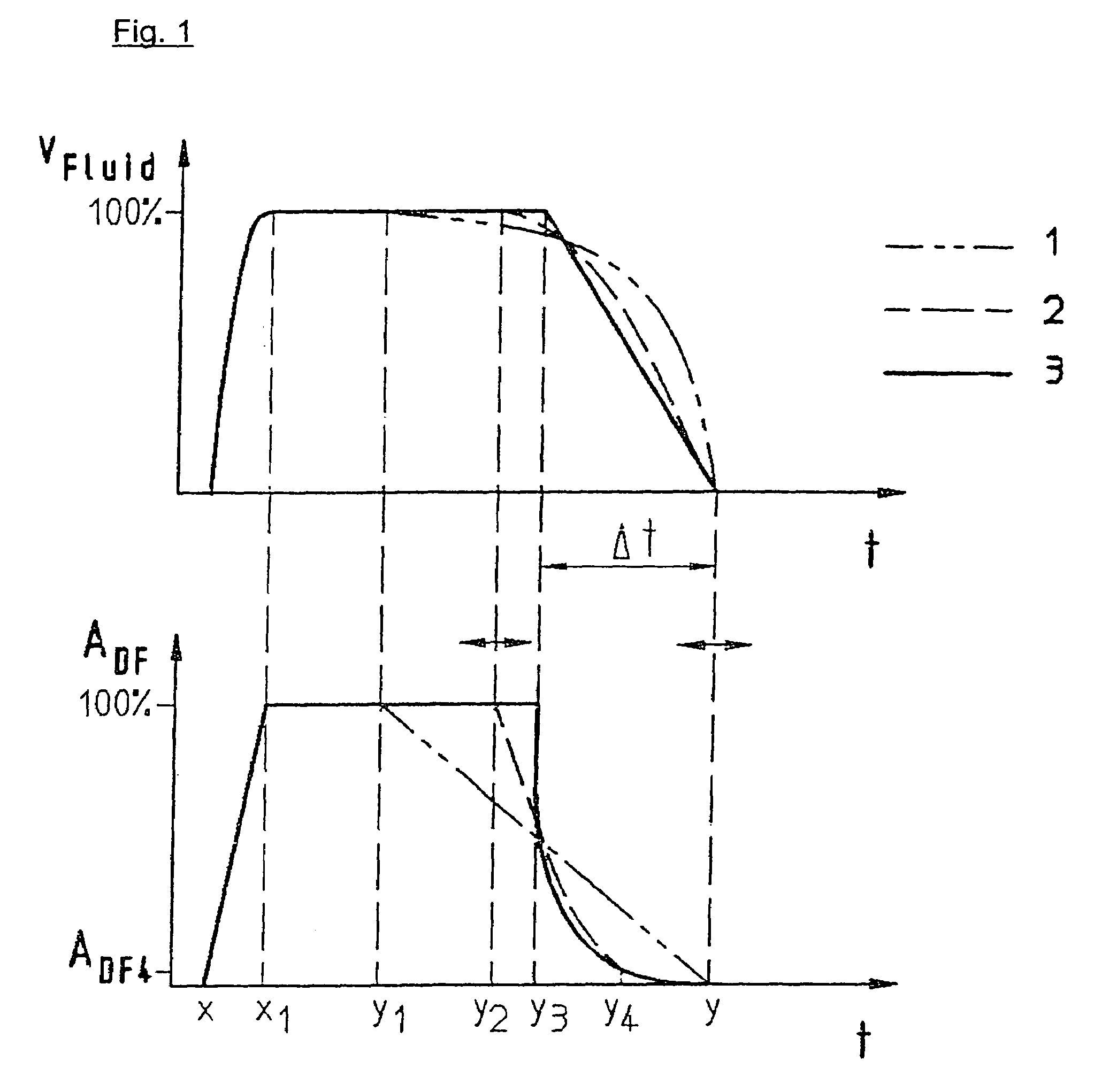

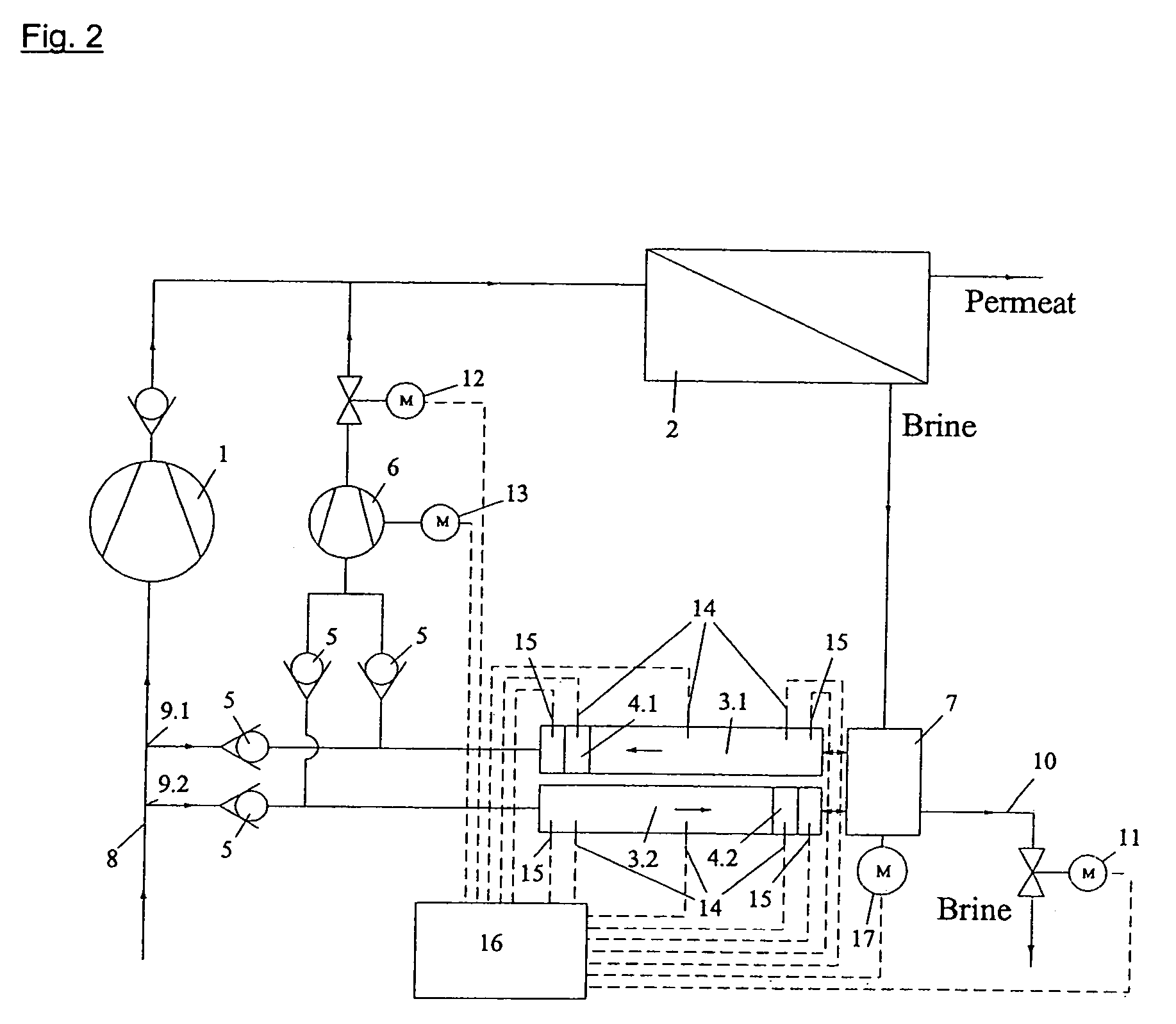

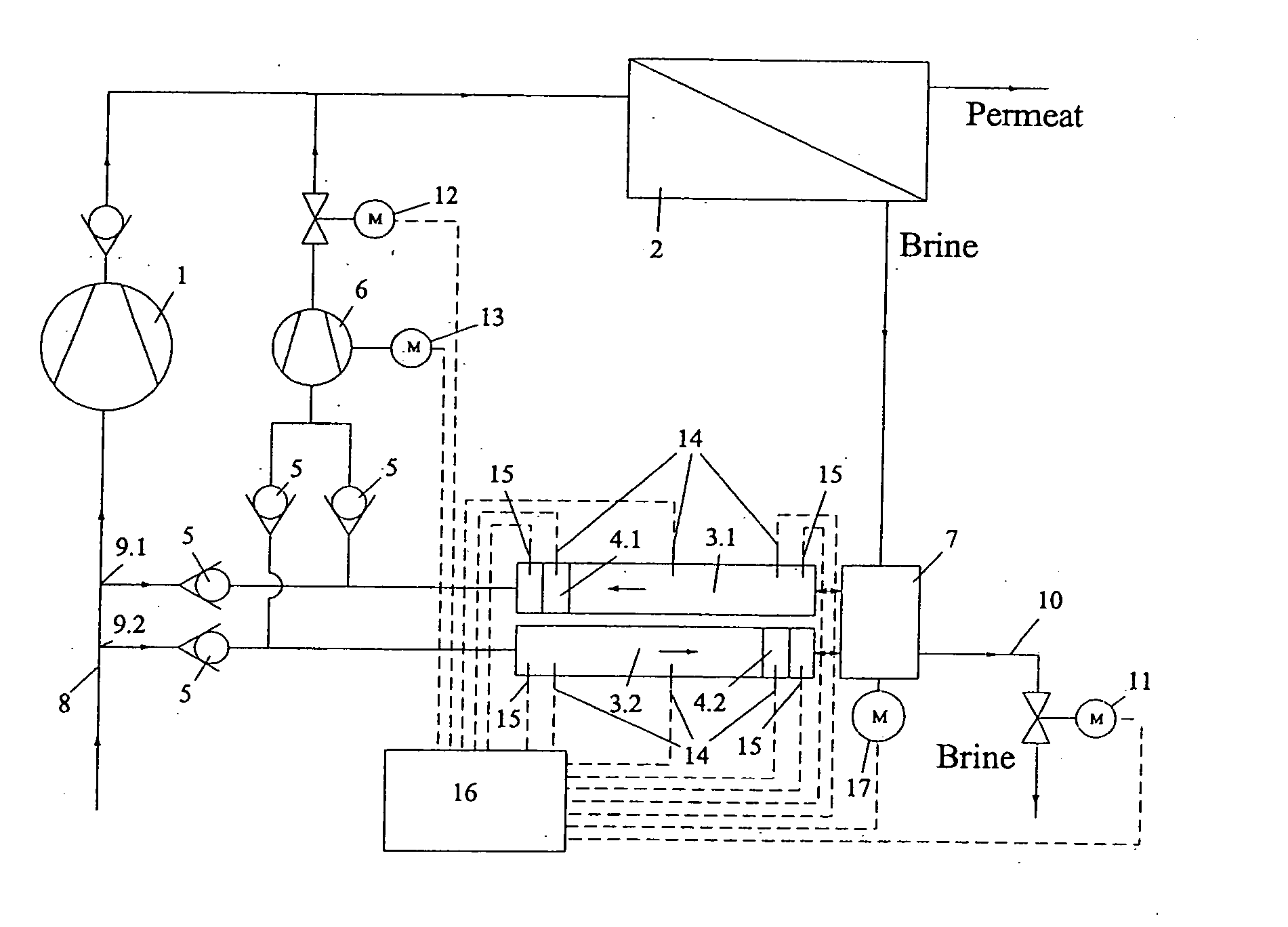

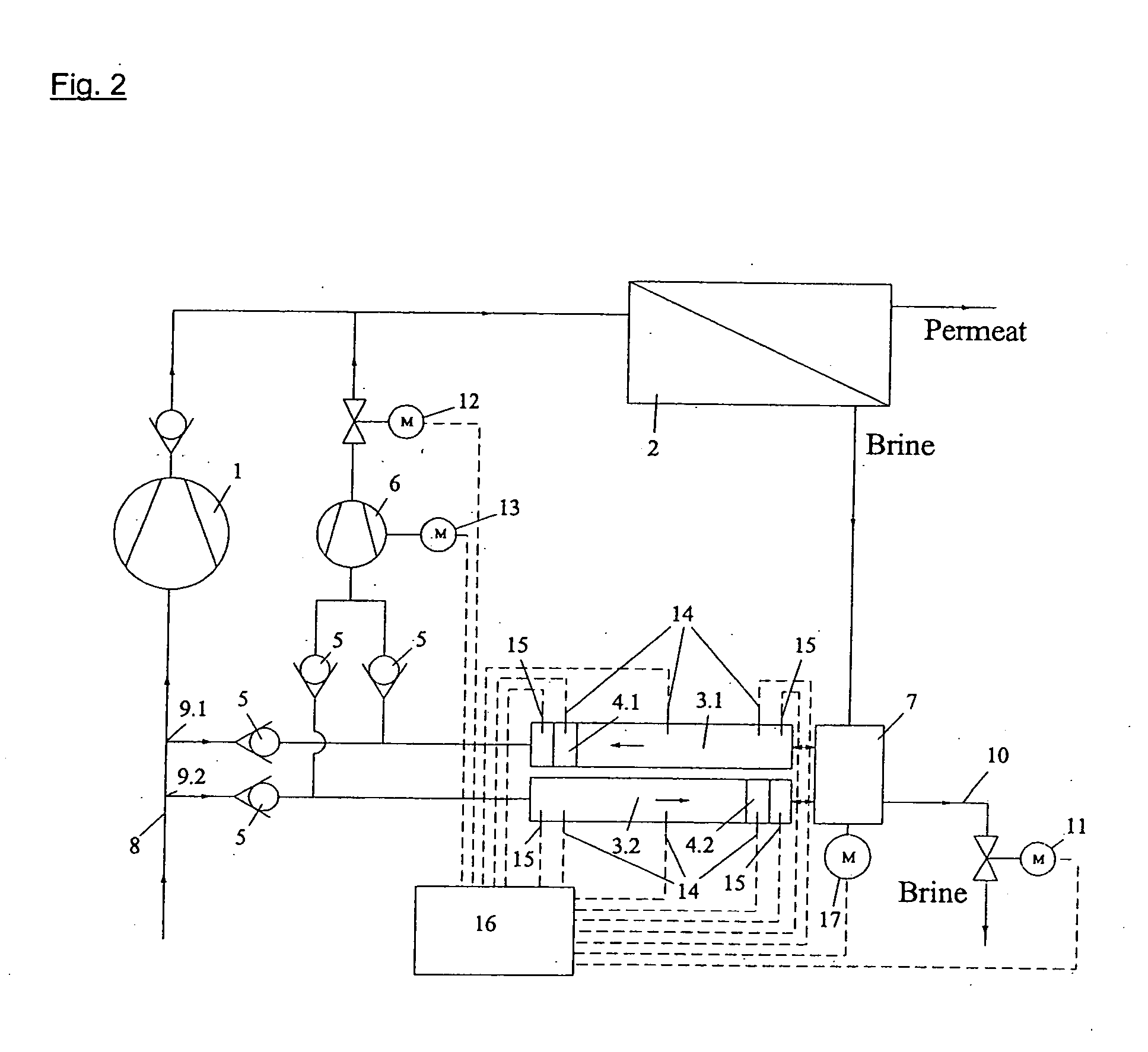

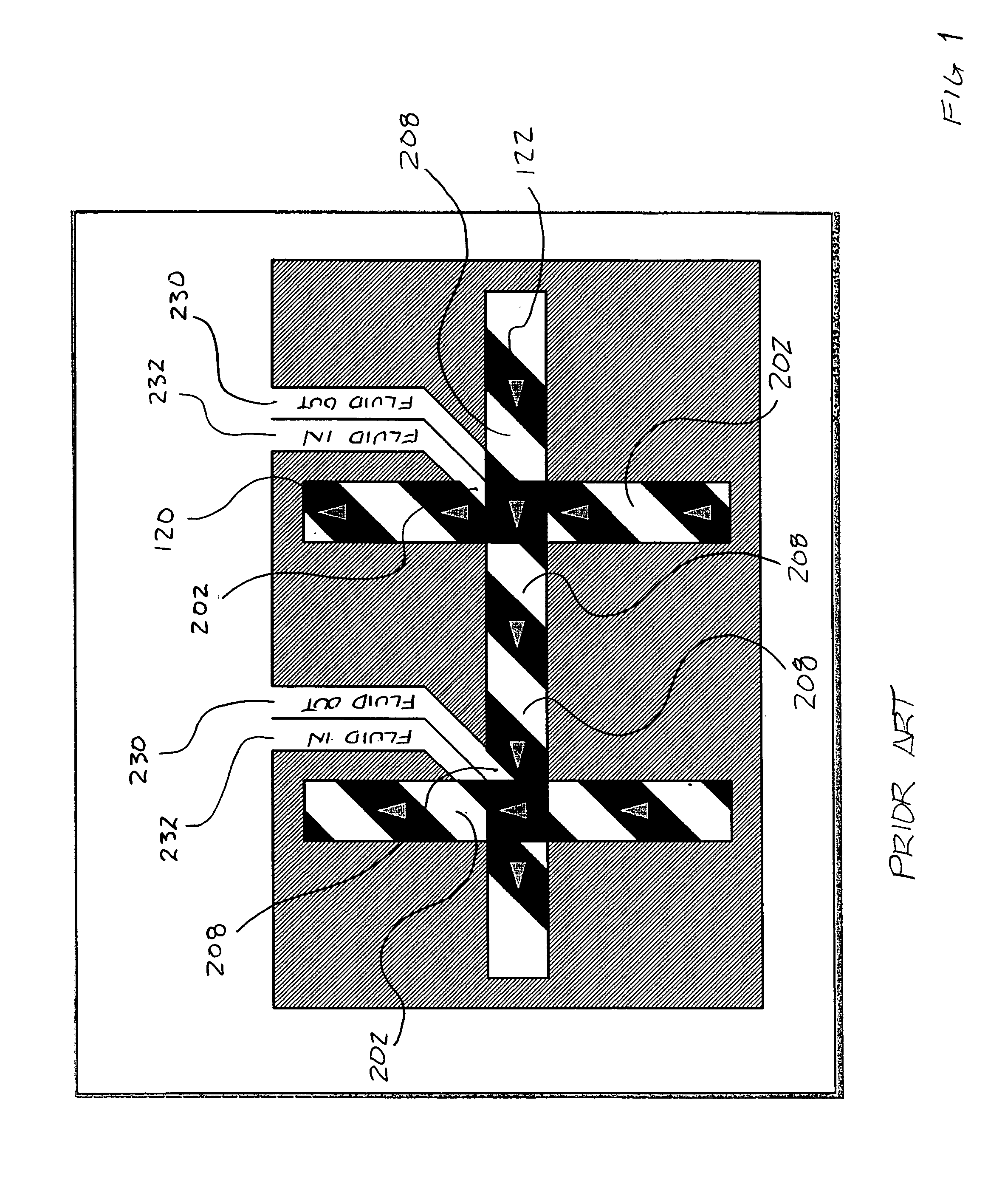

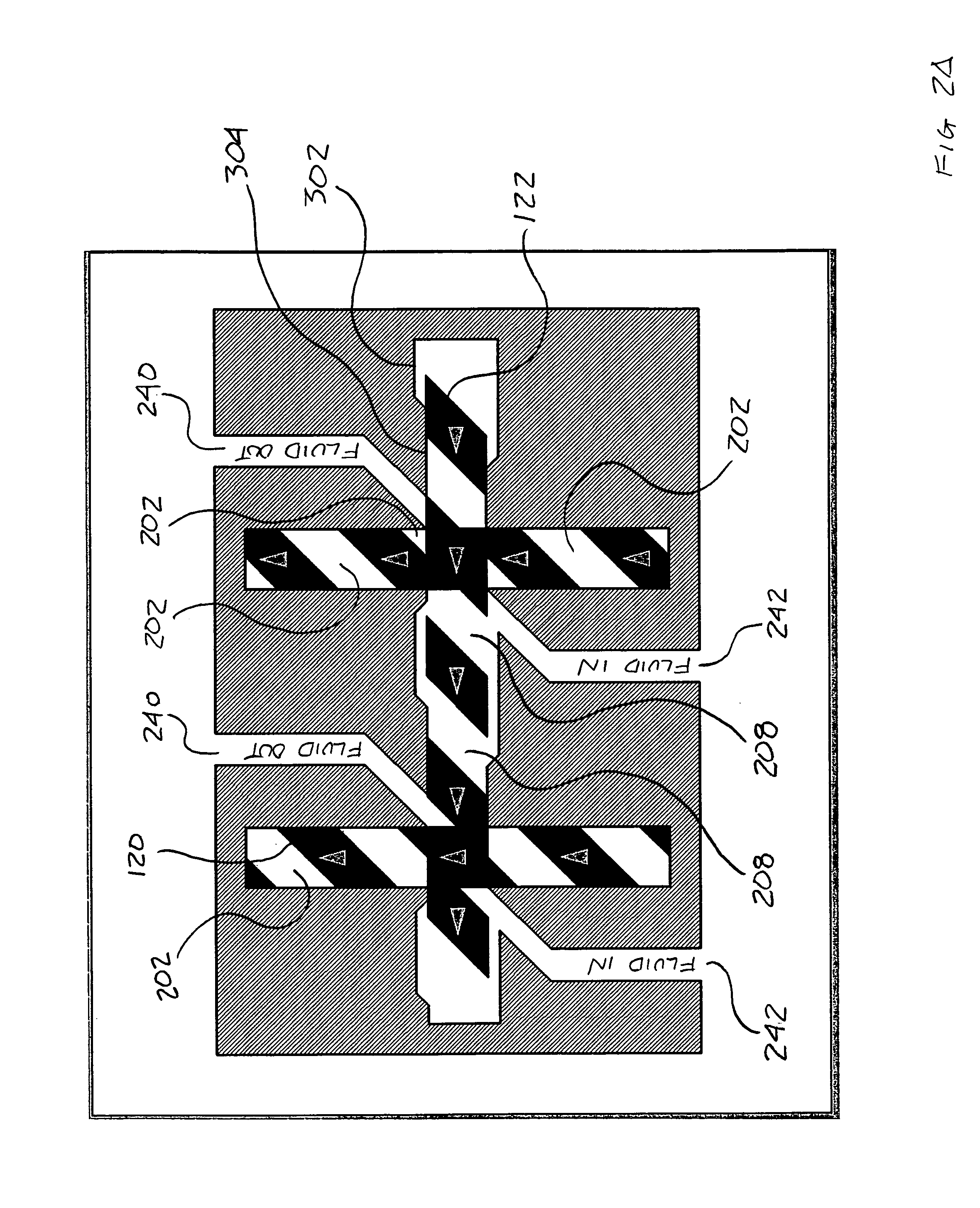

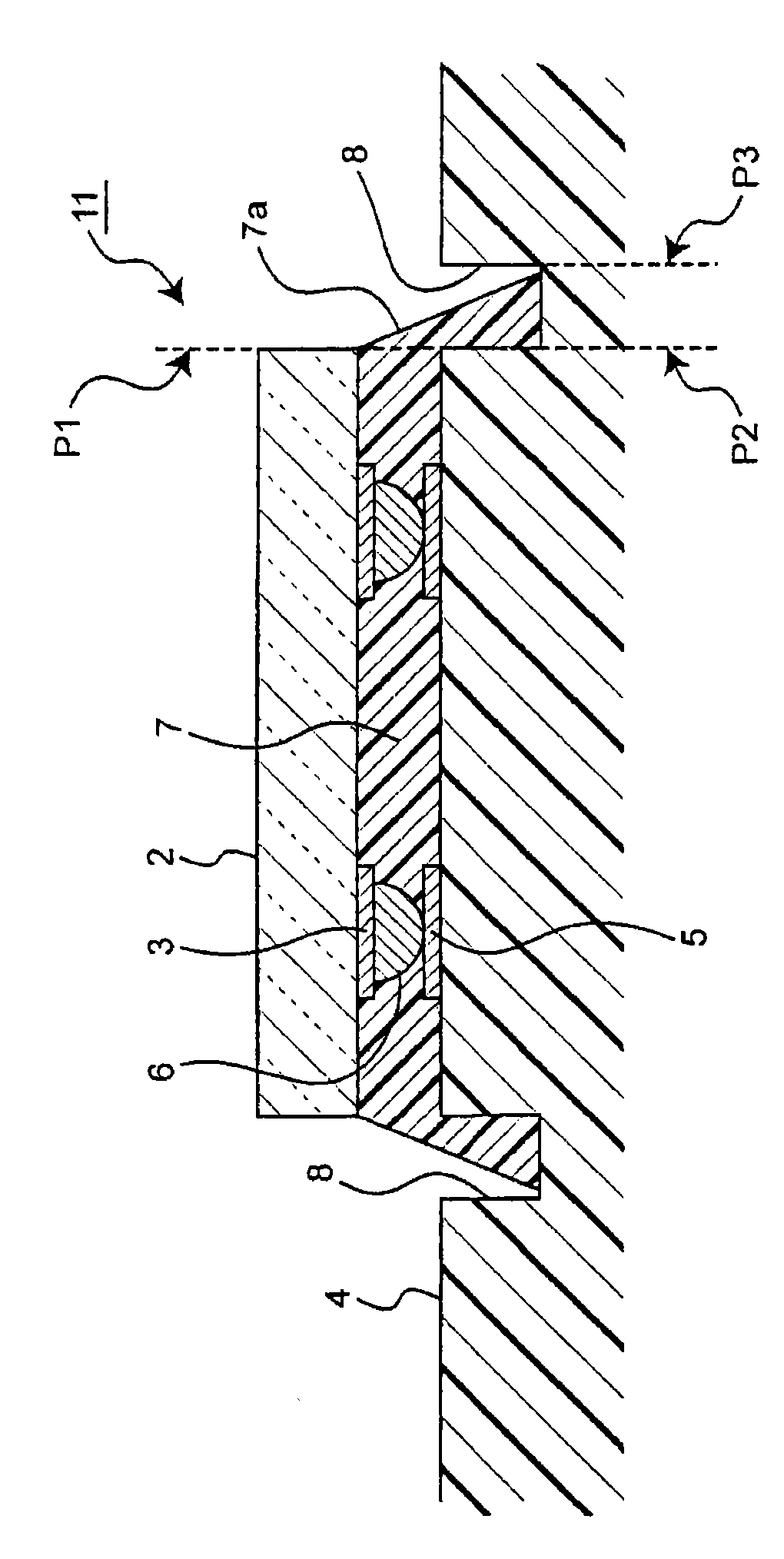

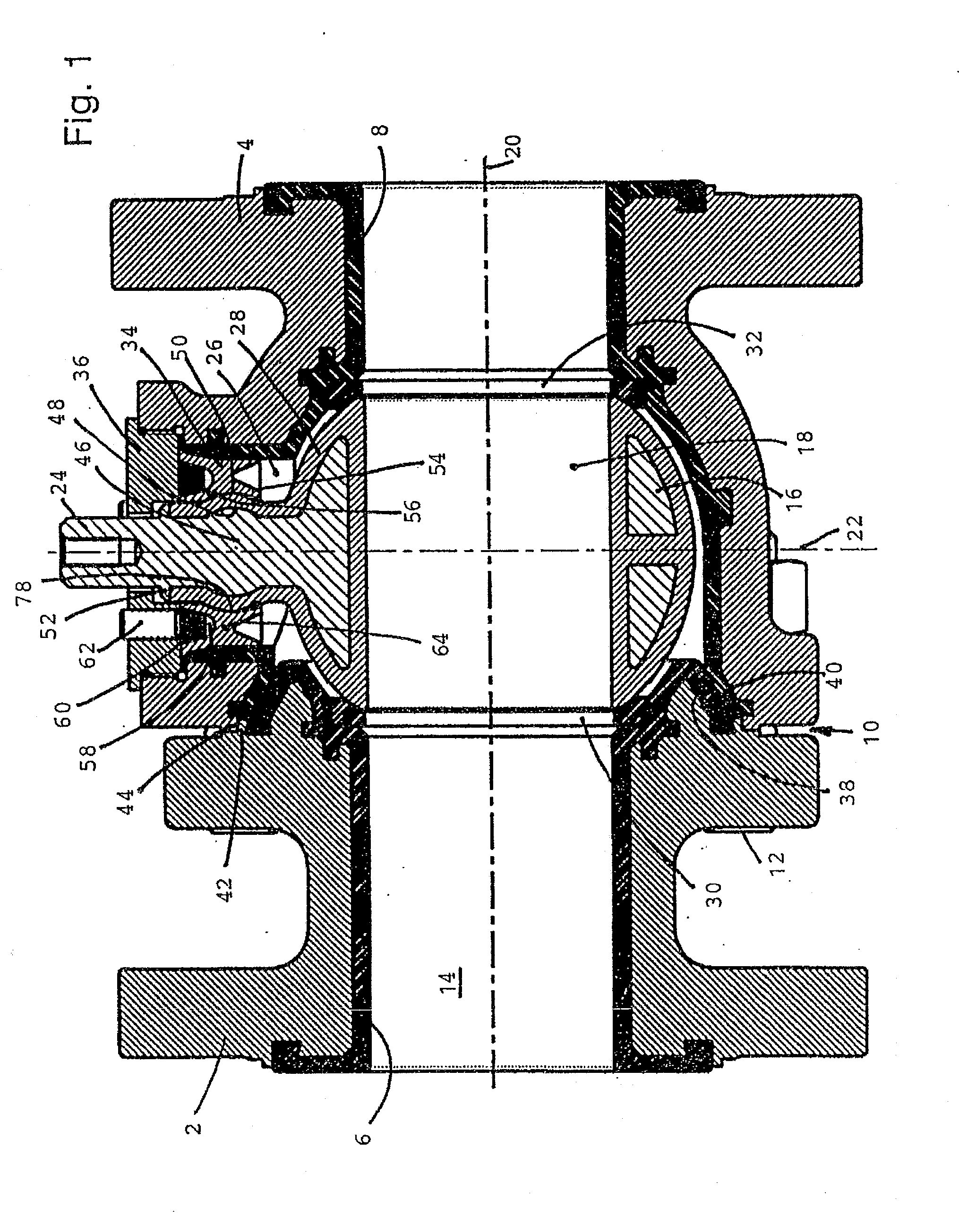

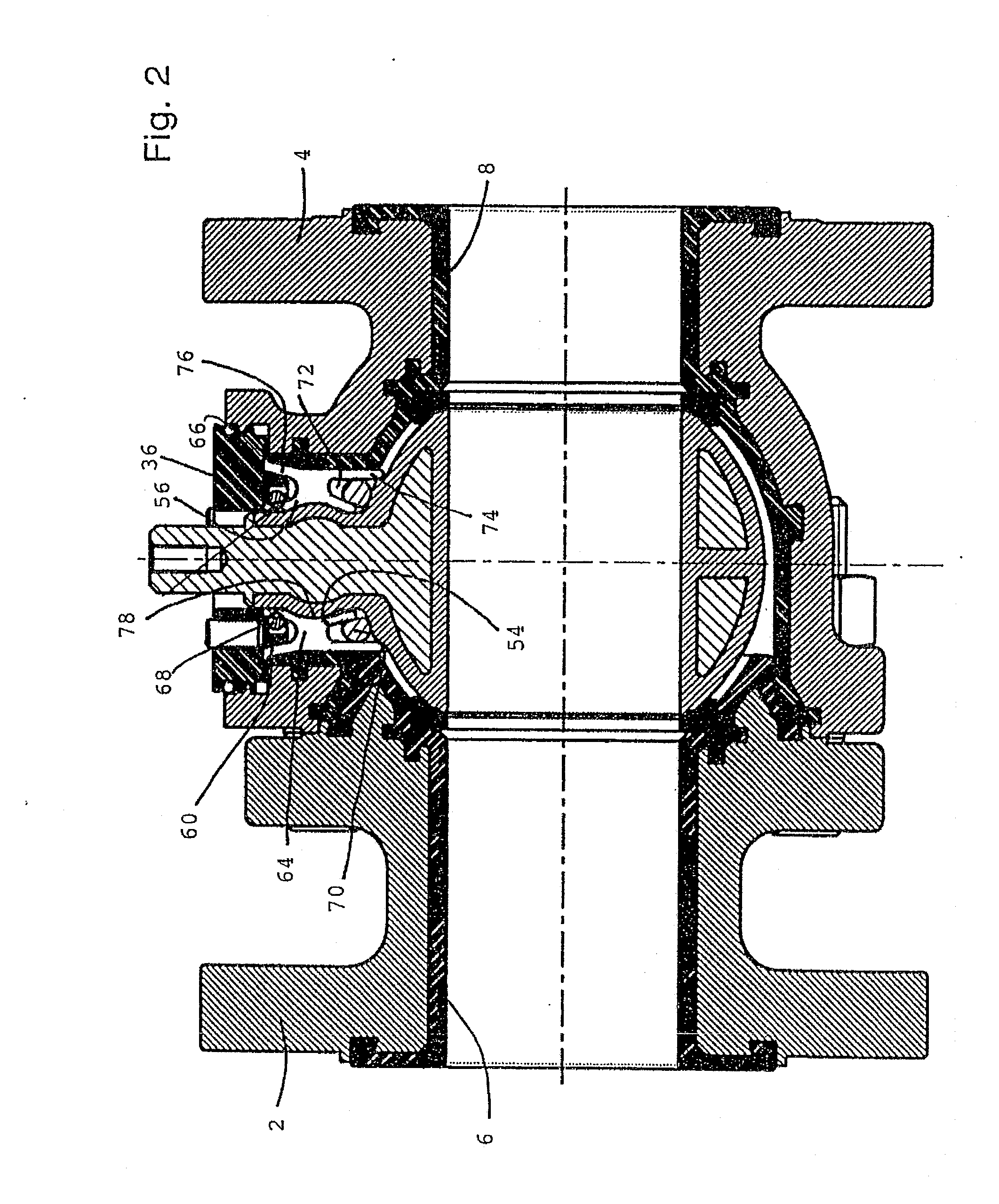

Pressure exchanger system

InactiveUS7168927B2Guaranteed uptimeIncrease loadPump componentsFluid-pressure convertersHigh energyEngineering

A pressure exchanger system having at least two tubular chambers, in which a plurality of reversing valves reverse the flow paths of fluid flows through the at least two tubular chambers. At least one driven reversing valve alternately reverses the flow paths between a supply source, which supplies a high-energy high-pressure fluid, and the tubular chambers. In reversing the liquid flows and shutting off previously open flow paths, the driven reversing element in the reversing valve executes a discontinuous or variable movement sequence.

Owner:KSB AG

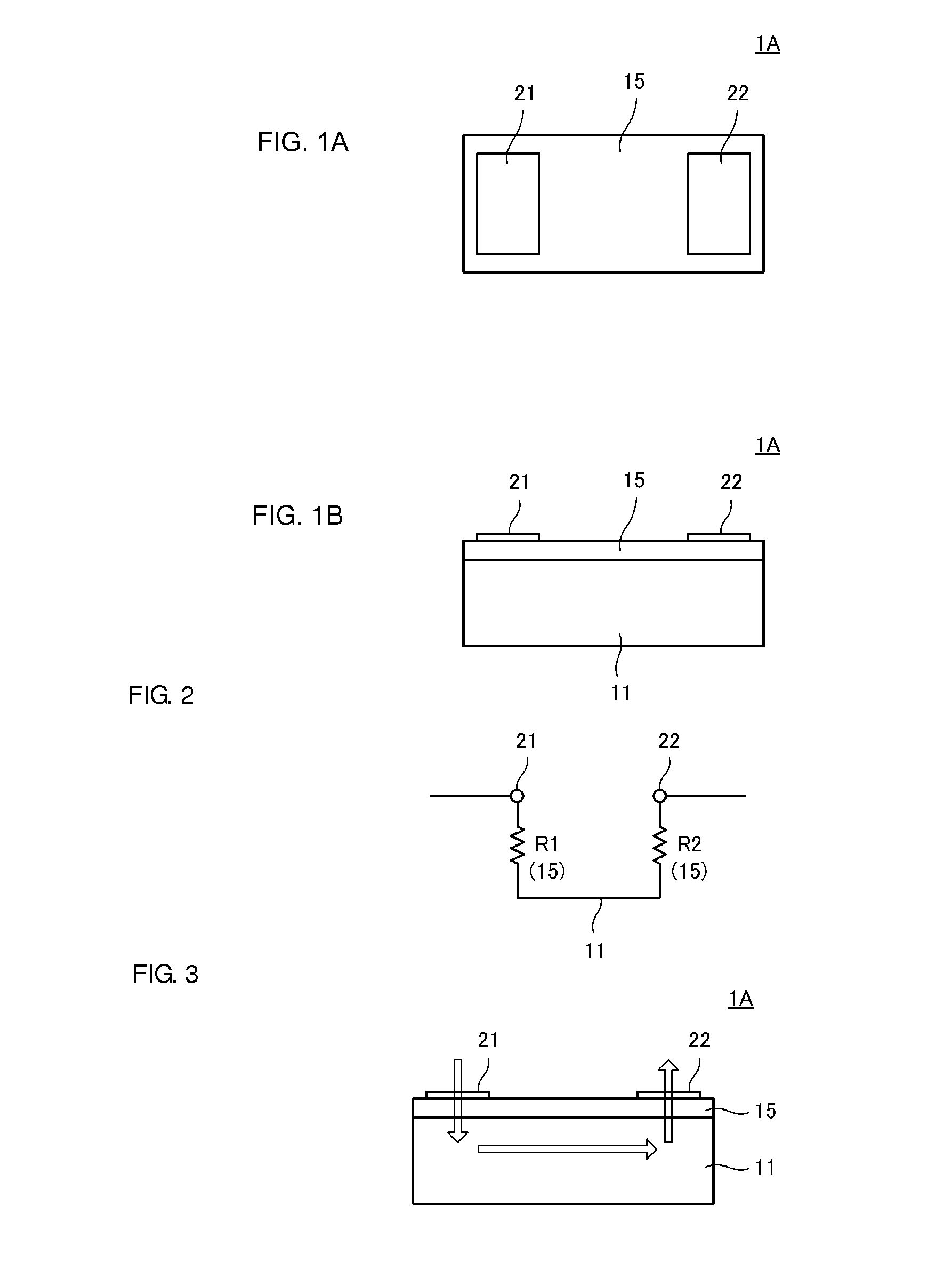

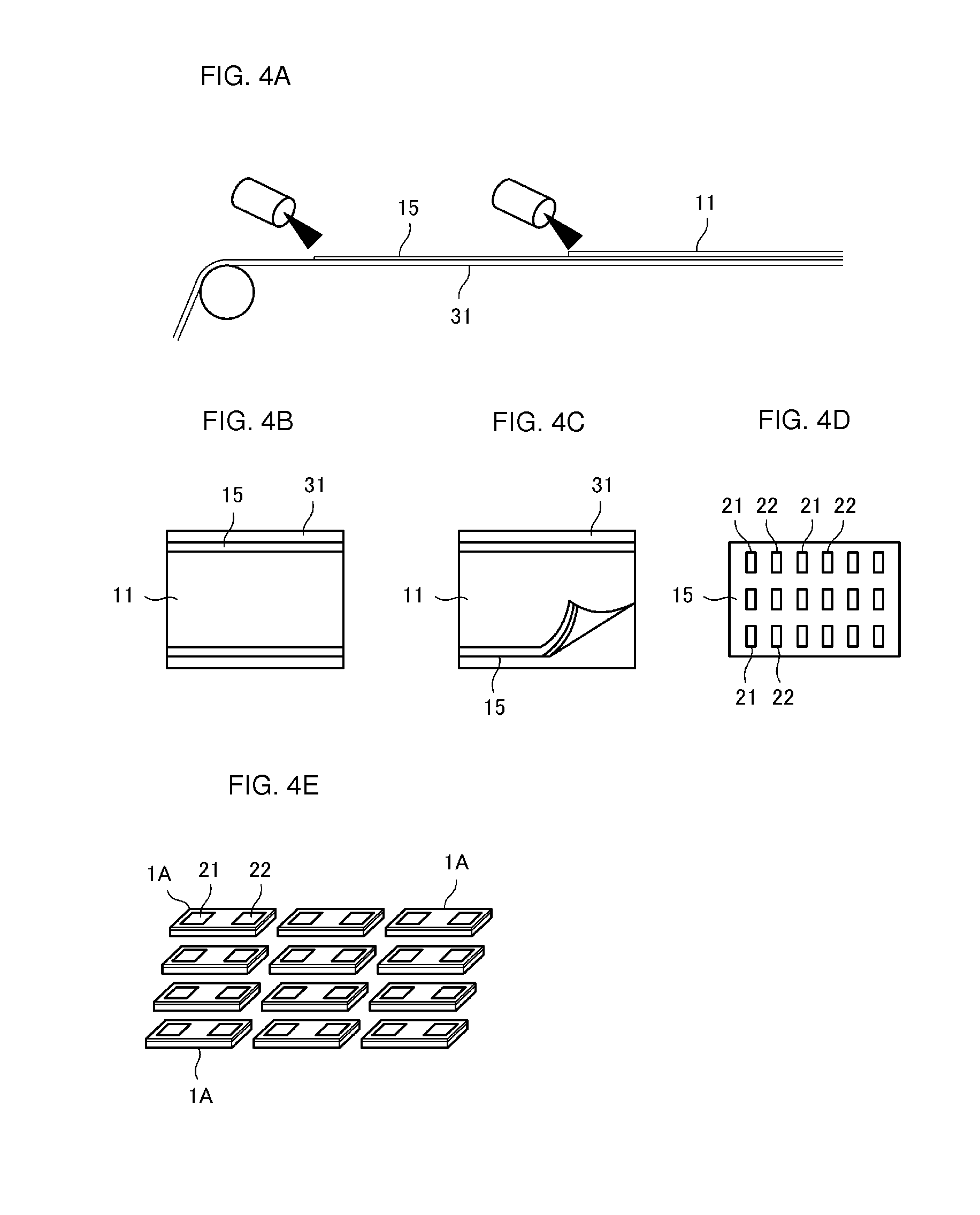

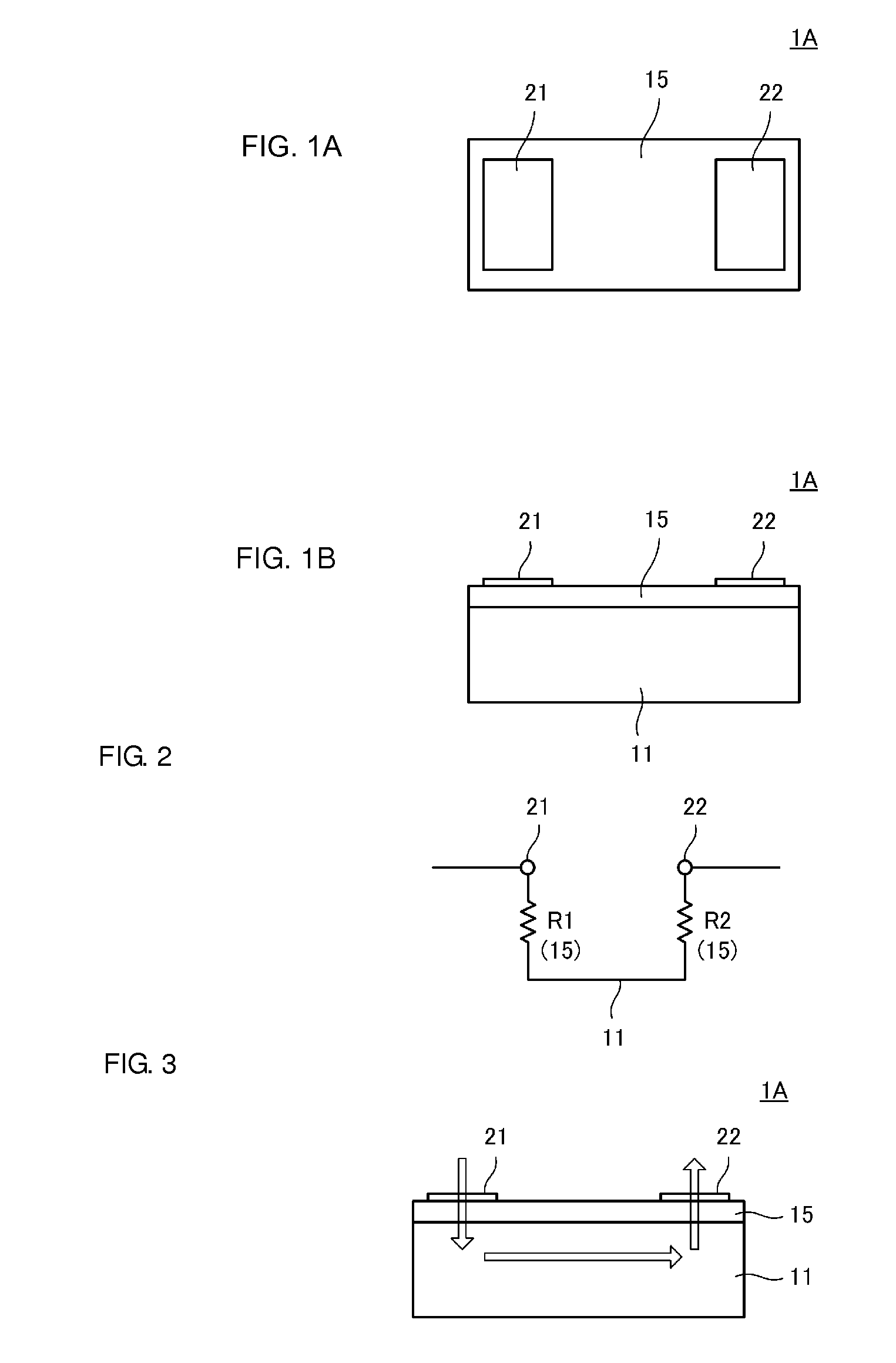

Temperature sensor and temperature sensor attaching structure

ActiveUS20130288091A1Does not affect flexibilityDetectable heatingThermometer detailsThermometers using electric/magnetic elementsElectrical conductorEngineering

A flexible board includes a base layer, a wiring conductor layer that is located on the base layer, and a cover layer that is stacked over the base layer and covers the wiring conductor layer. A portion of the wiring conductor layer defines connecting portions that connect each of split electrodes of a flexible thermistor. The cover layer includes an opening that exposes the connecting portions, and receives the flexible thermistor. The split electrodes of the flexible thermistor are mounted on the connecting portions of the wiring layer. The height of the exposed surface of the flexible thermistor from the opening is substantially equal to the height of the surface of the cover layer.

Owner:MURATA MFG CO LTD

Pressure exchanger system

InactiveUS20050166978A1Guaranteed uptimeIncrease loadPump componentsFluid-pressure convertersHigh energyEngineering

A pressure exchanger system having at least two tubular chambers, in which a plurality of reversing valves reverse the flow paths of fluid flows through the at least two tubular chambers. At least one driven reversing valve alternately reverses the flow paths between a supply source, which supplies a high-energy high-pressure fluid, and the tubular chambers. In reversing the liquid flows and shutting off previously open flow paths, the driven reversing element in the reversing valve executes a discontinuous or variable movement sequence.

Owner:KSB AG

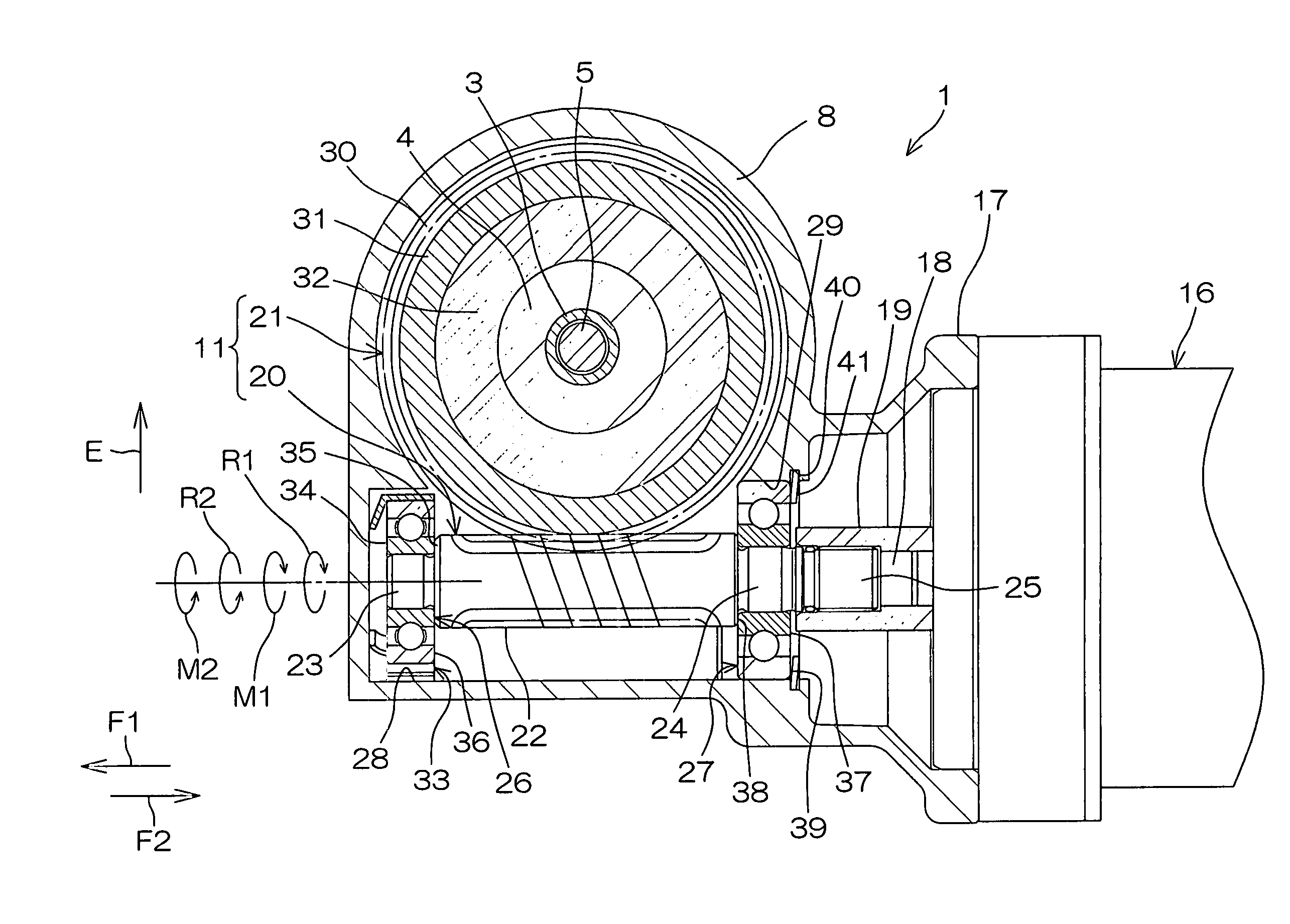

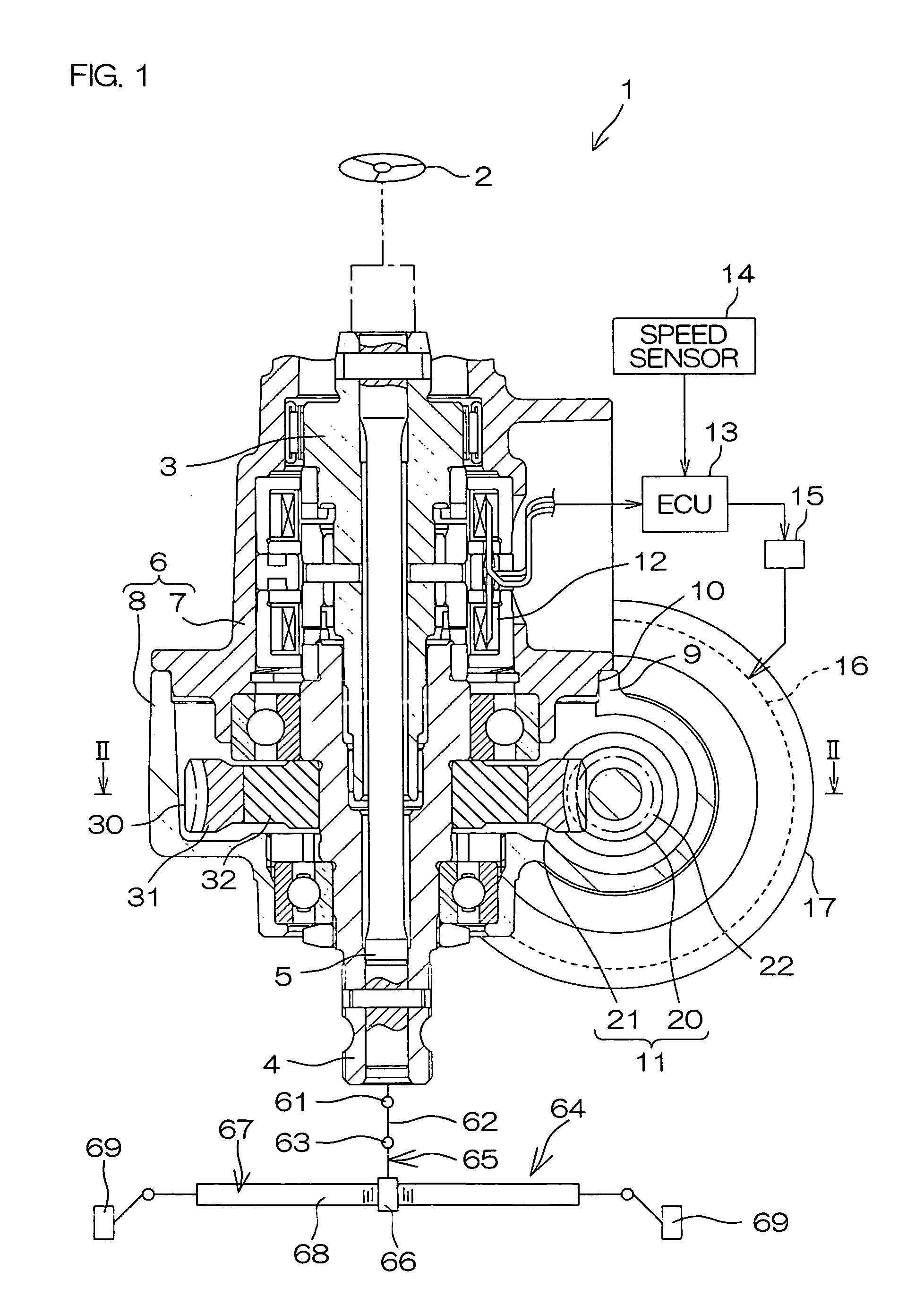

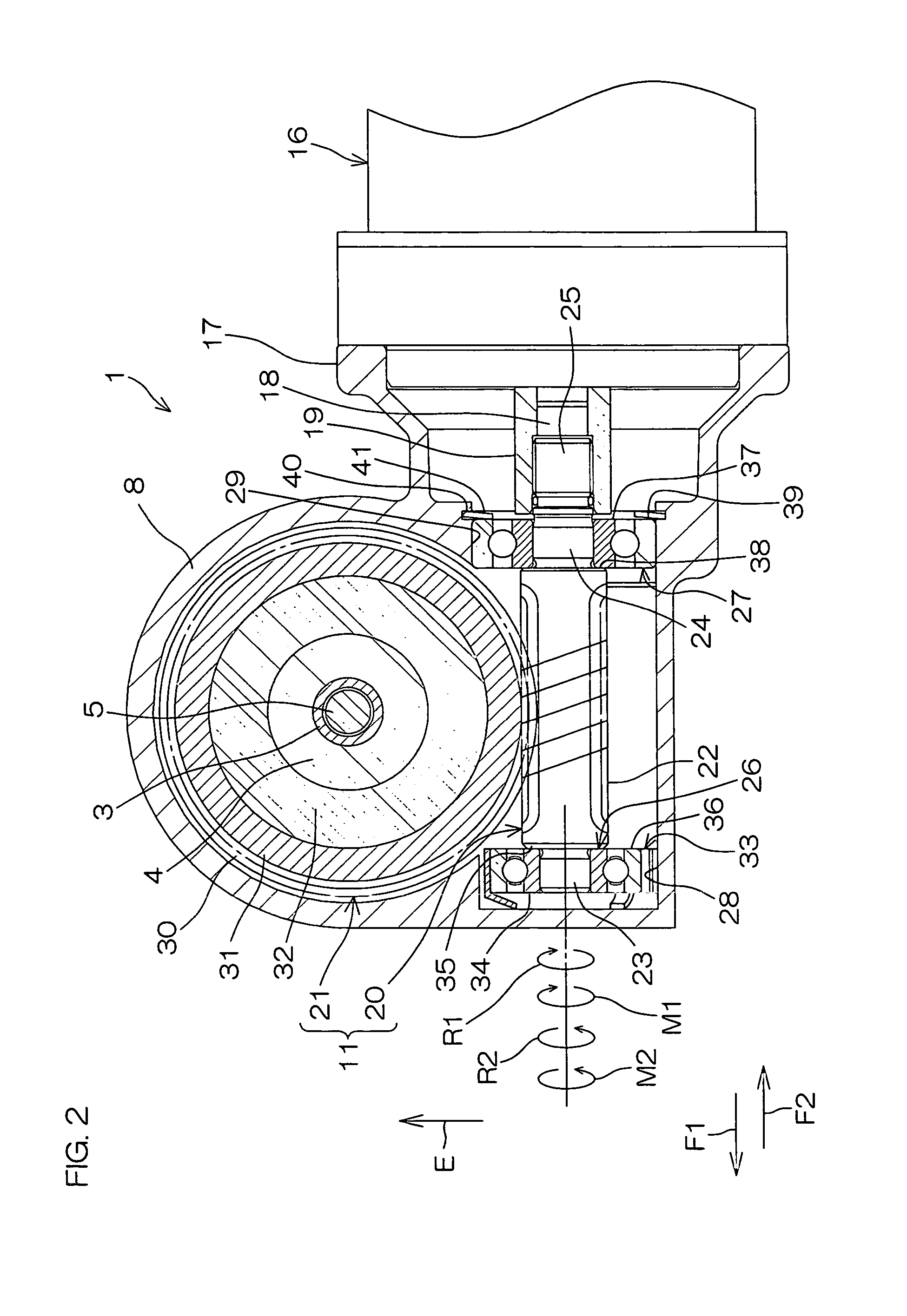

Electric power steering device

InactiveUS20070193819A1Increased durabilitySmall sizeRolling contact bearingsPortable liftingElectric power steeringEngineering

An electric power steering device (1) is provided which transmits output rotation of an electric motor for generating a steering assist force (16) to a steering mechanism (64) via a driving gear (22) and a driven gear (21). A housing (8) has a support hole (28) for supporting one end portion (23) of a shaft (20) co-rotatable with the driving gear (22) via a bearing (26) in such a manner as to permit the one end portion (23) to be offset toward the driven gear (21) radially of the driving gear (22). A biasing member (33) which biases the driving gear (22) toward the driven gear (21) includes an arcuate main portion (47) fitted around an outer peripheral surface (58) of an outer ring (36) of the bearing (26) and opposed to an inner peripheral surface (42) of the support hole (28). A pair of movement restriction portions (50, 51) which restrict circumferential movement of the main portion (47) are respectively provided at a pair of arc ends (48, 49) of the main portion (47). A resilient tongue (52) which biases the driving gear (22) toward the driven gear (21) via the bearing (26) is provided only on one of the movement restriction portions (50).

Owner:JTEKT CORP

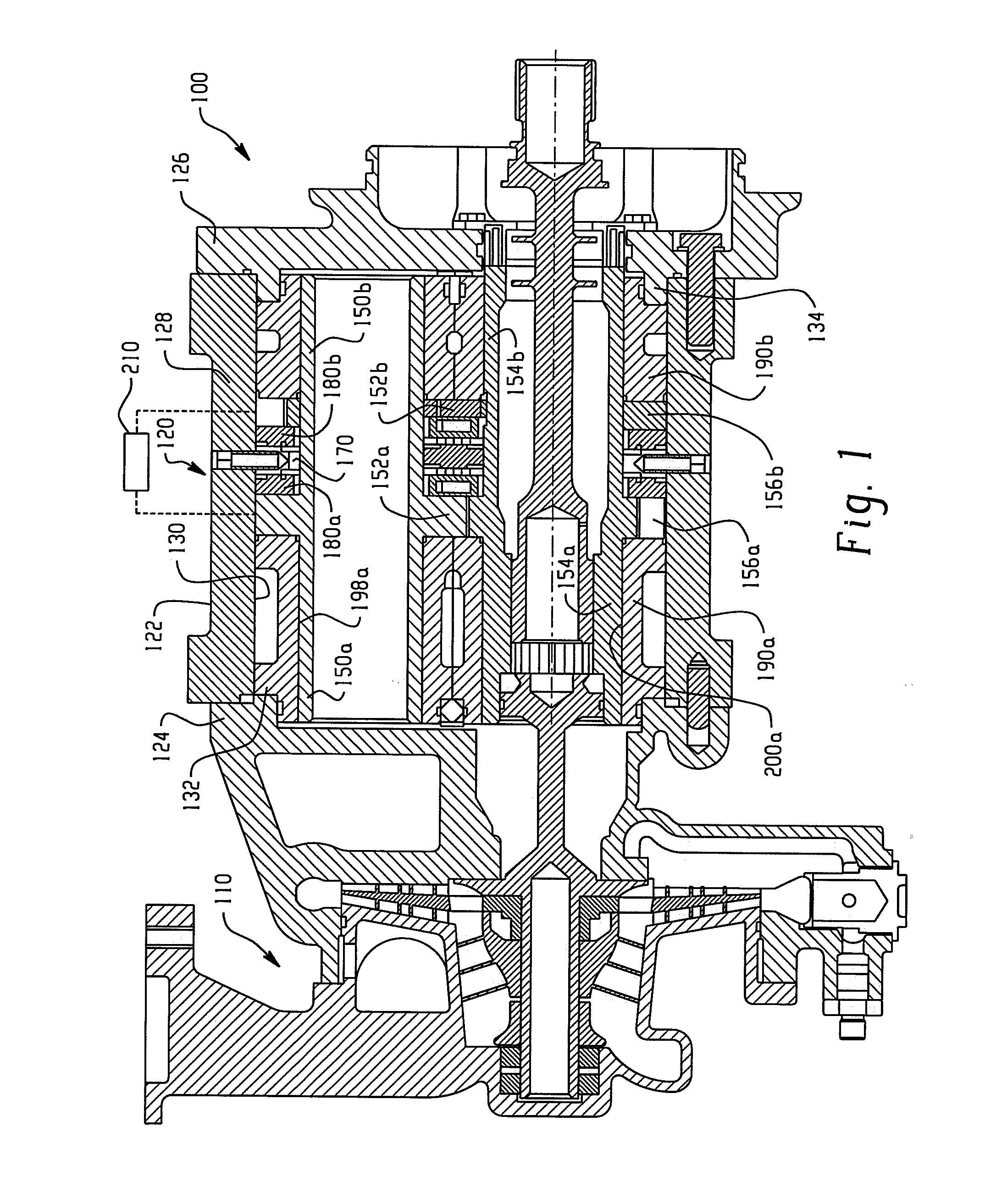

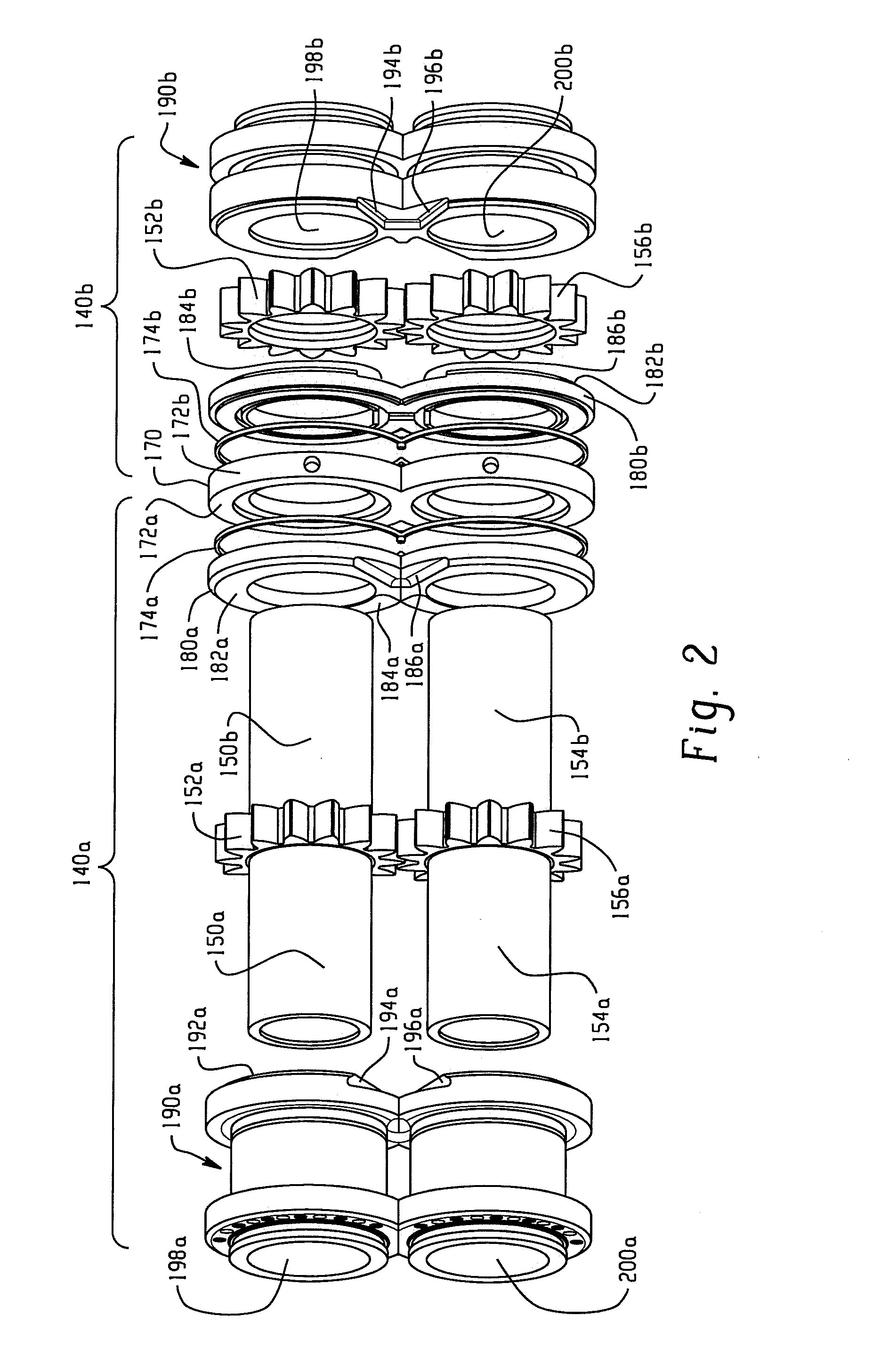

Aircraft main engine fuel pump with multiple gear stages using shared journals

InactiveUS20100266437A1Mitigate prospectLimit wearPump componentsOscillating piston enginesGear pumpEngineering

A multistage gear pump assembly includes first and second gear pumps that use common shafts and are axially separated by a spacer plate secured within a common bore and secured to the housing. Pressurized bearings are provided at opposite axial ends of the first and second gear pumps. The second gear pump handles cruise and idle operations of the aircraft while the first gear pump stage assists in meeting higher demand modes of engine operation. Otherwise, the first gear pump is maintained at a minimal pressure to reduce energy consumption and still provide desired stability and eliminate issues associated with bearing oil whirl associated with prior known arrangements. However, when additional assistance is required, such as during takeoff, climb, or windmill relight, the first gear pump advantageously contributes to the increased pressure.

Owner:EATON INDAL CORP

Aircraft main engine fuel pump with multiple gear stages using shared journals

ActiveUS20140003987A1Limit premature wearMinimize energy consumptionRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesGear pumpEngineering

A multistage gear pump assembly includes first and second gear pumps that use common shafts and are axially separated by a fixed spacer within the housing. Pressurized bearings are provided at opposite axial ends of the first and second gear pumps. The second gear pump handles cruise and idle operations of the aircraft while the first gear pump stage assists in meeting higher demand modes of engine operation. Otherwise, the first gear pump is maintained at a minimal pressure to reduce energy consumption and still provide desired stability and eliminate issues associated with bearing oil whirl associated with prior known arrangements. When additional assistance is required, such as during takeoff, climb, or windmill relight, the first gear pump advantageously contributes to the increased pressure.

Owner:EATON INTELLIGENT POWER LIMITED

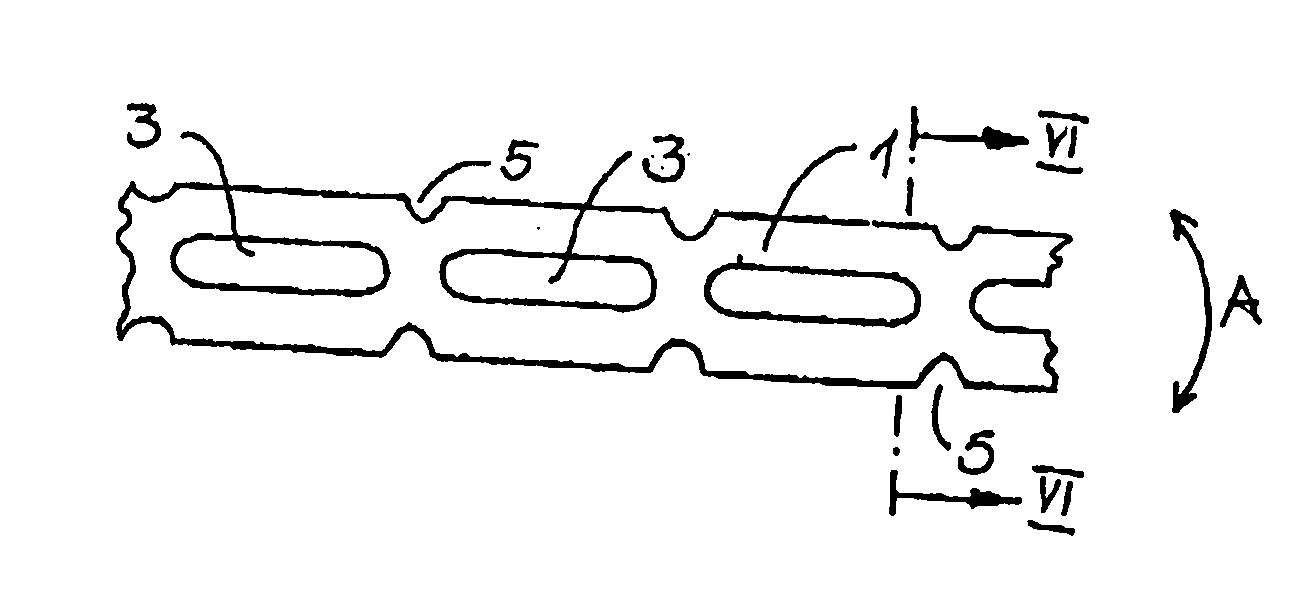

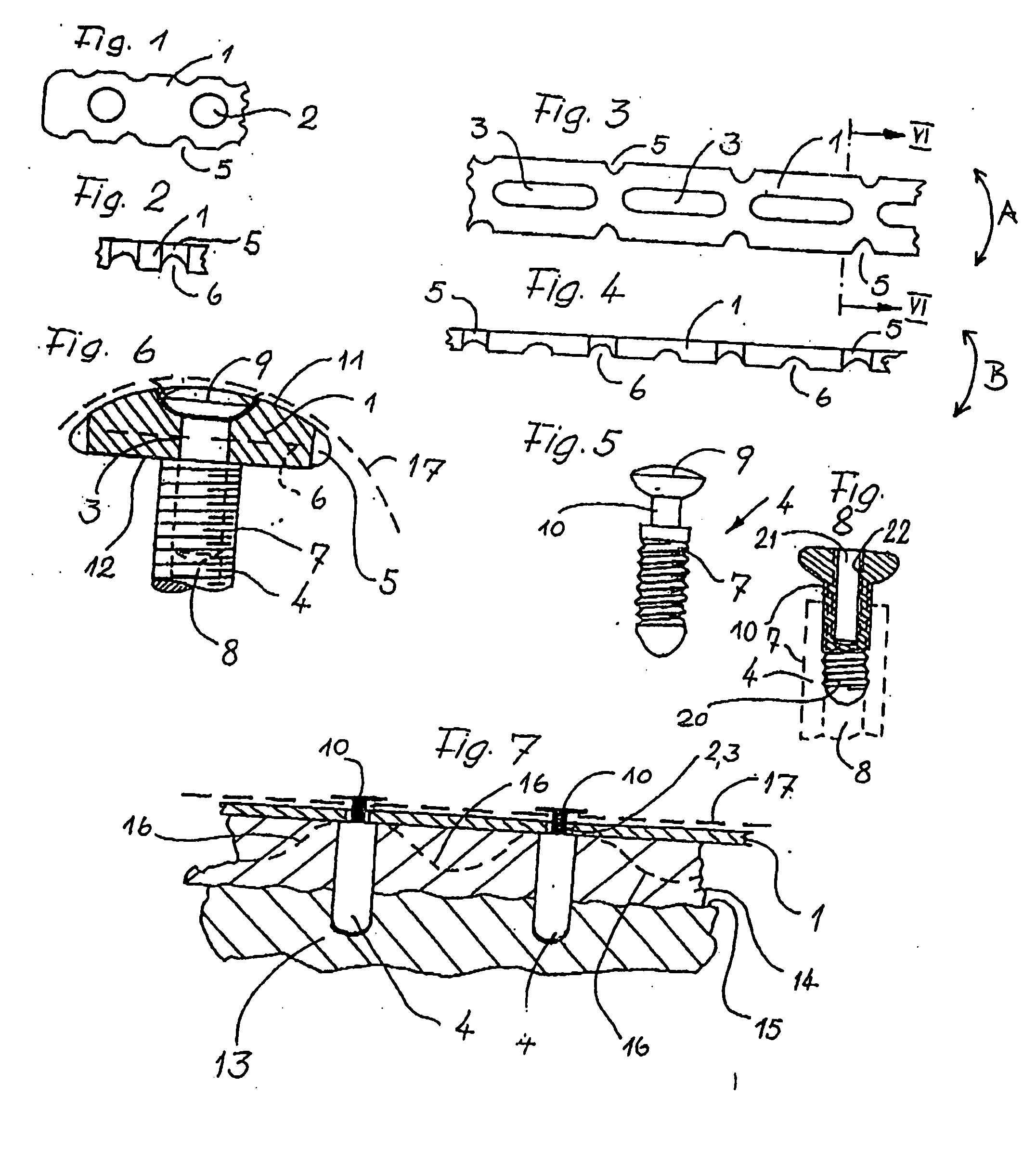

Device for regenerating, repairing, and modeling human and animal bone, especially in the jaw area for dental applications

InactiveUS20070134623A1Reduce stress loadRelieve pressureDental implantsInternal osteosythesisTransverse grooveBone replacement

A device for reshaping human or animal bone with bone replacement material includes at least two spaced apart implants and a bar connected to the at least two spaced apart implants and bridging at least one reshaping location. The bar has notches at the longitudinal sides and transverse grooves at the underside. The bar has slotted holes extending in the longitudinal direction of the bar for receiving the implants, respectively, fasteners of the implants.

Owner:ESSIGER HOLGER K

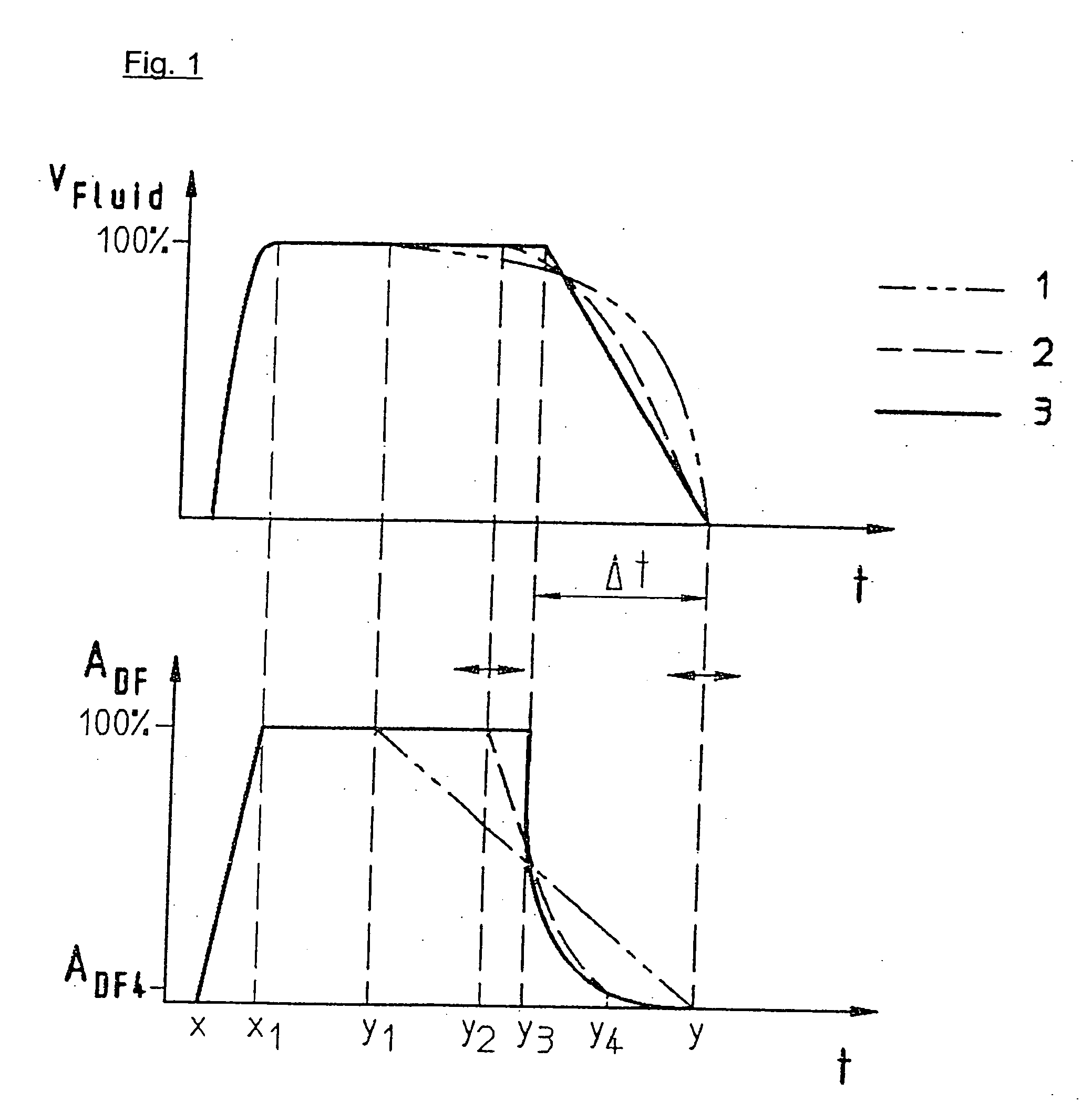

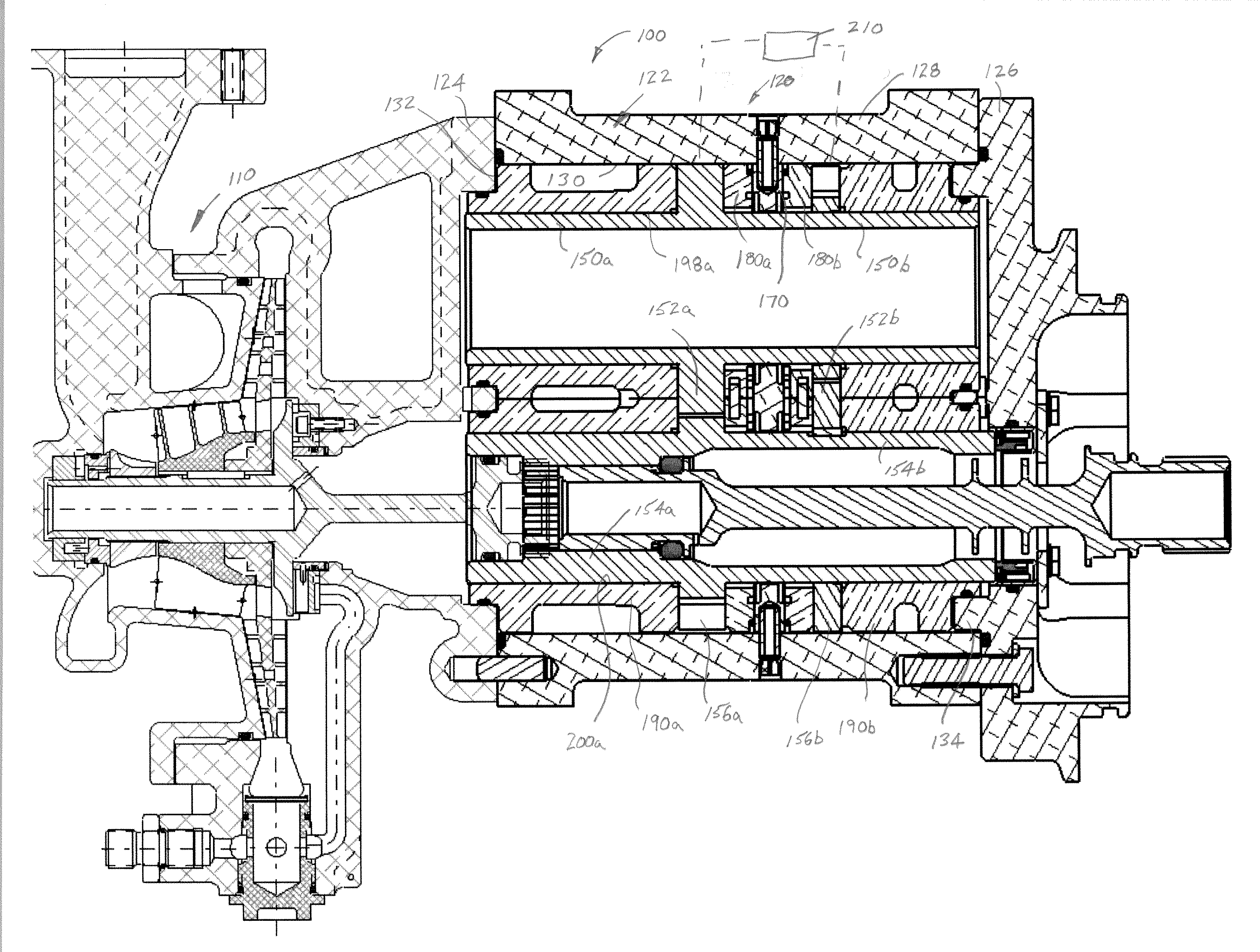

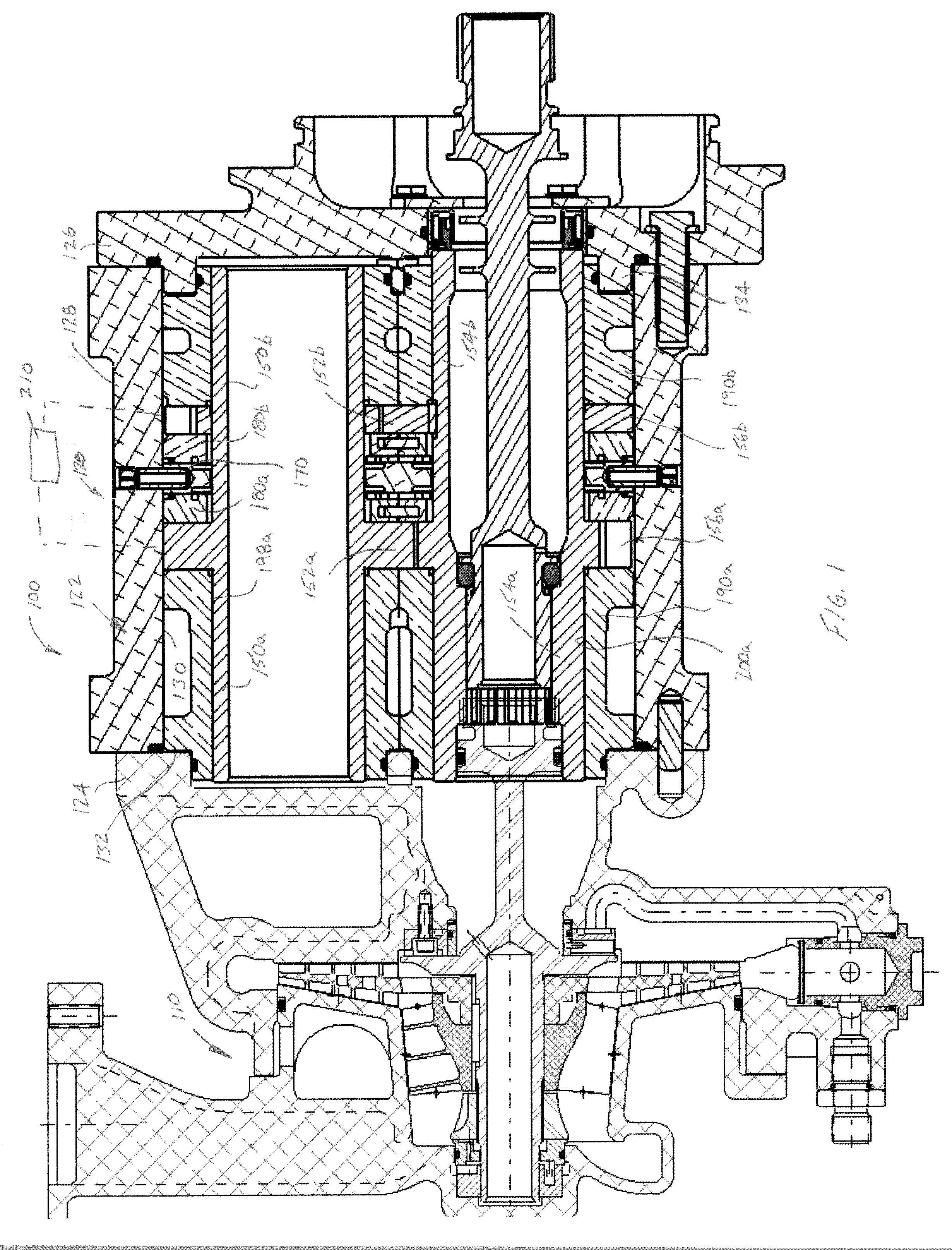

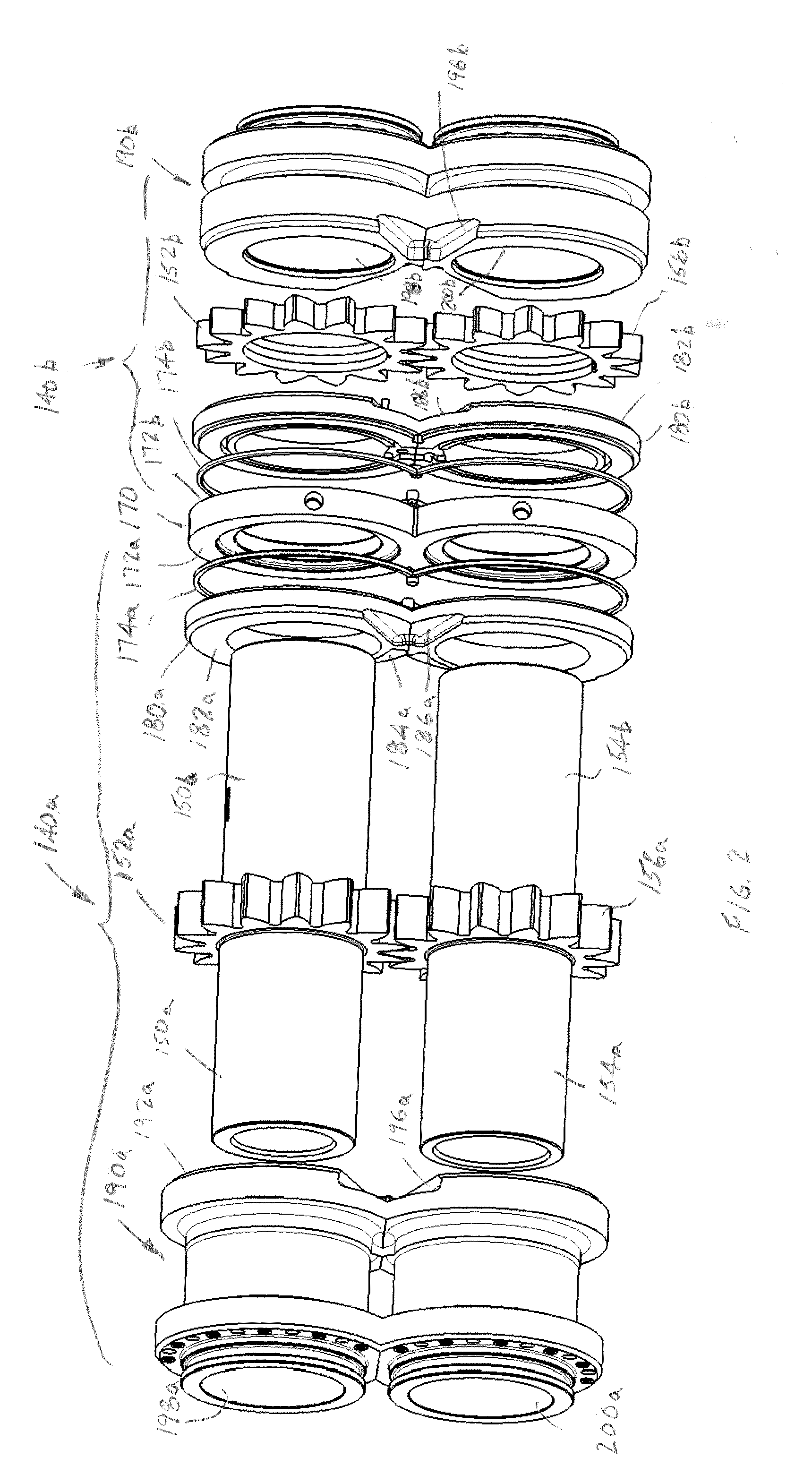

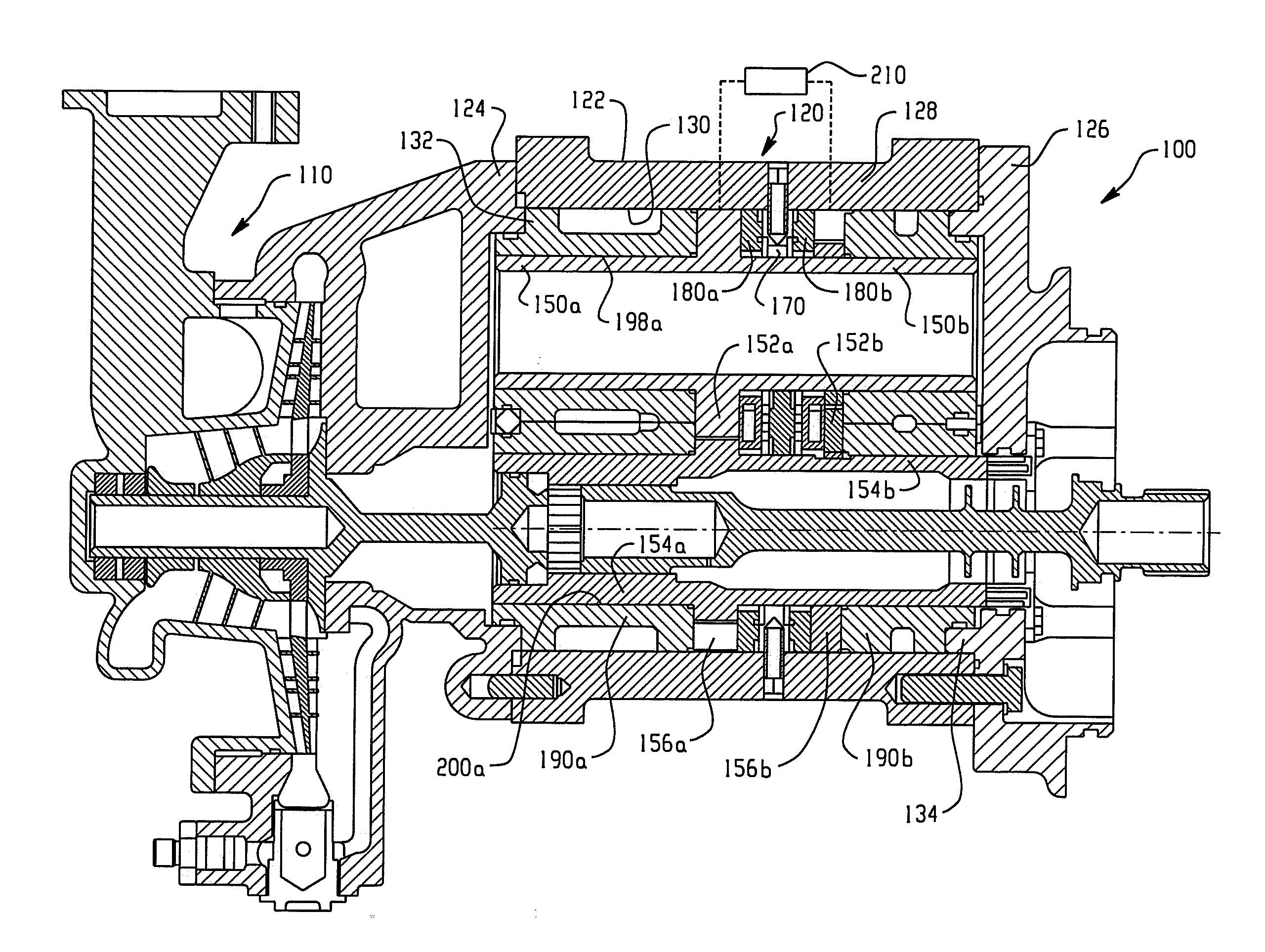

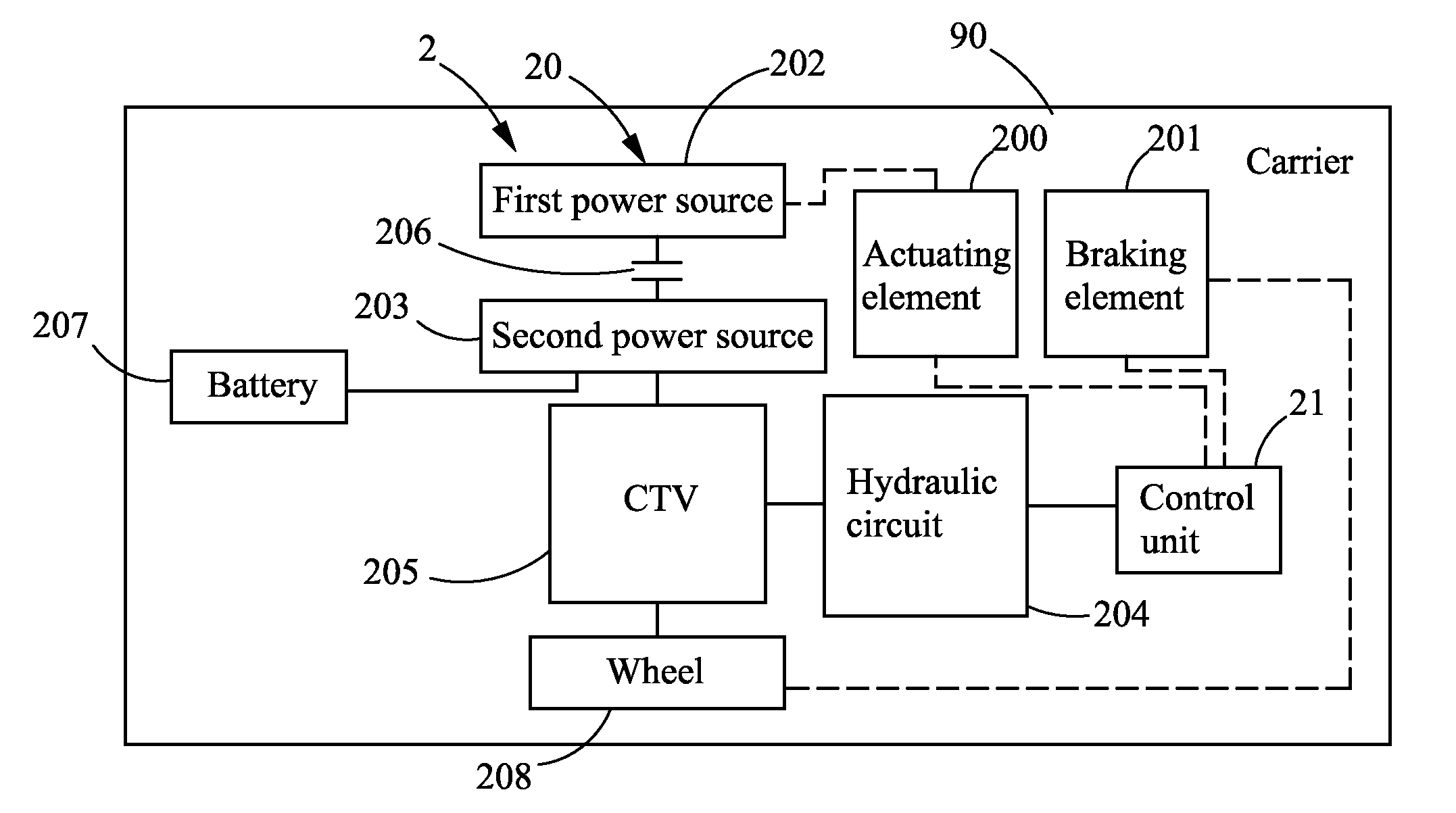

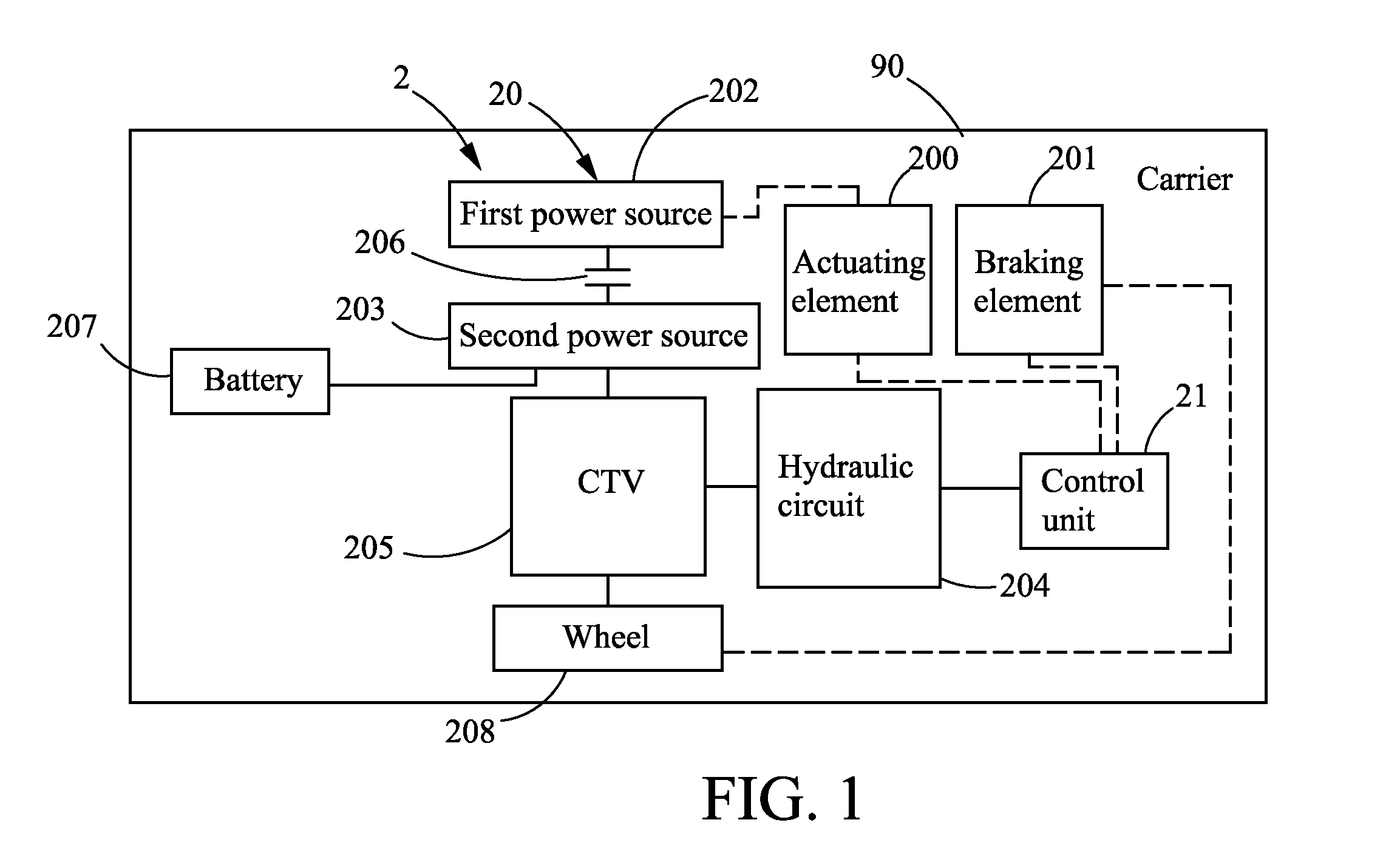

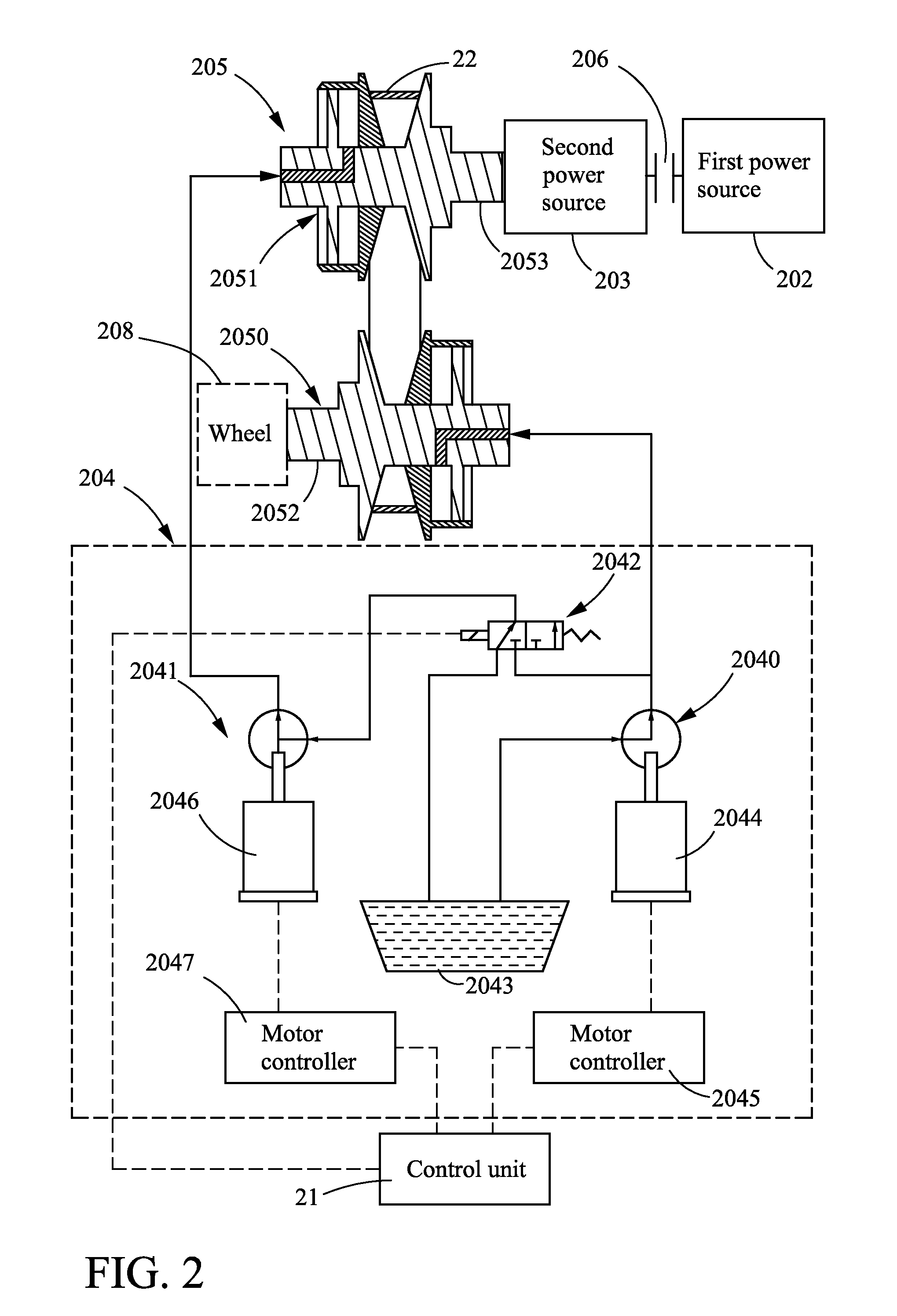

Method and system for controlling hydraulic apparatus for continuously variable transmission of hybrid vehicle system

InactiveUS20110301793A1Reduced pressure loadingReduce stress loadHybrid vehiclesDigital data processing detailsVariatorGear ratio

The present invention provides a method and system for controlling hydraulic apparatus for CVT of a hybrid vehicle system, which adjust rotation speed of an input axial and output axial by means of hydraulic pressure generated from a first and a second hydraulic pump and guided through hydraulic circuits coupled to the input and output shafts for controlling gear ratio and output torque of the CVT. Meanwhile the present invention determines serial or parallel connection between the first and second hydraulic pumps according to the operation mode and status of the hybrid vehicle system so as to control the output of the CVT effectively. Besides, the present invention controls the hydraulic pressure of the first and second hydraulic pump for controlling the gear ratio of CVT such that the input source such as engine or motor can be operated in the optimized zone thereby reducing the energy consumption.

Owner:IND TECH RES INST

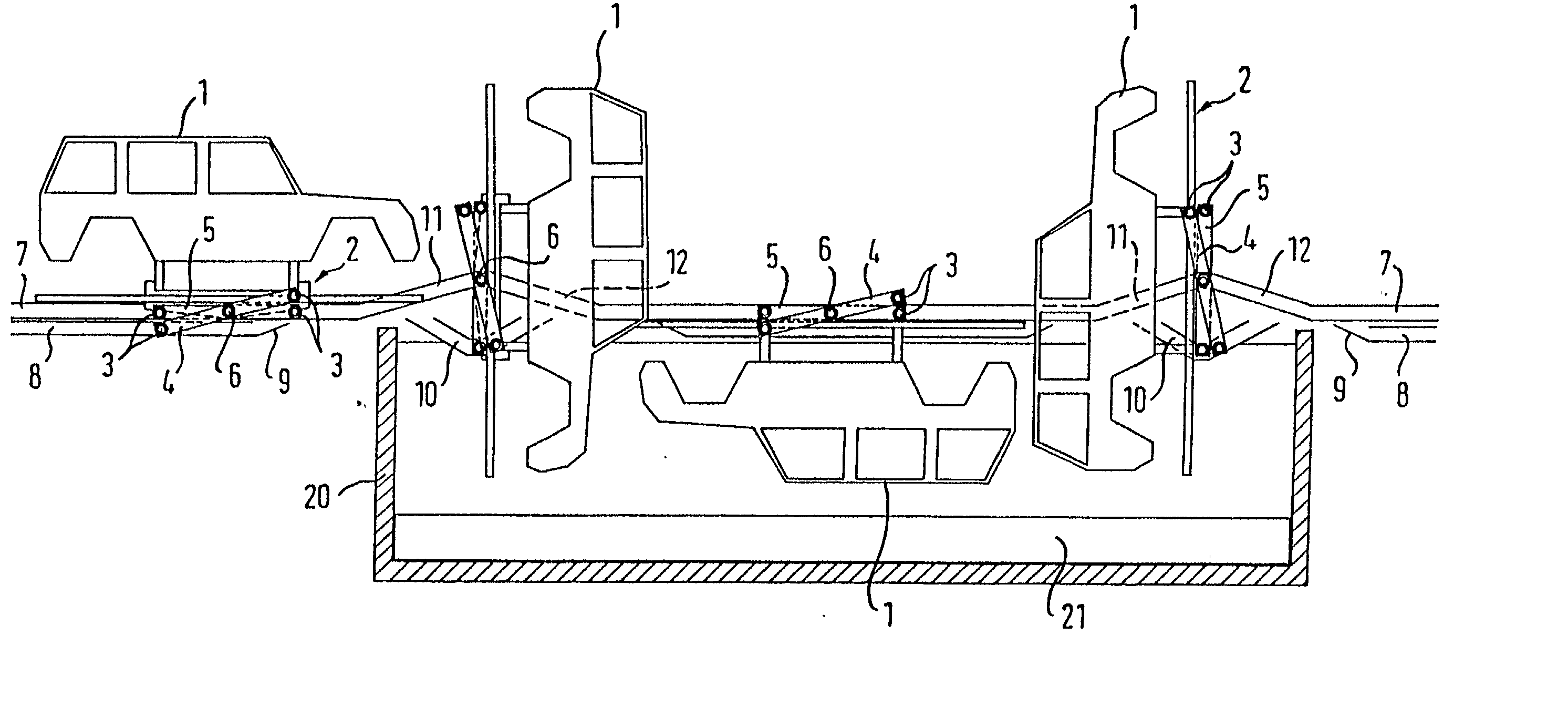

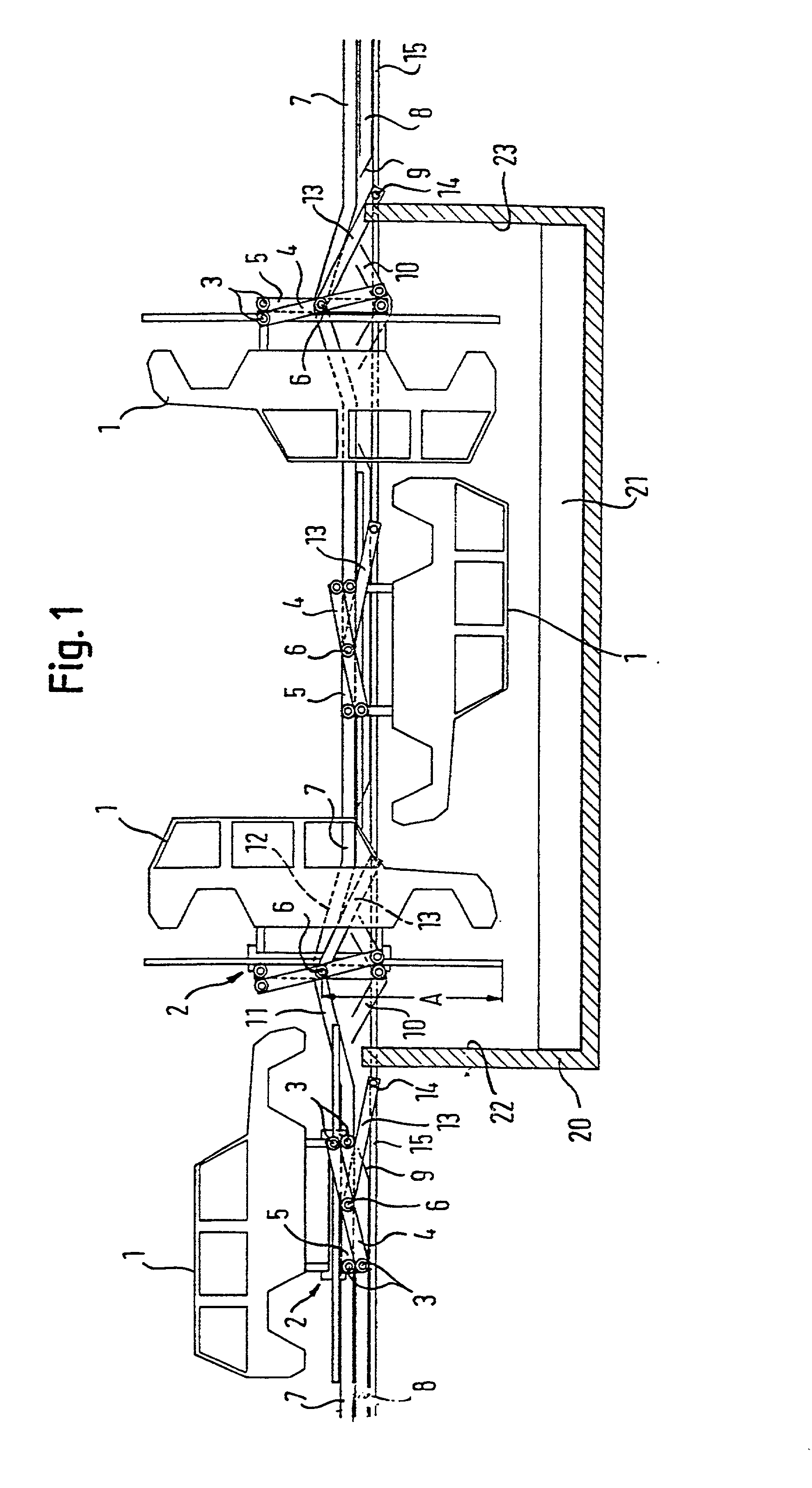

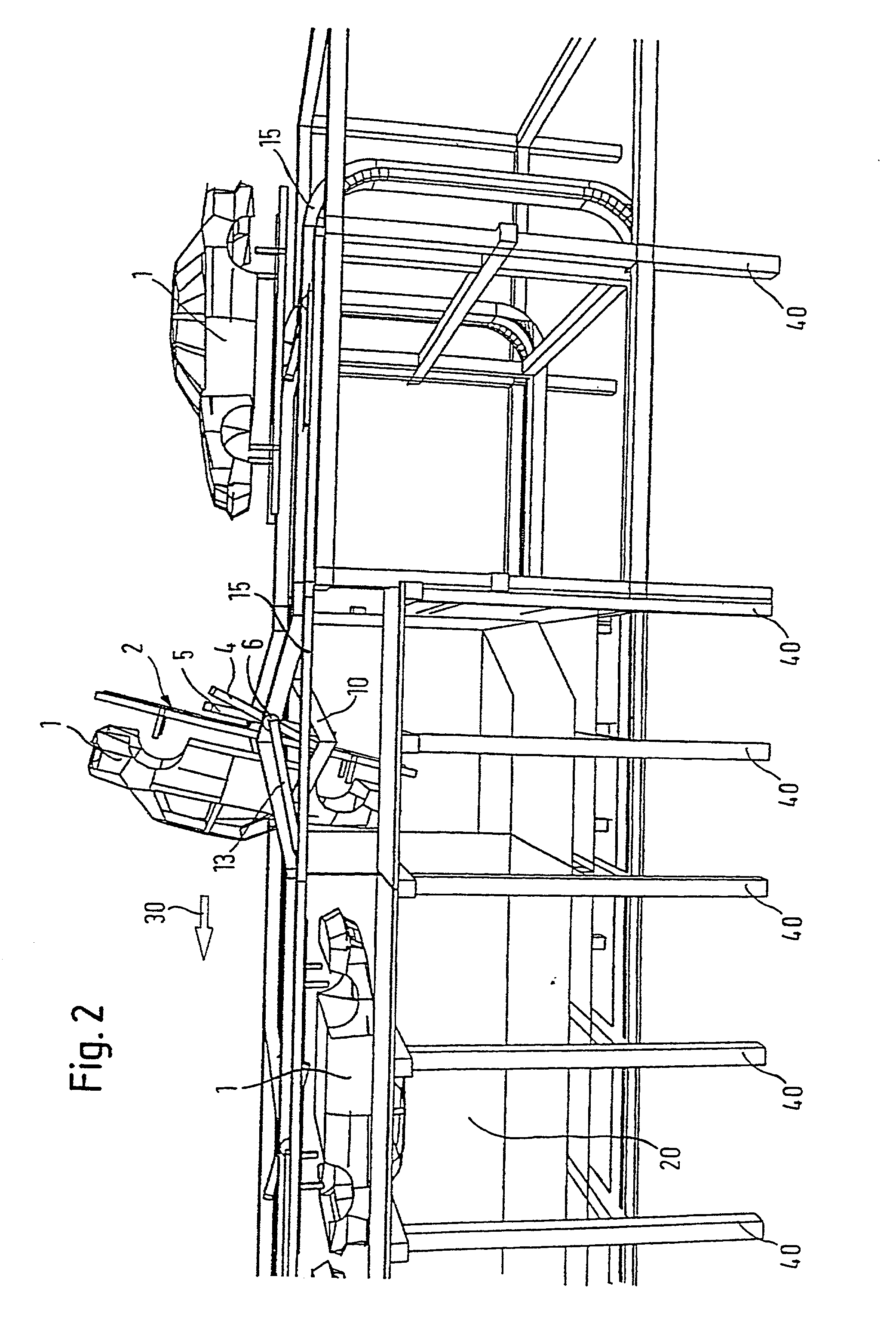

Method for introducing and removing workpieces into or from a surface treatment area, a surface treatment device and an arrangement for surface treatment

InactiveUS20020162504A1Less energyGreat expenditurePretreated surfacesCharge manipulationProcess regionTranslatory motion

The invention relates to a method for introducing and removing workpieces, especially vehicle bodies, into or from a treatment area (20) by rotational movements, whereby the treatment area serves for treating surfaces of the workpieces (1). A workpiece (1) is detachably fixed at a holding frame (2) which is moved together with at least one workpiece that is situated thereon at an essentially constant speed and by a continuous translation. The workpiece (1) is rotated around a rotational axle (6) at least at the beginning and end of the treatment area (20) and simultaneously with the translation movement. The rotational axle (6) is orientated vertically in relation to the moving direction of the holding frame (2) and is lifted and lowered during rotation.

Owner:ABB FLAEKT AB

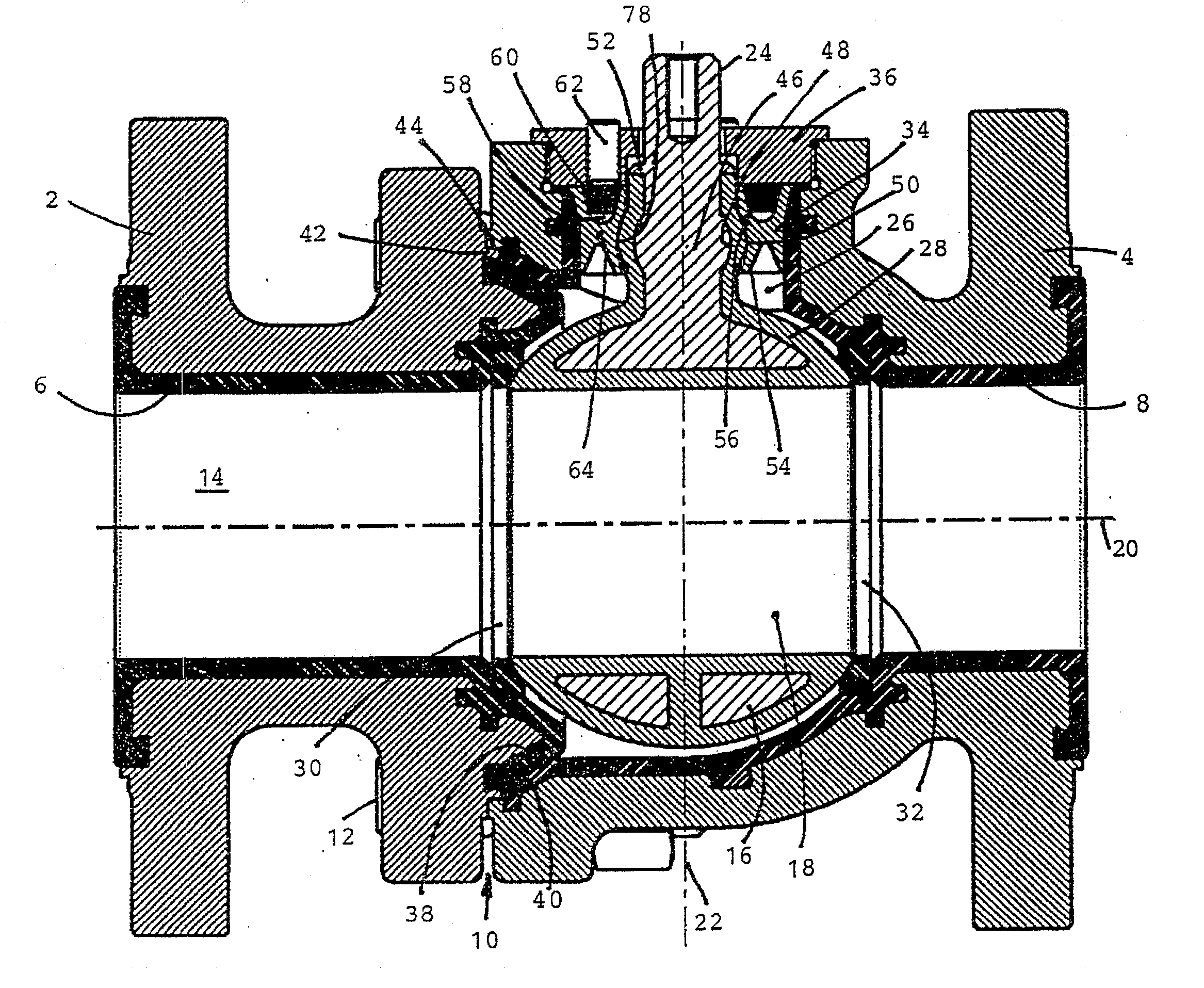

Sealing intersecting vane machines

InactiveUS6901904B1Reduce frictionMaximize efficiencyInternal combustion piston enginesOscillating piston enginesEngineeringMechanical engineering

The invention provides a toroidal intersecting vane machine incorporating intersecting rotors to form primary and secondary chambers whose porting configurations minimize friction and maximize efficiency. Specifically, it is an object of the invention to provide a toroidal intersecting vane machine that greatly reduces the frictional losses through intersecting surfaces without the need for external gearing by modifying the width of one or both tracks at the point of intermeshing. The inventions described herein relate to these improvements.

Owner:MECHANOLOGY INC

Induction System with Air Flow Rotation and Noise Absorber for Turbocharger Applications

InactiveUS20110299981A1Minimized pressure lossAssists functionalityInternal combustion piston enginesPump componentsImpellerHelical scan

An air induction system consisting of a cylindrical main flow tube, a helical vane disposed within the main flow tube, and, preferably, a noise absorbing perforated tube disposed within the main flow tube in concentric relation to the helical vane. The twist direction of the helical vane provides air flow rotation in the same direction of rotation as the turbine wheel. The helical vane causes noise reflection and enhancement of noise attenuation by the perorated tube and its adjoining one or more acoustic cavities.

Owner:GM GLOBAL TECH OPERATIONS LLC

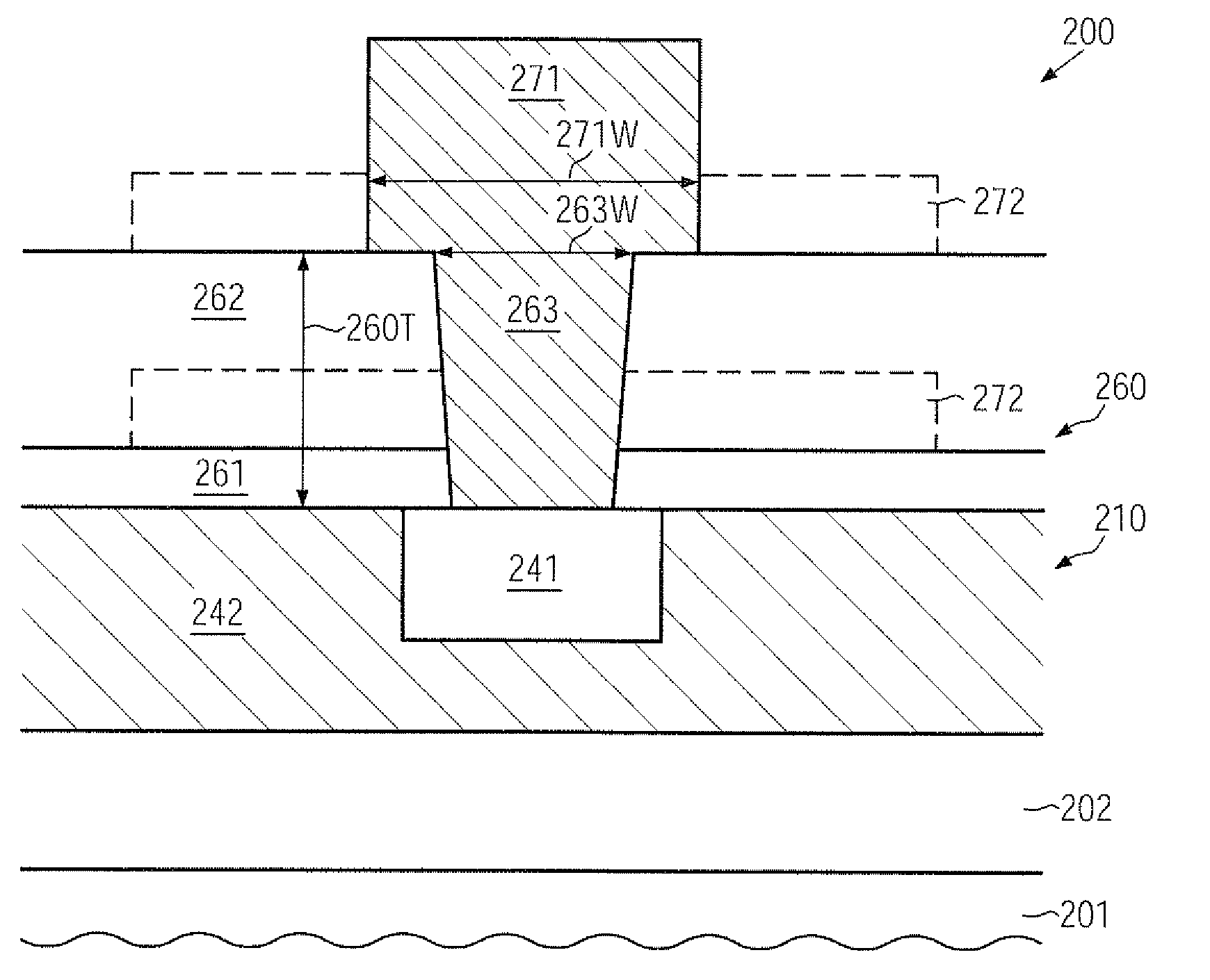

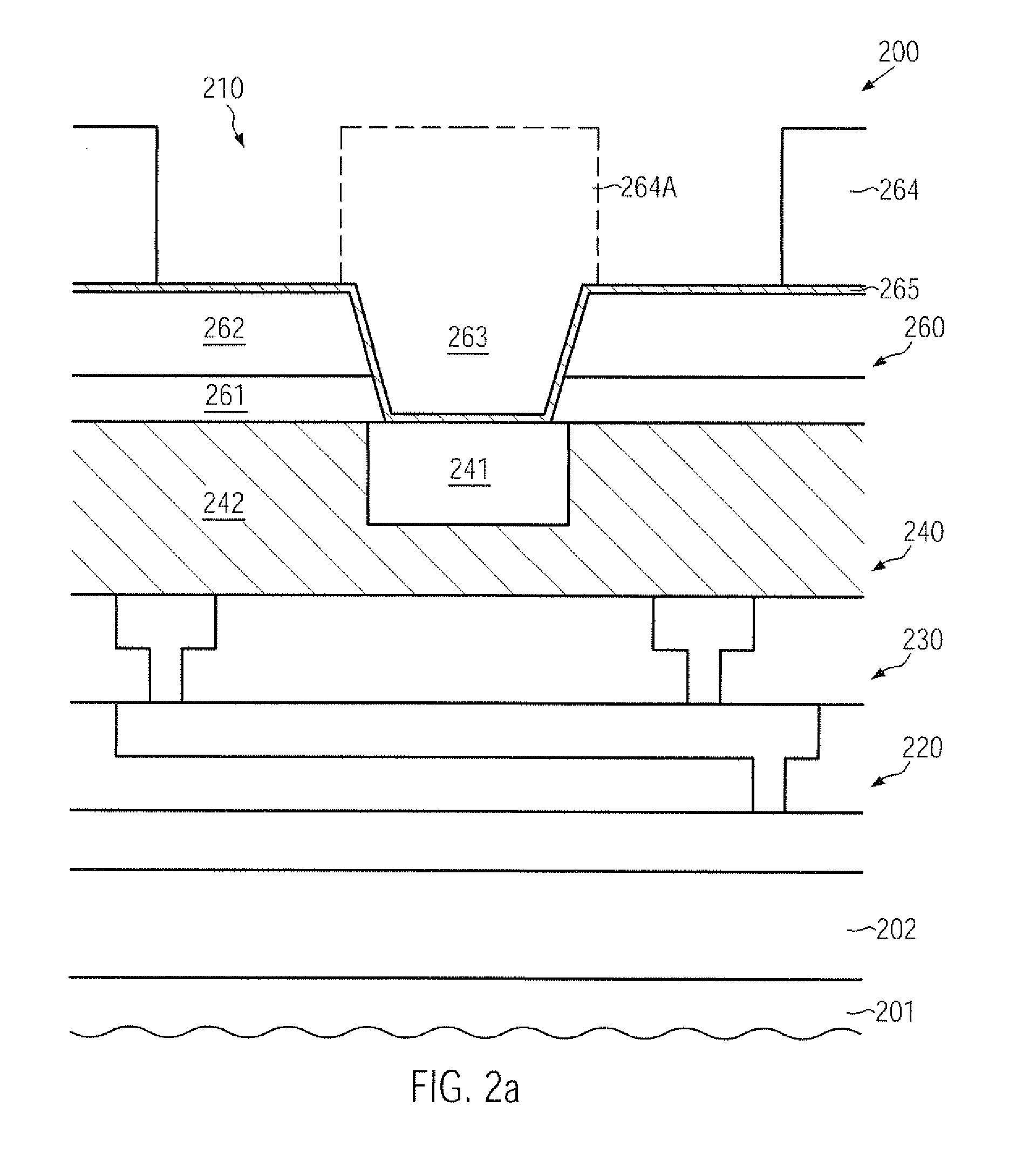

Semiconductor device including a reduced stress configuration for metal pillars

ActiveUS20100109158A1Reducing local stress loadAdding to undue process complexitySemiconductor/solid-state device detailsSolid-state devicesSemiconductorMaterials science

In a metallization system of a sophisticated semiconductor device, metal pillars may be provided so as to exhibit an increased efficiency in distributing any mechanical stress exerted thereon. This may be accomplished by significantly increasing the surface area of the final passivation layer that is in tight mechanical contact with the metal pillar.

Owner:ADVANCED MICRO DEVICES INC

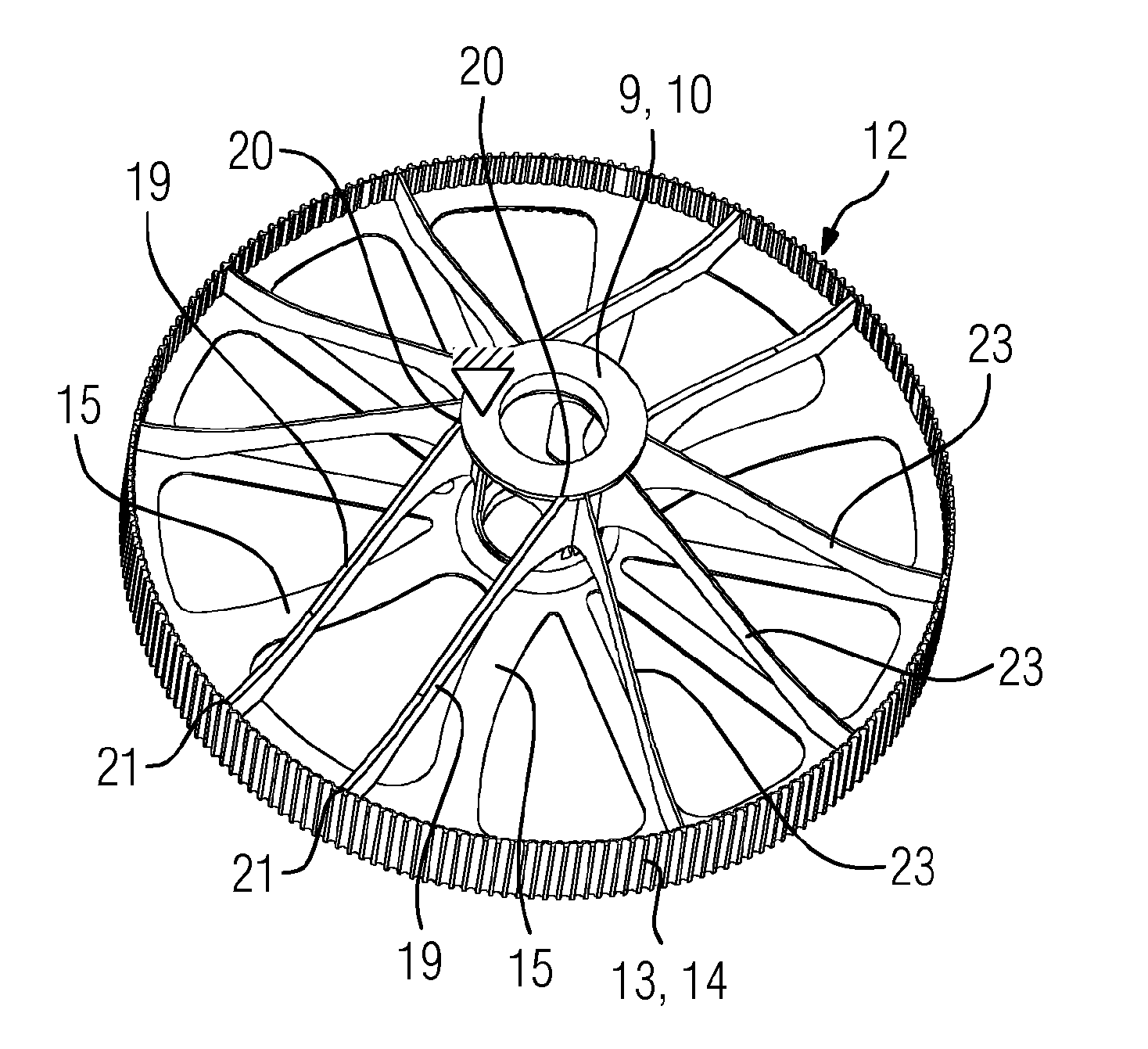

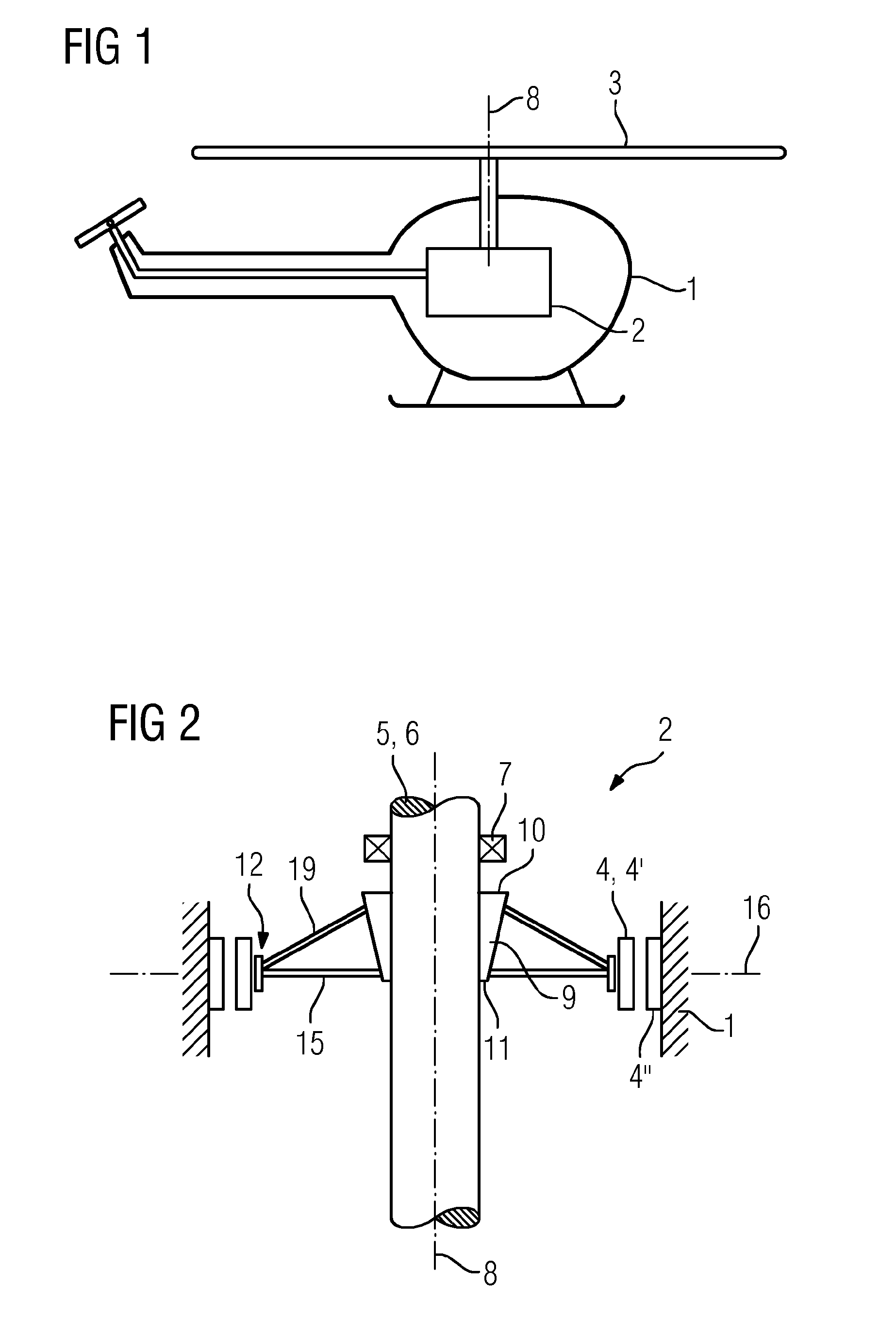

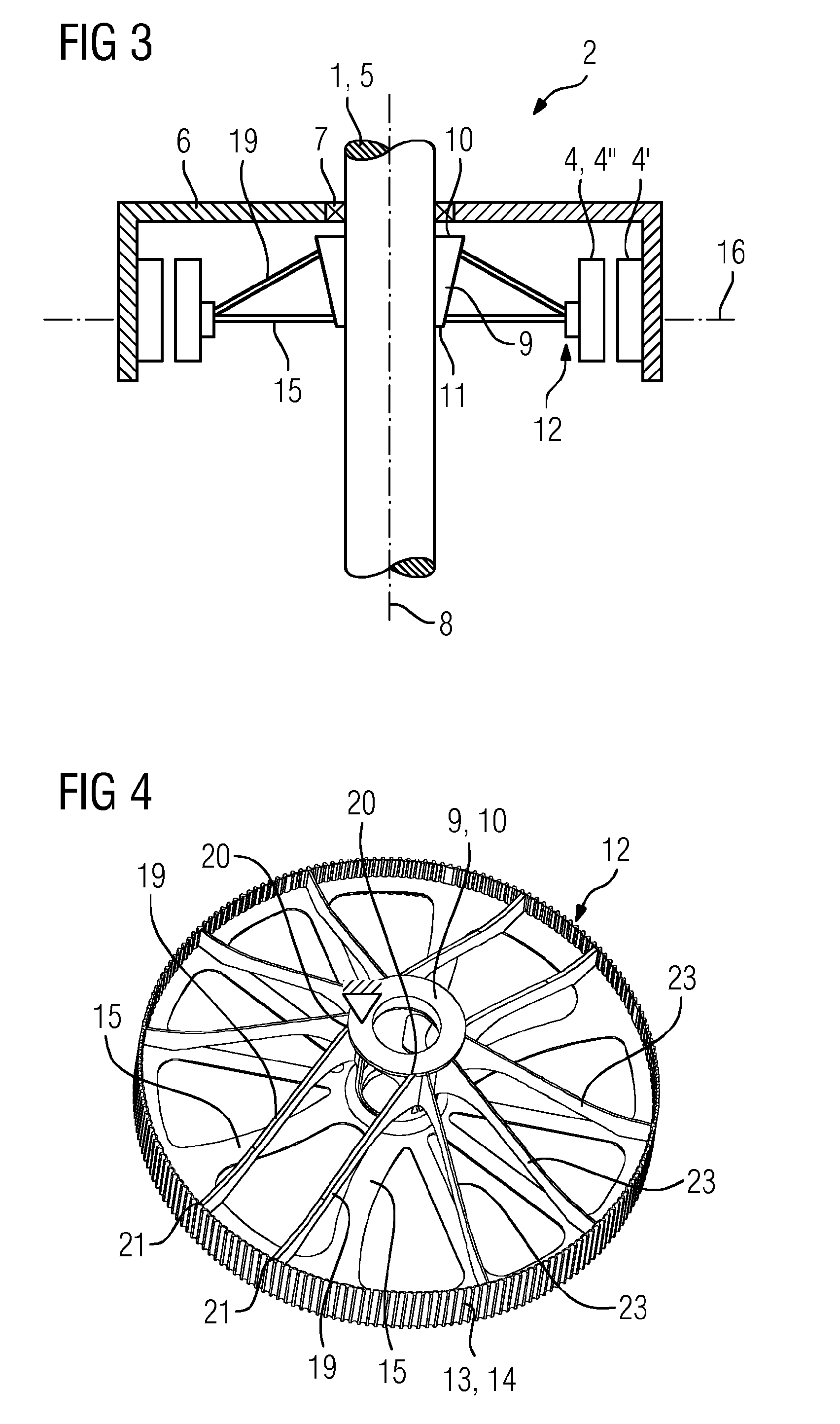

Device including an electric machine with a lightweight design

ActiveUS20170040870A1Improve stabilityReduce stress loadMagnetic circuit rotating partsMagnetic circuit stationary partsRadial planeElectric machine

An active part (4) of an electric machine (2) is connected to a supporting body (5) via a connecting structure and is fixed relative to the supporting body (5). A rotor (4′) of the electric machine interacts electromagnetically with a stator core (4″) and is mounted rotatably relative to the stator core (4″) so that the rotor (4′) is rotatable about an axis of rotation (8). The connecting structure comprises at least one hub (9), a supporting ring (12) and first and second struts (15, 19). The hub (9) surrounds the axis of rotation (8) and extends in the axial direction from an upper hub end (10) to a lower hub end (11). The hub (9) adjoins, with the upper hub end (10), the supporting body (5) and is fastened there to the supporting body (5). The supporting ring (12), on the outer side (13) thereof, adjoins the active part (4) and is connected to the active part (4). The first struts (15) extend in a radial plane (16) radially outwards from the lower hub end (11) to the supporting ring (12). The first struts (15) merge with the hub (9) in a respective radially inner transition region (17) and with the supporting ring (12) in a respective radially outer transition region (18). The second struts (19) extend from the upper hub end (10) to the supporting ring (12). In relation to the radial plane (16), the radially inner transition region (17) and the radially outer transition region (18) of a respective first strut (15) each form an angle (a) with the axis of rotation (8).

Owner:ROLLS ROYCE DEUT LTD & CO KG

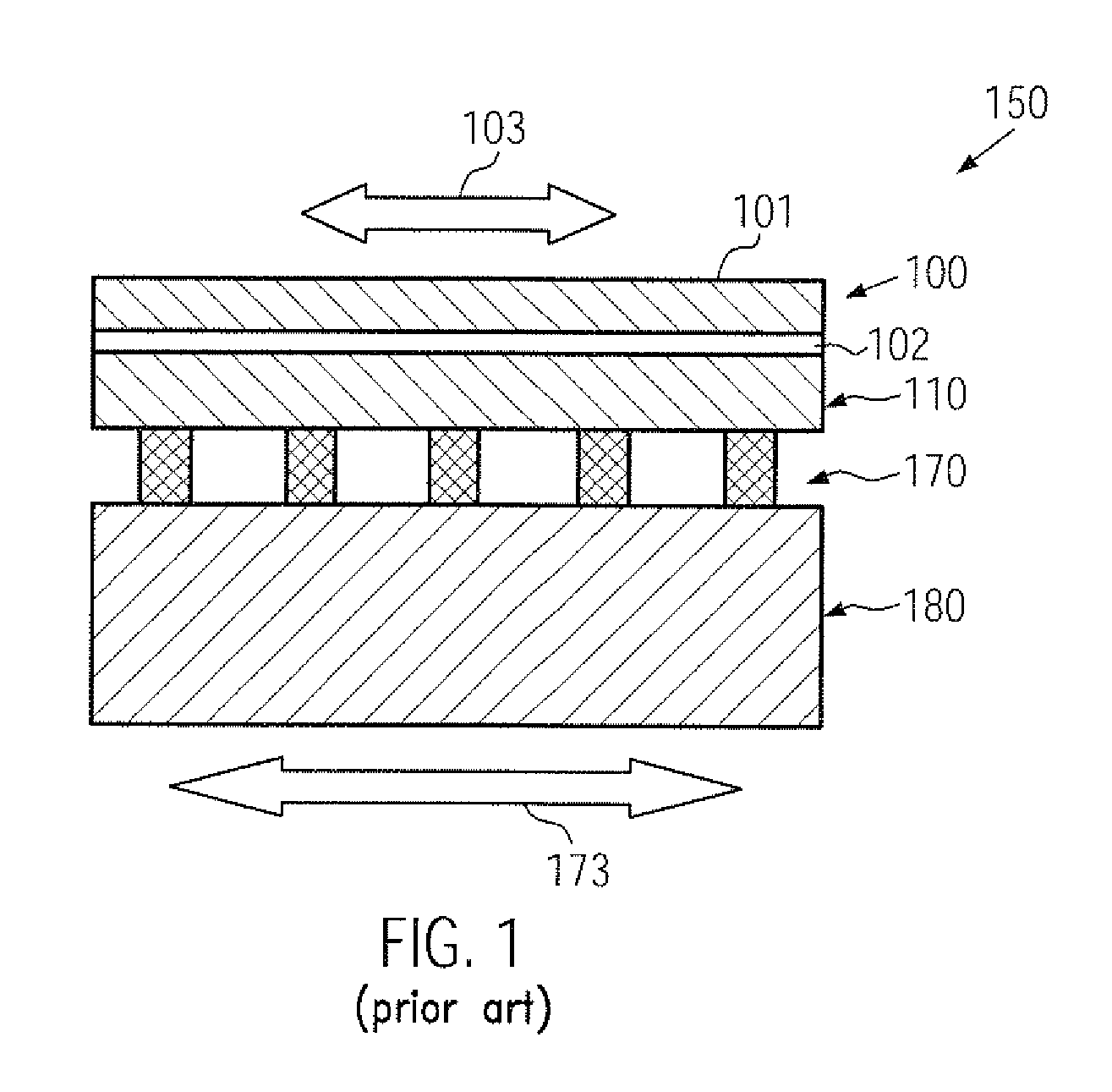

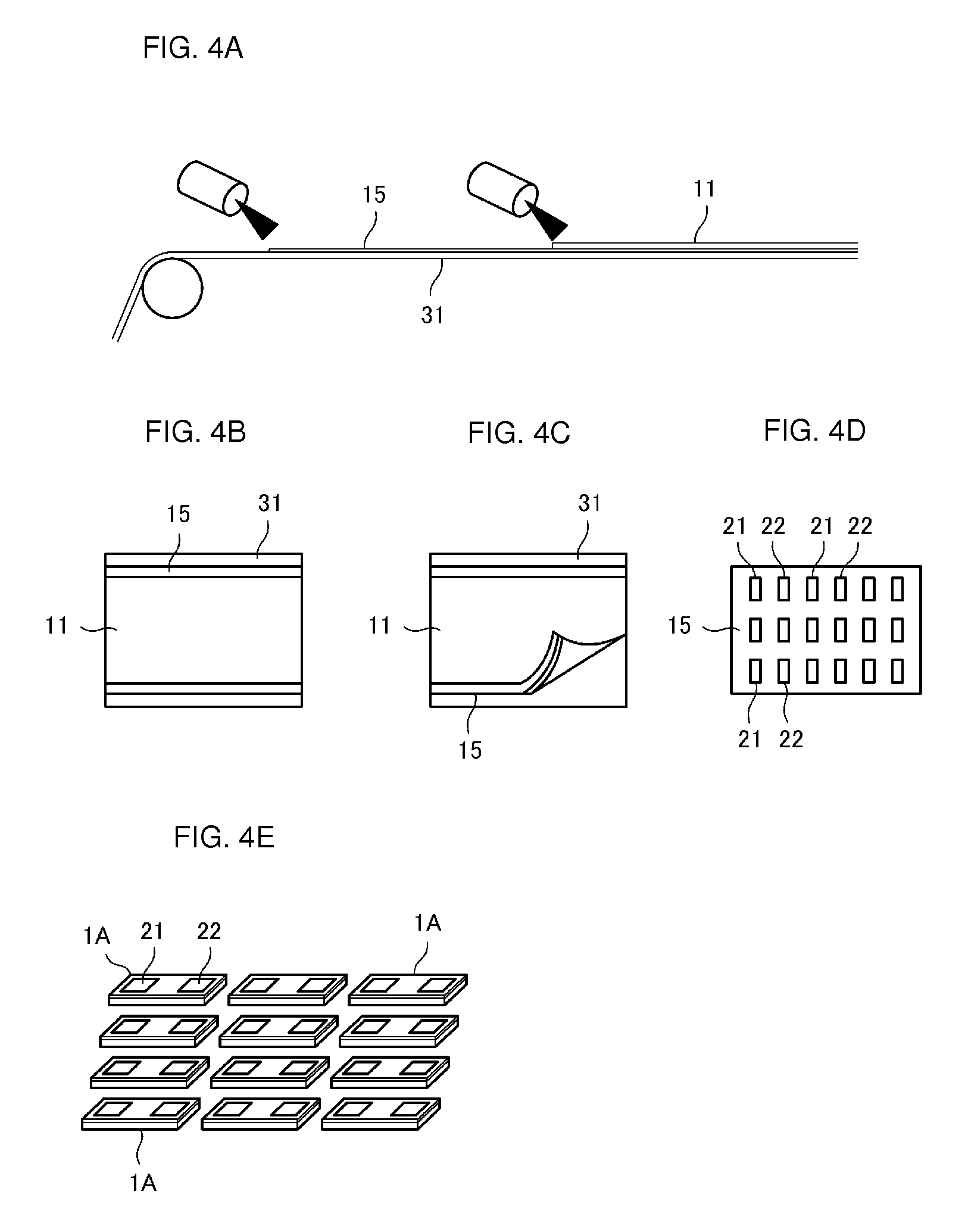

Semiconductor element mounting structure and semiconductor element mounting method

InactiveCN101578695AAvoid internal damageReduced extension areaSemiconductor/solid-state device detailsSolid-state devicesThermal expansionEngineering

On a substrate surface at a position facing an outer circumference end portion of a semiconductor element, a recessed section wherein a sealing adhesive resin is partially arranged is formed. Thus, while suppressing expansion of an arrangement region of a fillet portion (a portion spreading toward bottom) of the sealing adhesive resin, the inclination angle is increased. A stress load generated at the periphery of the semiconductor element due to thermal expansion differences and thermal shrinkage differences between members due to heating process and cooling process for mounting is reduced, and internal breakage of a semiconductor element mounting structure is eliminated.

Owner:PANASONIC CORP

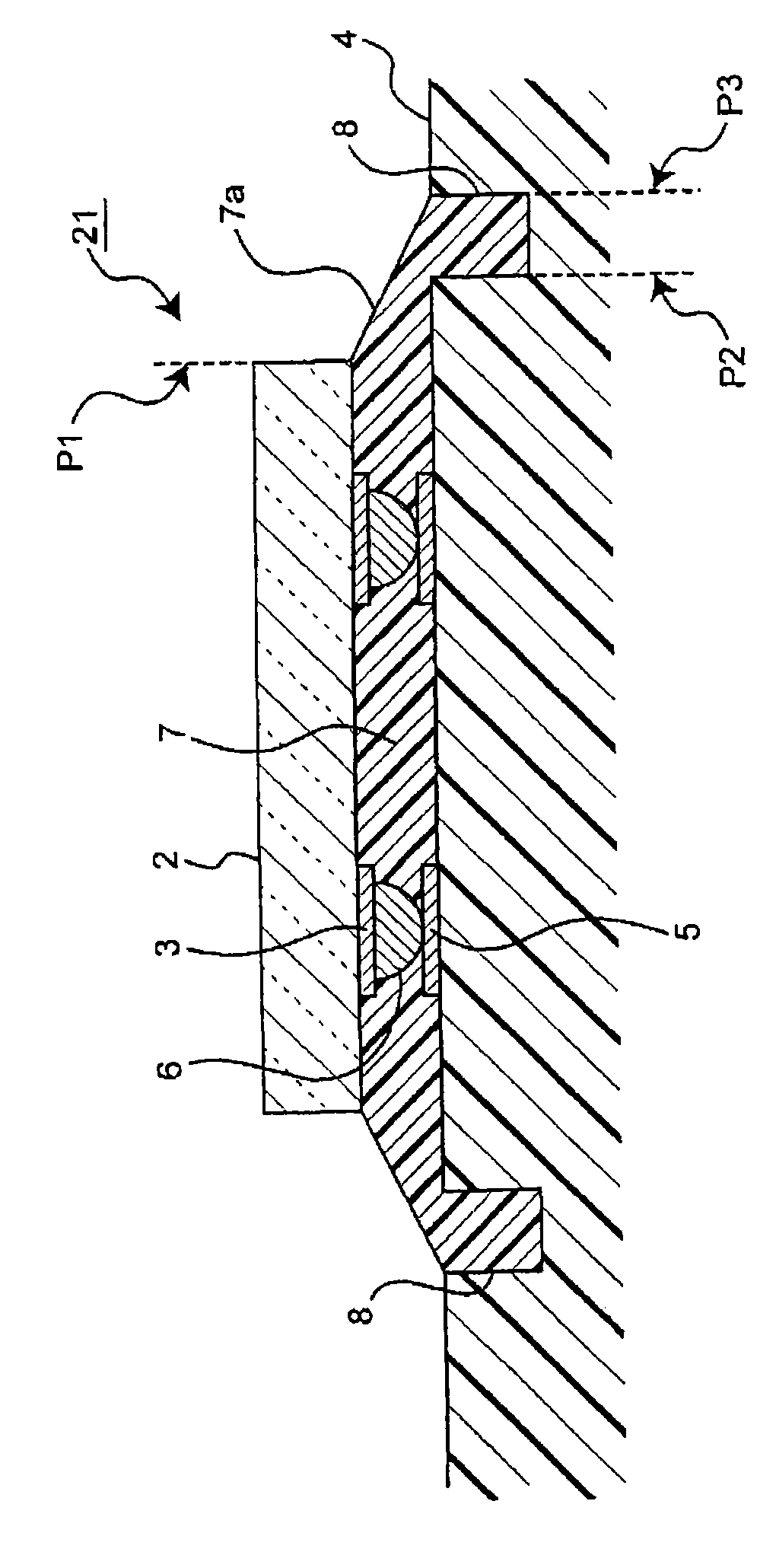

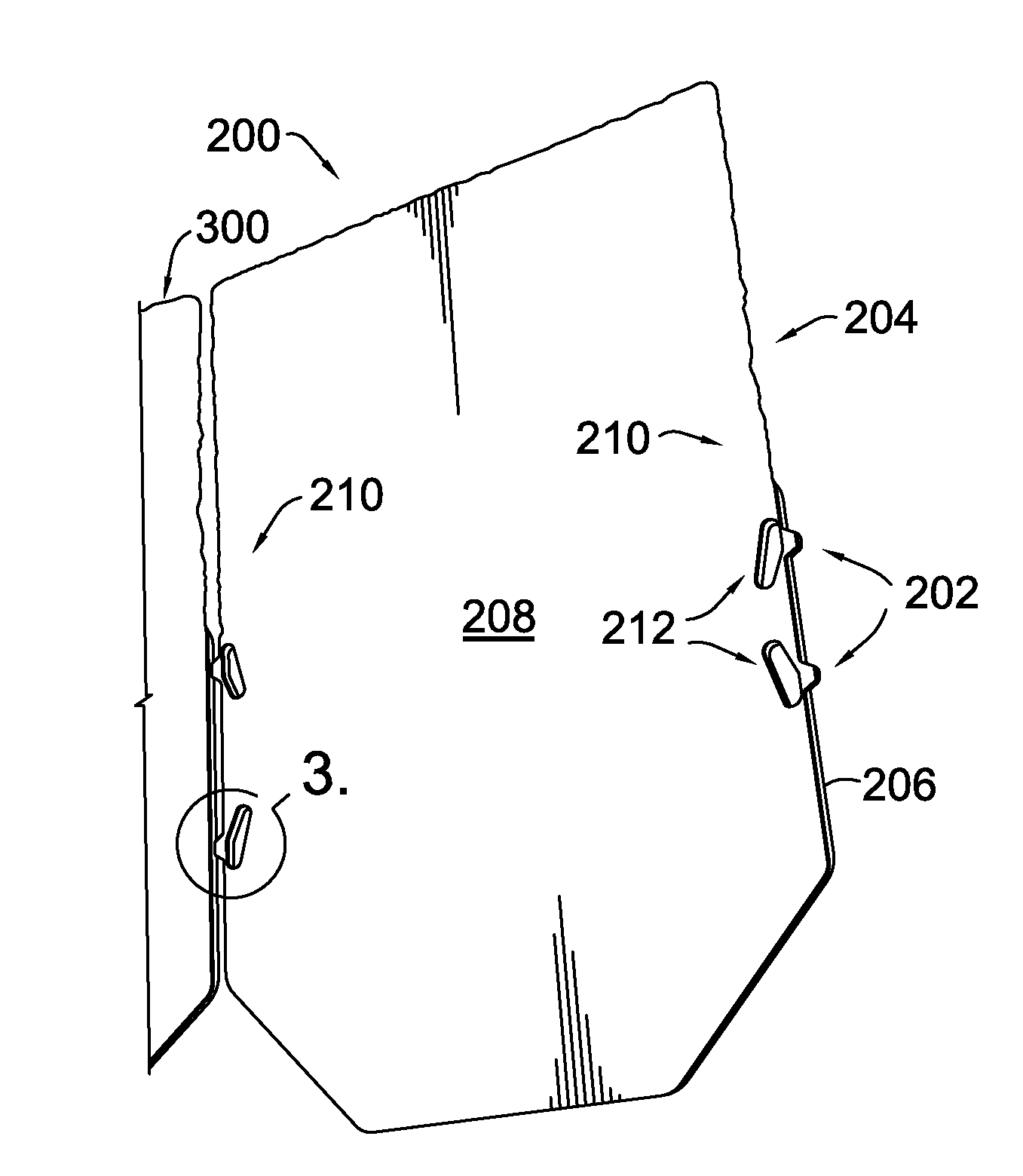

Roofing product possessing thermal expansion relief characteristics

InactiveUS7631461B2Reduce stress loadImprove system performanceRoof covering using tiles/slatesBuilding componentsThermal dilatationEngineering

Owner:TAMKO BUILDING PRODS

Valve

ActiveUS20110012044A1Increase stiffnessReliable designSpindle sealingsPlug valvesRotational axisEngineering

A valve includes a housing, a rotational body, two seat rings, a shaft integrally linked to the rotational body, and a sealing element. The rotational body is arranged rotatably in the housing and has a through-opening. The seat rings are spaced apart in the housing, each positioned against an outer surface of the rotational body to seal against leakage. The shaft extends outwardly through a housing opening. Part of the shaft has a spherical outer surface. The sealing element is positioned against the spherical outer surface, and includes a sealing lip and a support ring. The support ring has a spherical inner surface with a curvature corresponding to the spherical outer surface. The shaft is supported on the support ring at the shaft part's spherical outer surface. A flow path is defined by a housing through-opening and a rotational body through-opening, and is closed or at least partially open as determined by a rotational angle position of the rotational body about a rotational axis. The rotational body and shaft move together pivoting about a pivot axis that is orthogonal to the rotational axis. The pivot axis is determined by the shaft part's spherical outer surface.

Owner:XOMOX INT

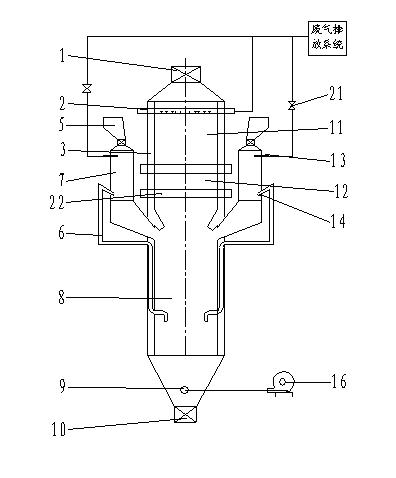

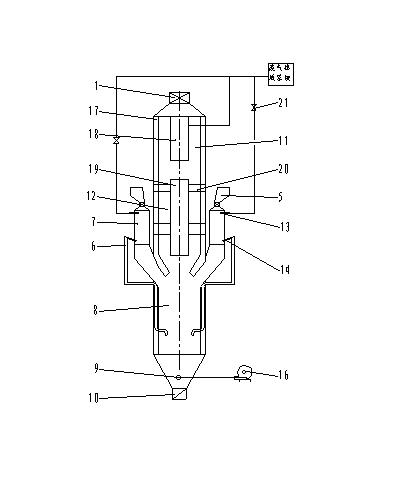

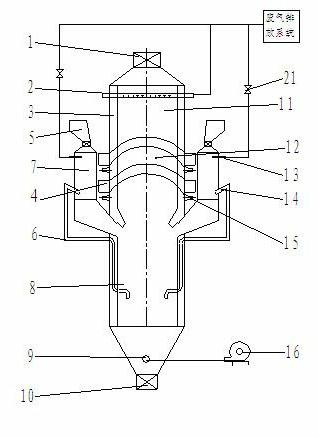

Compound lime kiln

ActiveCN102627418AEfficient use ofImprove calcination effectLime productionControl systemExhaust gas emissions

The invention relates to a compound lime kiln, comprising a kiln body, a charging equipment, a discharging equipment, a control system and an exhaust system.A preheating zone, a\calcining zone and a cooling zone are in the kiln body. A smoke outlet or a fume extractor is arranged in the preheating zone, and the smoke outlet or the fume extractor is connected with the exhaust system. A cooling tuyere is arranged in the cooling zone, and a cooling air inlet is connected with a cooling fan. Two to four granule kiln bins are arranged in the device. Granule hoppers, granule charging locks and cooling air outlets are arranged in the granule kiln bins. The underpart of the granule kiln bins are connected with the cooling zone. The cooling air outlet is connected with the exhaust system. Granule kiln bins are arranged in the device in the invention, exhaust gas after lime cooling is utilized to preheat granule limestone materials, and simultaneously large particle and granule materials are calcined, so that the preheating fully utilizes resources of limestones, effectively utilizes energy, reduces consumption and improves productivity. The cooling air does not enter the calcining zone, which is beneficial to an improving of calcining effects of the calcining zone, a reducing of a pressure load of the kiln body and an improving of qualities of the lime products.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

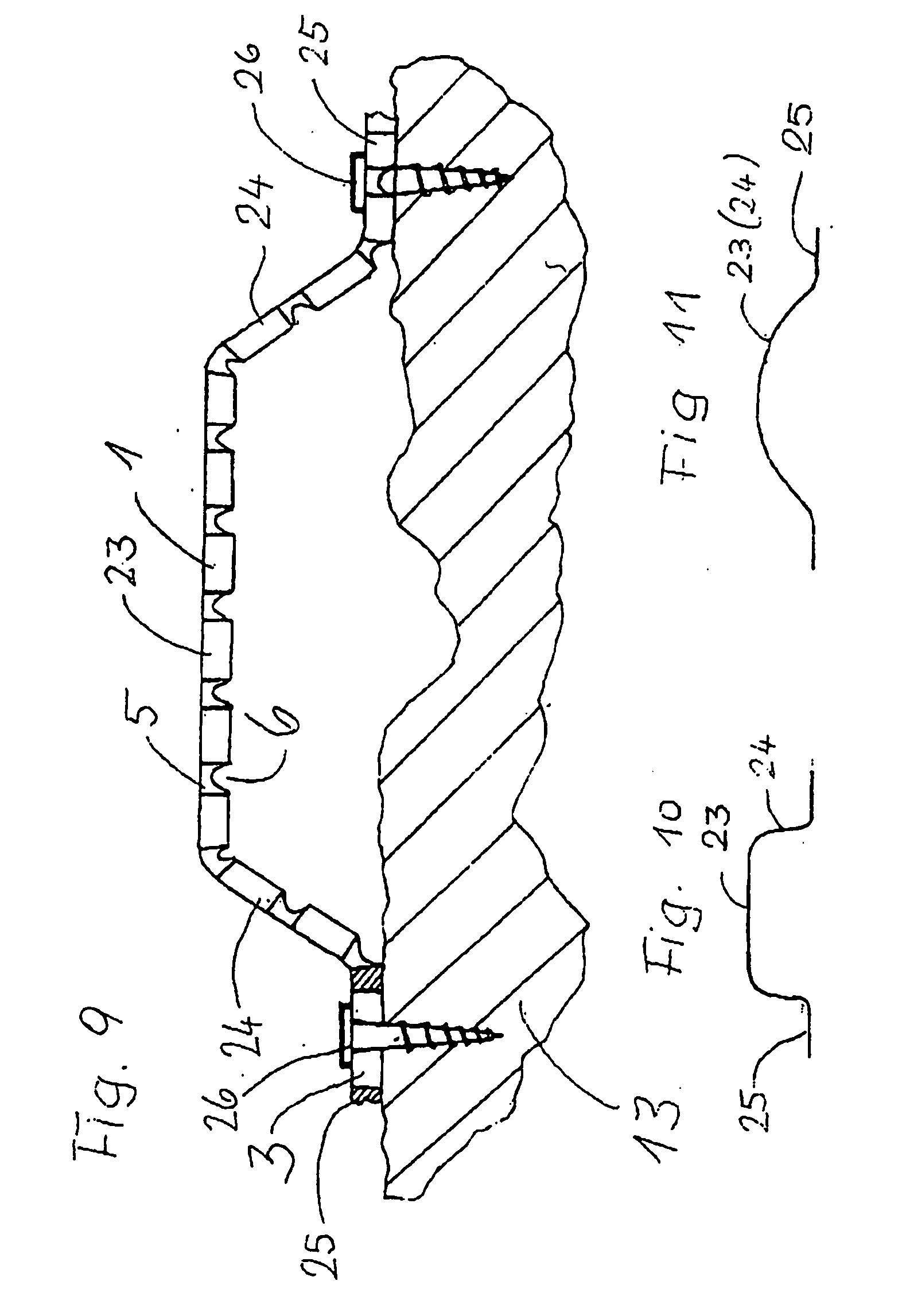

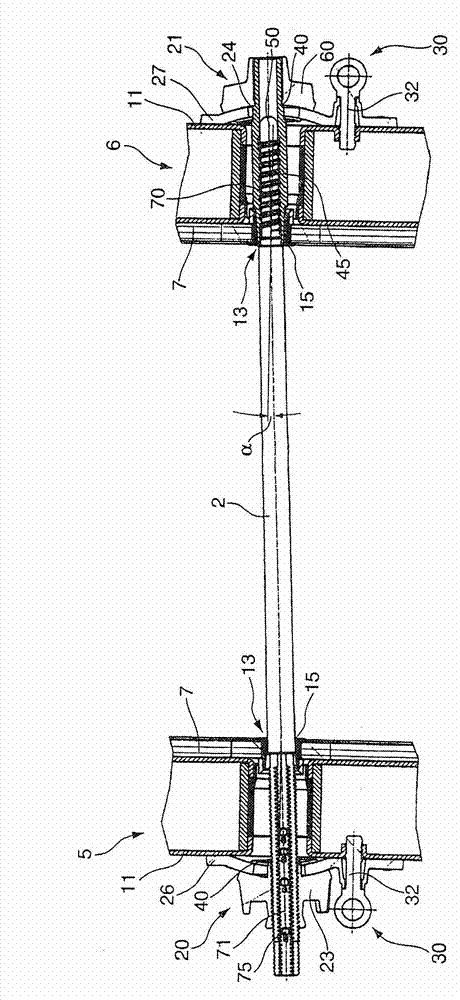

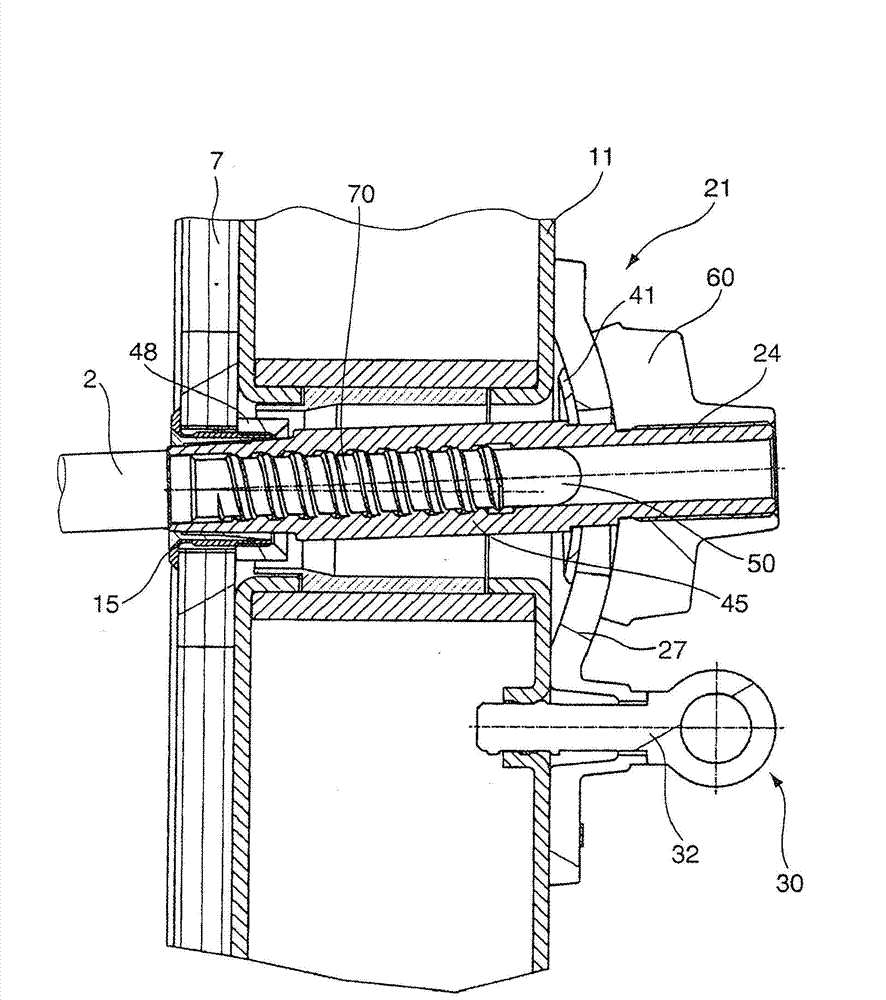

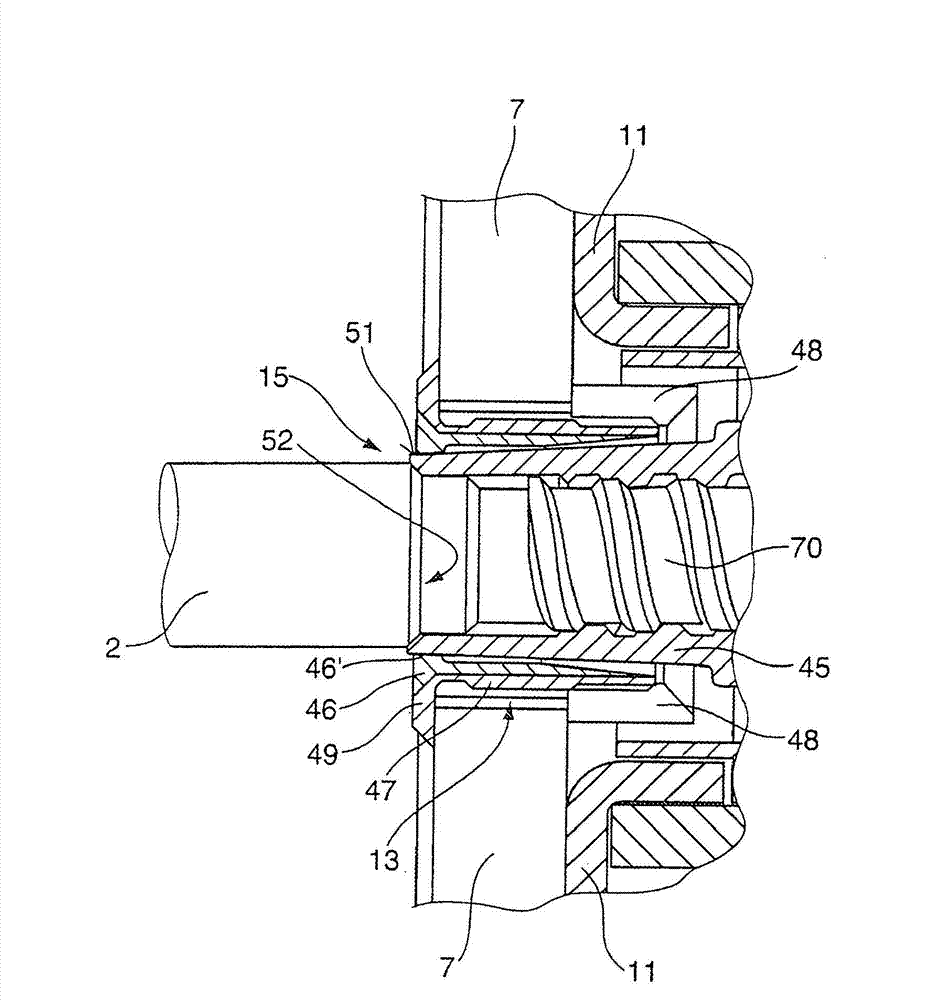

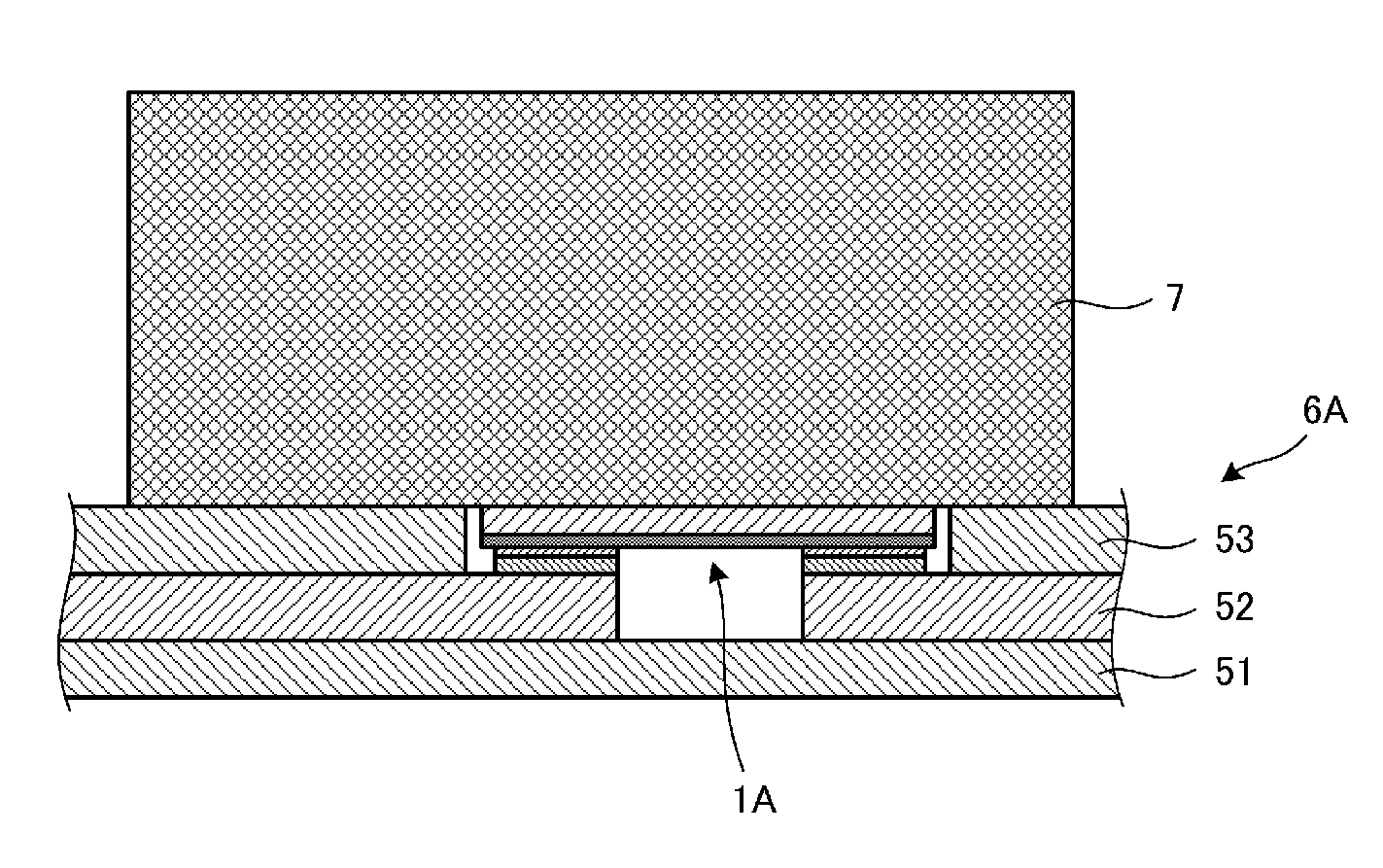

Anchor system of a concrete wall formwork

ActiveCN102791939AAvoid damageReduce stress loadAuxillary members of forms/shuttering/falseworksRubber elasticityArchitectural engineering

The invention relates to a locking device (21) for an anchor bar (2) of an anchor system of a concrete wall formwork, having a formwork element (6) comprising a formwork facing (7), having an annular sealing element (15) for sealing off an anchor penetration hole (13) in the formwork facing (7), a threaded nut element (24) for threading the anchor bar (2) into a threaded nut thread of the threaded nut element (24), and a cap plate (27) that can be fastened by means of fastening means (30) to a rear face of the formwork element (6) of the concrete wall formwork and comprises a spherically designed plate region having an opening in which the threaded nut element (24) is disposed having radial clearance, wherein the threaded nut element (24) comprises a groove-like radially circumferential receptacle (40) in which the edges of the opening in the spherical plate region are received, and wherein a tubular guiding device (45) flush with the threaded nut thread of the threaded nut element (24) is provided on the end of the threaded nut element (24) to be located at the concrete formwork side. The sealing element (15) thereby comprises an elastic rubber inner sealing ring (46) and the free end (51) of the guiding device (45) to be located at the formwork element side is sealingly inserted with the inner sealing ring (46) into the sealing element (15).

Owner:PERI欧洲公司

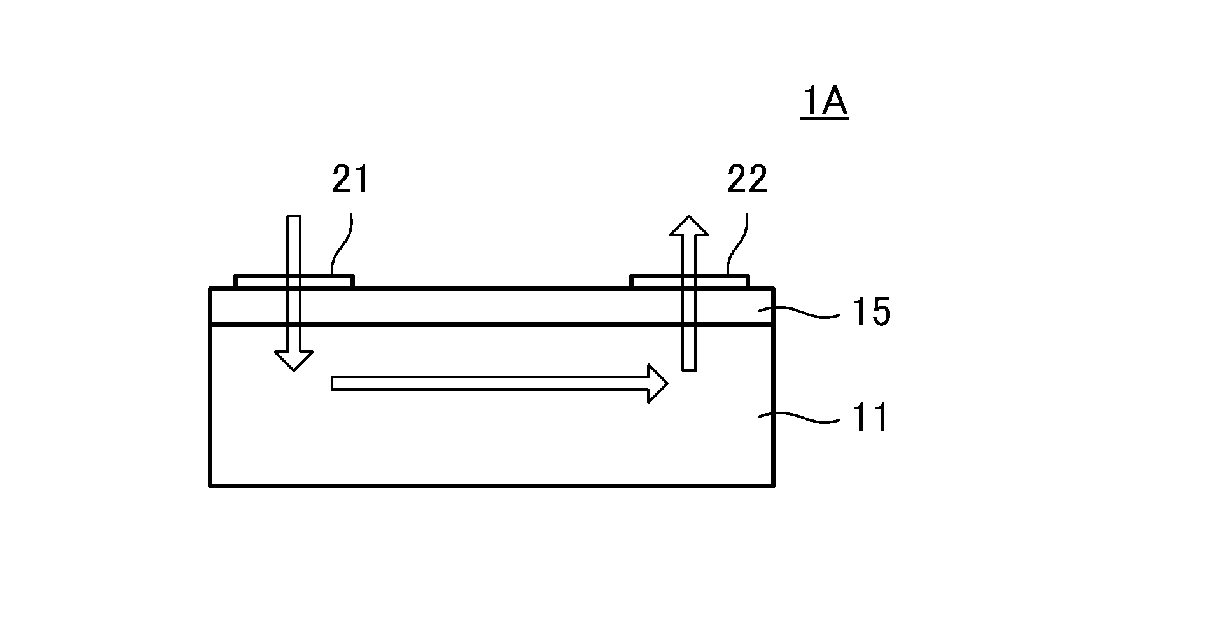

Temperature sensor and temperature sensor attaching structure

ActiveUS9316546B2Does not affect flexibilityDetectable heatingThermometer detailsThermometers using electric/magnetic elementsElectrical conductorThermistor

A flexible board includes a base layer, a wiring conductor layer that is located on the base layer, and a cover layer that is stacked over the base layer and covers the wiring conductor layer. A portion of the wiring conductor layer defines connecting portions that connect each of split electrodes of a flexible thermistor. The cover layer includes an opening that exposes the connecting portions, and receives the flexible thermistor. The split electrodes of the flexible thermistor are mounted on the connecting portions of the wiring layer. The height of the exposed surface of the flexible thermistor from the opening is substantially equal to the height of the surface of the cover layer.

Owner:MURATA MFG CO LTD

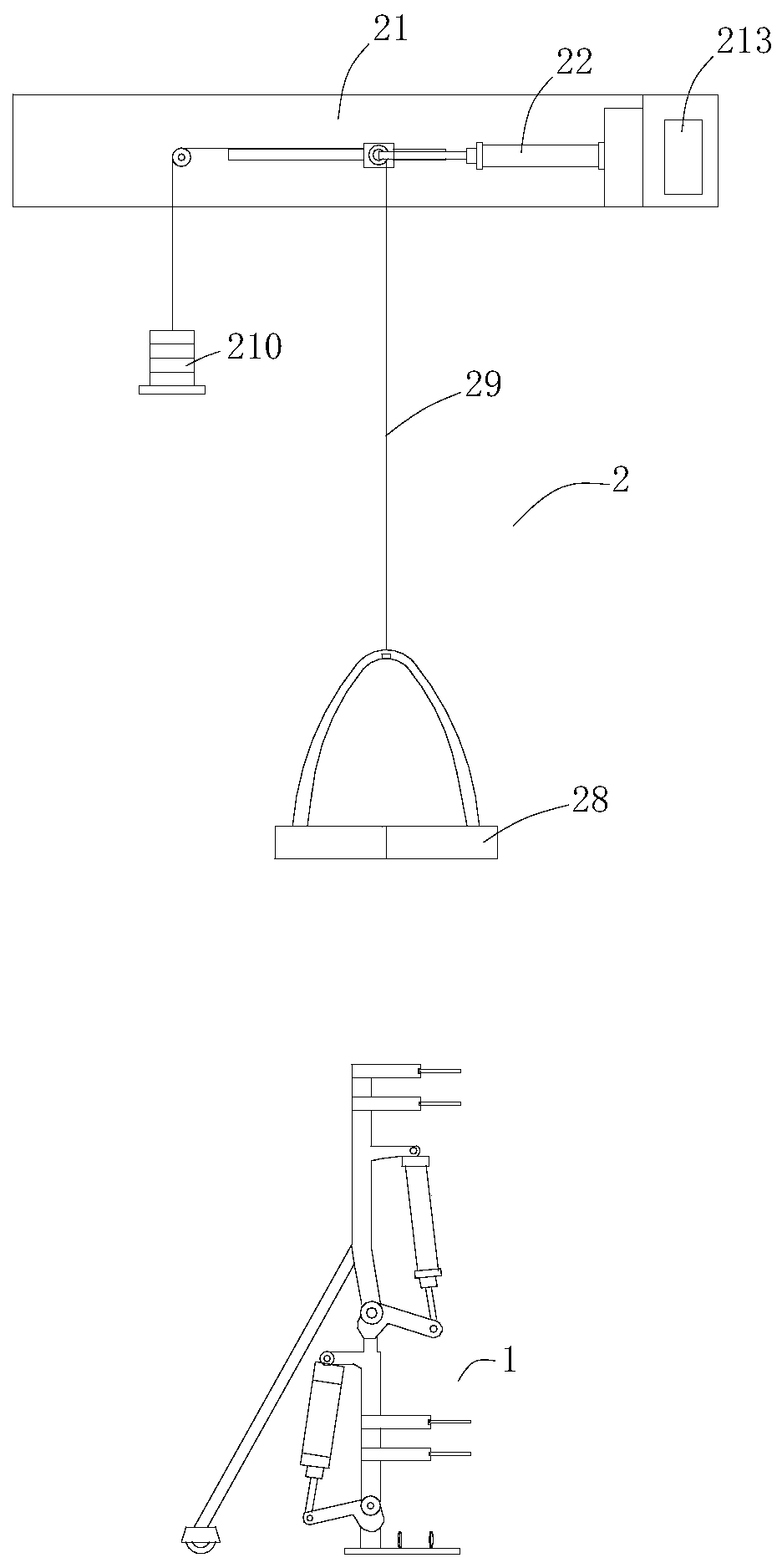

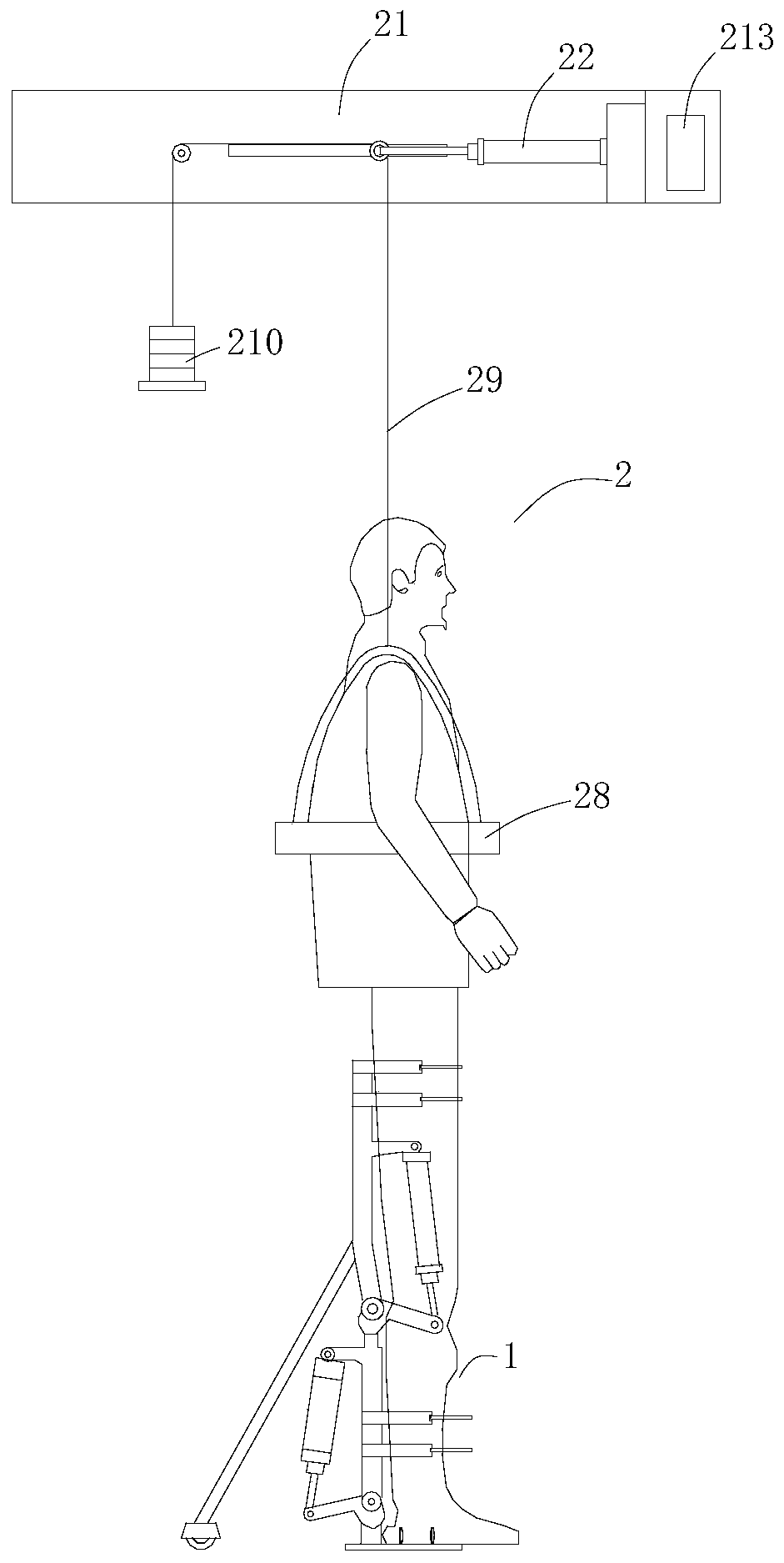

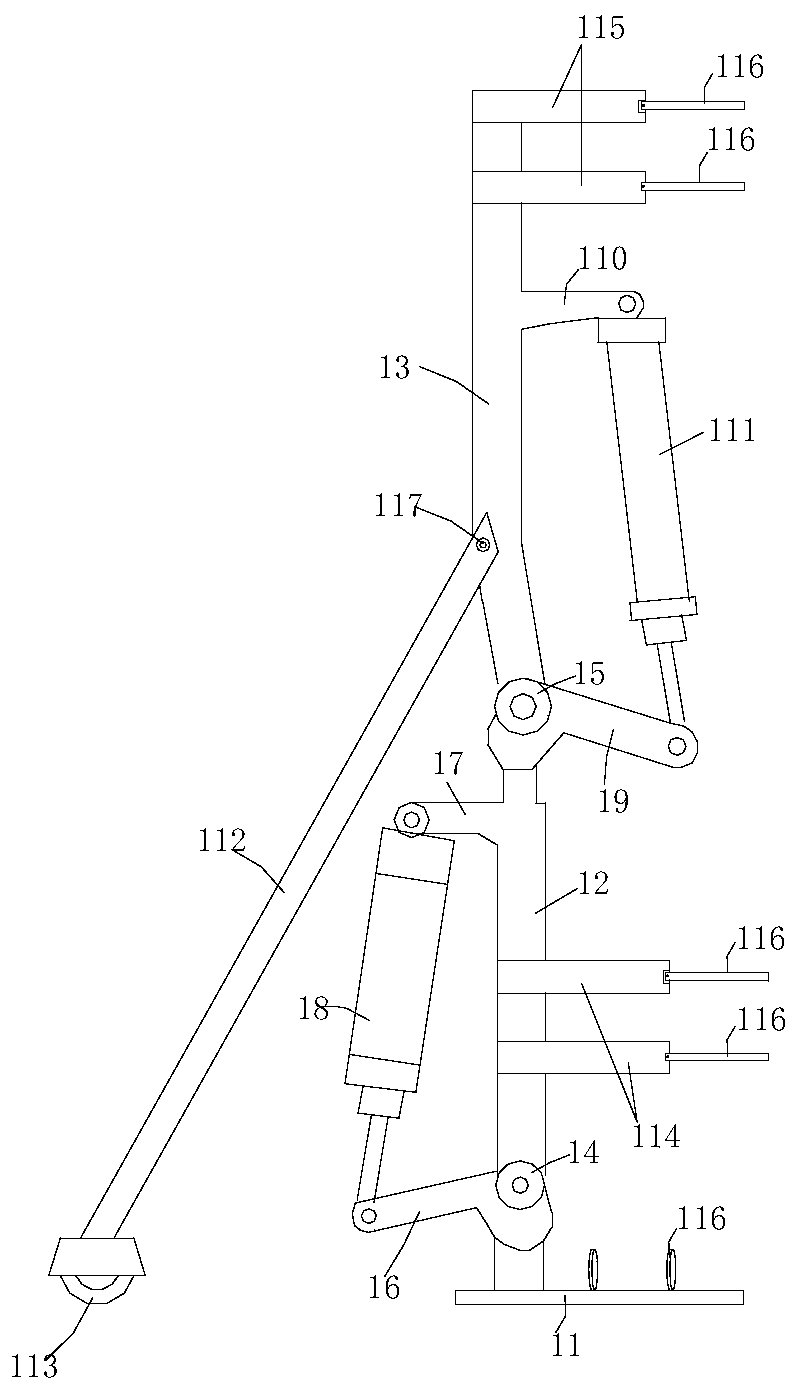

Interactive lower limb rehabilitation training system

The invention relates to an interactive lower limb rehabilitation training system. The system comprises a wearable lower limb rehabilitation robot body and a weight reduction traction mechanism arranged above the wearable lower limb rehabilitation robot body. The weight reduction traction mechanism comprises a hanging plate which is arranged above the wearable lower limb rehabilitation robot and is fixed, an air cylinder and a first roller are fixedly installed on the hanging plate, the end of an air cylinder rod of the air cylinder is fixedly connected with a sliding block, a fixing shaft isinstalled on the side face of the sliding block, the end of the fixing shaft is connected with a second roller, and a guide rail groove is formed in the hanging plate and located in the guide rail groove. A body binding sleeve is arranged between the hanging plate and the wearable lower limb rehabilitation robot, a steel rope is wound around a first rolling wheel and a second rolling wheel, a balancing weight is installed at one end of the steel rope, and the other end of the steel rope is connected with the body binding sleeve. The steel rope always plays a longitudinal traction role on the body binding sleeve, transverse traction force cannot be applied to a rehabilitative person, and therefore the effect of reducing the leg pressure load of the rehabilitative person is truly achieved, and the using effect is very good.

Owner:MBZ TIANJIN REHABILITATION EQUIP CO LTD

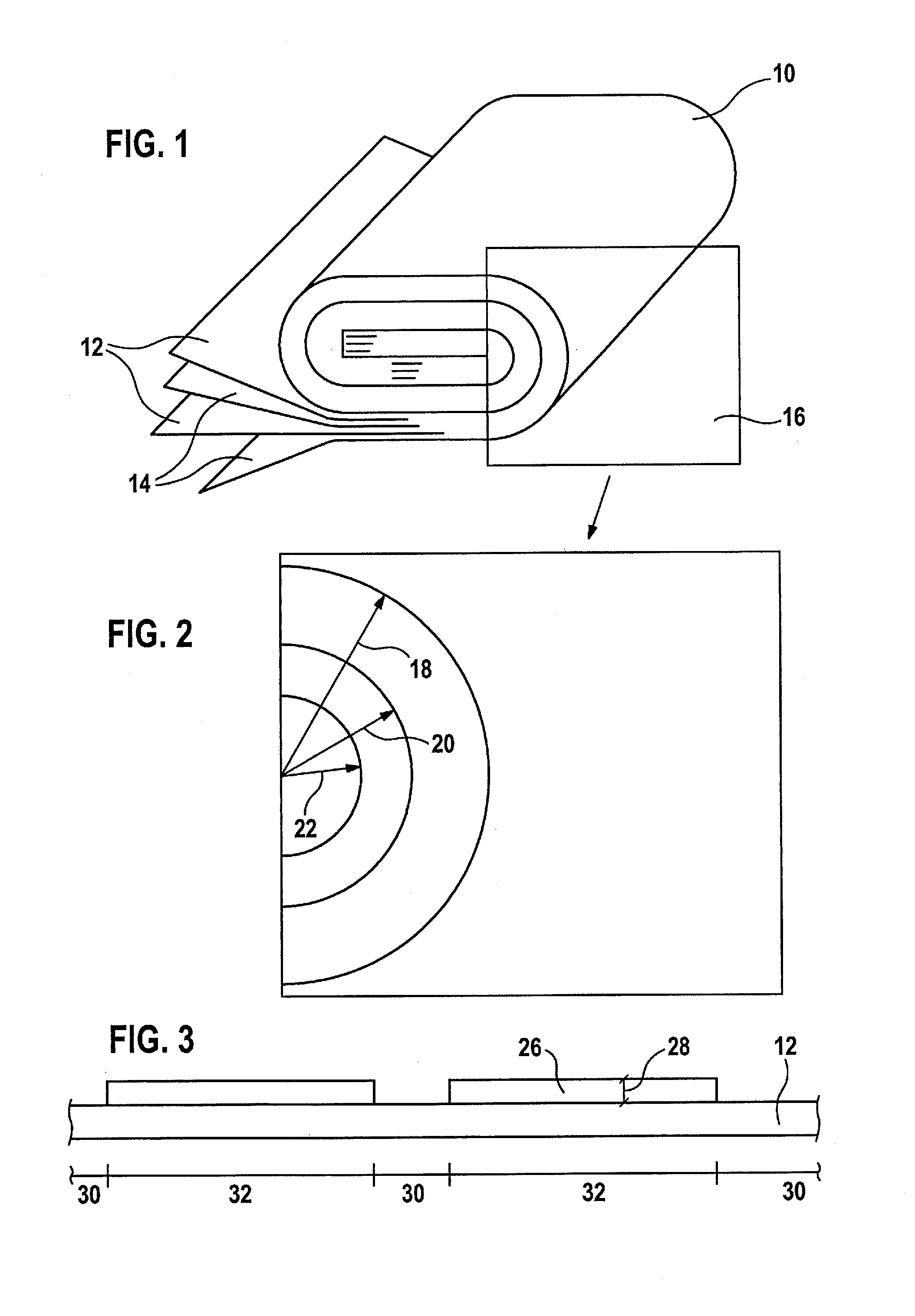

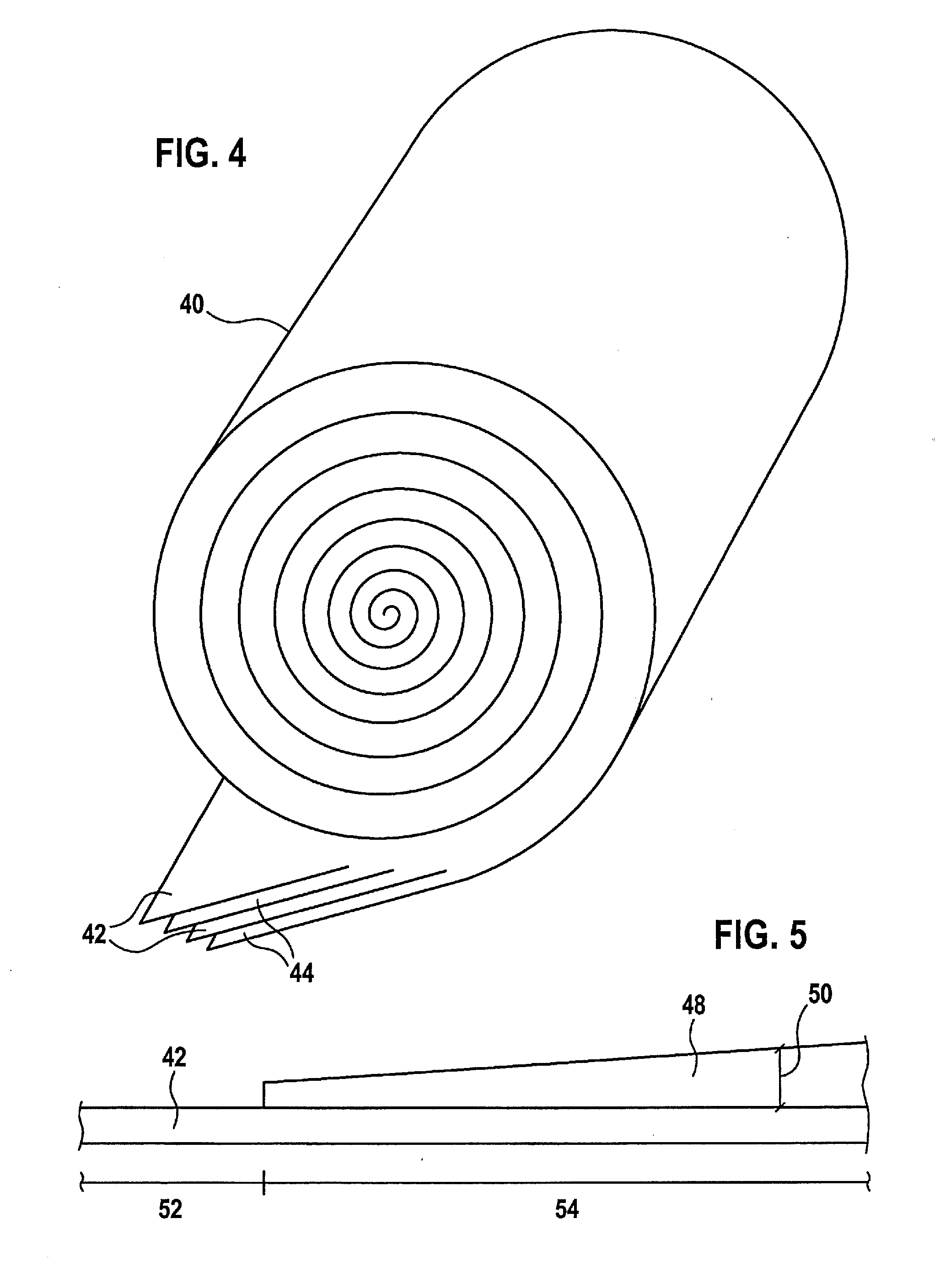

Cell coil of a lithium ion rechargeable battery and method for producing a cell coil

InactiveUS20140120395A1Stress resultingExtended service lifeFinal product manufactureElectrode carriers/collectorsEngineeringElectrical conductor

The invention relates to a cell coil of a lithium ion rechargeable battery, including at least two conductors (90) and at least two separators, the conductors (90) being separated from one another by the separators; the active material (92) being applied onto the conductors (90); the thickness (94) of the active material varying along the conductors (90). By varying the thickness (94) of the active material along the conductors (90), the service life of the cell coil is increased and an increased storage capacity is able to be implemented.

Owner:ROBERT BOSCH GMBH

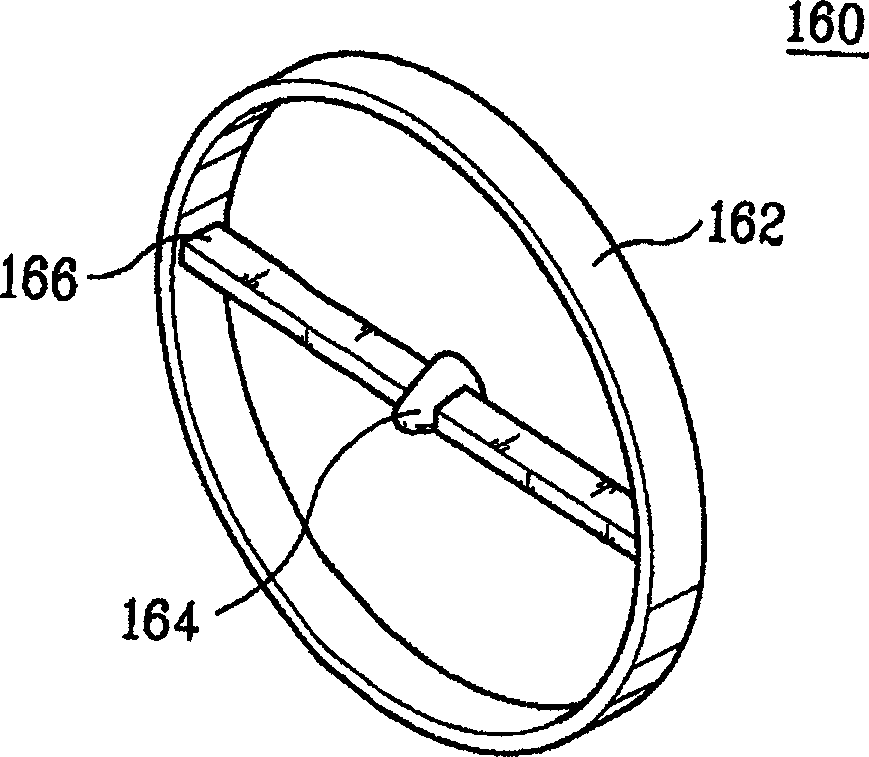

Refrigerant filtering apparatus for air conditioners

InactiveCN1773196ALow operating efficiencyLow flow resistanceSpace heating and ventilation detailsRefrigeration componentsEngineeringRefrigerant

The invention discloses a refrigerant filtering device for an air conditioner, which can filter the refrigerant to remove impurities from the refrigerant. The refrigerant filtering device includes: a refrigerant flow channel; a filter net that is formed into a tapered shape and installed in the refrigerant flow channel so that the top of the filter net is disposed on the upstream side in the refrigerant flow direction, and the filter net The circumferential portion of the mesh is disposed on the downstream side along the refrigerant flow direction, the filter mesh is used to filter the refrigerant to separate impurities from the refrigerant, and the filter mesh is configured to allow impurities to collect on the filter mesh and the refrigerant flow channel and a sediment cup for collecting impurities, the sediment cup is detachably connected to the refrigerant flow channel.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com