Patents

Literature

41results about How to "Reduce structural loads" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

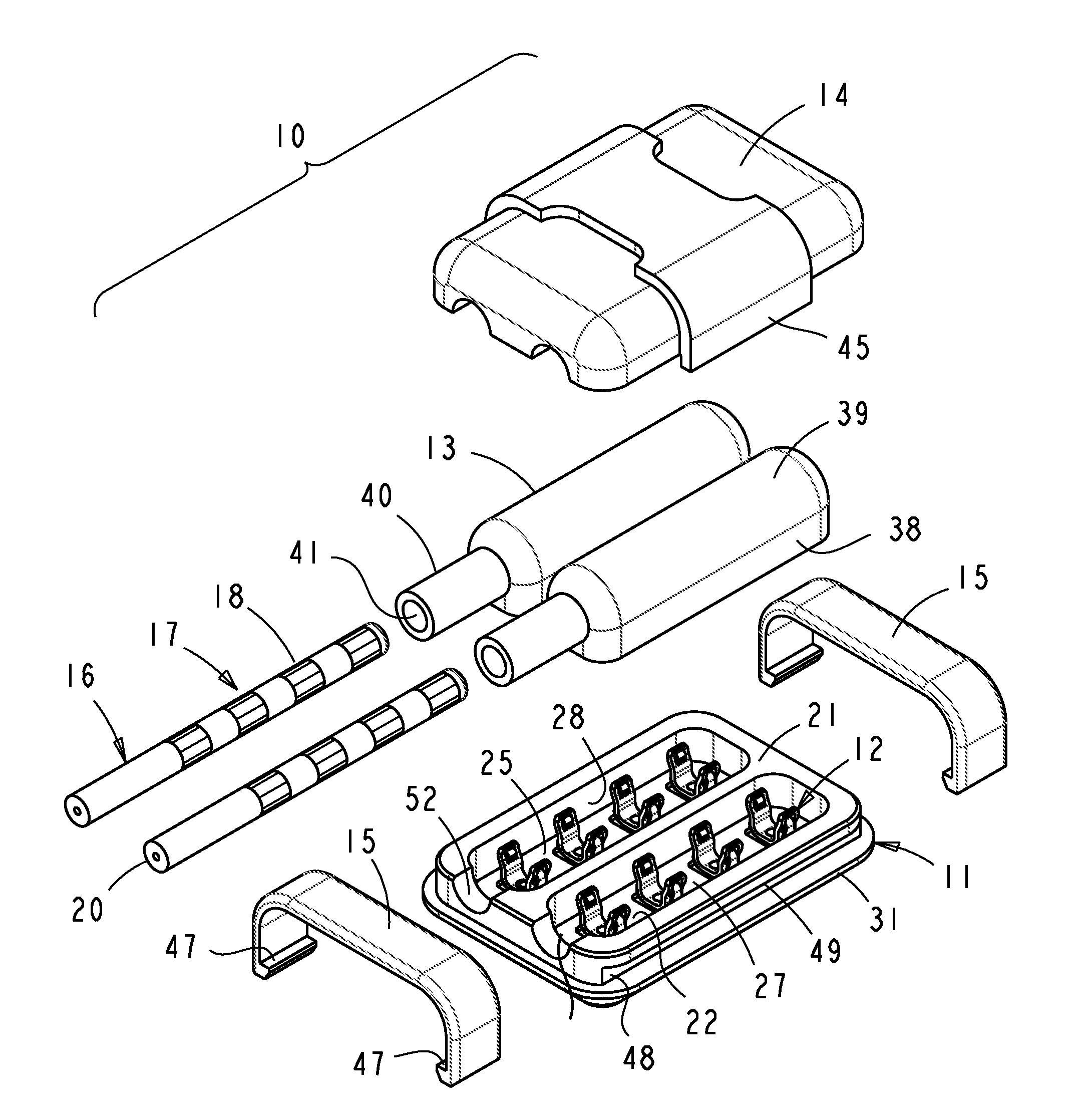

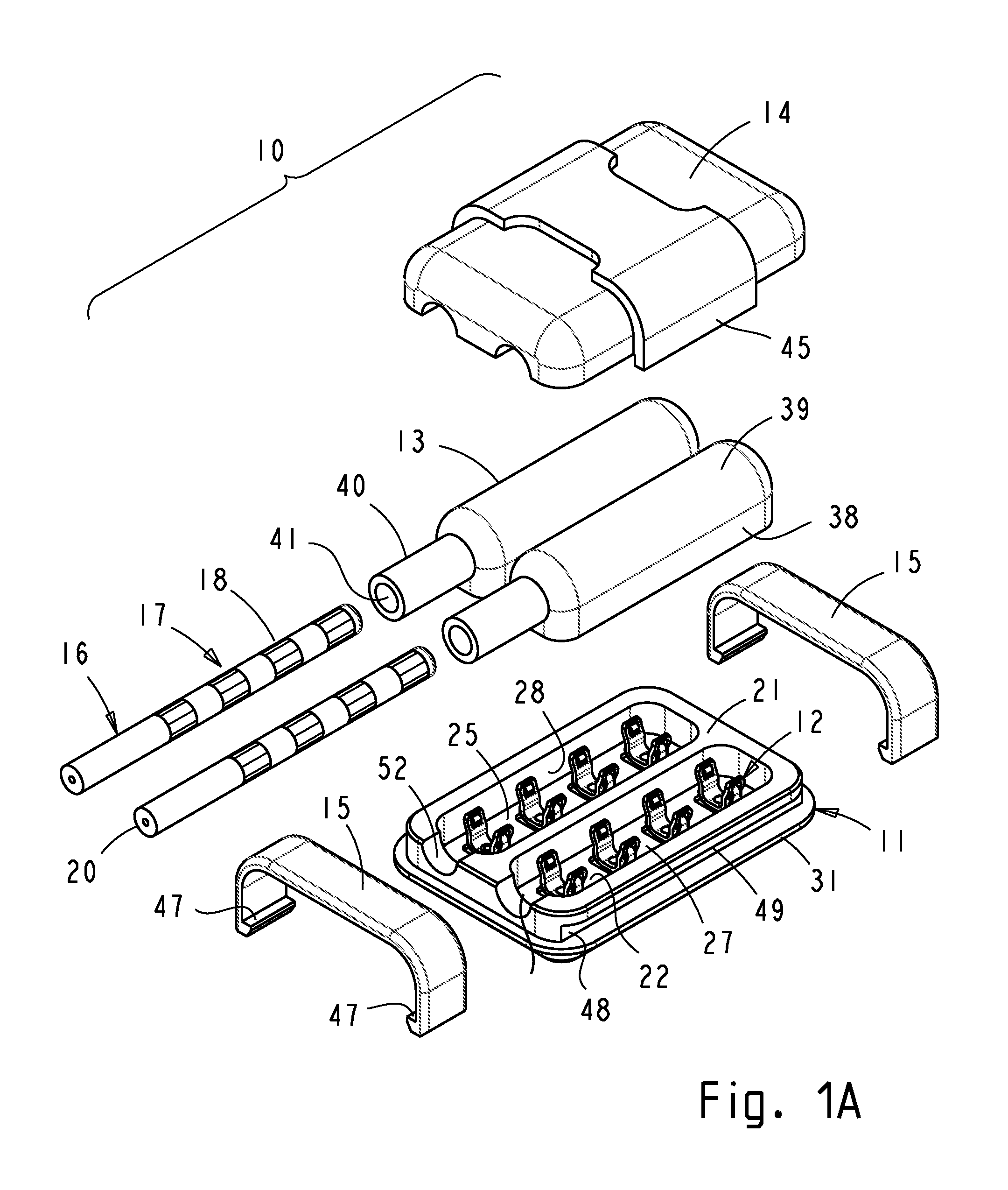

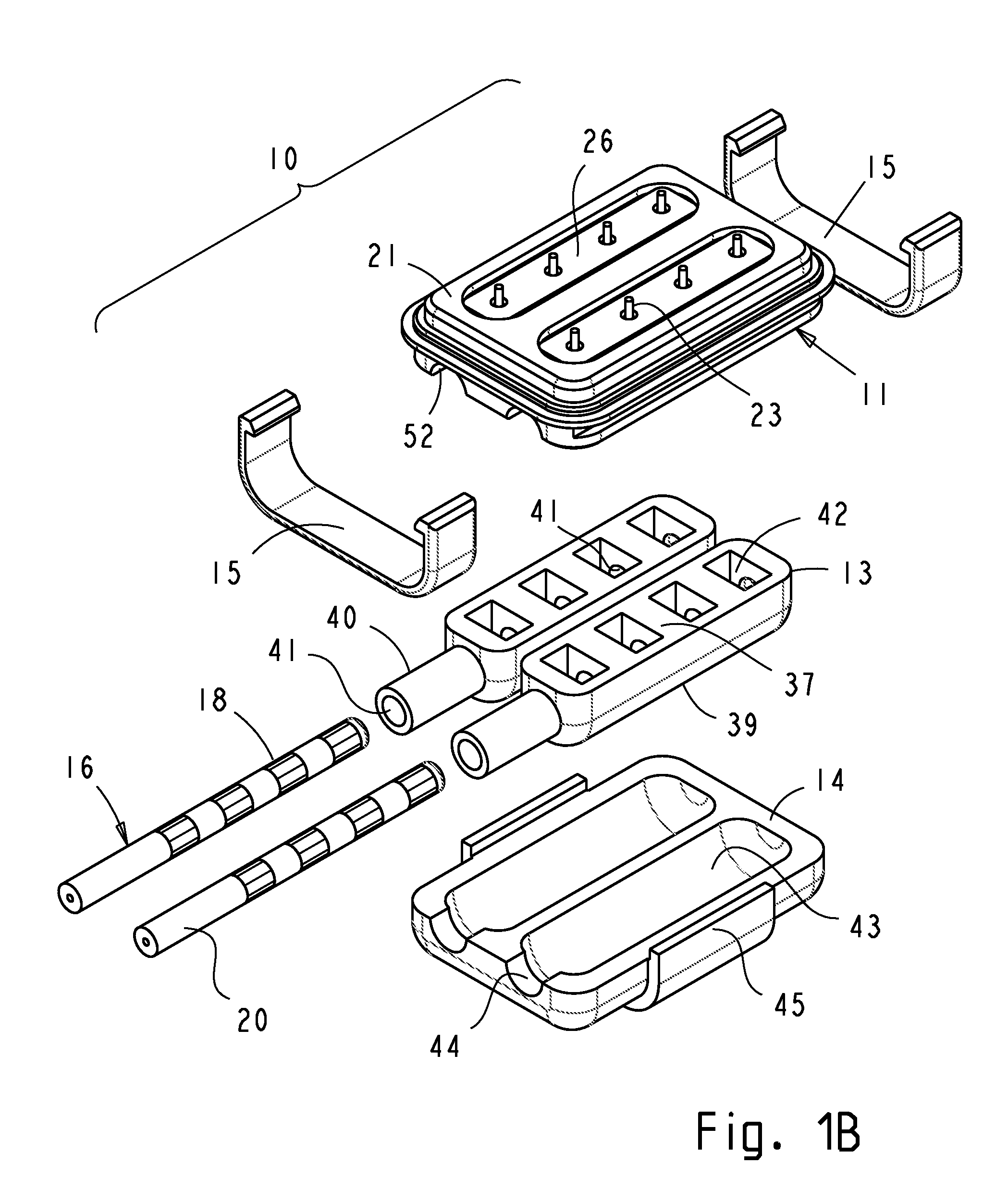

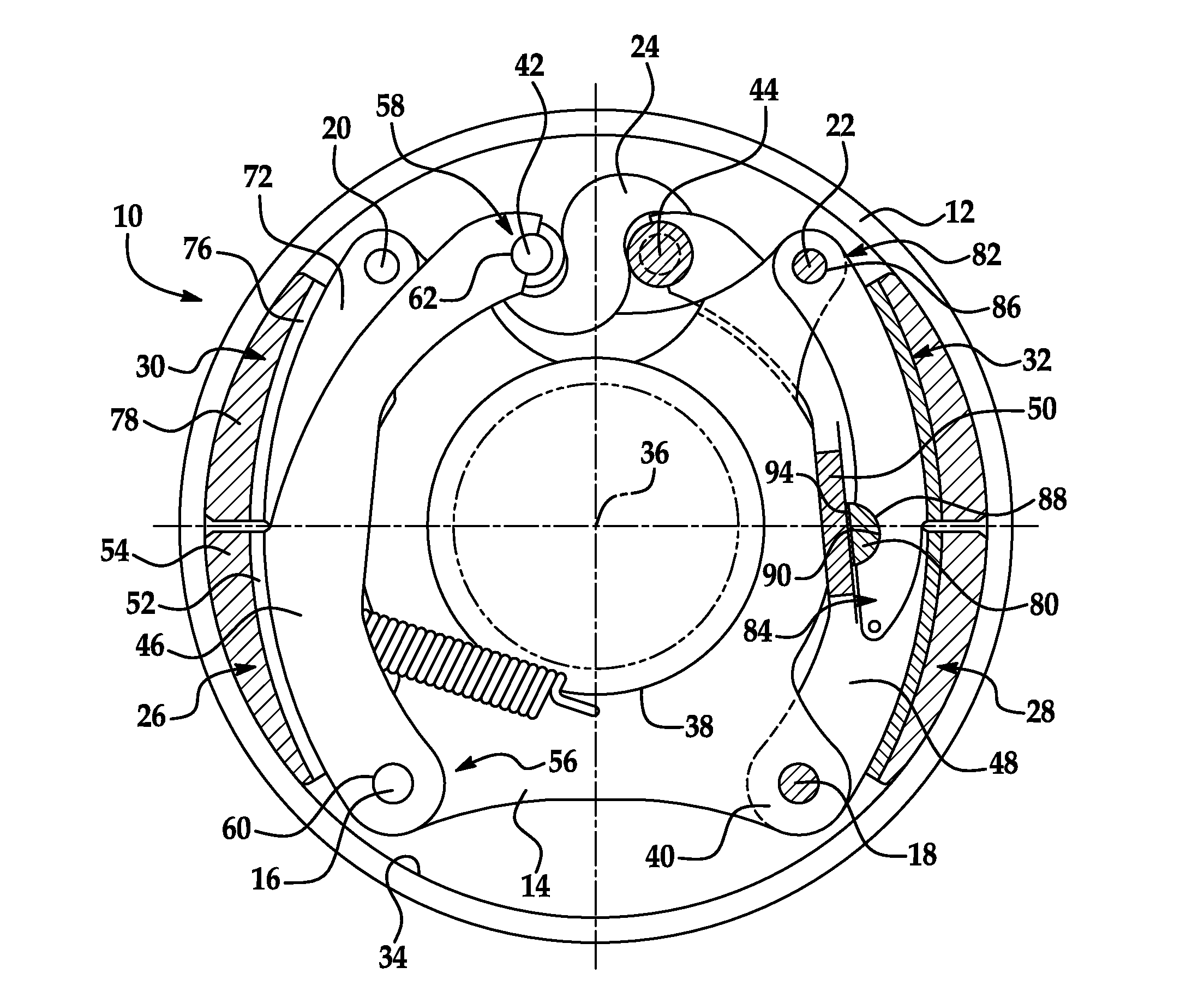

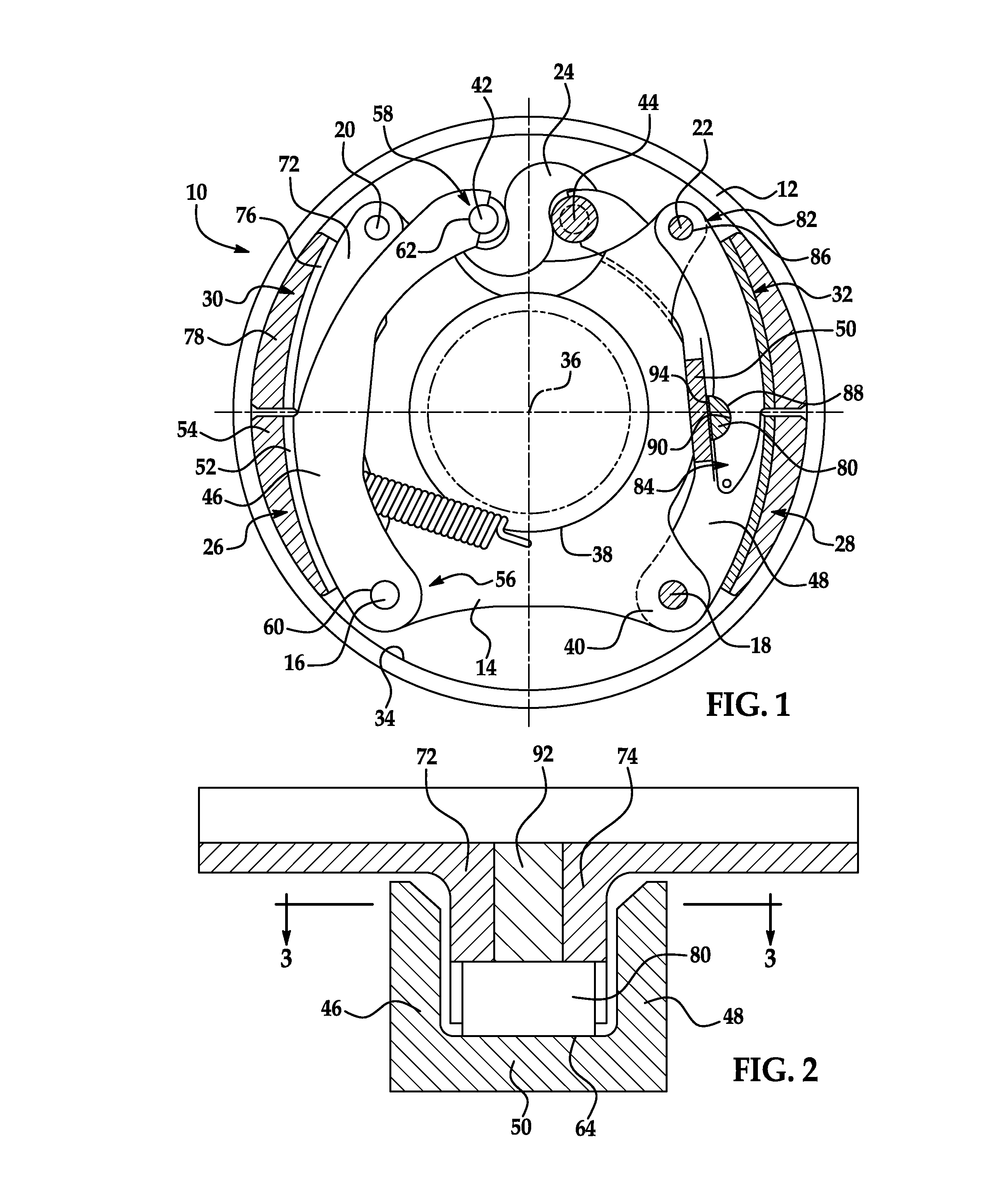

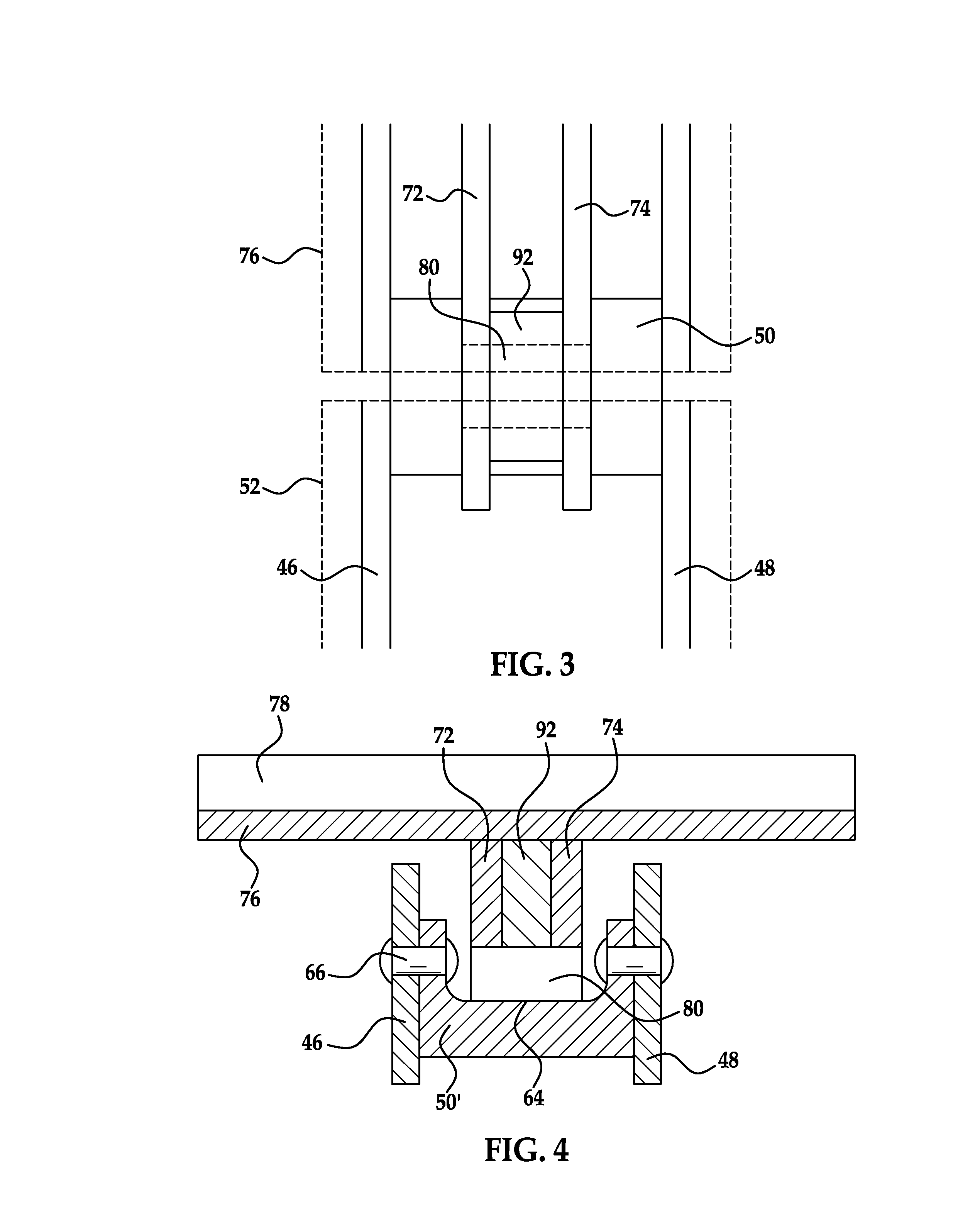

Implantable connector with protected contacts

InactiveUS7736191B1Avoid deformationAvoid accidental damageElectrotherapyCoupling device detailsElectrical conductorMedical device

An implantable connector electrically connects multi-conductor leads to an implantable medical device such as a neurostimulator. The connector is assembled directly into a hermetic feedthrough of the implantable device and utilizes the feedthrough housing as a sustaining structure for connector clamping. The receptacle contacts detachably connect proximal lead contacts to corresponding feedthrough pins, which provide pass-through connections to electronic circuitry contained in a hermetically sealed case. The receptacle contact has resilient contact tines designed to engage a corresponding lead contact in a sliding manner. The receptacle contact is integrated with a contact guard which protects the receptacle contact from inadvertent handling damage. The contact guard is substantially more rigid than the resilient contact to resist deformation. The contact guard protectively shields the receptacle contact tines and prevents unintended contact tine excursion. In one embodiment, the contact guard is pre-attached to the receptacle contact prior to joining to the feedthrough pin. In another embodiment, the contact guard is an integral part of the feedthrough pin. Numerous embodiments with contact preload are provided.

Owner:SOCHOR JERZY ROMAN

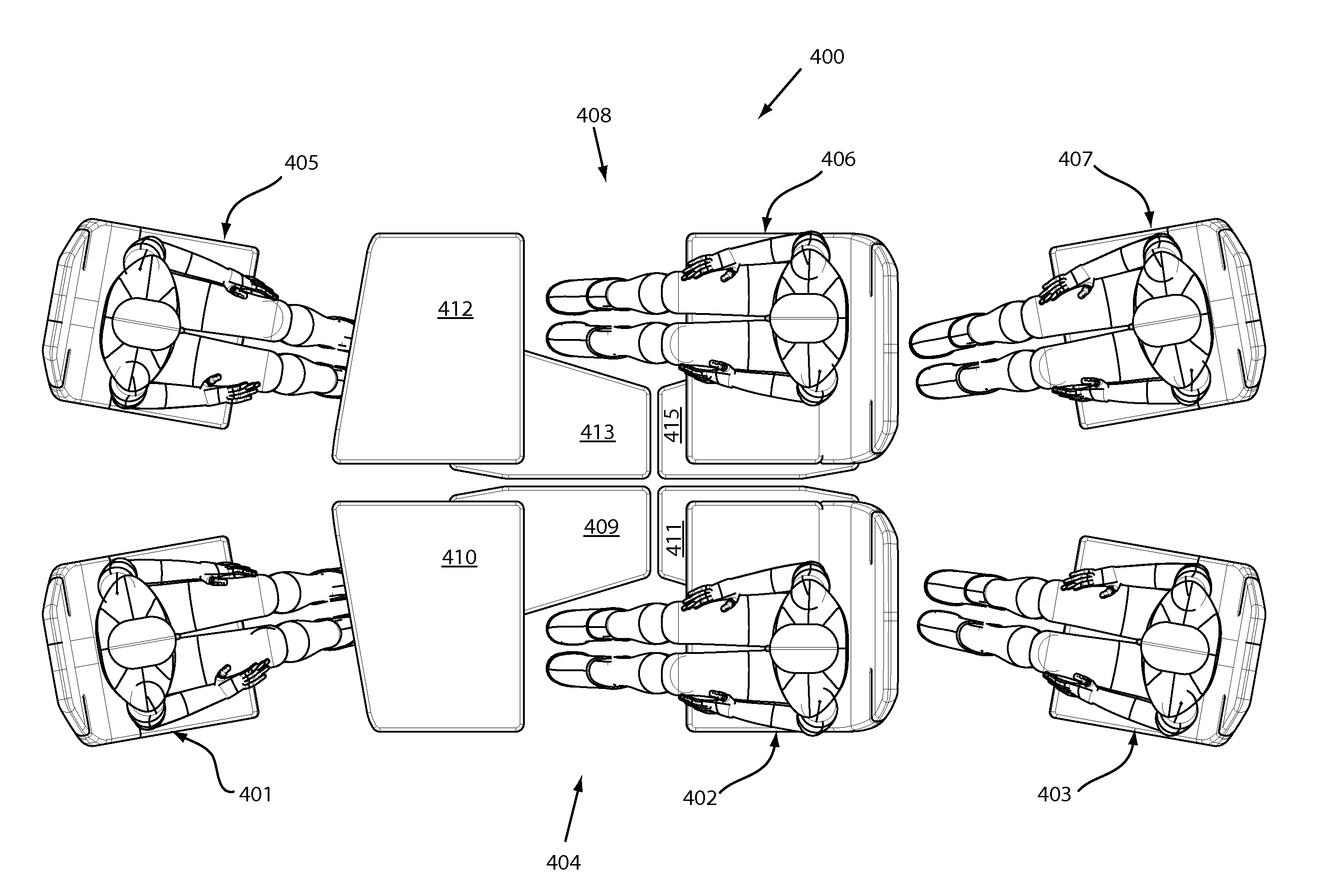

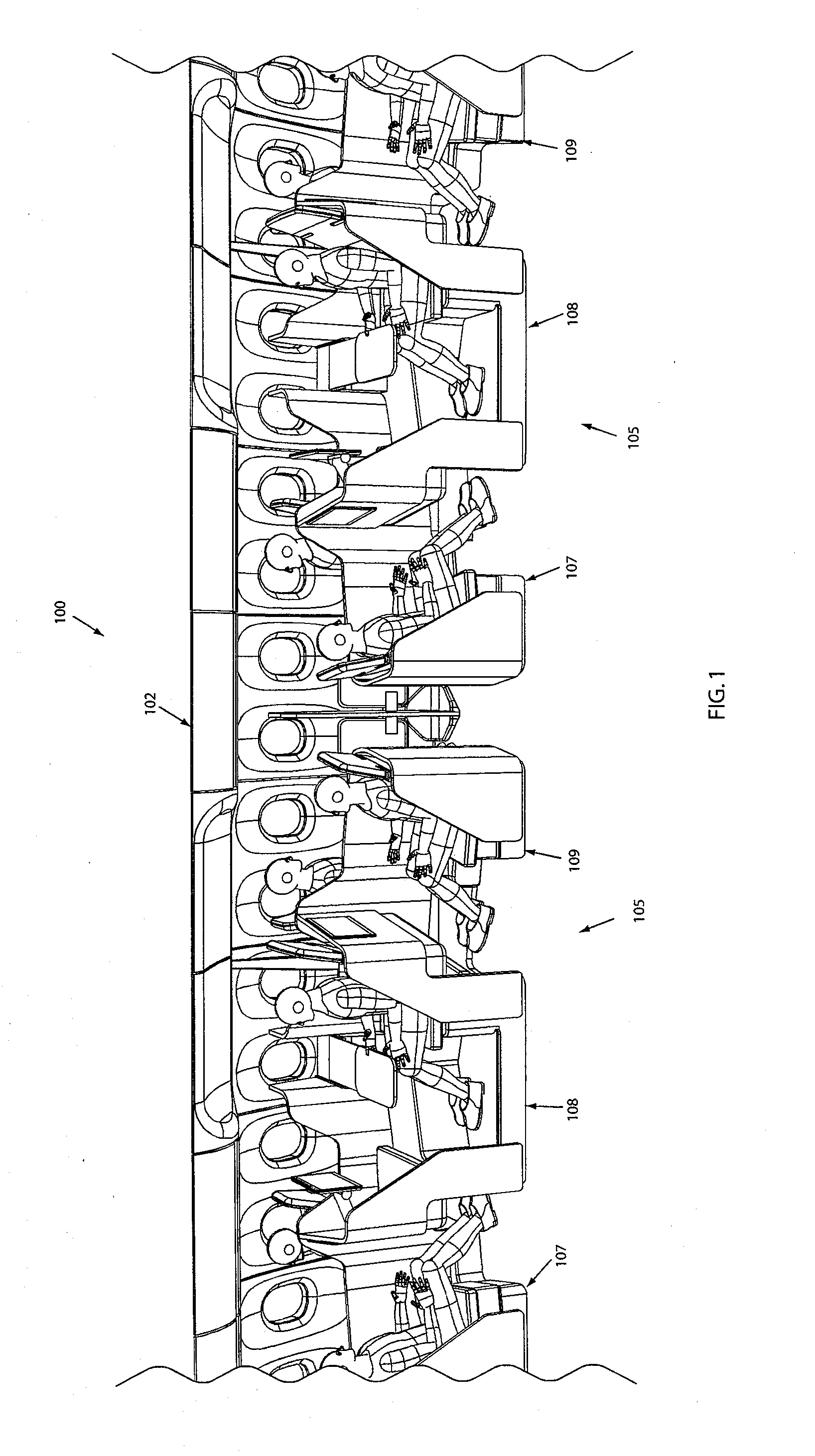

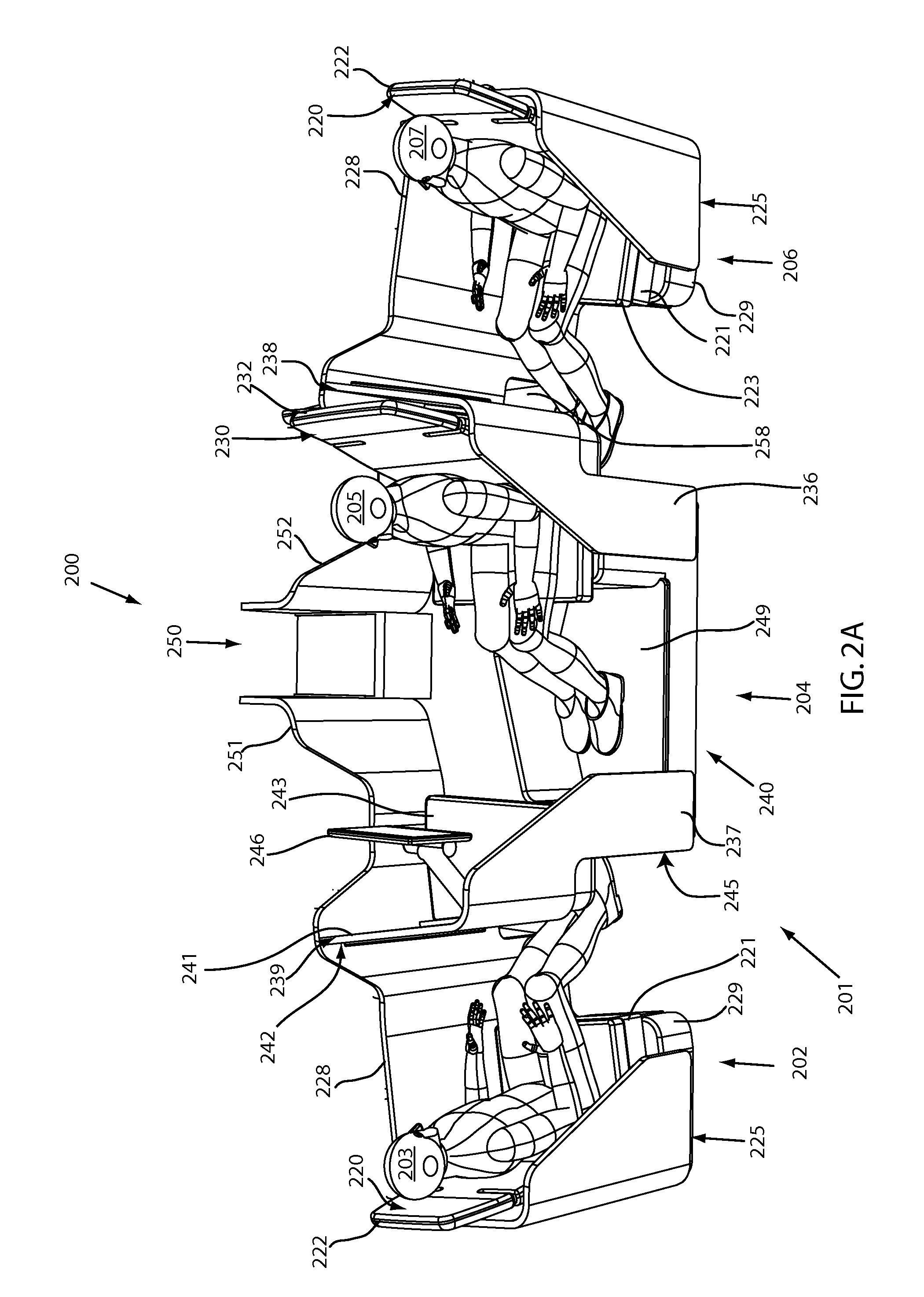

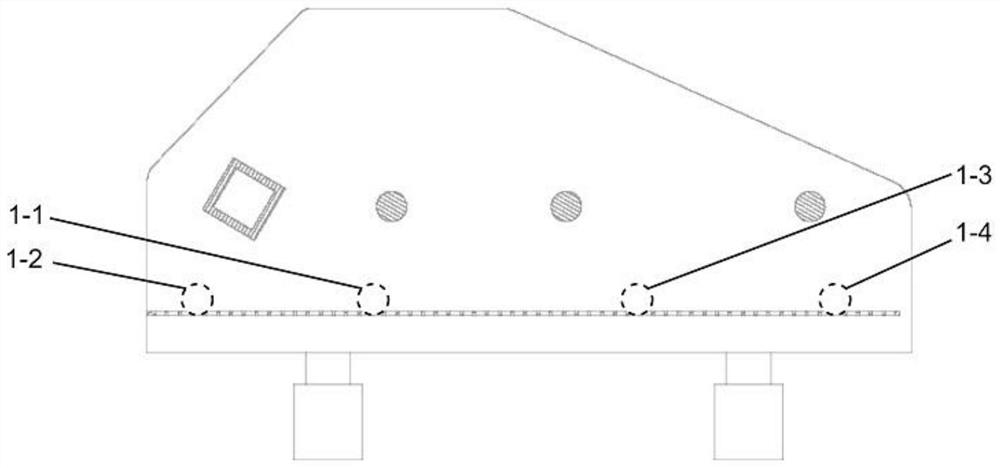

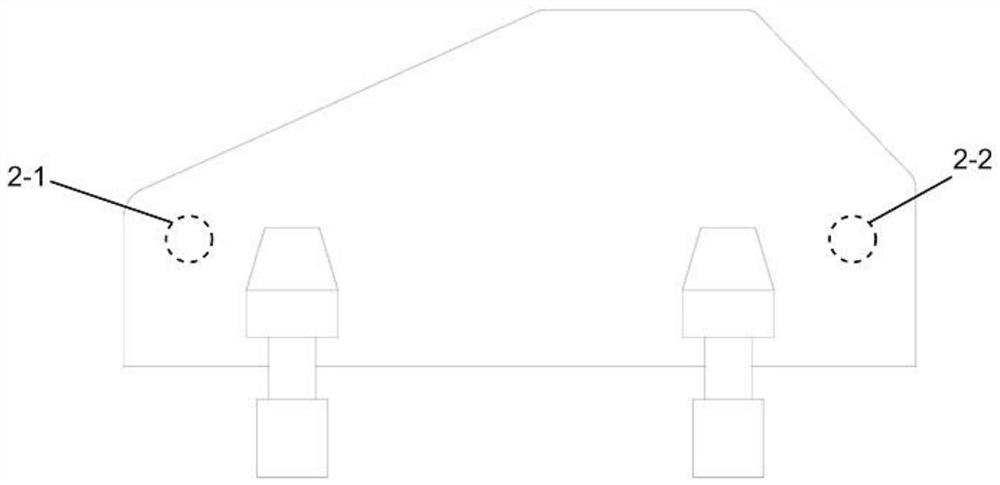

Aircraft seating arrangement

ActiveUS20120223186A1Save spaceEfficiently provideSeating arrangementsAir-treatment apparatus arrangementsEngineeringAirplane

A vehicle seating arrangement can comprise a fore-facing lower seating assembly, an aft-facing lower assembly, and an upper seating assembly positioned between the fore-facing and aft-facing lower assemblies. The lower and upper assemblies can be configured to form a 3-seat unit in which a portion of a seat of said fore-facing and aft-facing lower seat assemblies underlaps a portion of an upper seating assembly. At least one of the fore-facing and aft-facing lower assemblies can be angled with respect to the upper seating assembly to shorten the overall linear dimension of the 3-seat unit and provide egress areas for lower passengers to aisle access. A vertical member can be configured to attach to the upper seating assembly and to a ceiling structure to reduce the load on the floor.

Owner:BE AEROSPACE INCORPORATED

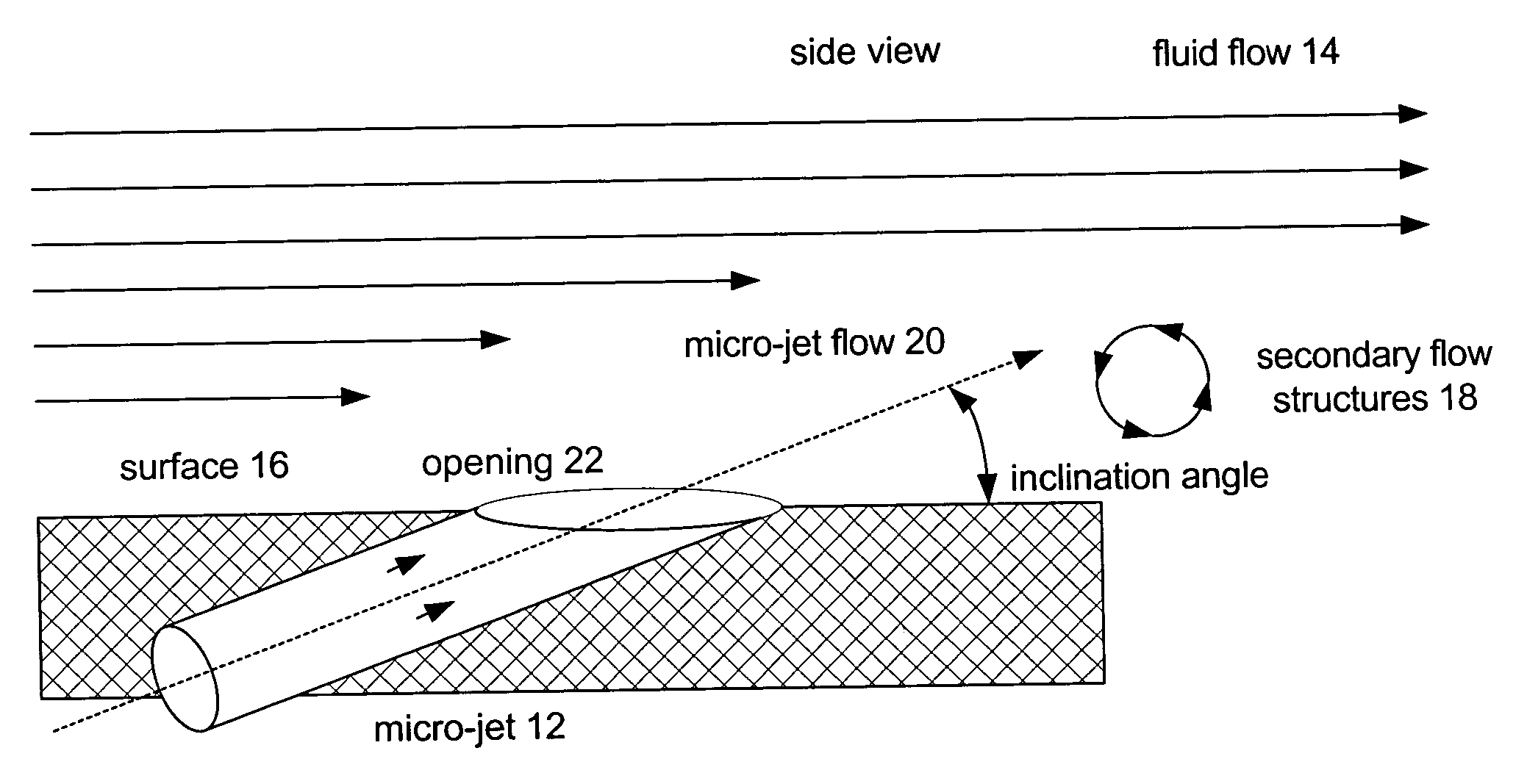

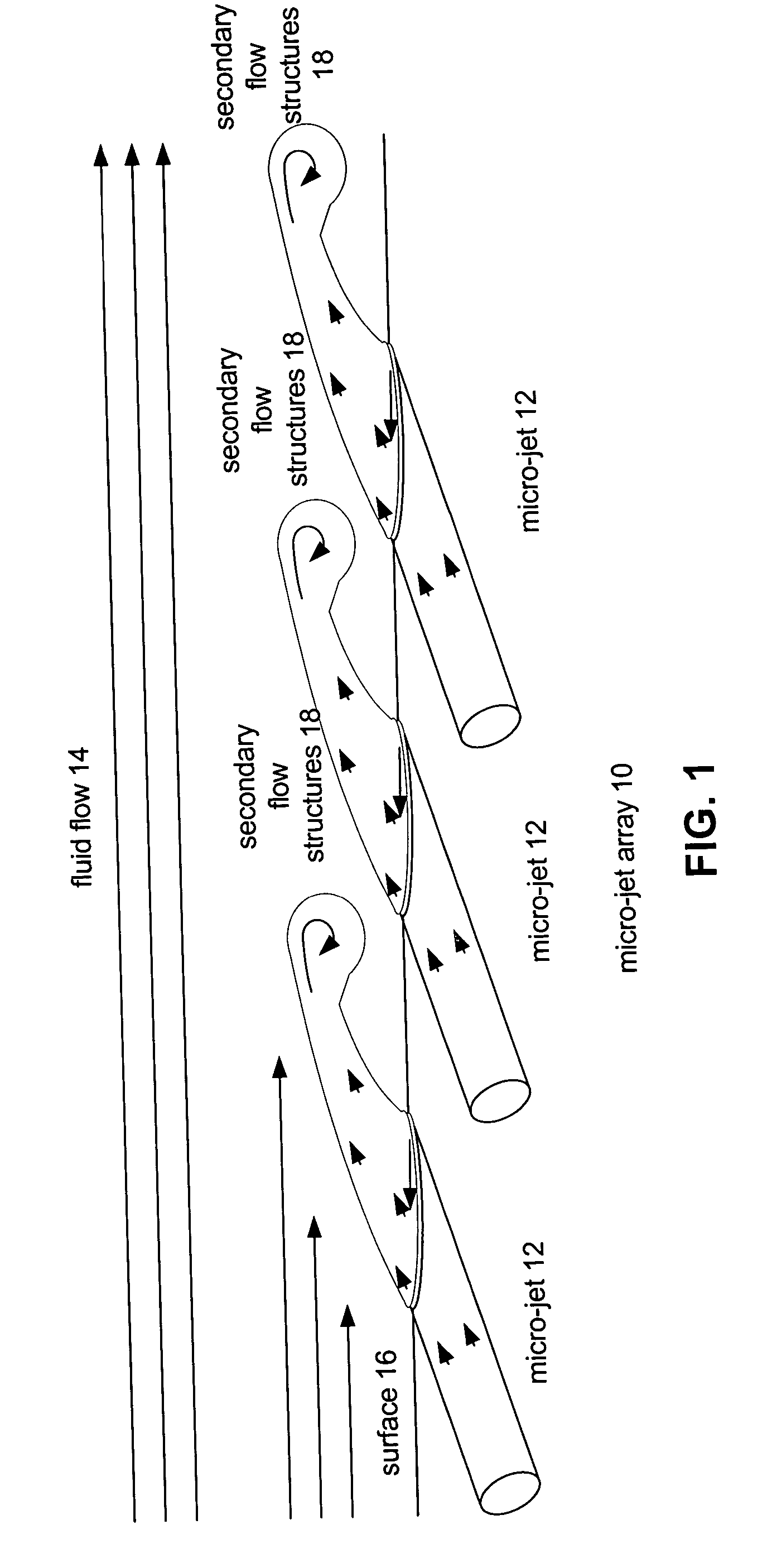

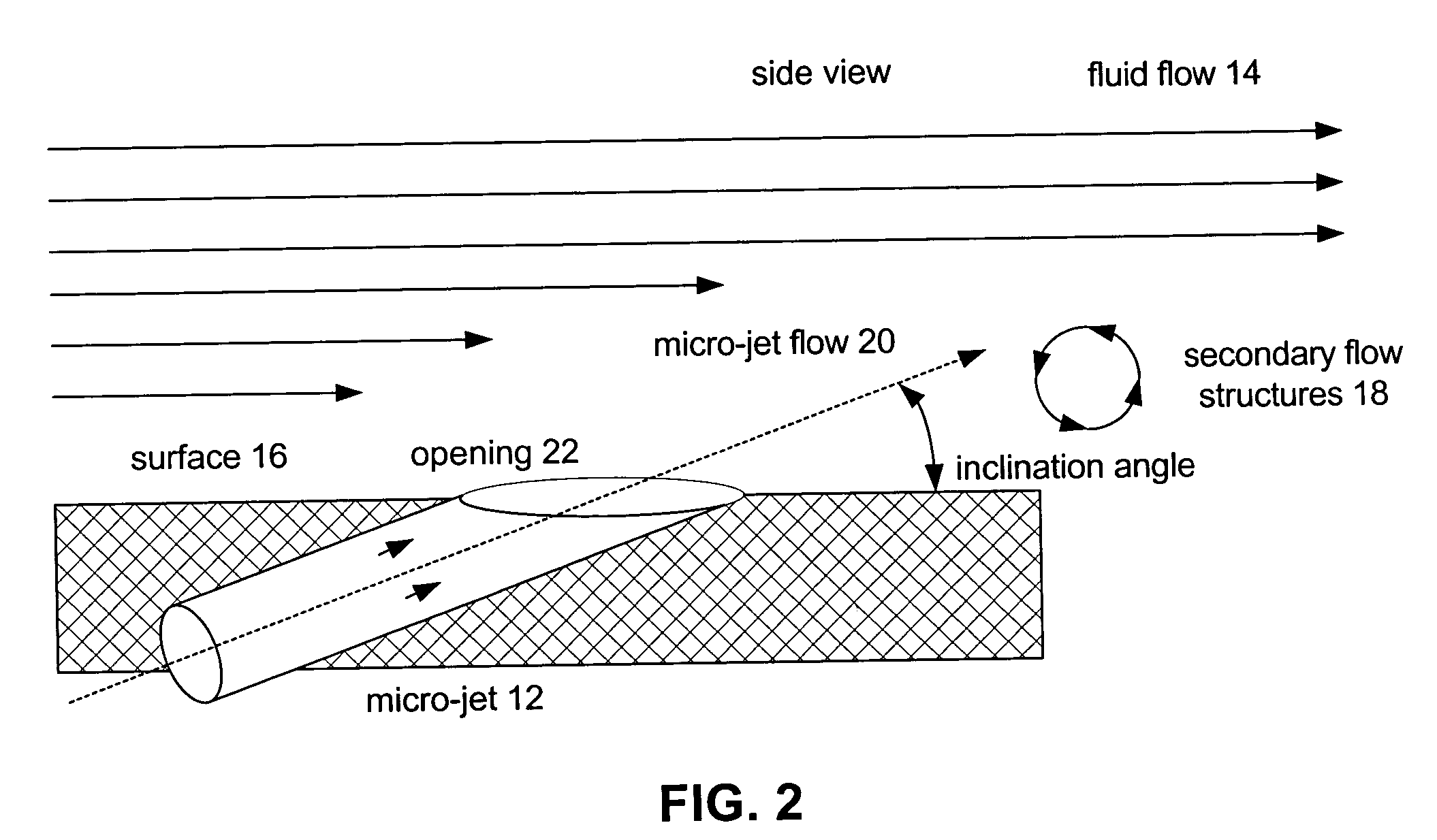

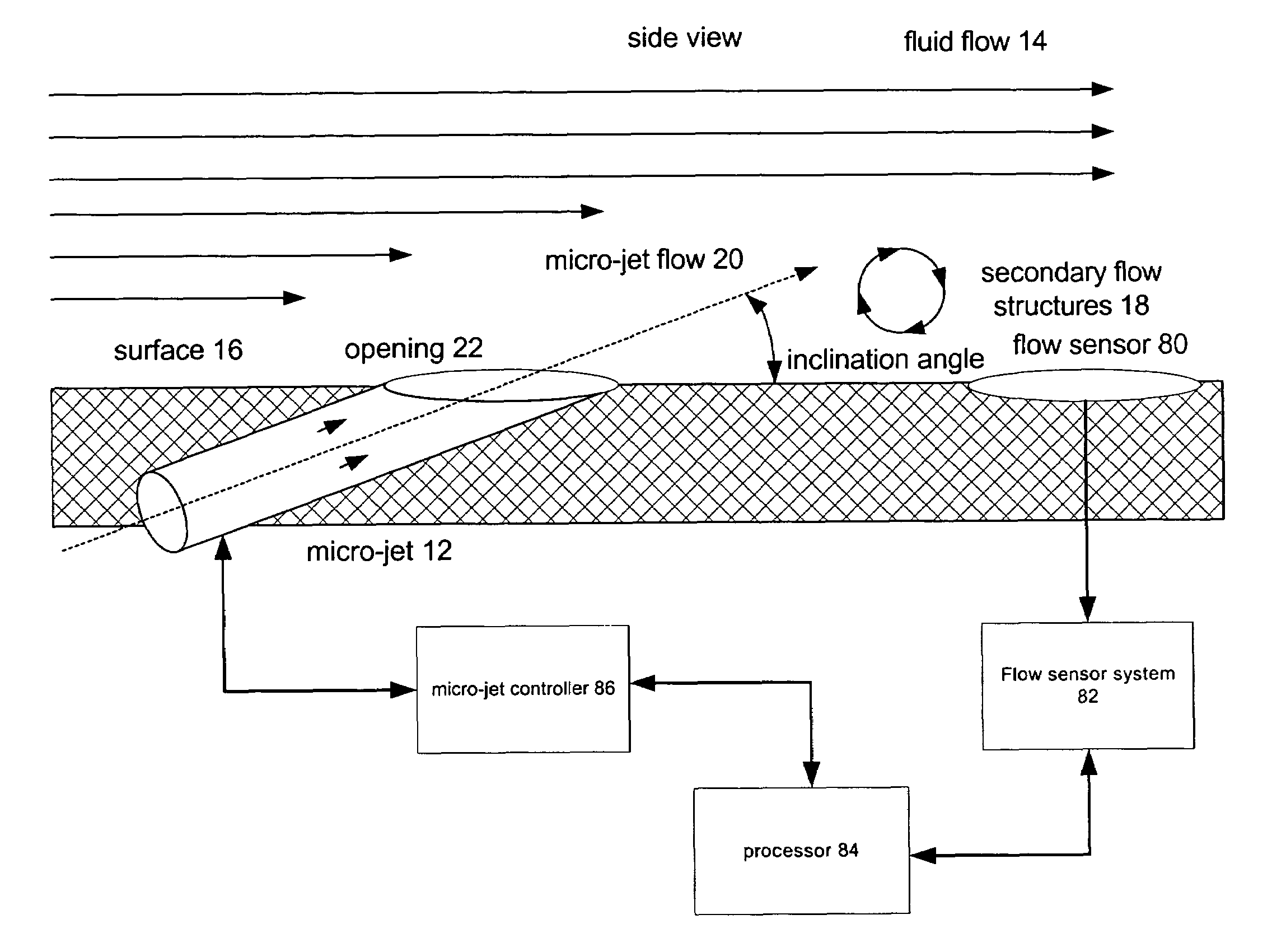

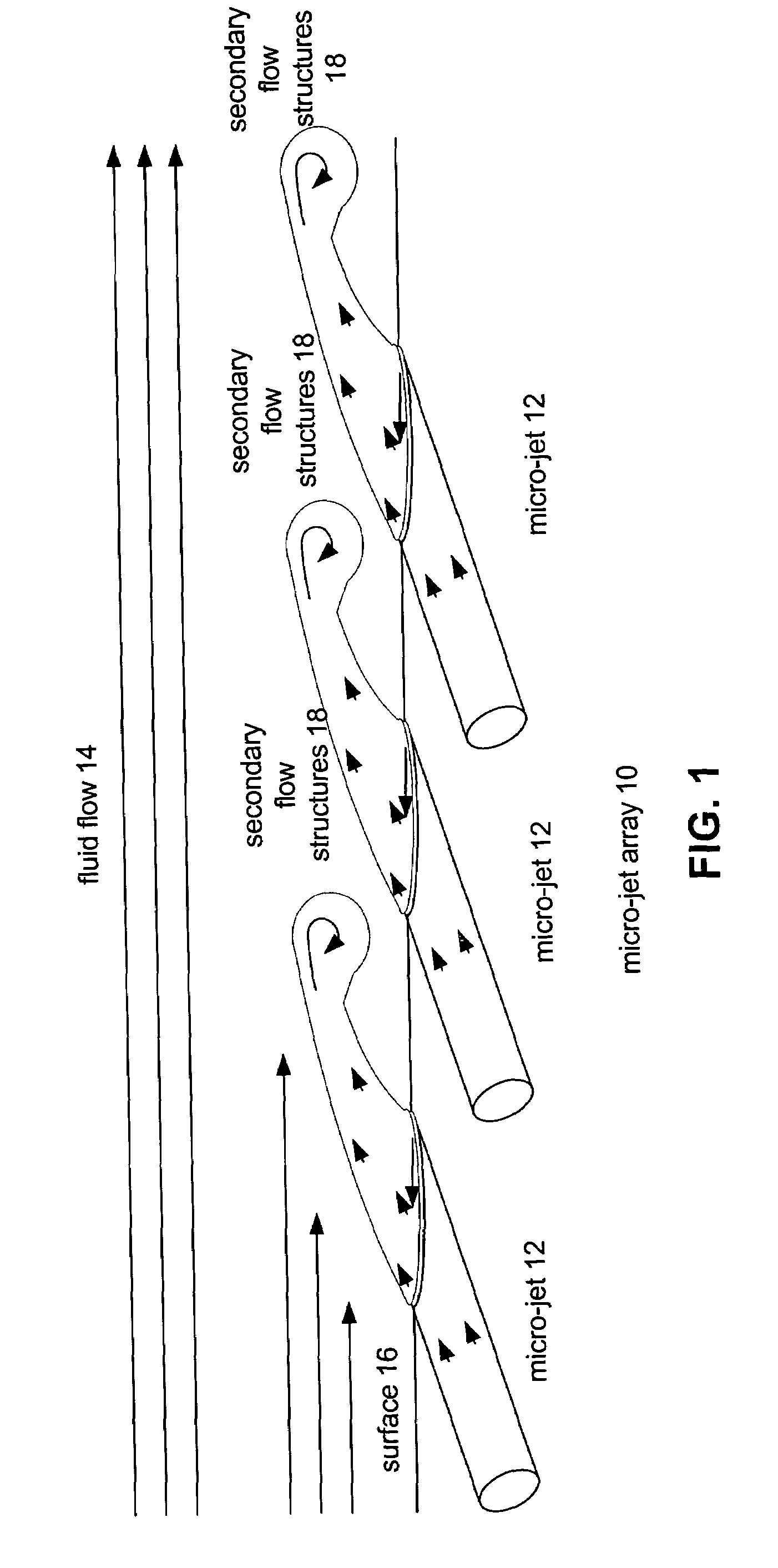

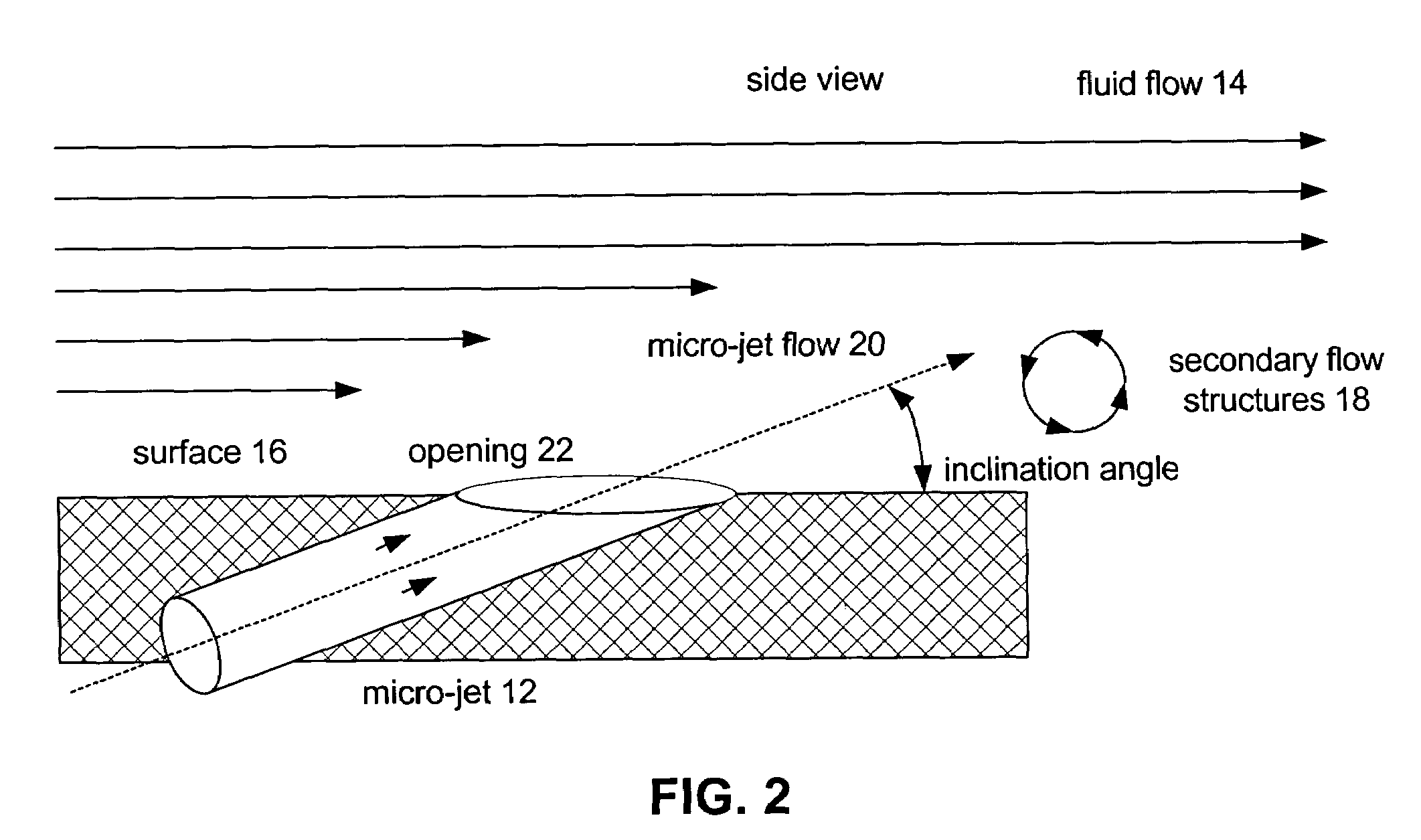

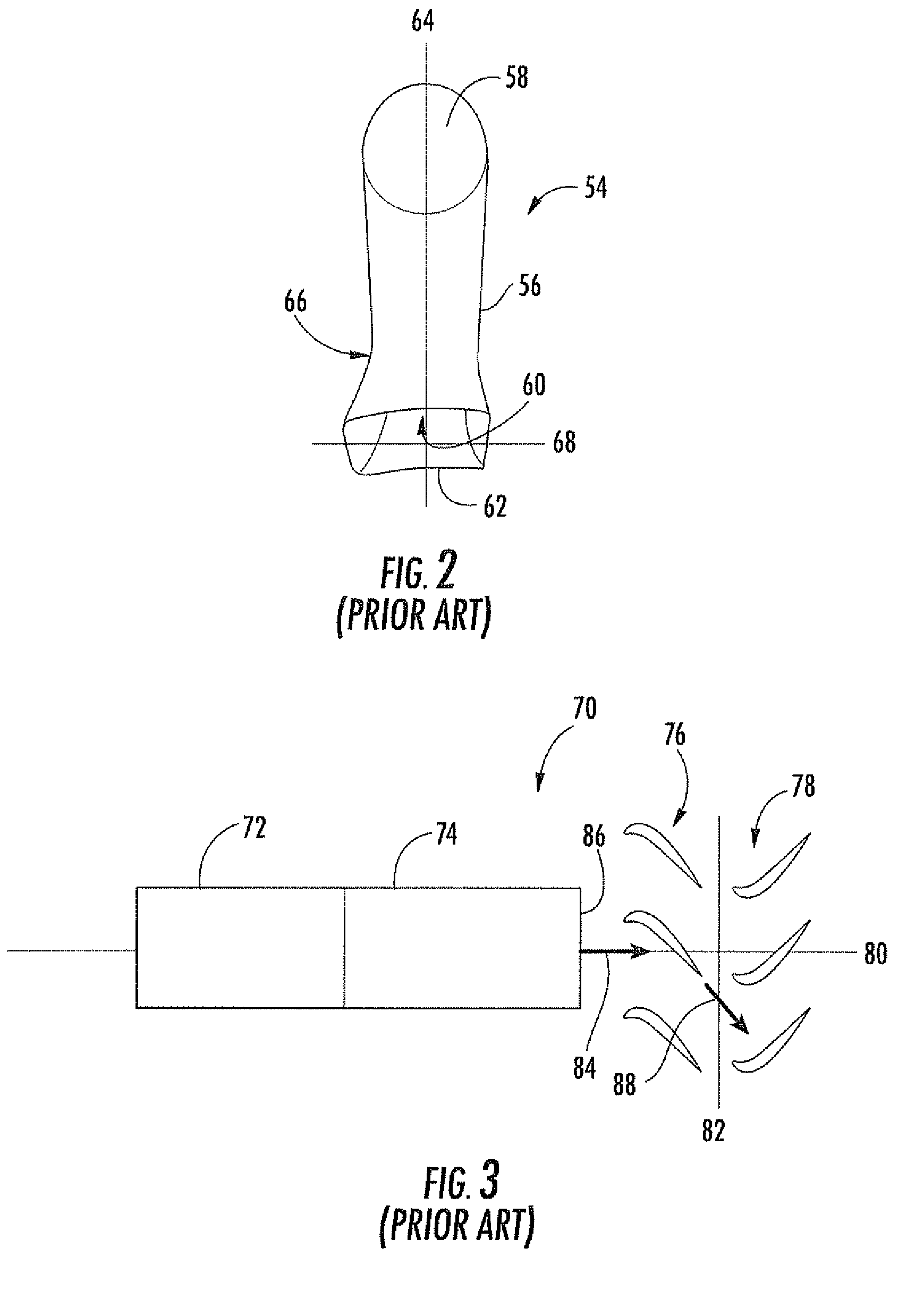

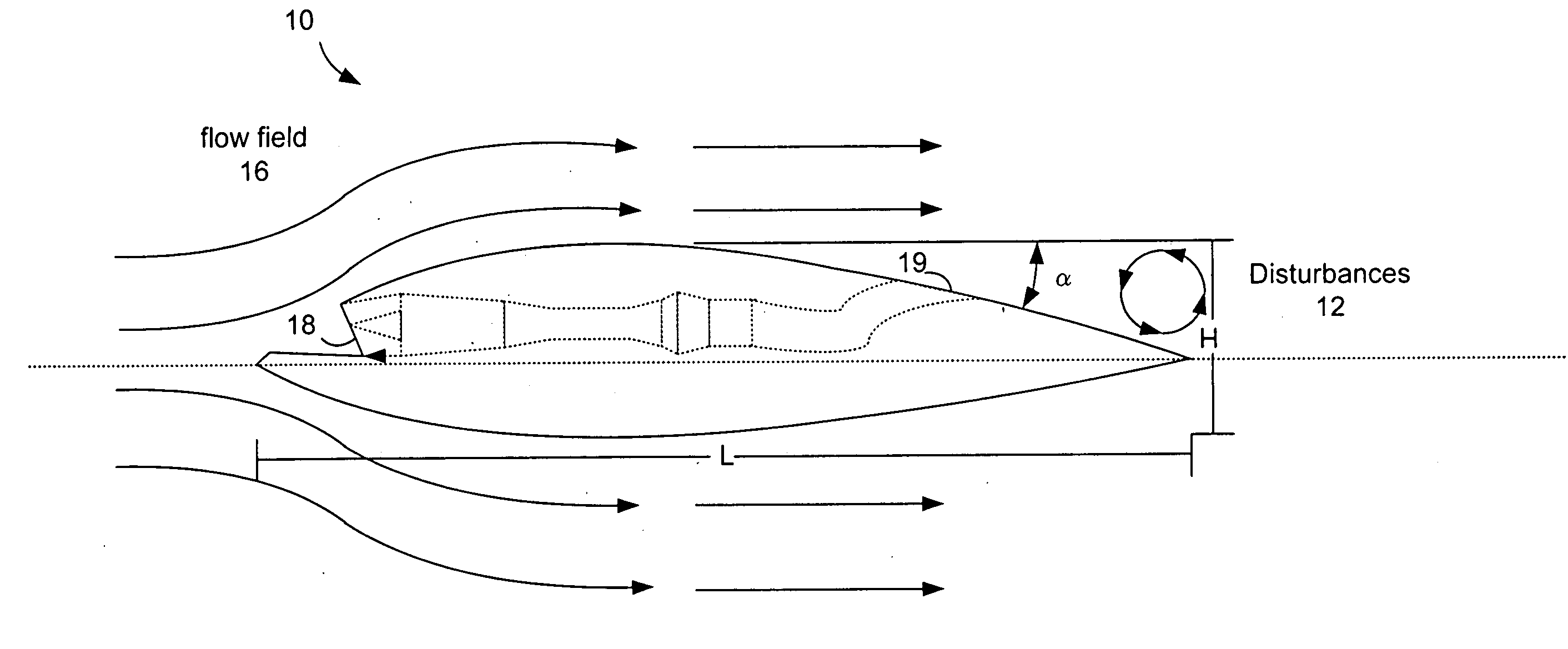

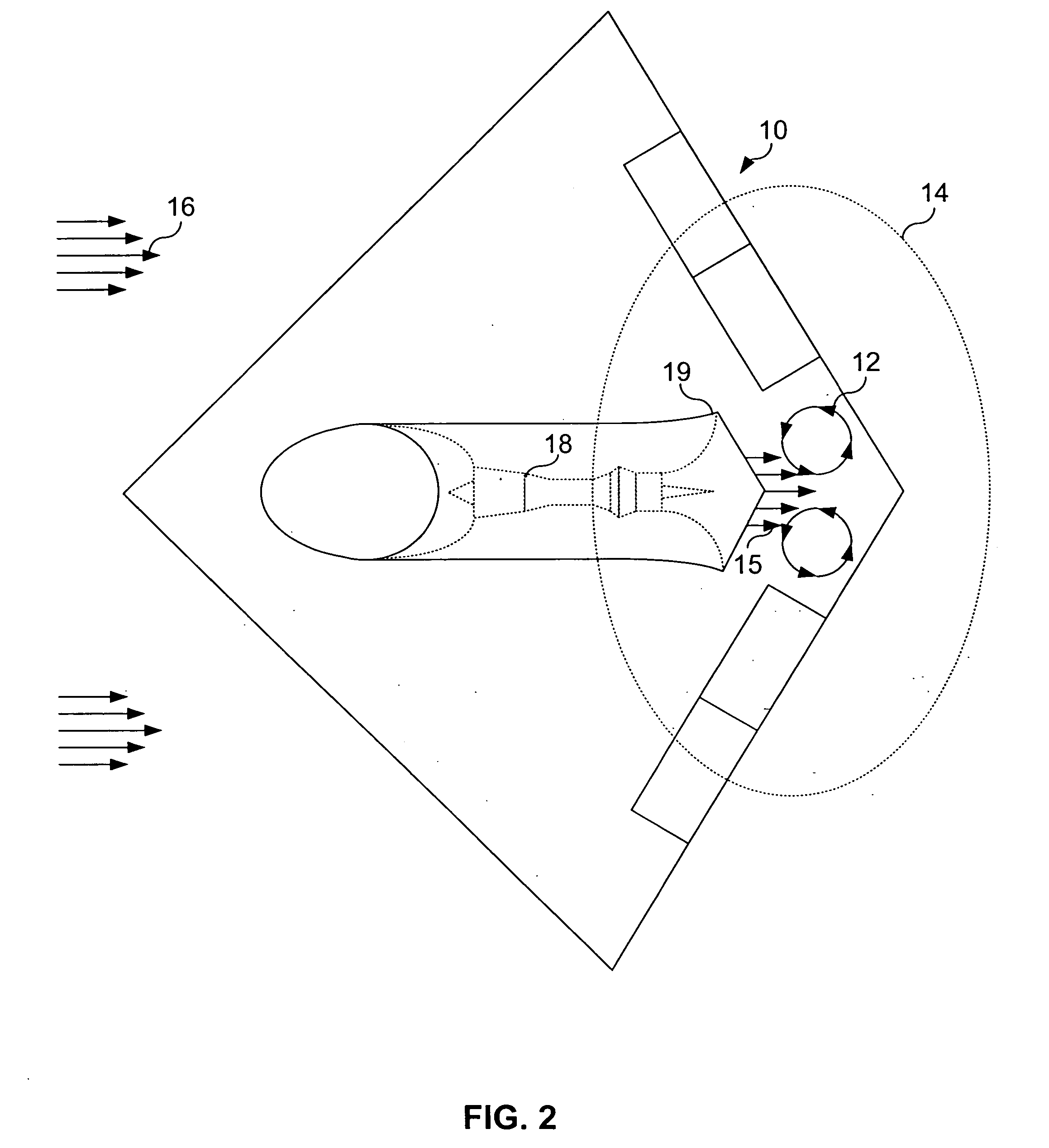

System and method to control flowfield vortices with micro-jet arrays

ActiveUS20060022092A1Reduce downstream buffetingReduce fatigueBoundary layer controlsWingsEngineeringFluid field

The present invention provides a system and method for actively manipulating and controlling aerodynamic or hydrodynamic flow field vortices within a fluid flow over a surface using micro-jet arrays. The system and method for actively manipulating and controlling the inception point, size and trajectory of flow field vortices within the fluid flow places micro-jet arrays on surfaces bounding the fluid flow. These micro-jet arrays are then actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

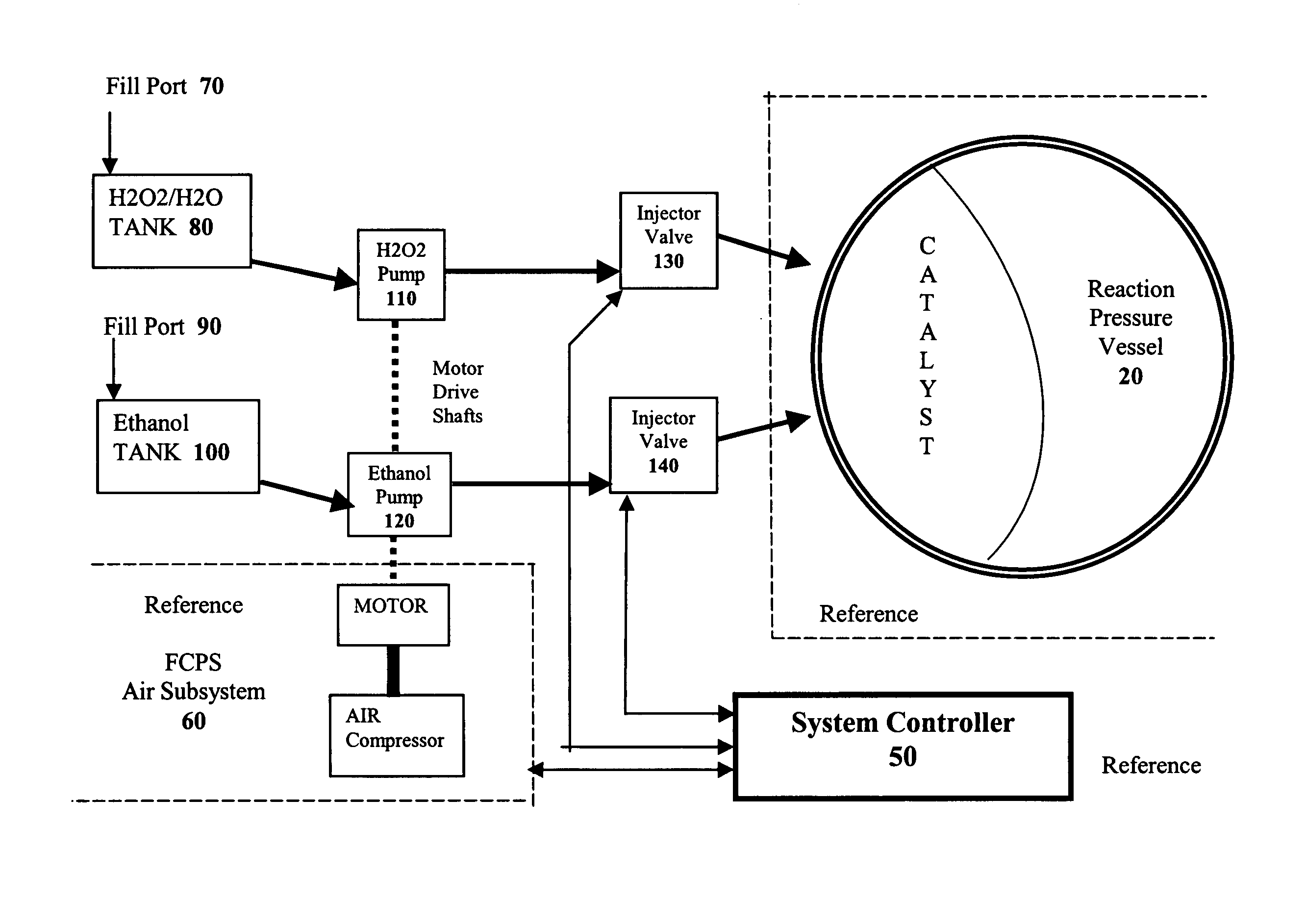

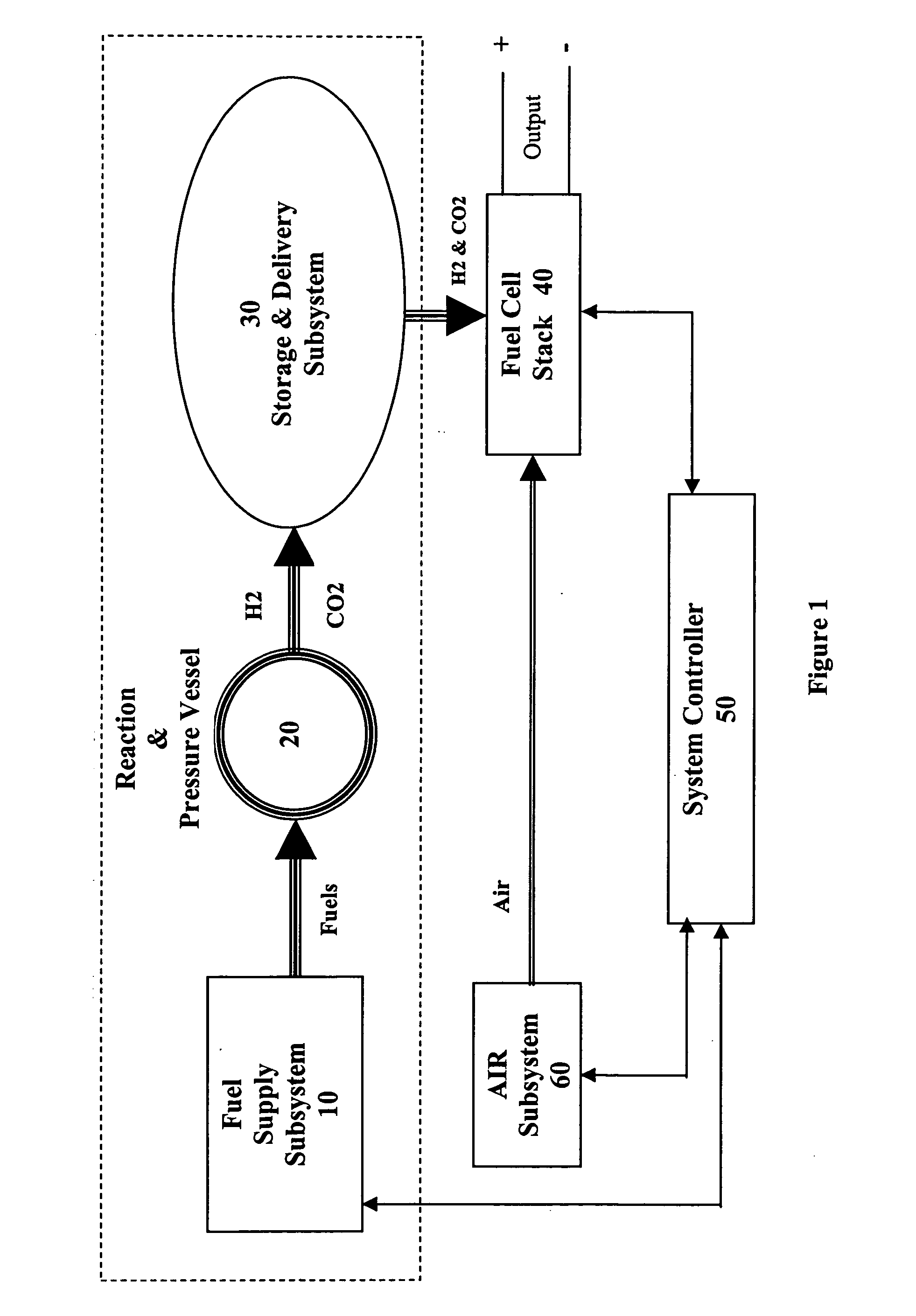

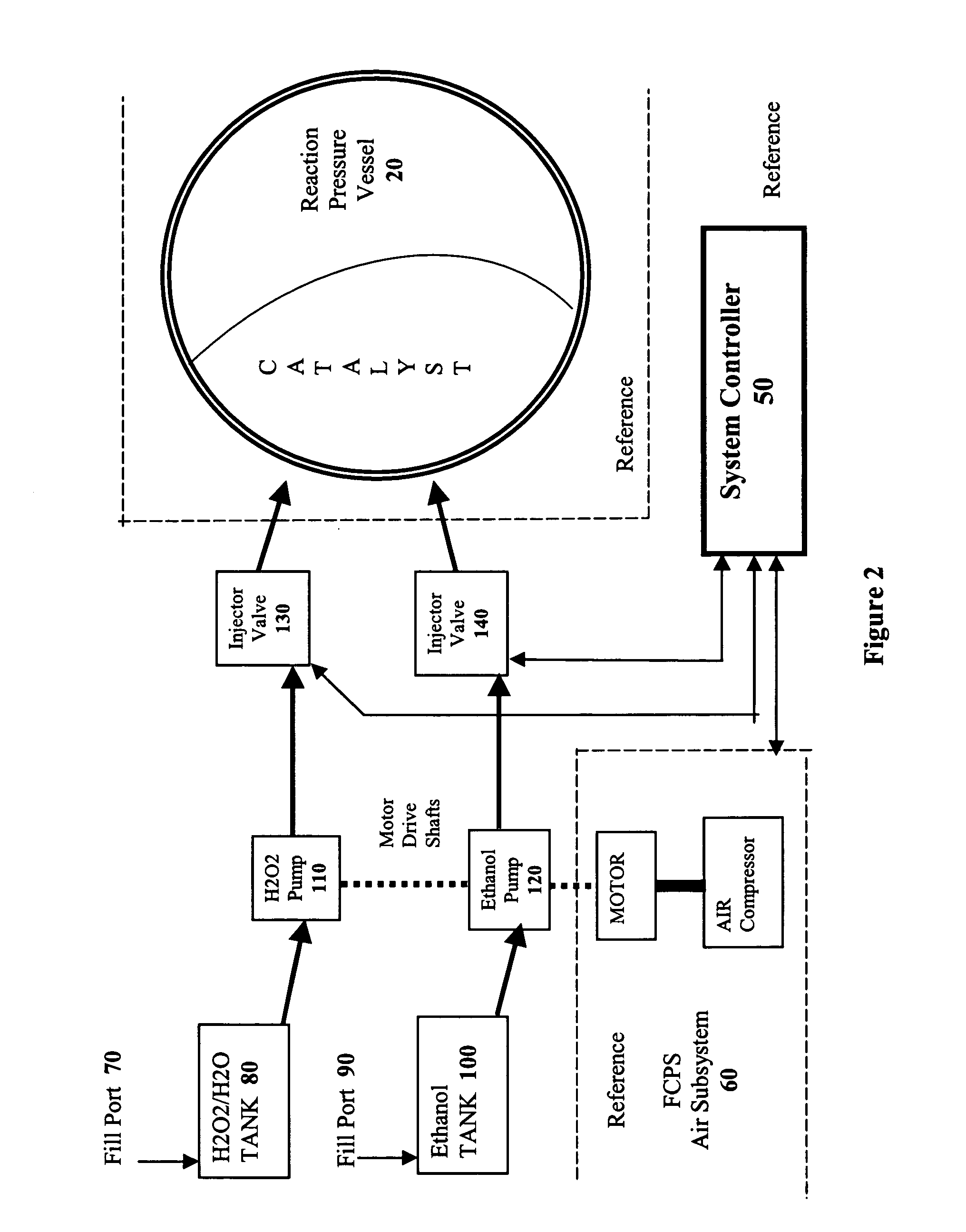

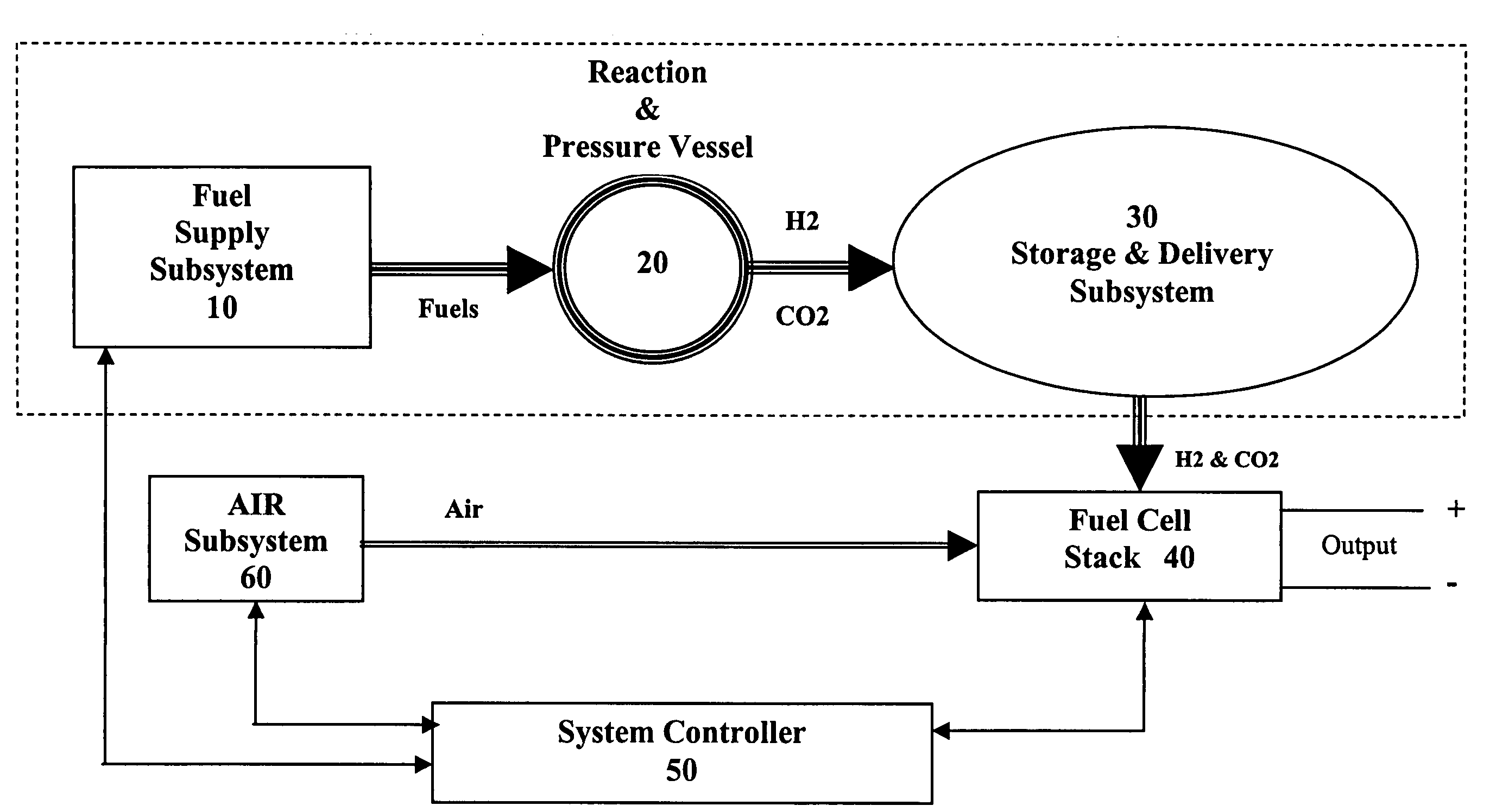

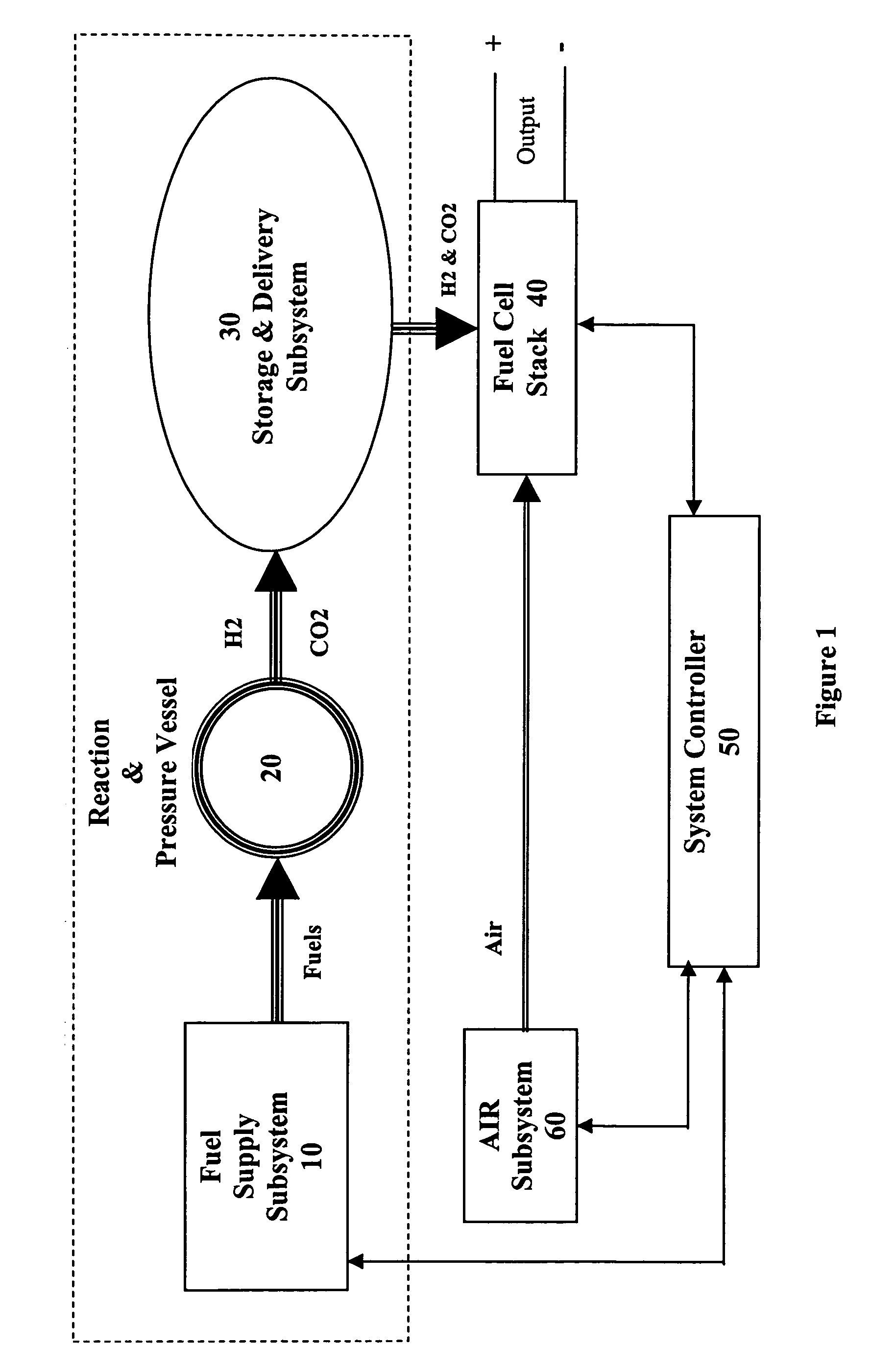

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS20050031918A1Increased electrical power densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesHydrocotyle bowlesioidesOxygen

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

System and method to control flowfield vortices with micro-jet arrays

ActiveUS7510149B2Reduce downstream buffeting and fatigueReduce buffeting and fatigueBoundary layer controlsWingsEngineeringAerodynamics

The present invention provides a system and method for actively manipulating and controlling aerodynamic or hydrodynamic flow field vortices within a fluid flow over a surface using micro-jet arrays. The system and method for actively manipulating and controlling the inception point, size and trajectory of flow field vortices within the fluid flow places micro-jet arrays on surfaces bounding the fluid flow. These micro-jet arrays are then actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

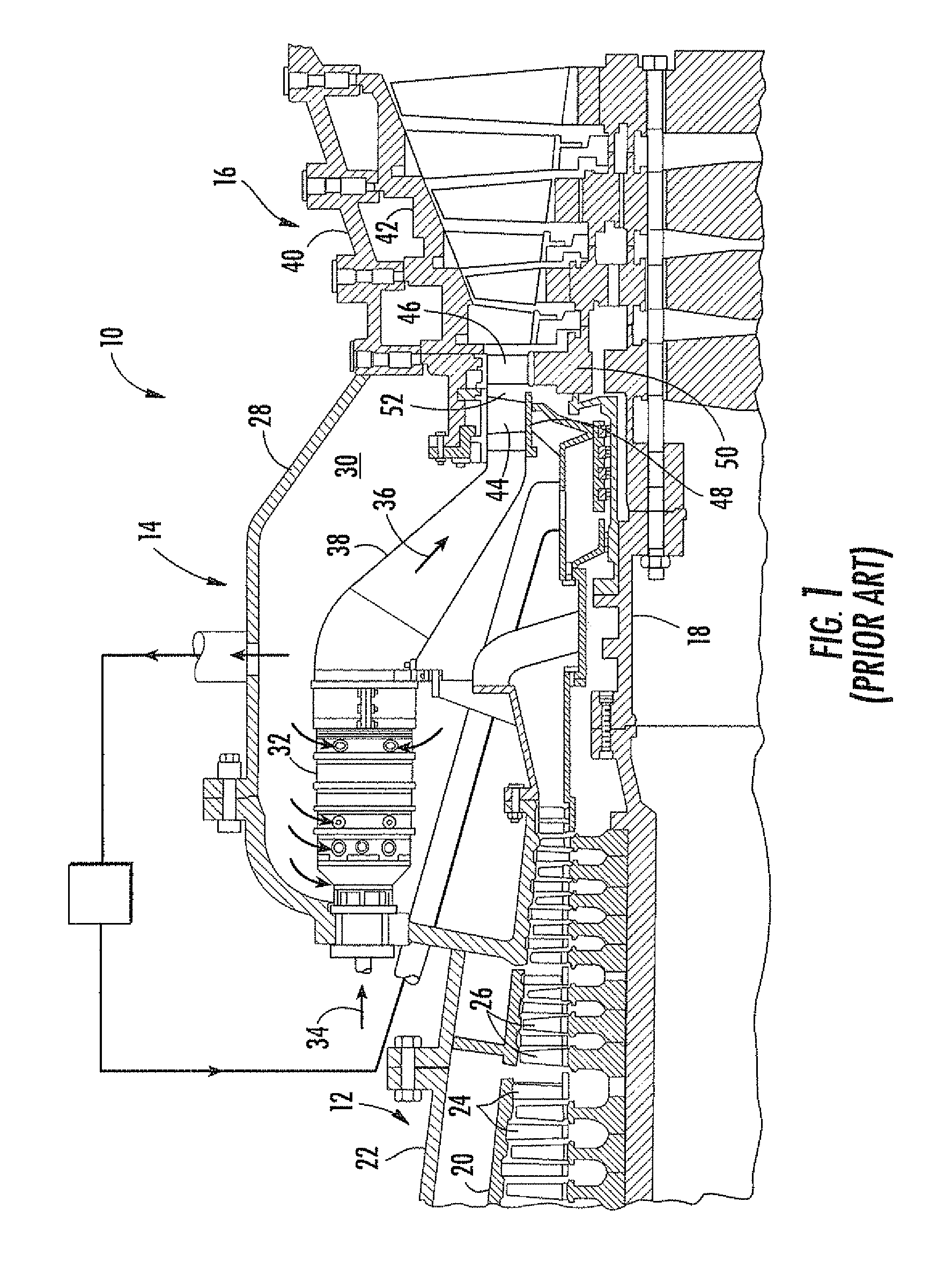

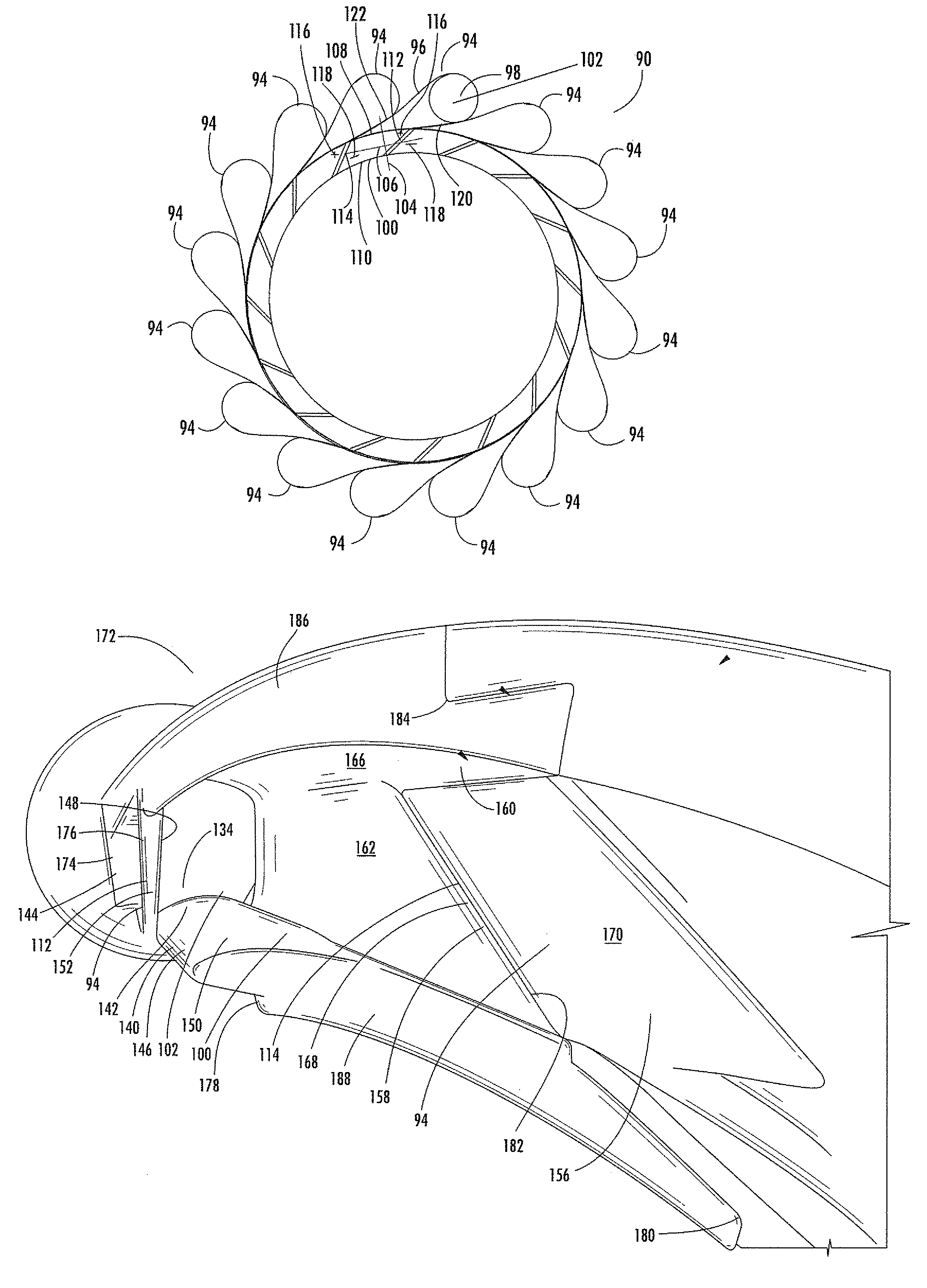

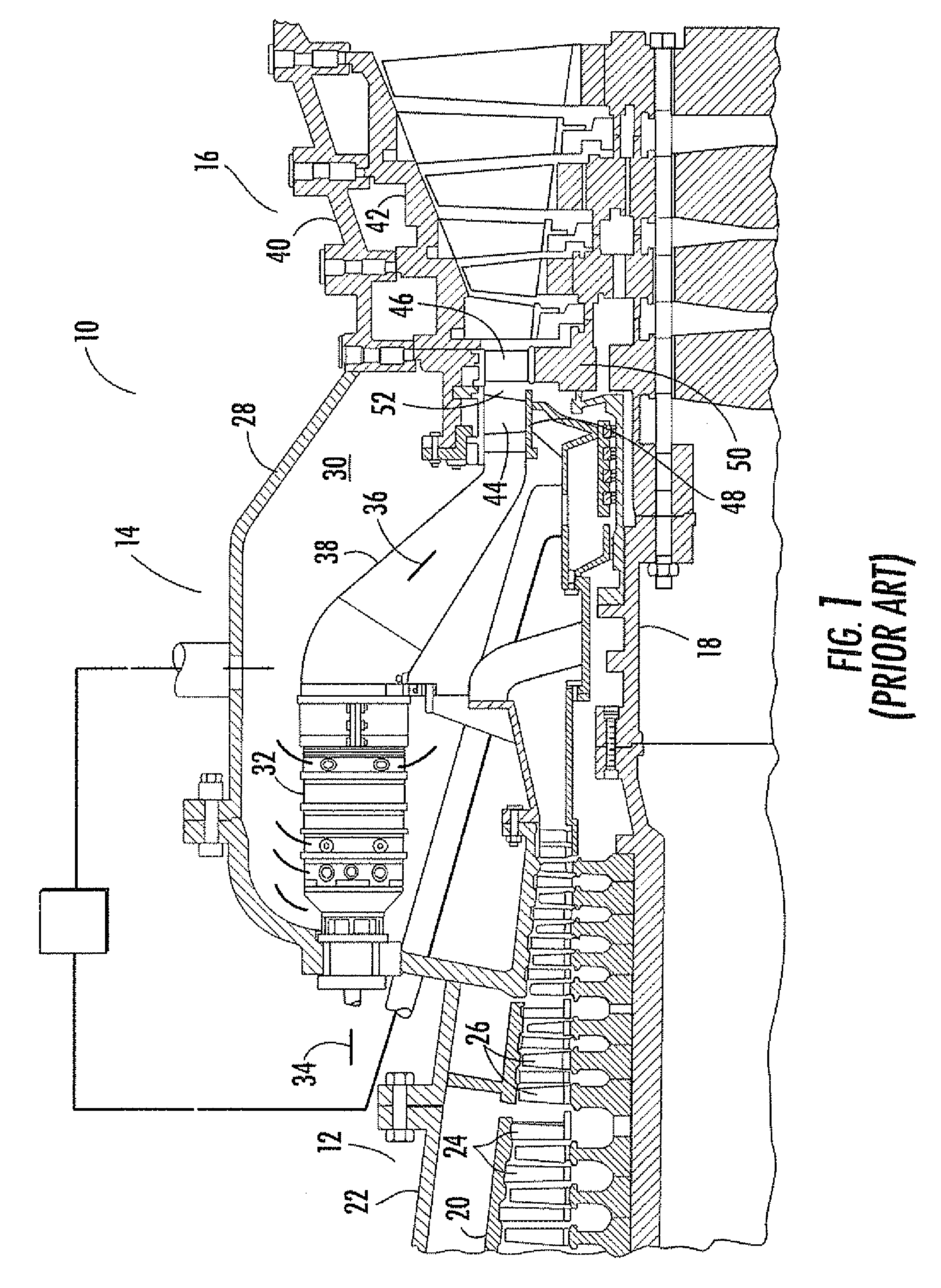

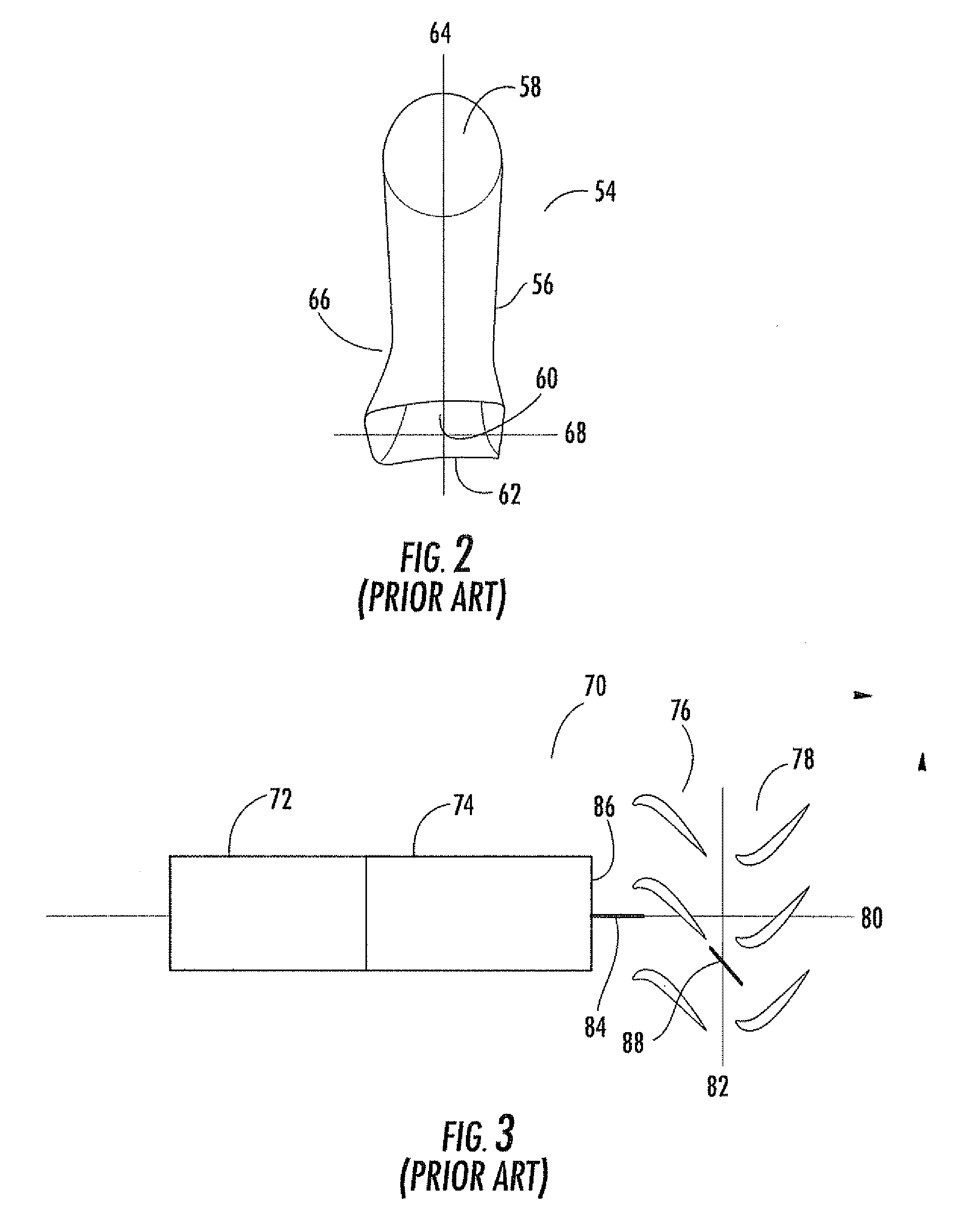

Transition with a linear flow path for use in a gas turbine engine

InactiveUS8113003B2Reduced excitation and stressHarmful stressEngine manufacturePump componentsCombustorTurbine blade

A transition duct for routing a gas flow from a combustor to the first stage of a turbine section in a combustion turbine engine is disclosed. The transition duct may have an internal passage extending between an inlet to an outlet. An axis of the transition duct body may be generally linear such that gases expelled from the transition duct body flow in a proper direction into the downstream turbine blades.

Owner:SIEMENS ENERGY INC

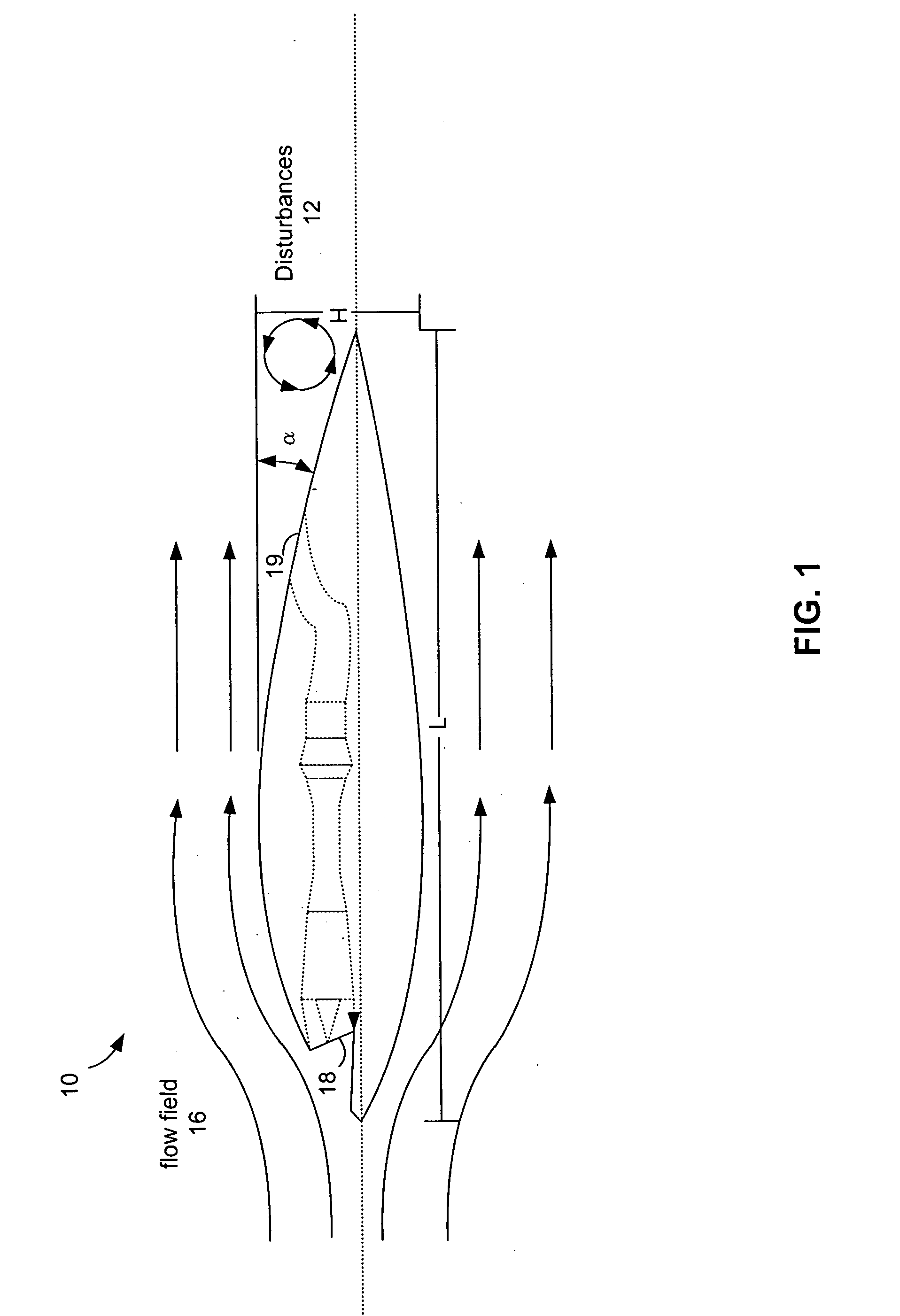

Conformal aero-adaptive nozzle/aftbody

InactiveUS20060219847A1Reduce resistanceLight weightAircraft stabilisationBoundary layer controlsInstabilityEngineering

The present invention provides flow field control techniques that adapt the aft body region flow field to eliminate or mitigate the development of massive separated flow field zones and associated unsteady vortical flow field structures. Embodiments of the present invention use one or more distributed arrays of flow control devices (submerged in the boundary layer) to create disturbances in the flow field that inhibit the growth of larger vortical structures and / or to energize the aft body shear layer to keep the shear layer attached the aft body surface. These undesirable aerodynamic phenomena produce increased vehicle drag which harms vehicle range, persistence, and loiter capabilities. Additionally, the unsteady nature of the turbulent vortical structures shed in the aft body wake region may produce increased dynamic buffeting and aft body heating by entraining nozzle jet exhaust (a.k.a. jet wash)—requiring additional structural support, shielding, and vehicle weight.

Owner:LOCKHEED MARTIN CORP

Transition with a linear flow path with exhaust mouths for use in a gas turbine engine

ActiveUS8065881B2Reduced excitation and stressHarmful stressPump componentsGas turbine plantsCombustorTurbine blade

A transition duct for routing a gas flow from a combustor to the first stage of a turbine section in a combustion turbine engine is disclosed. The transition duct may have an internal passage extending between an inlet to an outlet. An axis of the transition duct body may be generally linear such that gases expelled from the transition duct body flow in a proper direction into the downstream turbine blades. The linear transition duct may include an outlet with exhaust mouths that are configured such that sides of the transition duct are coplanar with adjacent transition ducts, thereby eliminating destructive turbulence between adjacent, linear transition ducts.

Owner:SIEMENS ENERGY INC

Hypergolic hydrogen generation system for fuel cell power plants

InactiveUS7344789B2High densityIncrease pressureHydrogen separation using solid contactFuel cell auxillariesOxygenContamination

The invention provides a controlled hypergolic approach to using concentrated hydrogen peroxide in combination with certain hydrocarbons such as ethanol, methanol, methane as well as more common fuels such as gasoline, diesel, DME, JP5, JP8 and the like to generate a gas mixture primarily composed of hydrogen and carbon dioxide. Because air is not used as the oxygen source, this novel process does not allow the formation of nitrous oxide (NOx) compounds, thereby avoiding the primary source of nitrogen contamination as well. The process is executed in a constraining system on a micro scale such that the resulting hydrogen supply is self-pressurizing. This enables the incorporation of an “on-demand” hydrogen fuel source for a variable output fuel cell power plant such as those proposed for use in automobiles, marine vessels and stationary power sources. In another embodiment of the present invention hydrogen peroxide is catalytically, or thermally reacted to provide H2O vapor and O2. When this gaseous stream is introduced to the cathode of the fuel cell, the percent concentration of oxygen is increased with no corresponding increase in the parasitic power demand made by an air-moving device. This use of H2O2 as an oxygen source may be continuous, intermittent or limited to specific instances when peak power output demands or high transient loads are placed upon the FCPS.

Owner:CBH2 TECH

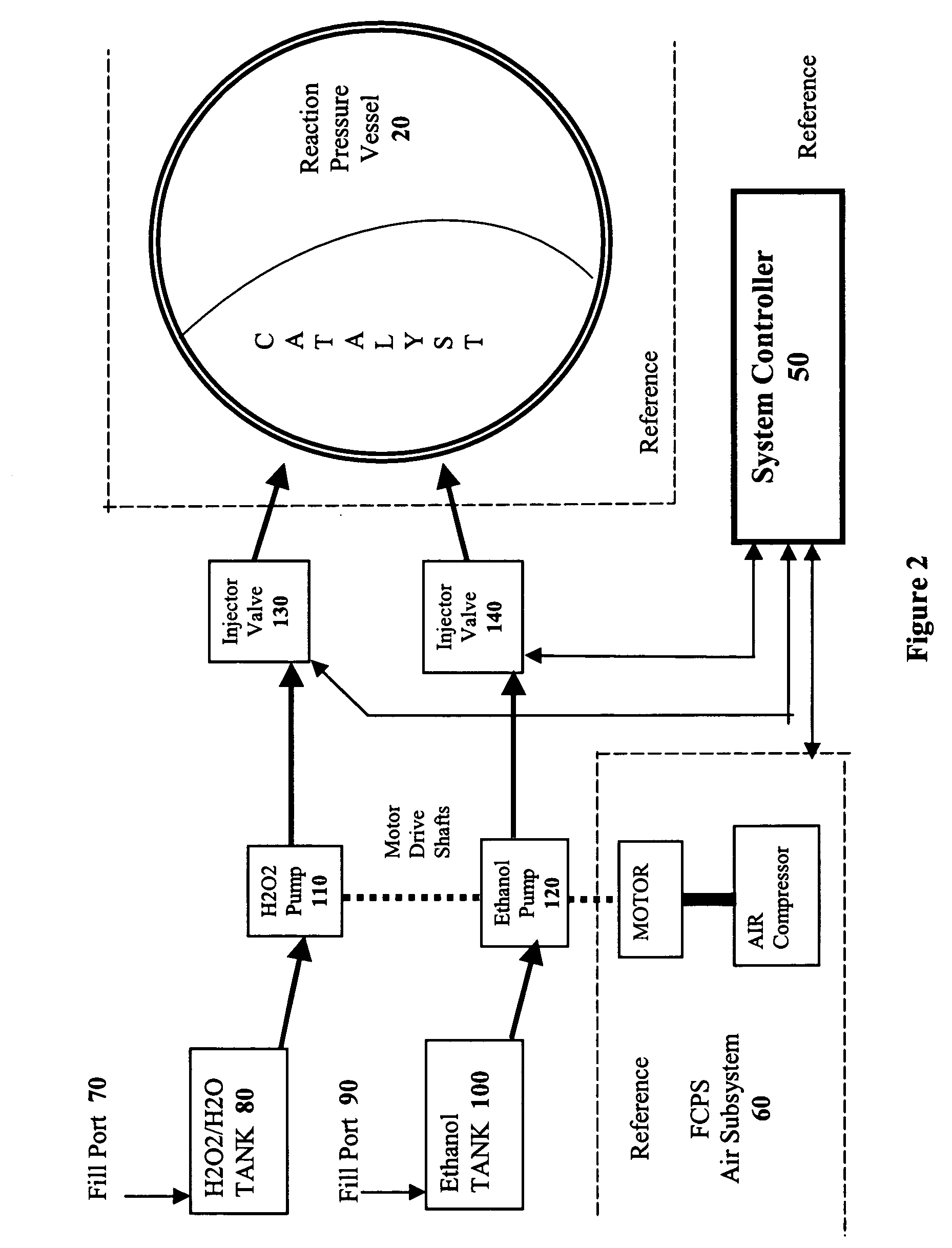

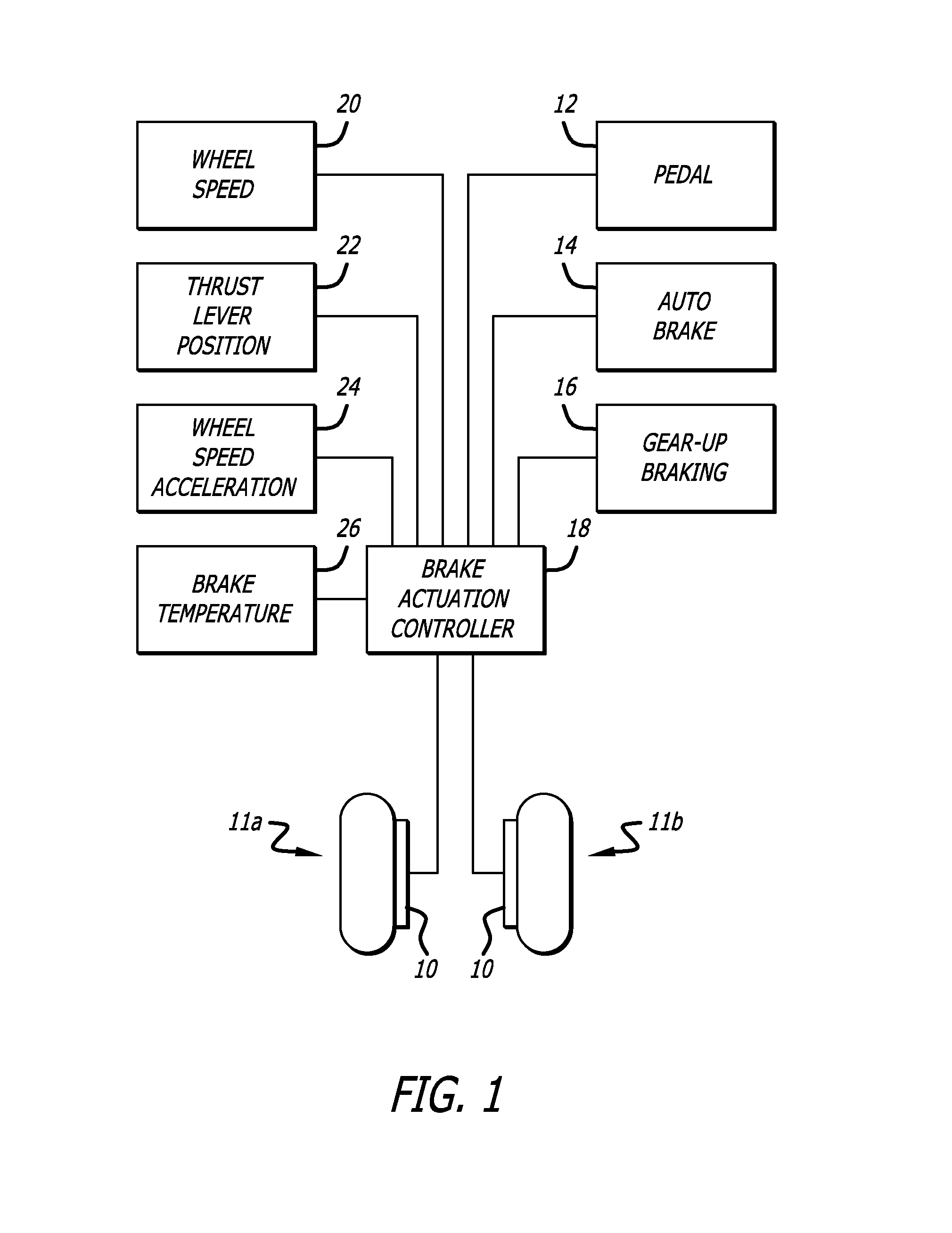

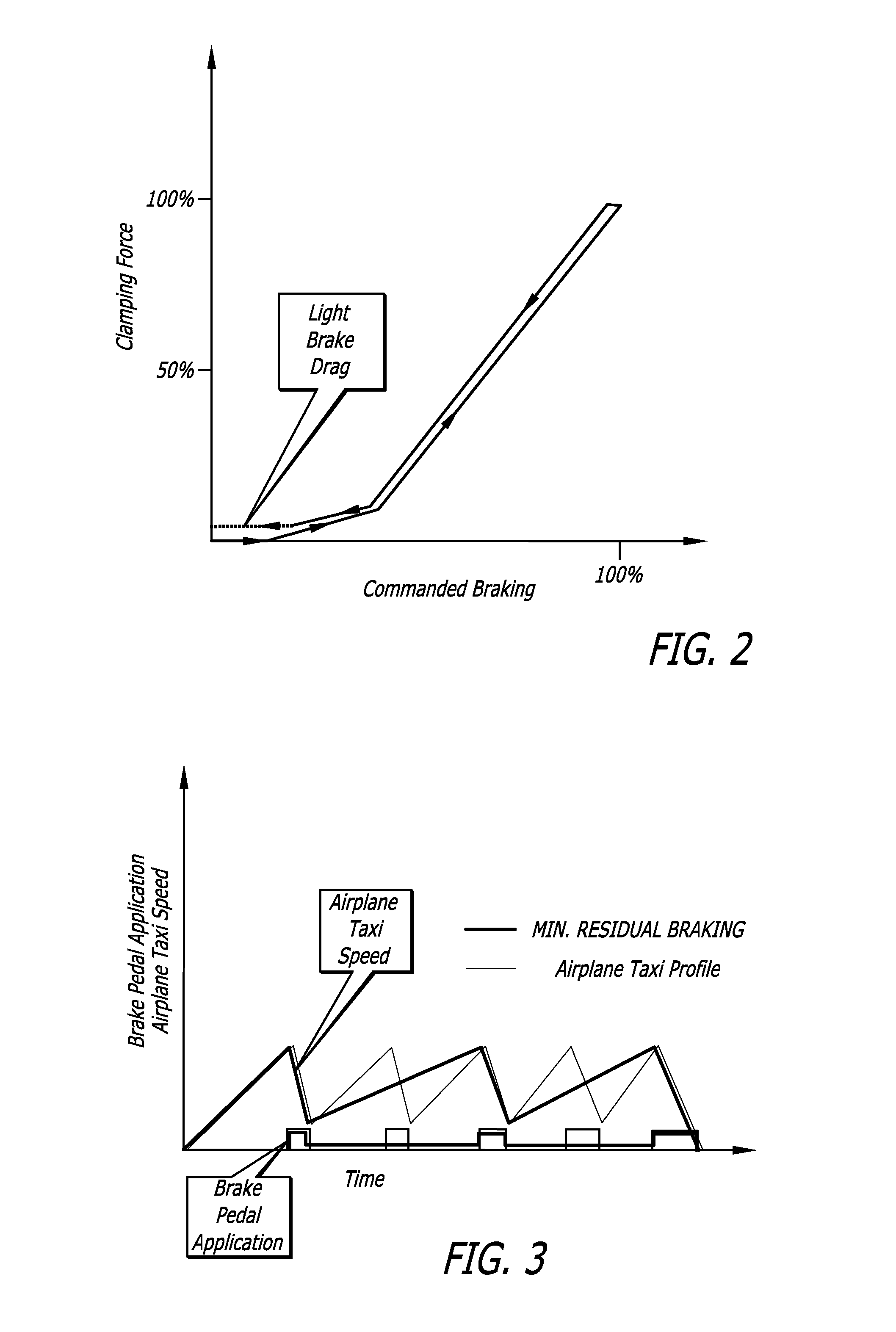

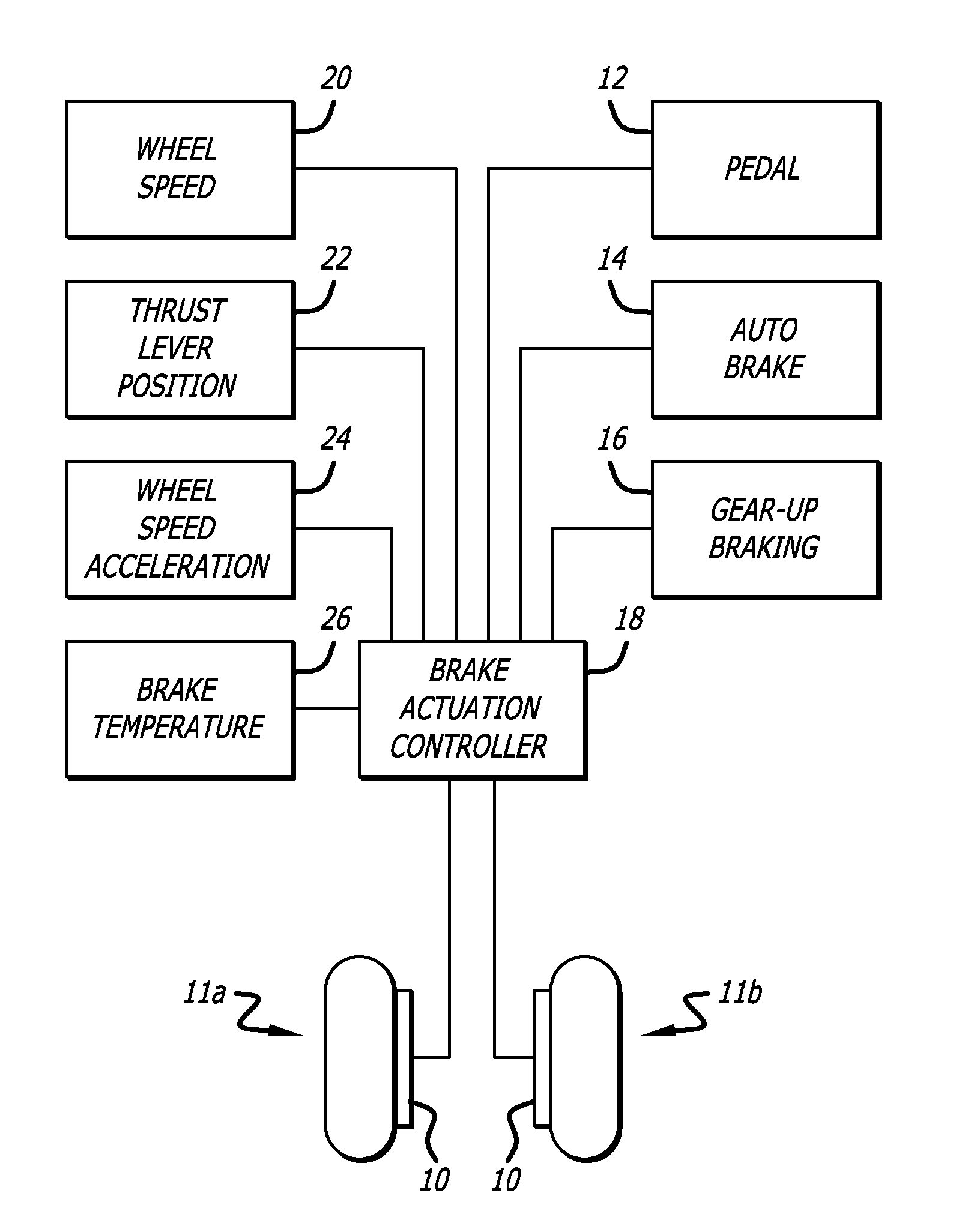

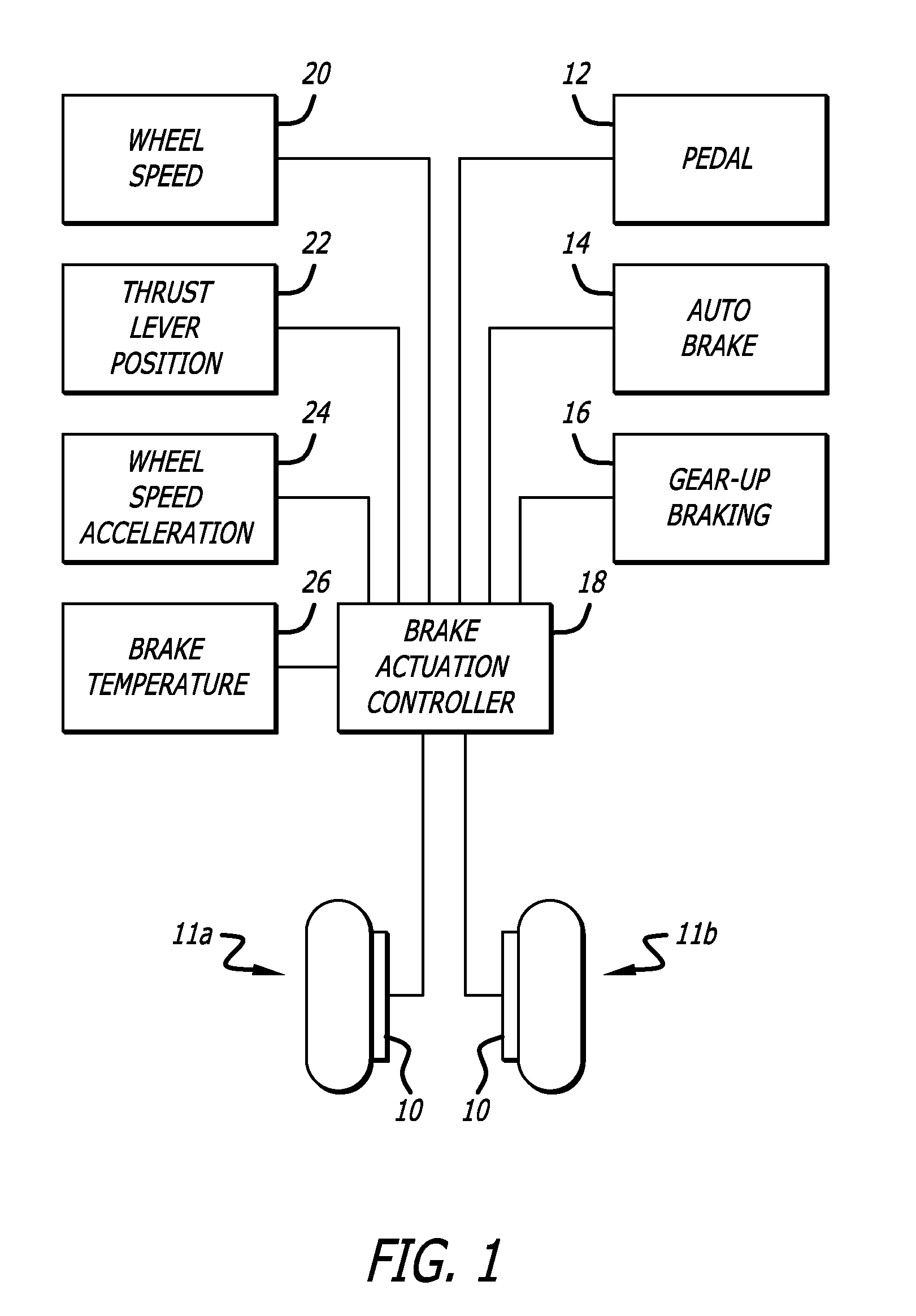

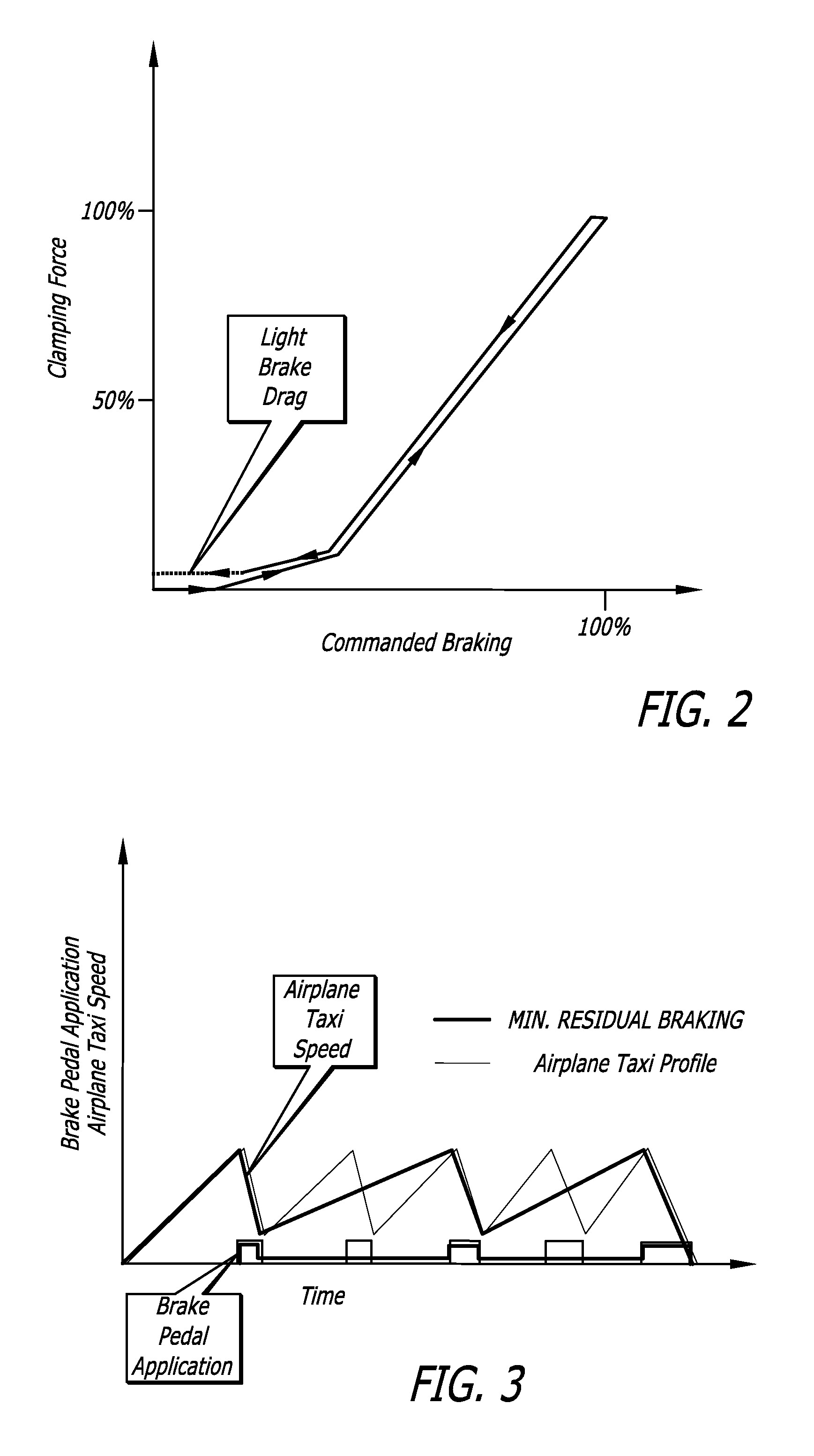

System and method for aircraft brake metering to alleviate structural loading

ActiveUS20140156160A1Increase accuracyGreat sensitivity and accuracyAnalogue computers for trafficAircraft brake actuating mechanismsAirplaneBrake force

In a system and method for aircraft brake metering to alleviate structural loading, one or more electric brake actuators for wheel brakes having a range of brake clamping force are provided, and a brake actuation controller is configured to monitor commanded initiation of the aircraft, to limit initial brake effort of the electric brake actuators to a preset fraction of a maximum possible braking effort for a preset period of time, and to permit brake effort of the electric brake actuators up to the maximum possible braking effort after the preset period of time after initiation of braking has been commanded. The preset fraction is preferably approximately 50% of the maximum possible braking effort, and may be tuneable. The preset period of time is preferably approximately one second, and also may be tuneable.

Owner:HYDRO AIRE AEROSPACE CORP

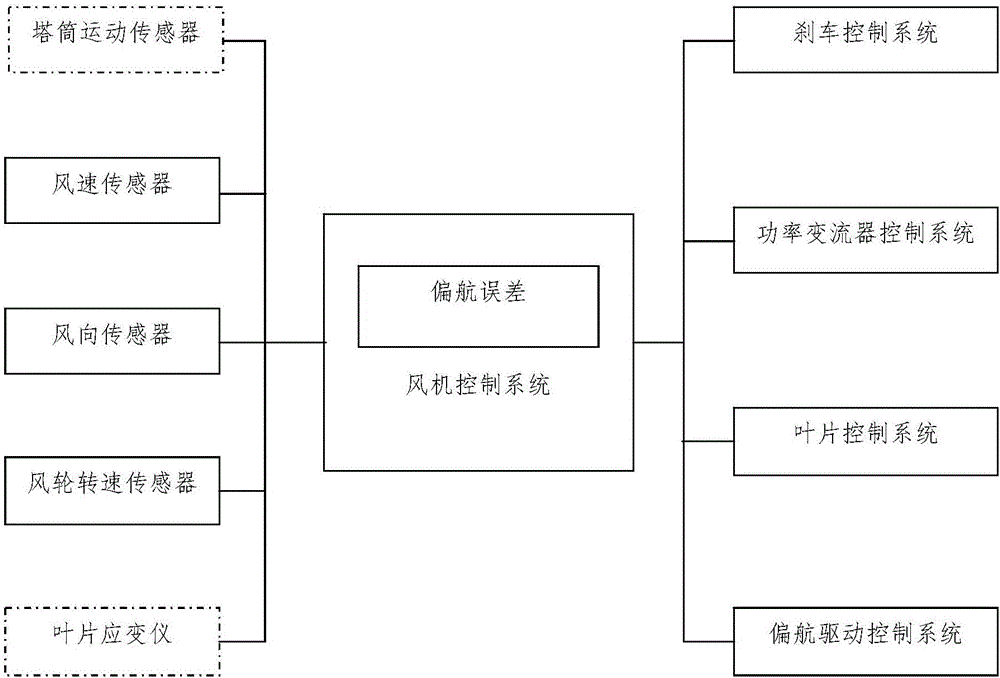

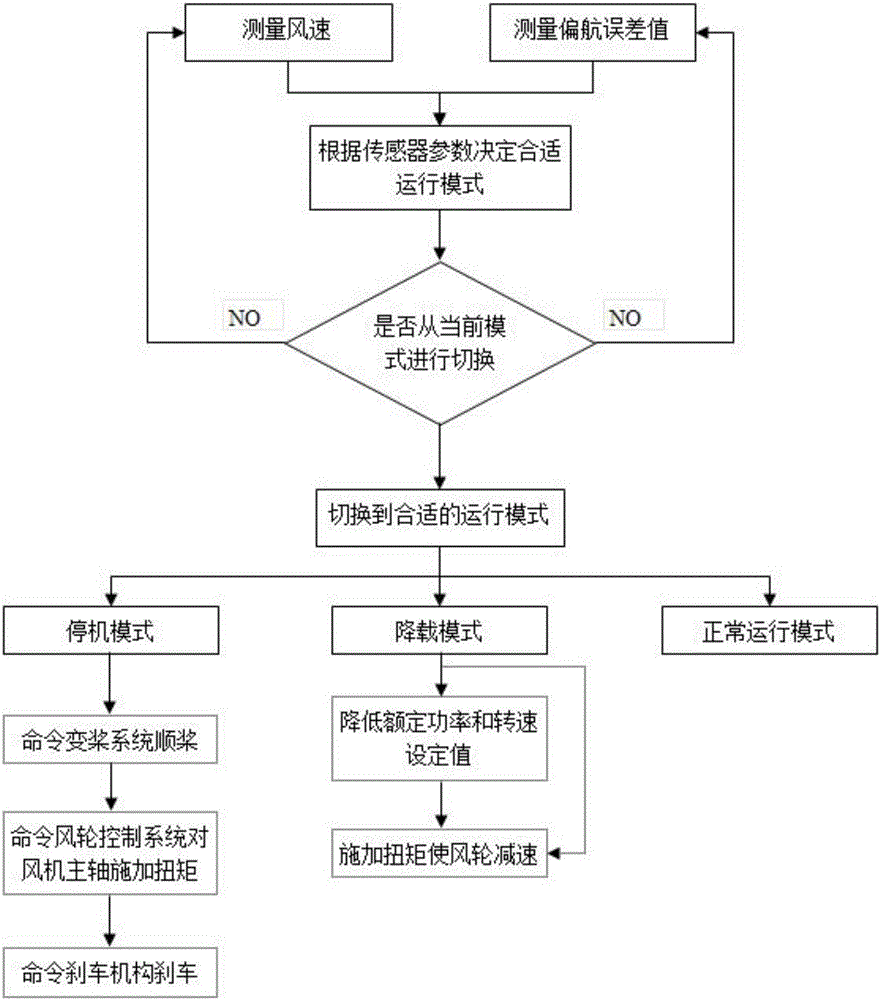

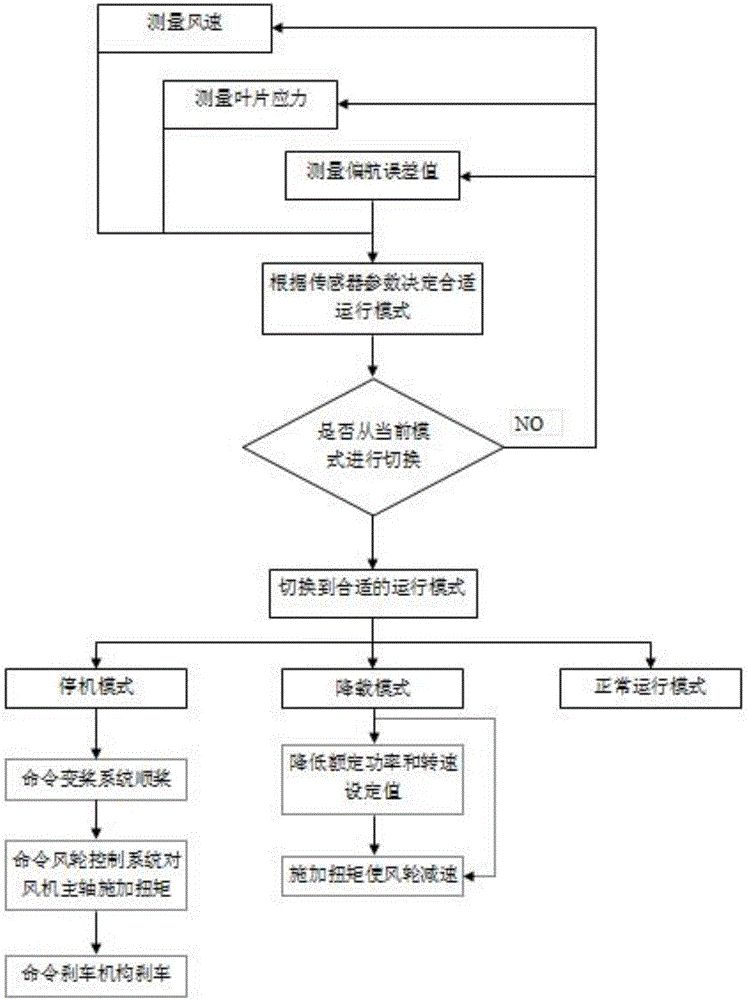

Load reducing system of wind generator set and working method of load reducing system

PendingCN106351792AReduce structural loadsOvercome limitationsWind motor controlMachines/enginesElectricityNetwork interface device

The invention discloses a load reducing system of a wind generator set and a working method of the load reducing system. The system comprises a machine readable storage device, display equipment, a display adapter, input equipment, sensors, a processor, a peripheral interface, a memory and network interface equipment, wherein the machine readable storage device, the display adapter, the input equipment, the sensors, the processor, the peripheral interface, the memory and the network interface equipment are in communication through a bus, the display equipment is in communication with the bus through the display adapter, and the network interface equipment is in communication with remote equipment through a network. The method includes the steps of inputting initial data, collecting parameters of all the sensors, selecting an operating mode and controlling a fan to enter the selected mode. According to the system and the method, various parameters in the operating process of the fan are collected, a variable pitch system, a yaw system, a braking system and the like are integrated, the structural load of the fan is effectively reduced, and the limitation of independent operation of the systems on reduction of the structural load is avoided.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

System and method for aircraft brake metering to alleviate structural loading

ActiveUS9085285B2Improve accuracyHigh sensitivityBraking action transmissionAircraft brake actuating mechanismsElectricityActuator

In a system and method for aircraft brake metering to alleviate structural loading, one or more electric brake actuators for wheel brakes having a range of brake clamping force are provided, and a brake actuation controller is configured to monitor commanded initiation of the aircraft, to limit initial brake effort of the electric brake actuators to a preset fraction of a maximum possible braking effort for a preset period of time, and to permit brake effort of the electric brake actuators up to the maximum possible braking effort after the preset period of time after initiation of braking has been commanded. The preset fraction is preferably approximately 50% of the maximum possible braking effort, and may be tuneable. The preset period of time is preferably approximately one second, and also may be tuneable.

Owner:HYDRO AIRE AEROSPACE CORP

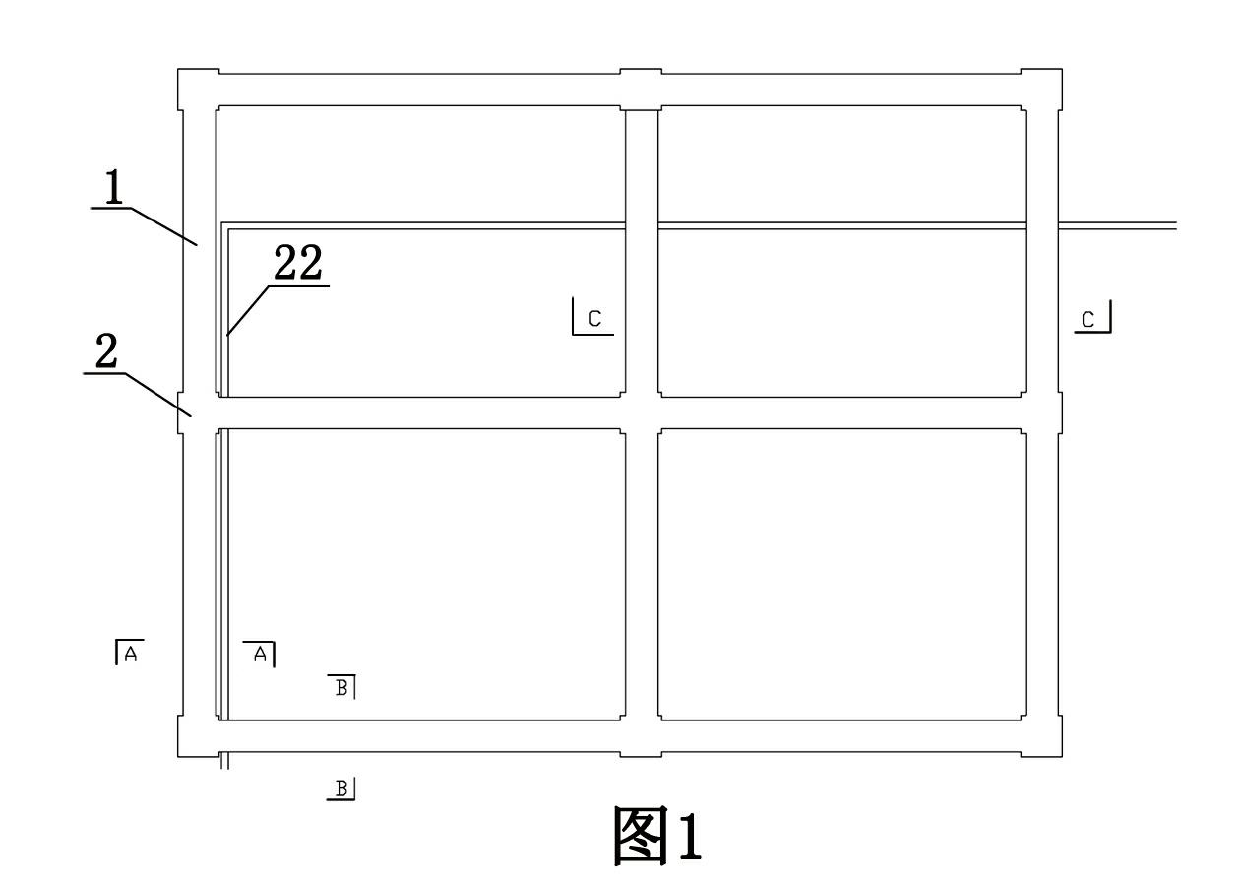

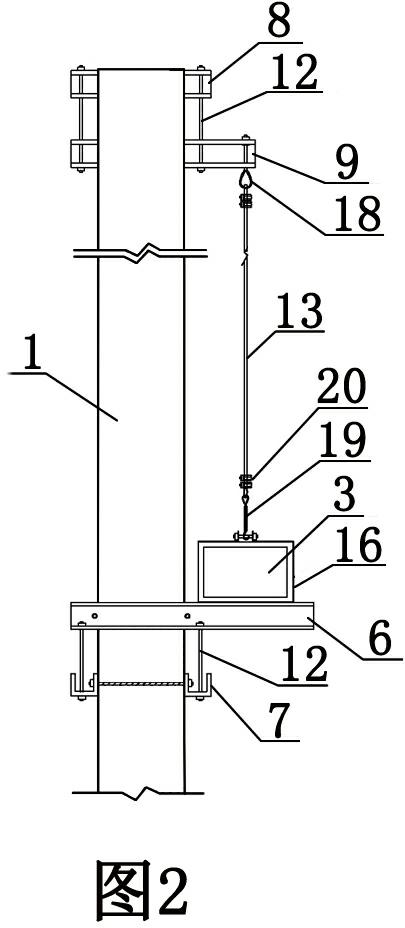

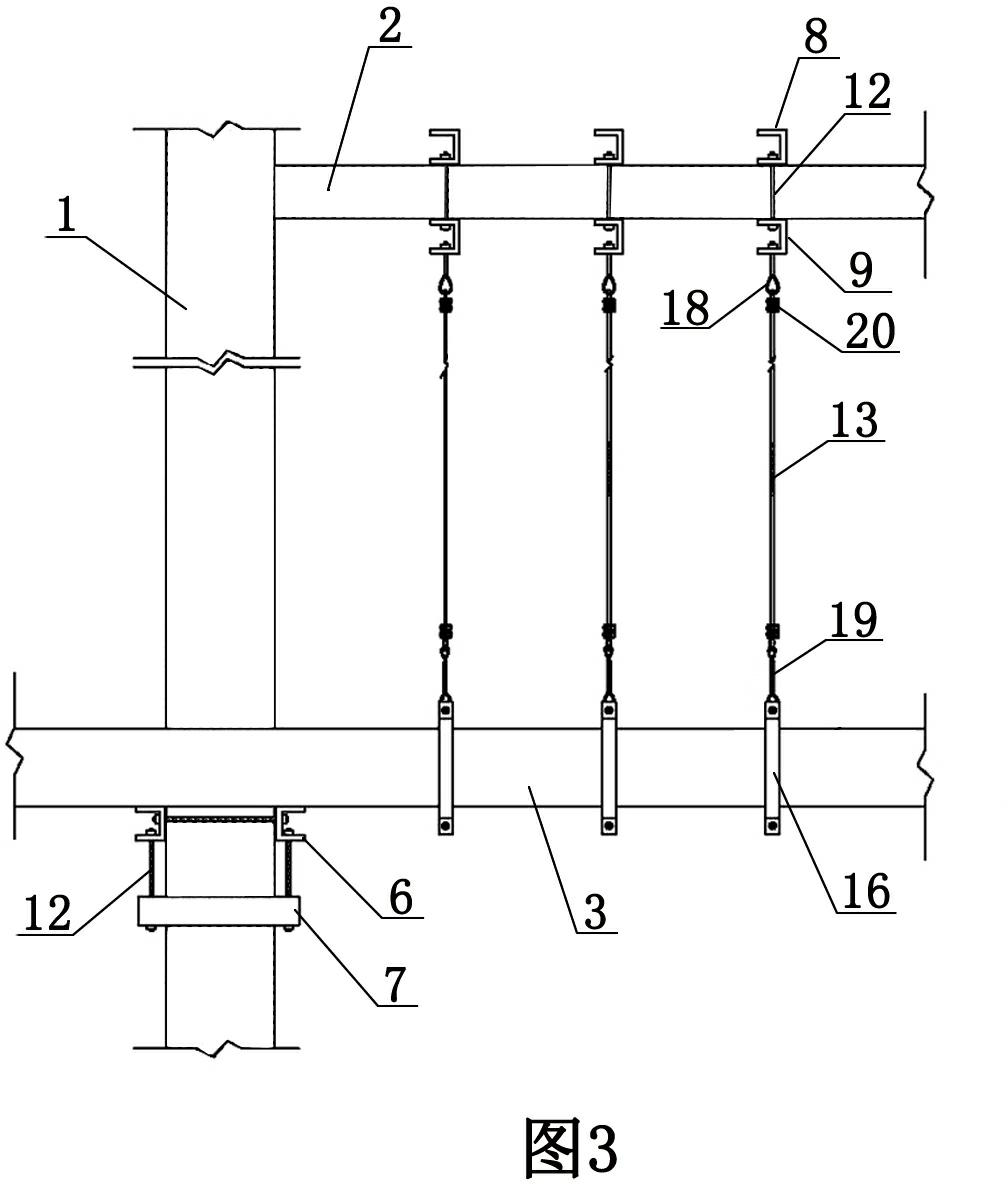

Steel wire hanging frame and construction method thereof

InactiveCN102174969AImprove stabilityFlexible choicePipe supportsBolt connectionBuilding construction

Owner:HUAJIANG CONSTR OF CHINA CONSTR FIRST BUILDING GROUP CORP +2

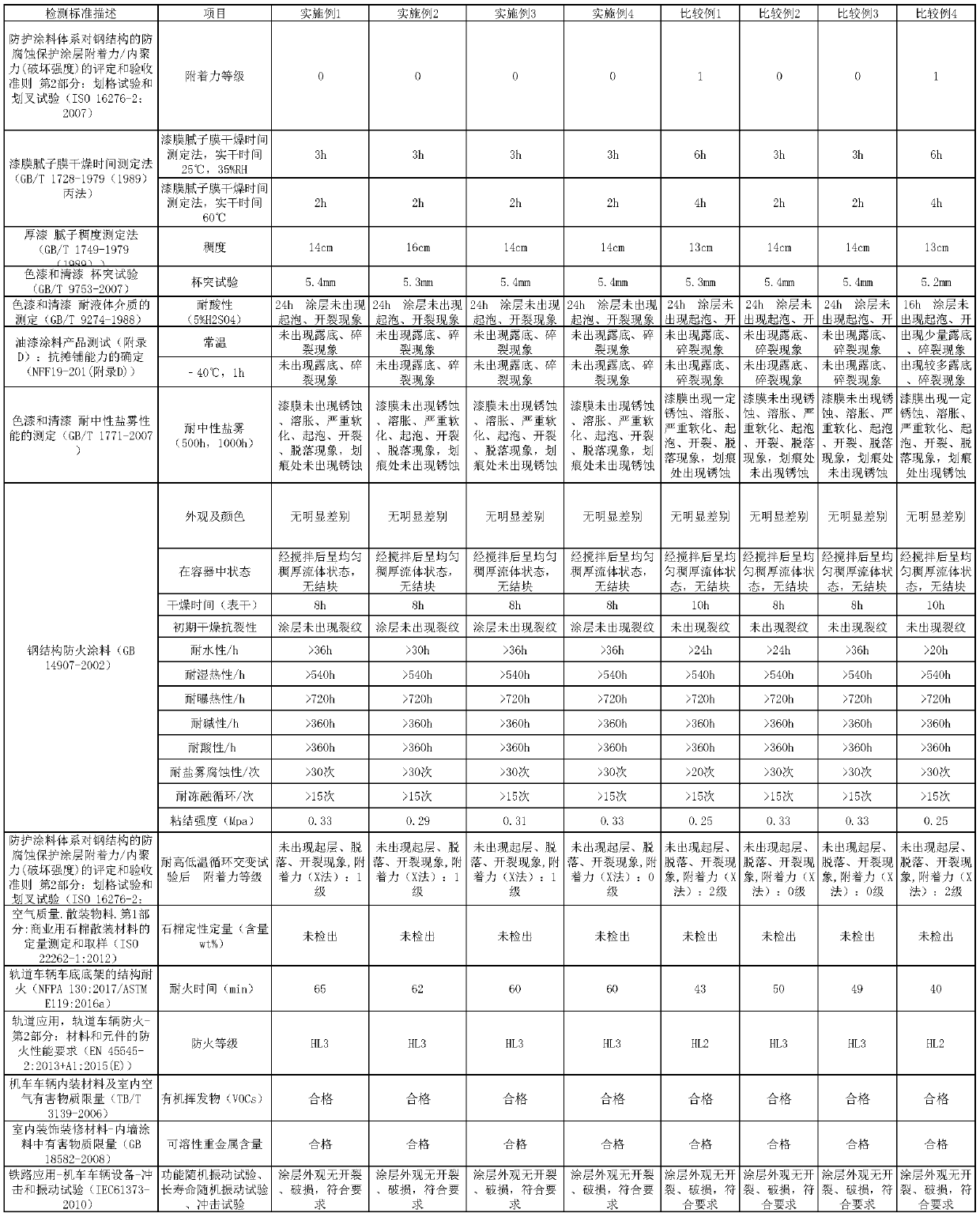

Water-based fireproof coating suitable for railway vehicle chassis and preparation method thereof

InactiveCN110591509AHigh expansion factorStable structureFireproof paintsEpoxy resin coatingsWater basedMelamine phosphate

The invention relates to a water-based fireproof coating suitable for railway vehicle chassis and a preparation method thereof, and belongs to the field of water-based fireproof coating. The water-based fireproof coating disclosed by the invention is prepared from the following substances in parts by mass: 20-30 parts of a film-forming substance, 40-60 parts of an intumescent flame-retardant system, 5-8 parts of titanium dioxide, 2-4 parts of nano magnesium aluminum hydroxide, 1-2 parts of organic bentonite, 1-3 parts of expandable graphite, 9-17 parts of deionized water, 0.8-1.3 parts of a film-forming aid, 0.2-0.5 part of a dispersing agent and 0.2-0.5 part of a defoaming agent; the intumescent flame-retardant system is prepared from melamine phosphate, dipentaerythritol and melamine, and the mass part ratio of the melamine phosphate to the dipentaerythritol to the melamine is 1.8-2.3: 0.8-1.2: 0.8-1.2. The water-based fireproof coating can met structure fire-resistant requirement of the chassis of the railway vehicles; no volatilization of harmful substances such as organic solvents is caused in the construction and drying processes; the occupational health and safety of constructors are guaranteed; equipment can be flexibly selected for use according to different scenes; investment of special equipment is reduced; and production cost is reduced.

Owner:河北萨迪科轨道交通科技有限公司

Brake having lever and idler brake shoes

InactiveUS20140116819A1Less variationEasy to brakeBraking element arrangementsBraking membersEngineeringBrake shoe

A brake includes a pair of lever brake shoes and a pair of idler brake shoes. The lever brake shoes are each pivotally coupled to a brake spider at a first end. The idler brake shoes are each pivotally coupled to the brake spider at a first end and to corresponding ones of the first and second lever brake shoes at a second end. The pivotal connections to the brake spider may be different for each of the lever and idler brake shoes. An actuating member engages the second end of each of the lever brake shoes and causes the lever brake shoes and idler brake shoes to move between positions of engagement and disengagement with a braking surface. The linings on the lever brake shoes may be circumferentially nearer to the first ends of each shoe than the second end of each shoe.

Owner:BENDIKS SPAJSER FAUNDEJSHN BREJK LLK

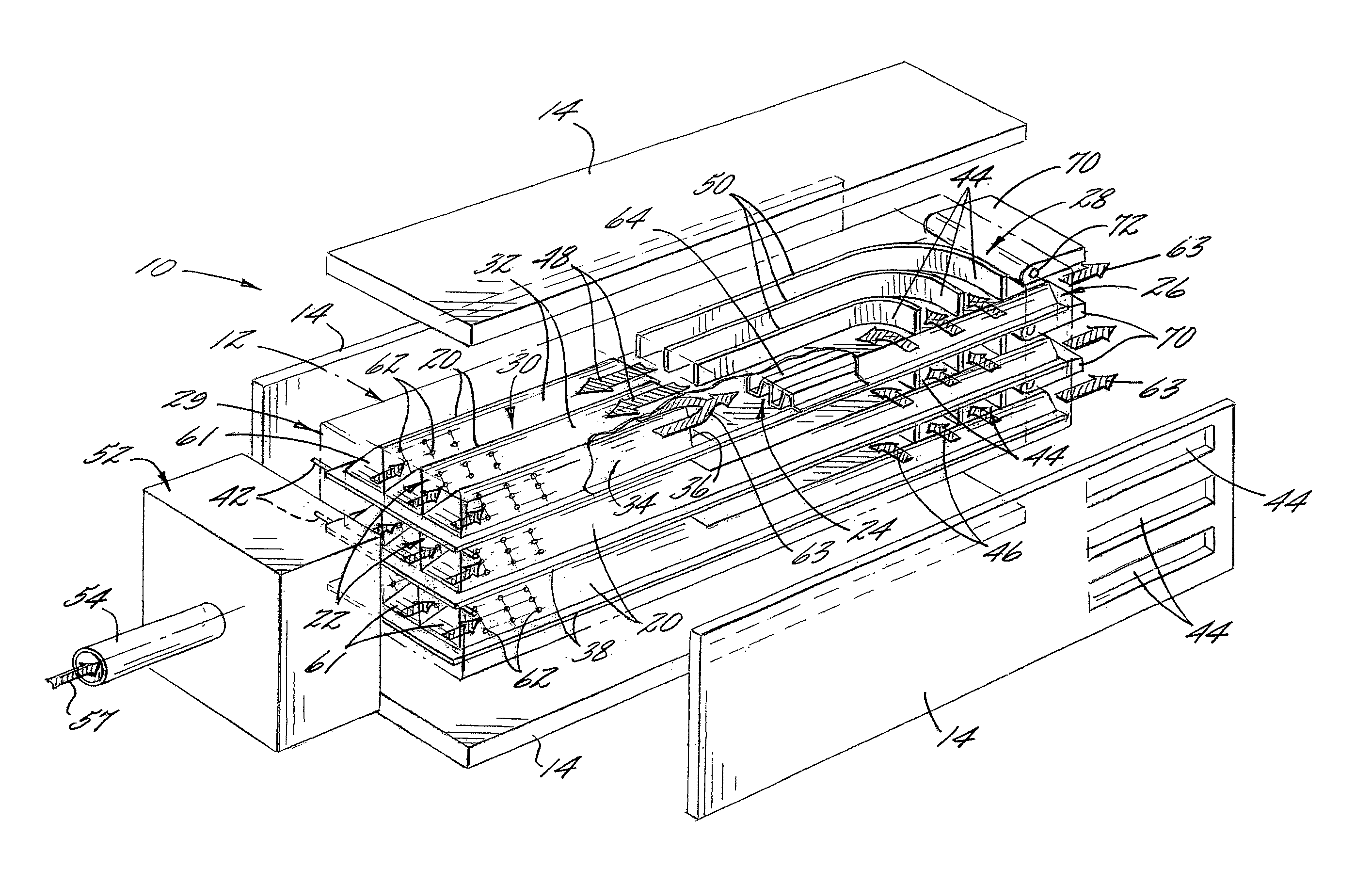

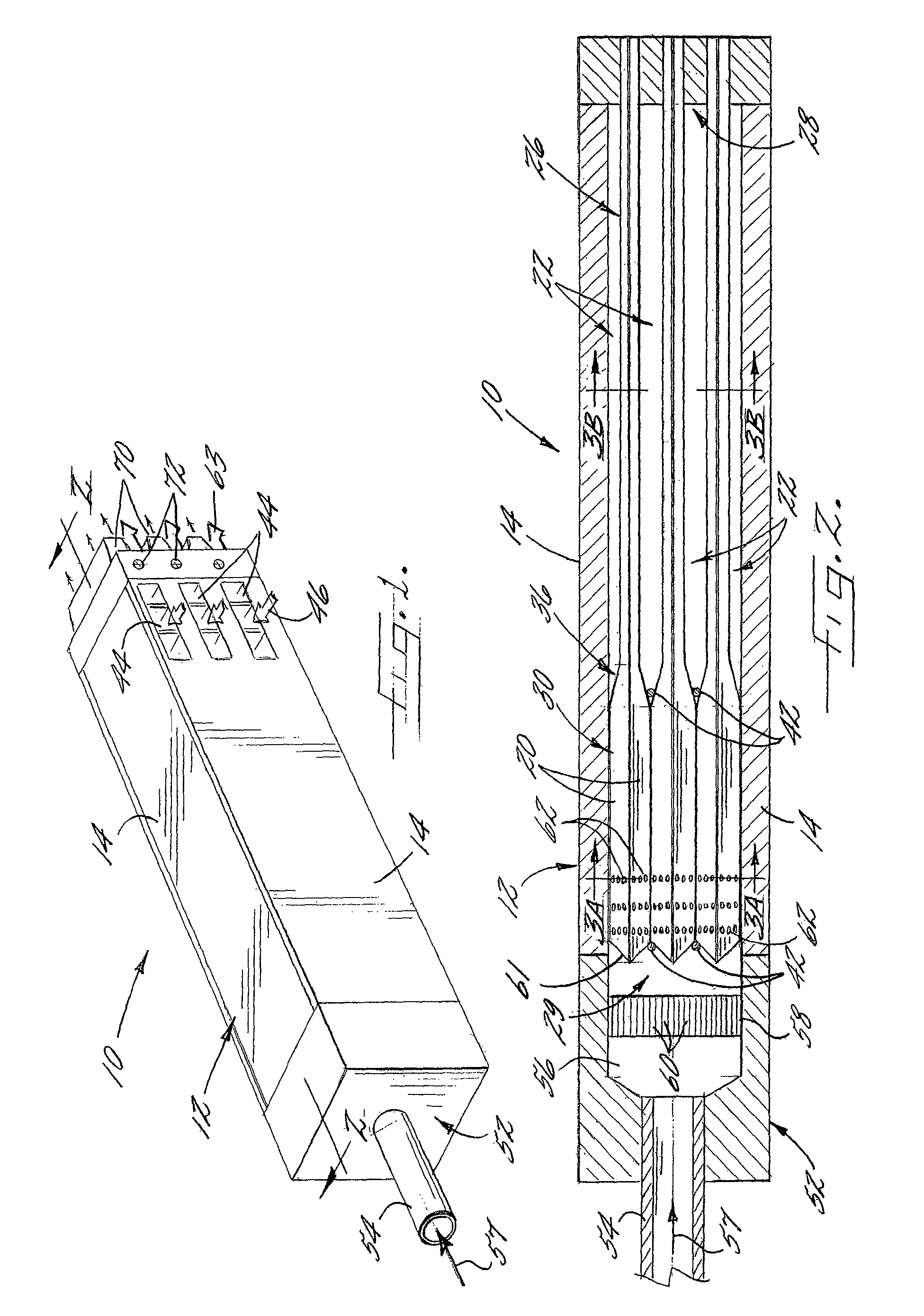

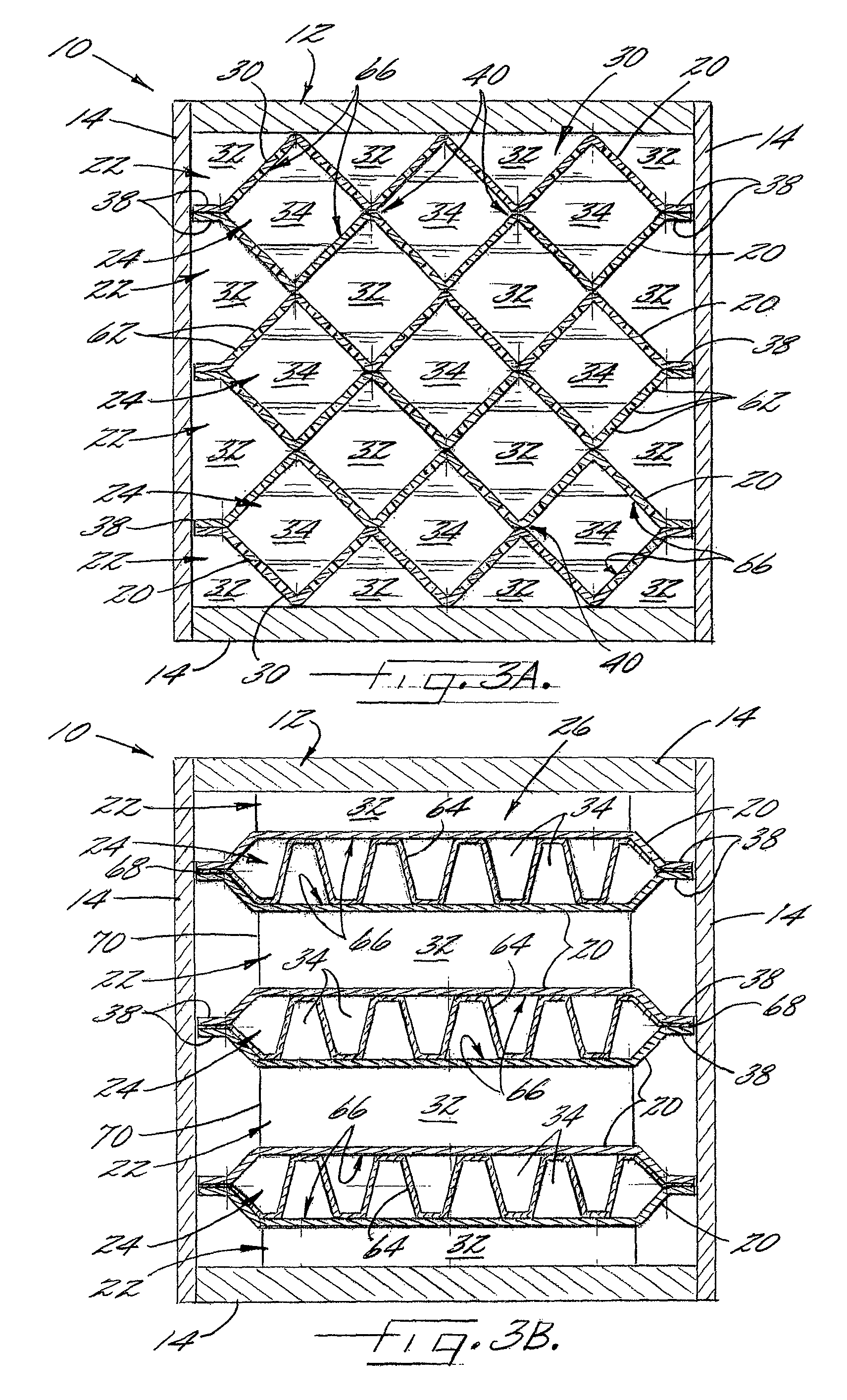

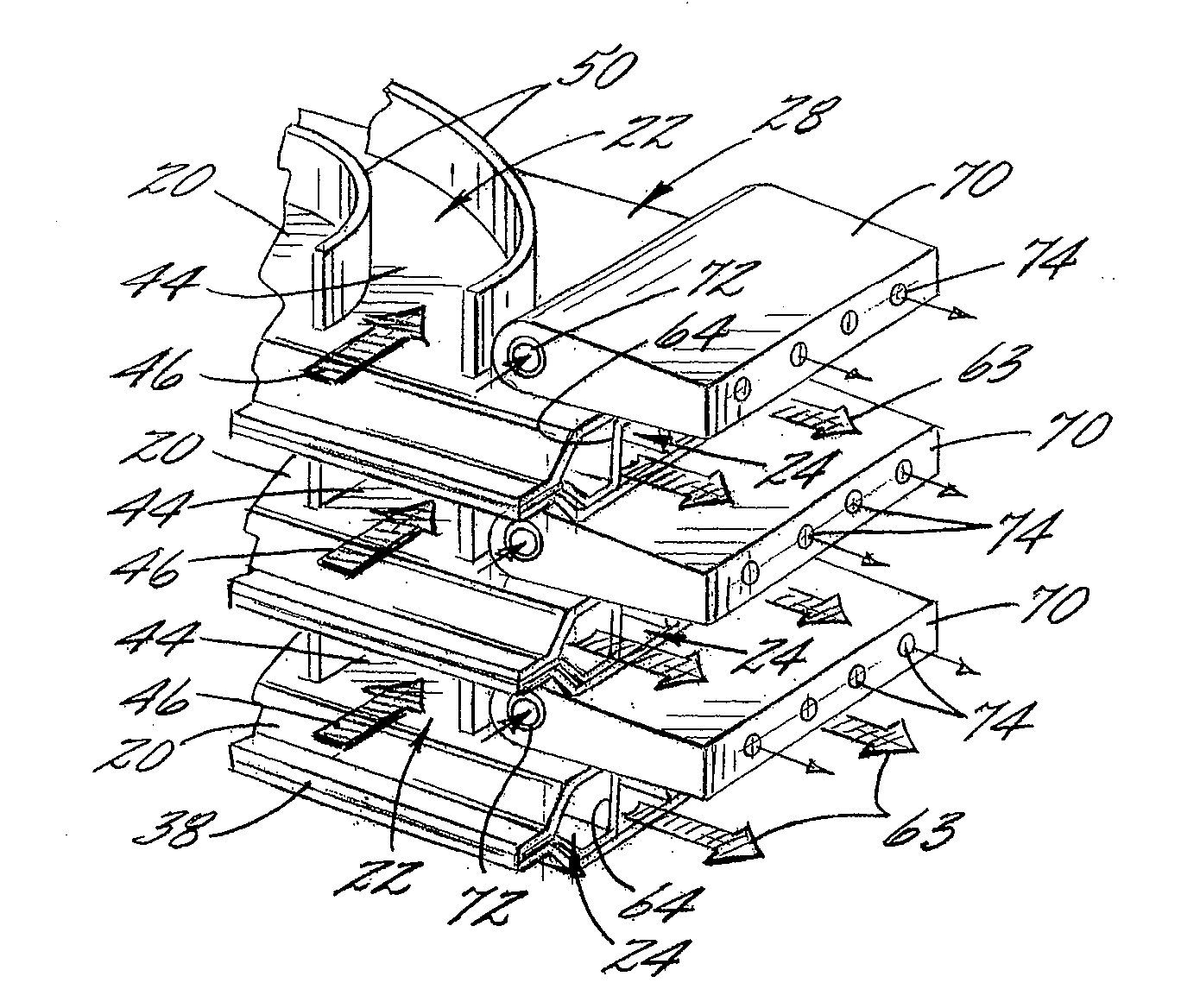

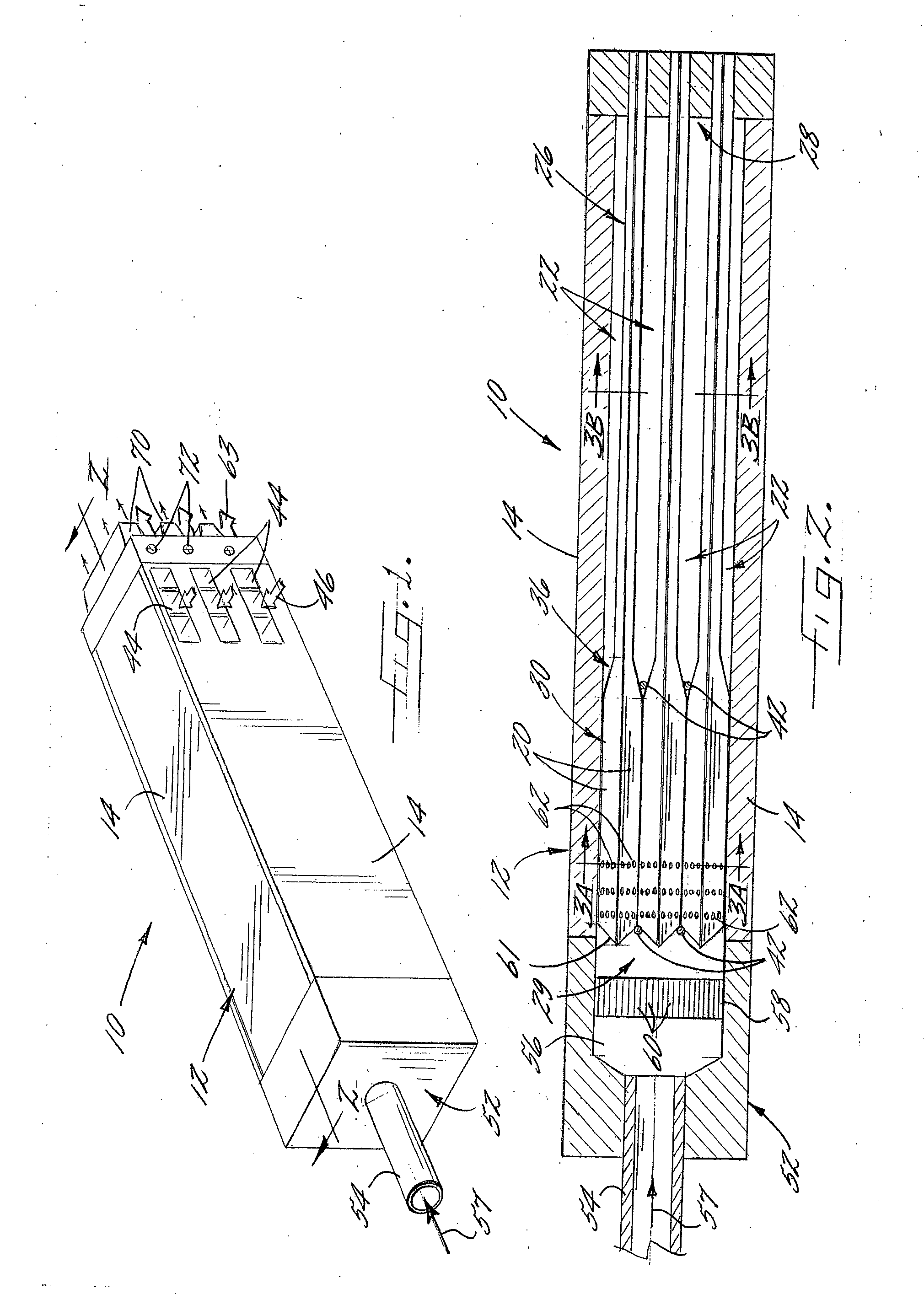

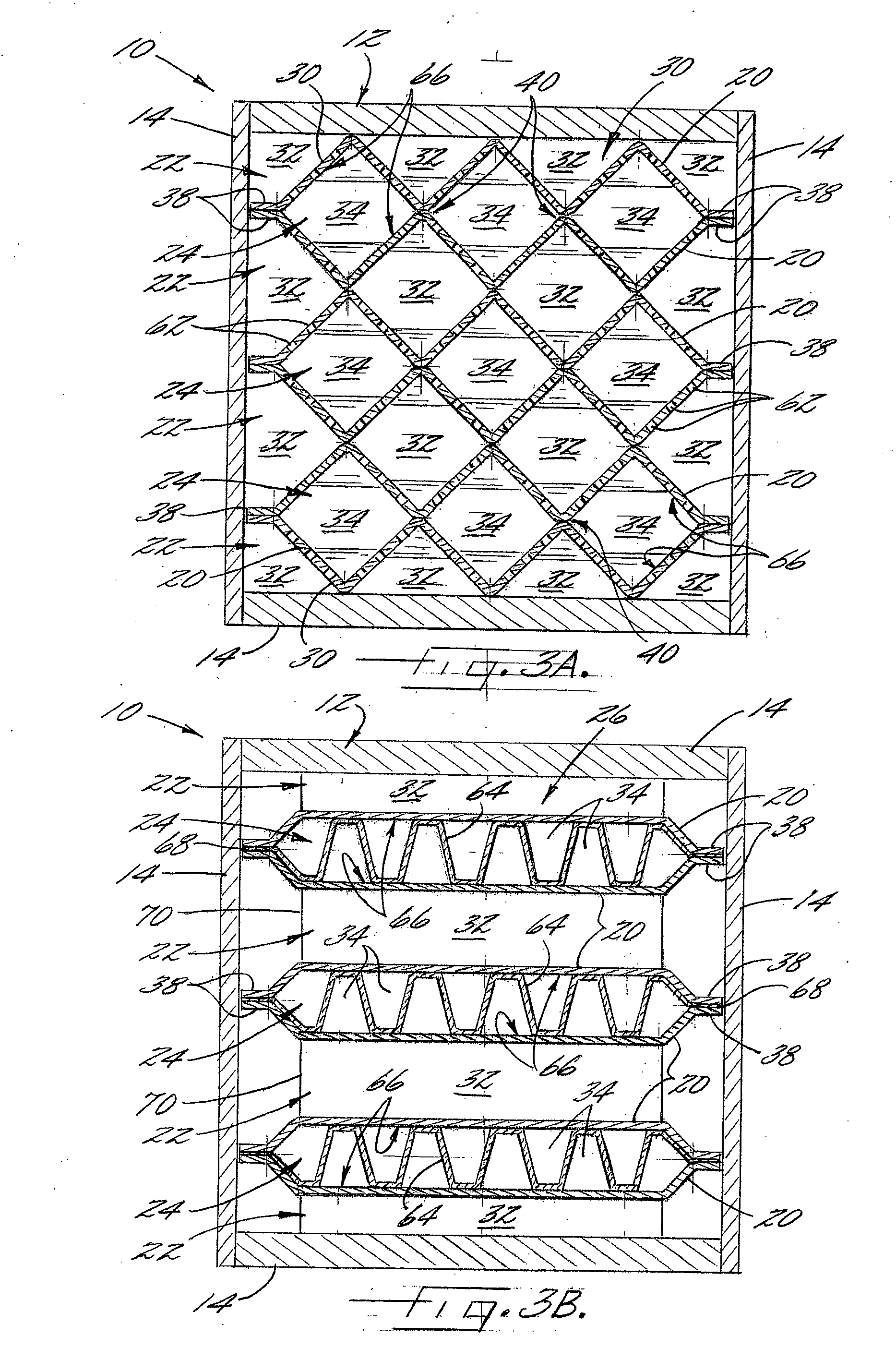

Formed sheet heat exchanger

ActiveUS7988447B2Improve thermal efficiencyEfficient heat exchangeBurnersTurbine/propulsion fuel supply systemsThermal energyPlate heat exchanger

A formed sheet heat exchanger is provided for exchanging heat between fluids is provided. The apparatus includes flow divider sheets that are positioned in a stacked configuration and extend in a longitudinal direction so that adjacent pairs of the sheets define flow passages therebetween for receiving first and second fluids. Each of the sheets is nonuniform in the longitudinal direction, having a manifold portion and a corrugated portion. The corrugated portions of each adjacent pair of sheets define a plurality of fluid channels therebetween that are connected to the portion of the flow passage defined between the manifold portions. The fluid channels are configured to receive the first or second fluids and transfer thermal energy therebetween through the flow divider sheets.

Owner:THE BOEING CO

Formed Sheet Heat Exchanger

ActiveUS20080047700A1Improve thermal efficiencyEfficient heat exchangeBurnersTurbine/propulsion fuel supply systemsThermal energyPlate heat exchanger

A formed sheet heat exchanger is provided for exchanging heat between fluids is provided. The apparatus includes flow divider sheets that are positioned in a stacked configuration and extend in a longitudinal direction so that adjacent pairs of the sheets define flow passages therebetween for receiving first and second fluids. Each of the sheets is nonuniform in the longitudinal direction, having a manifold portion and a corrugated portion. The corrugated portions of each adjacent pair of sheets define a plurality of fluid channels therebetween that are connected to the portion of the flow passage defined between the manifold portions. The fluid channels are configured to receive the first or second fluids and transfer thermal energy therebetween through the flow divider sheets.

Owner:THE BOEING CO

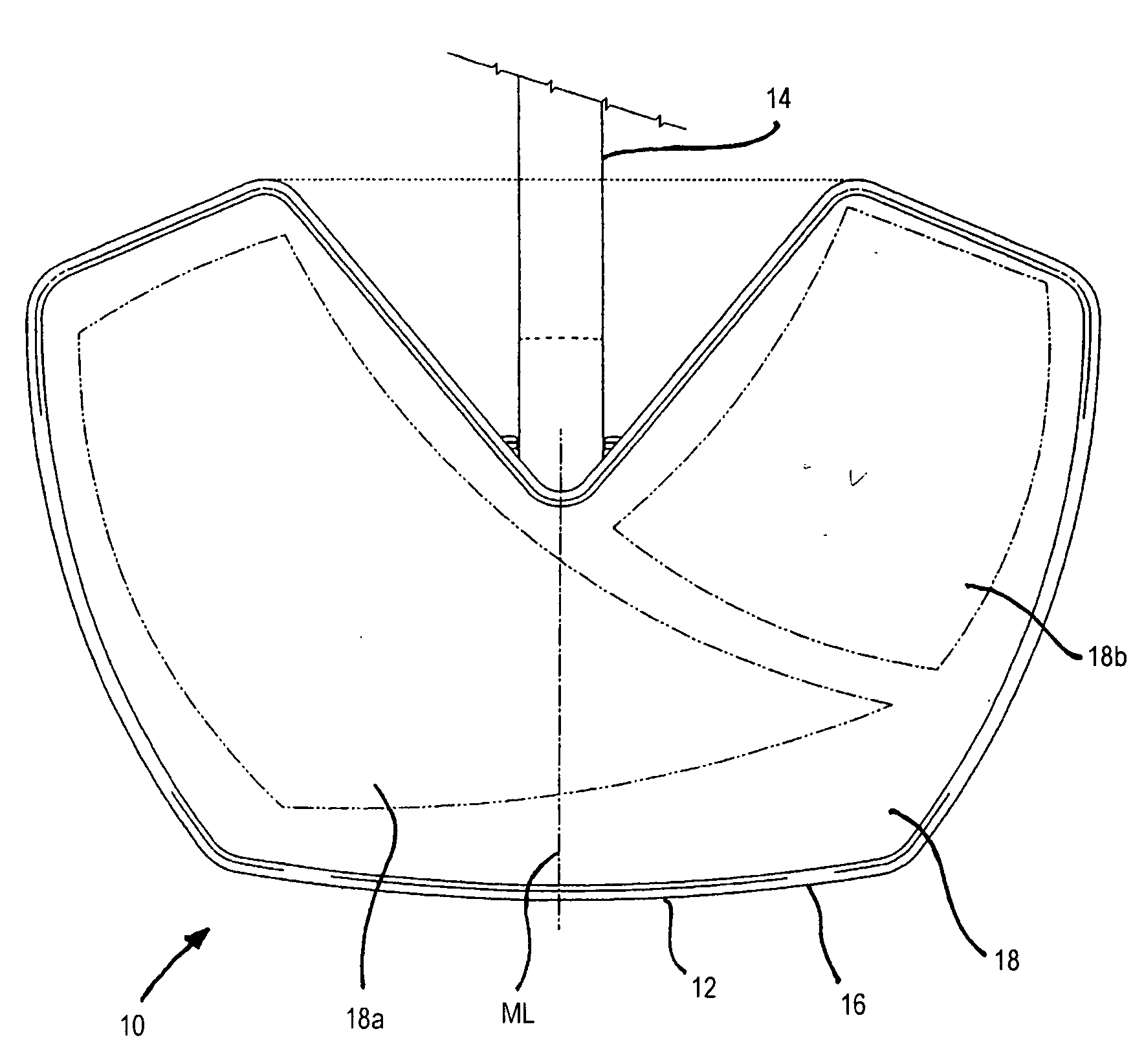

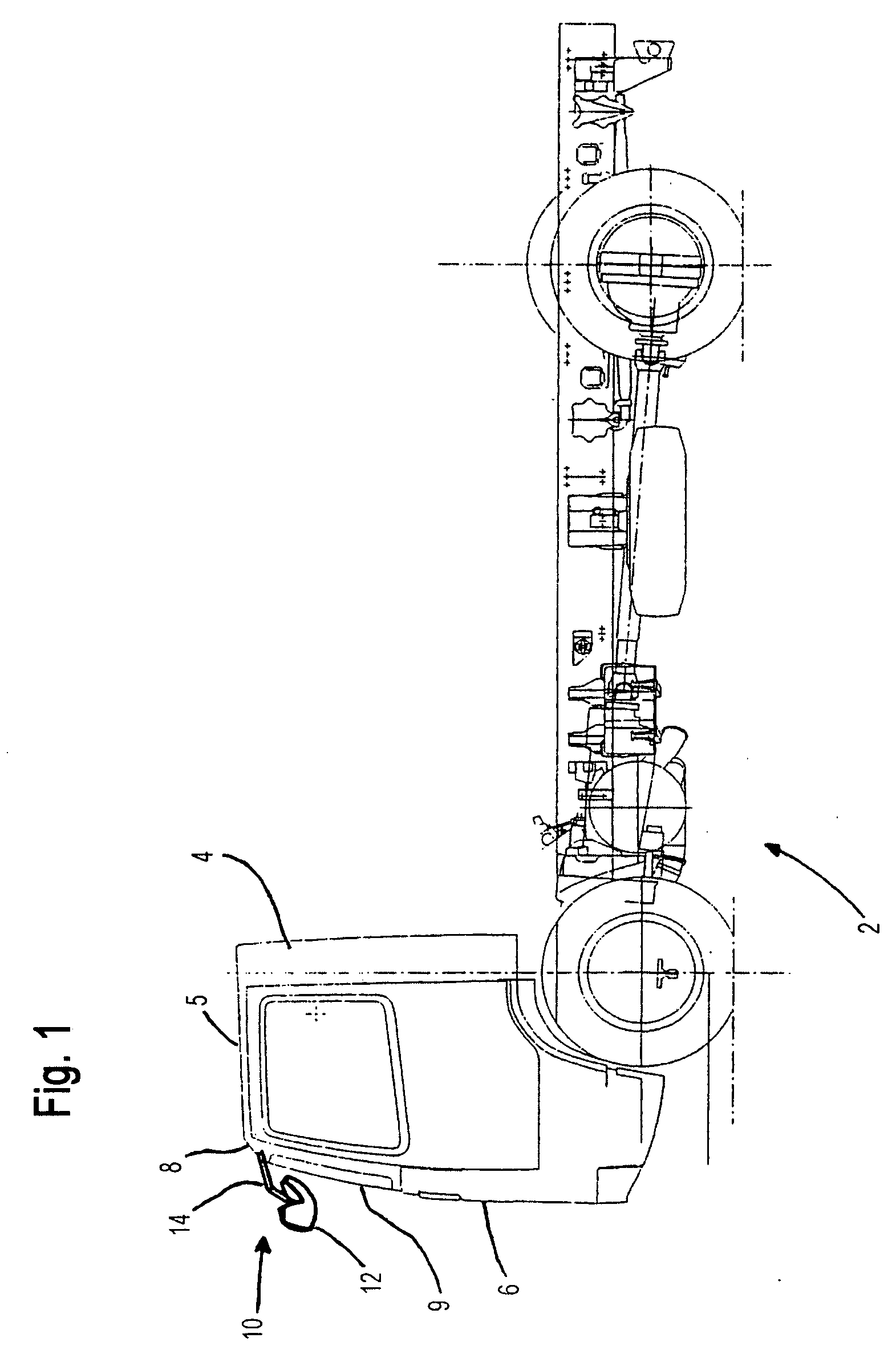

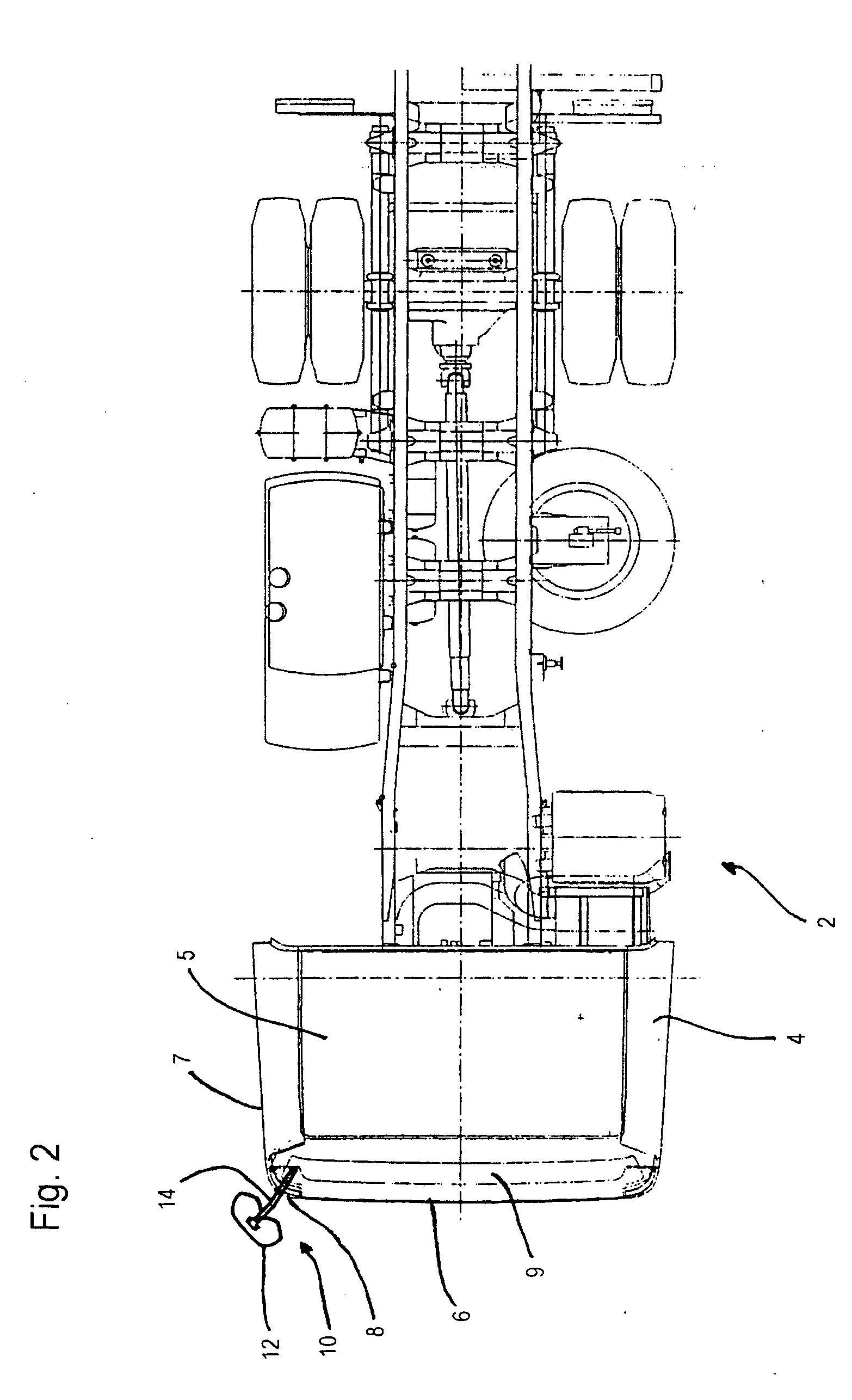

Combined roof and front mirror description

The invention concerns an external mirror arrangement comprising a front mirror of the Group of the Directive 2005 / 27 / EG for the visual transmission of a first field of view and for the visual transmission of a second field of view contains a safety mirror. In accord with the invention, the front mirror and the safety mirror are integrated in one mirror head.

Owner:LANG MEKRA NORTH AMERICA LLC

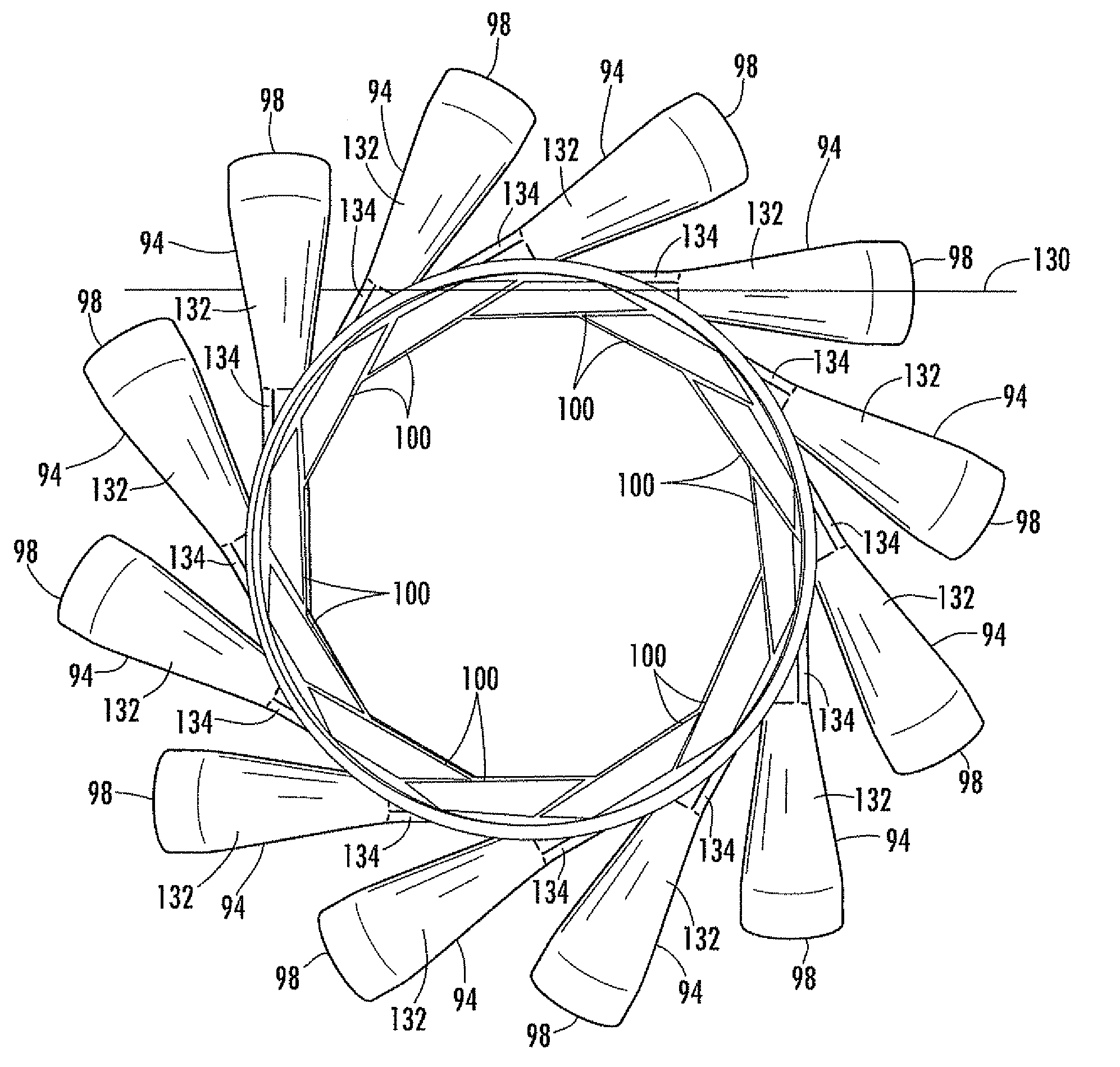

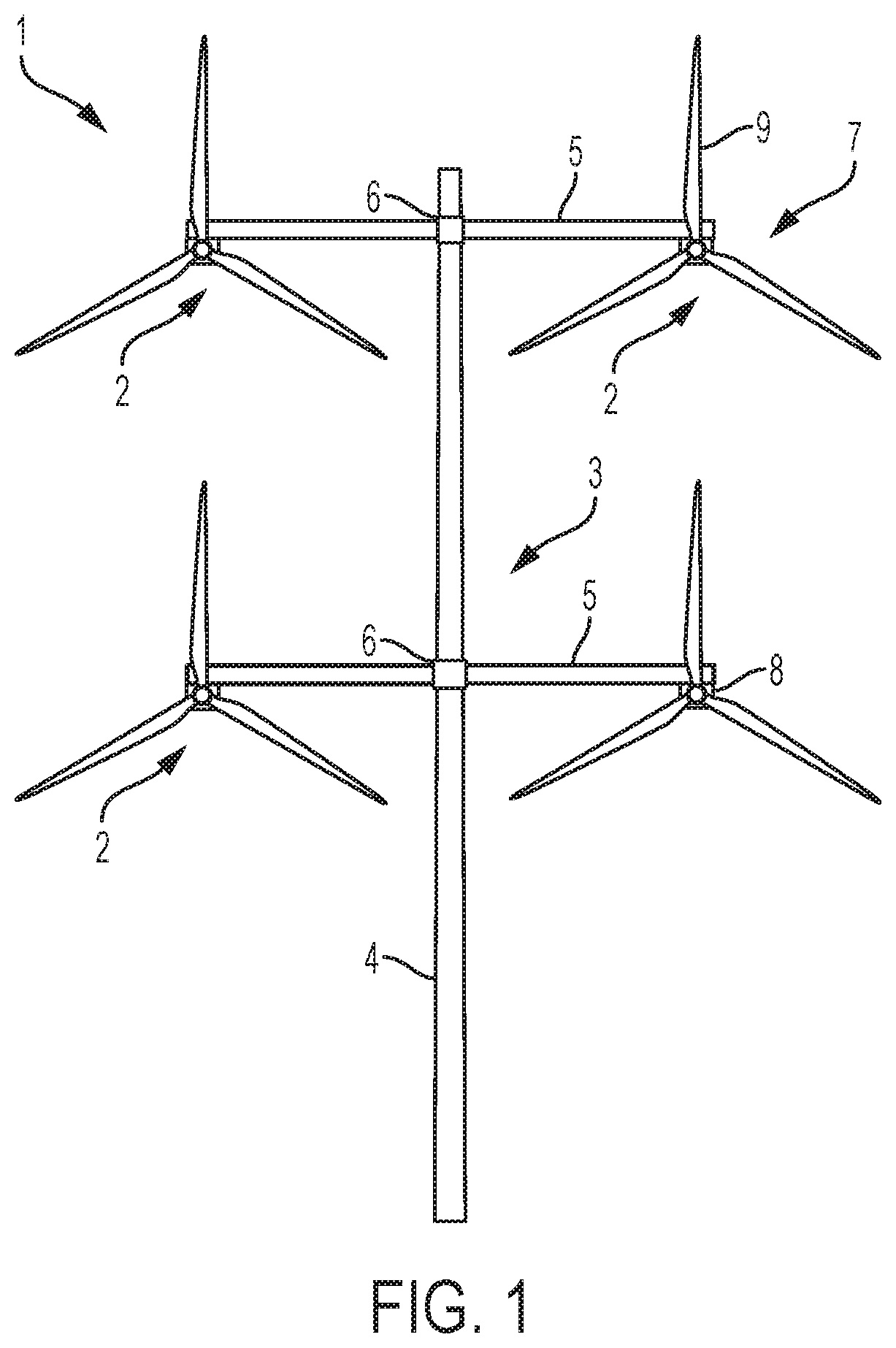

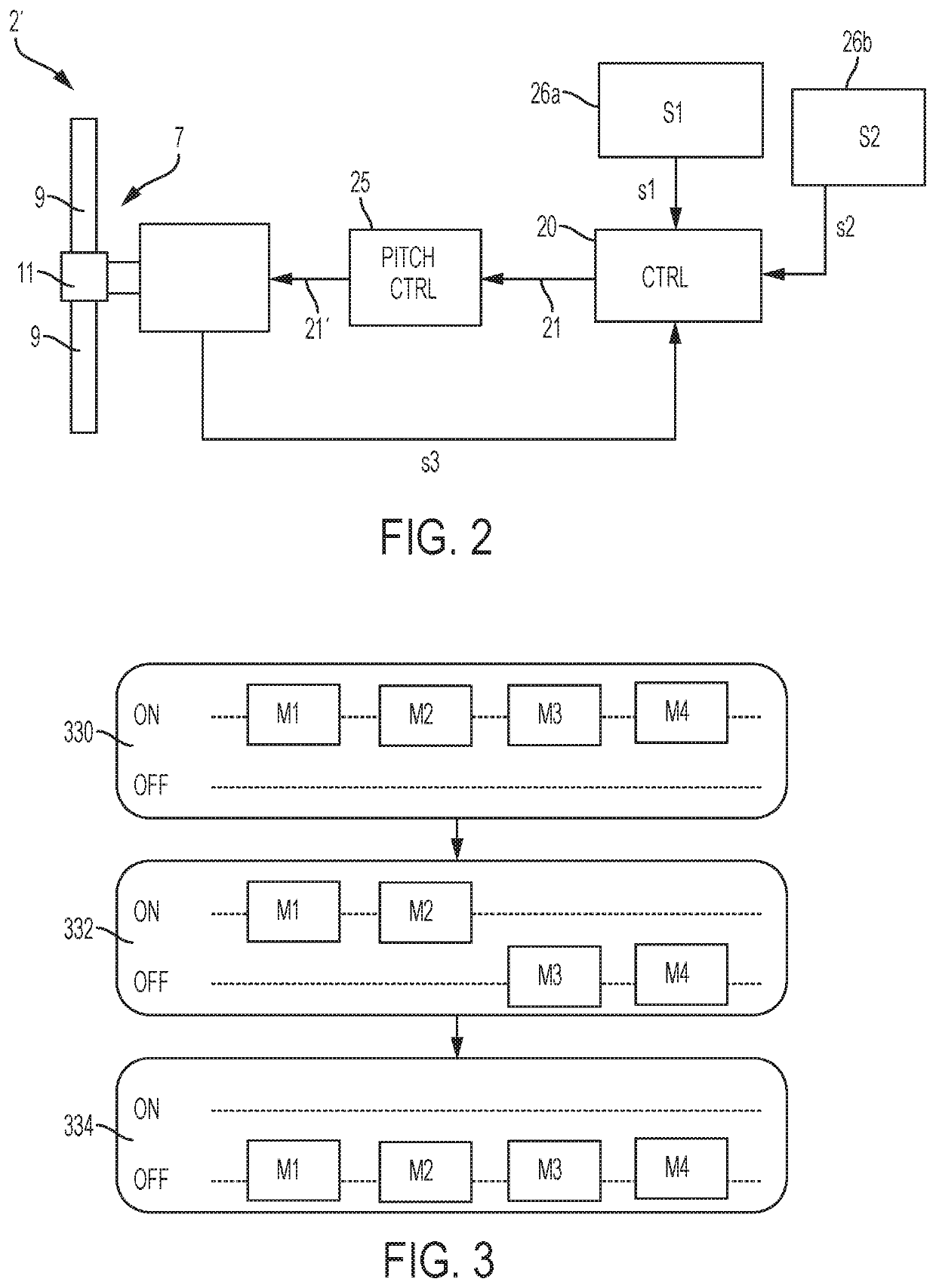

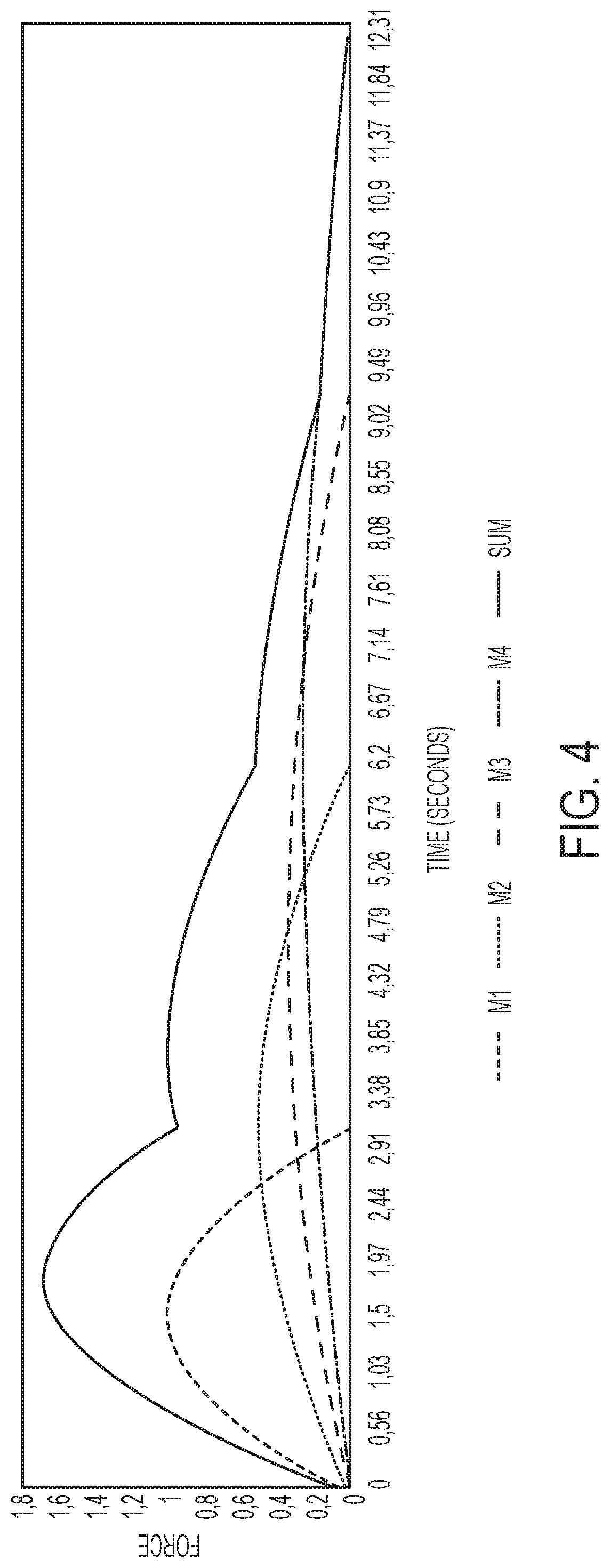

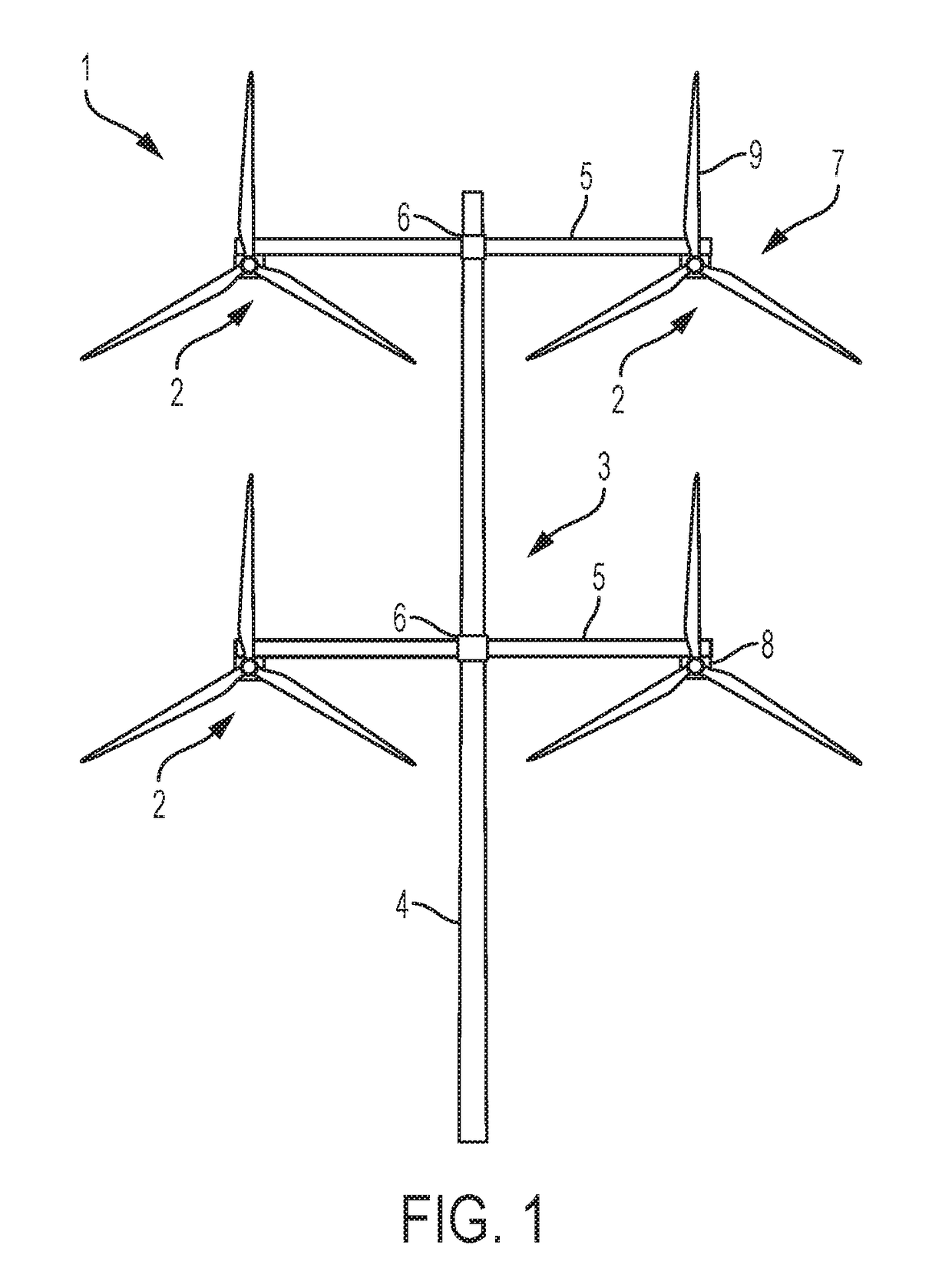

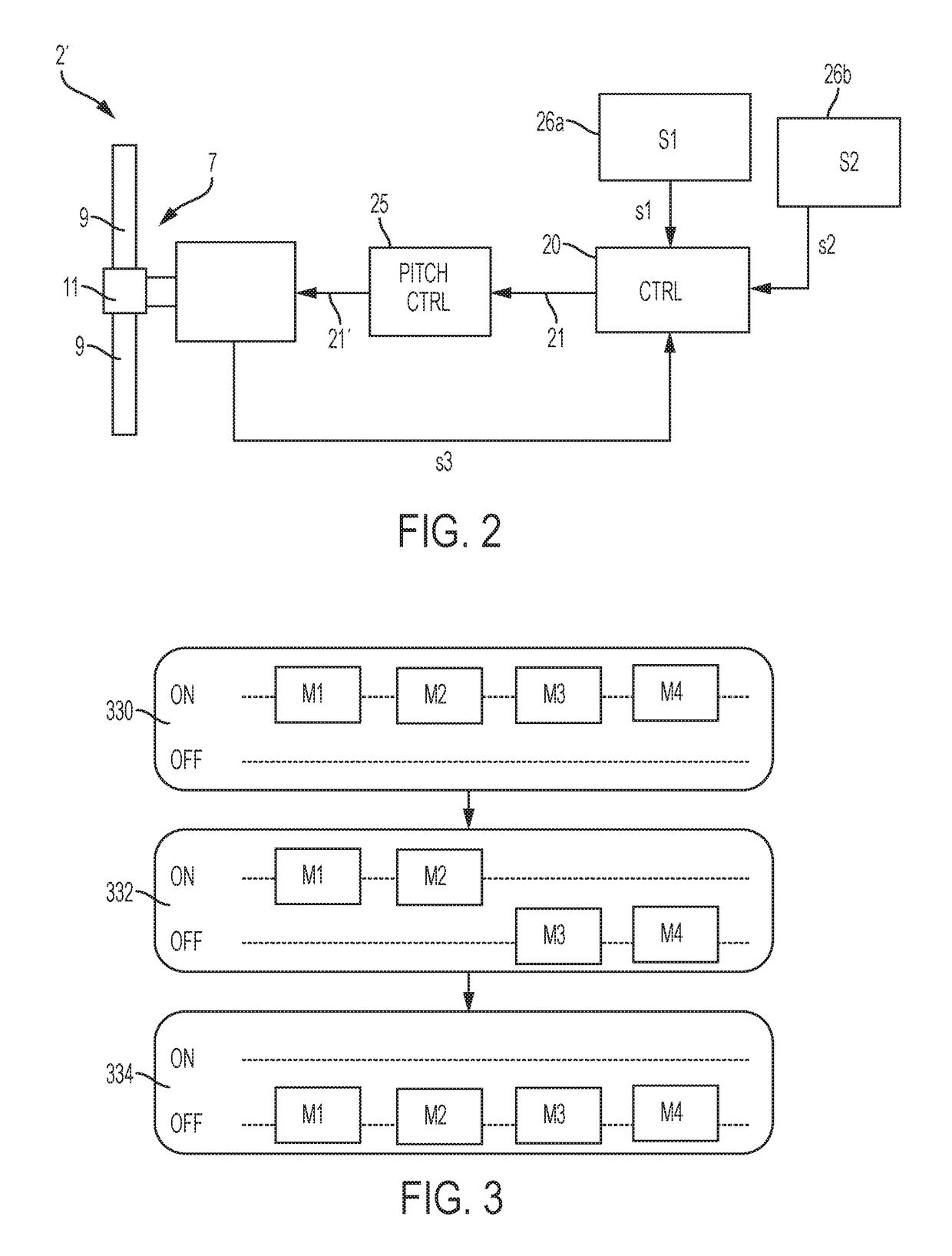

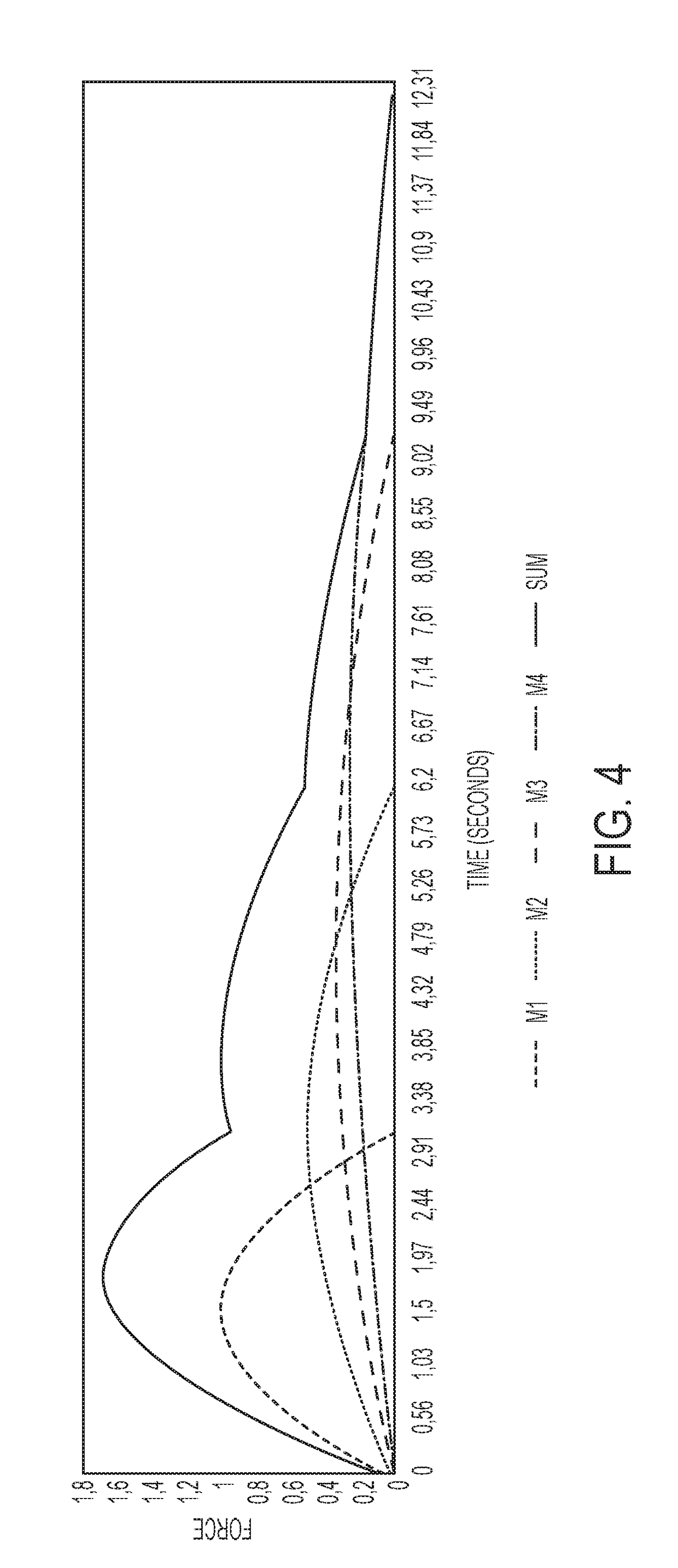

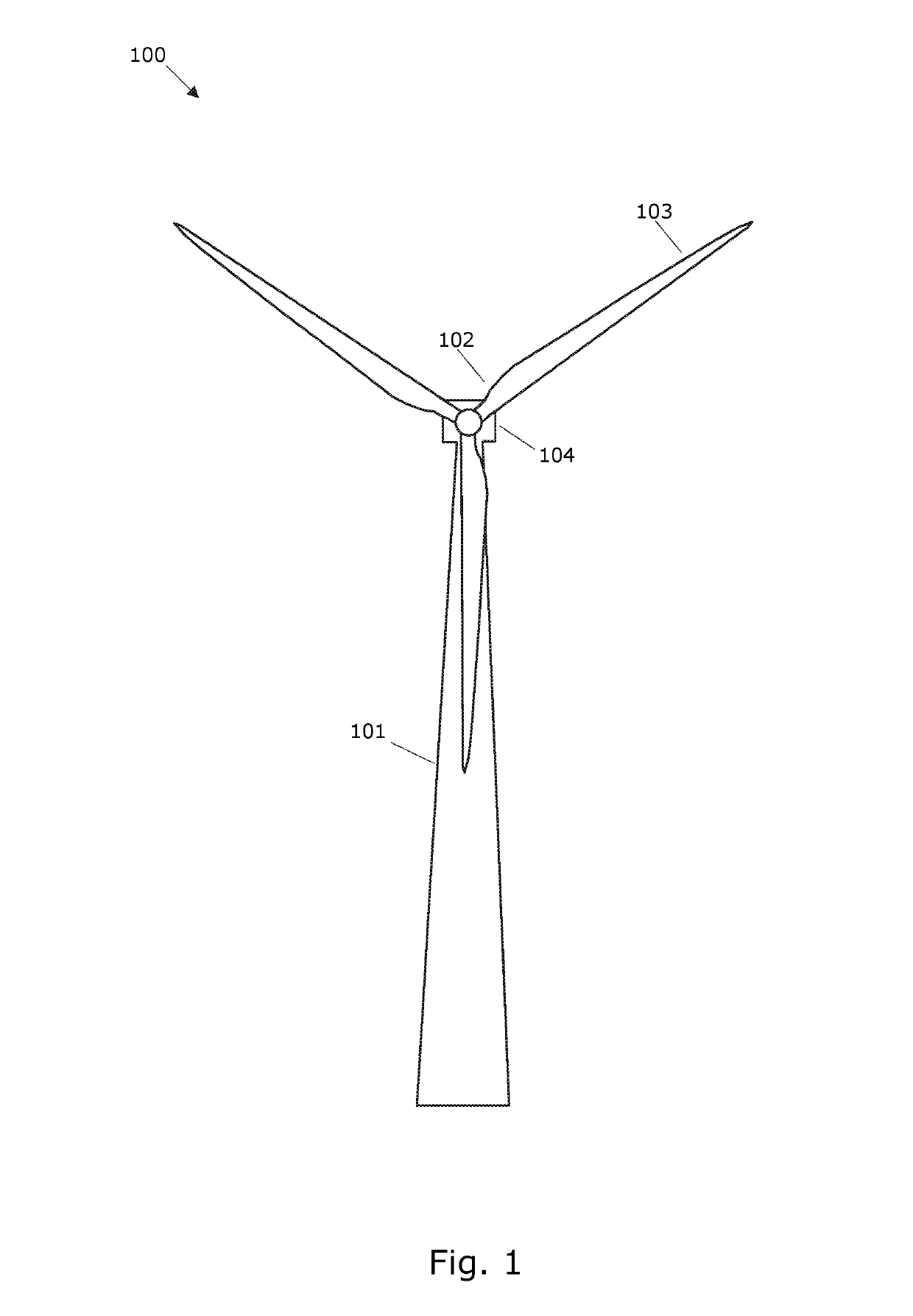

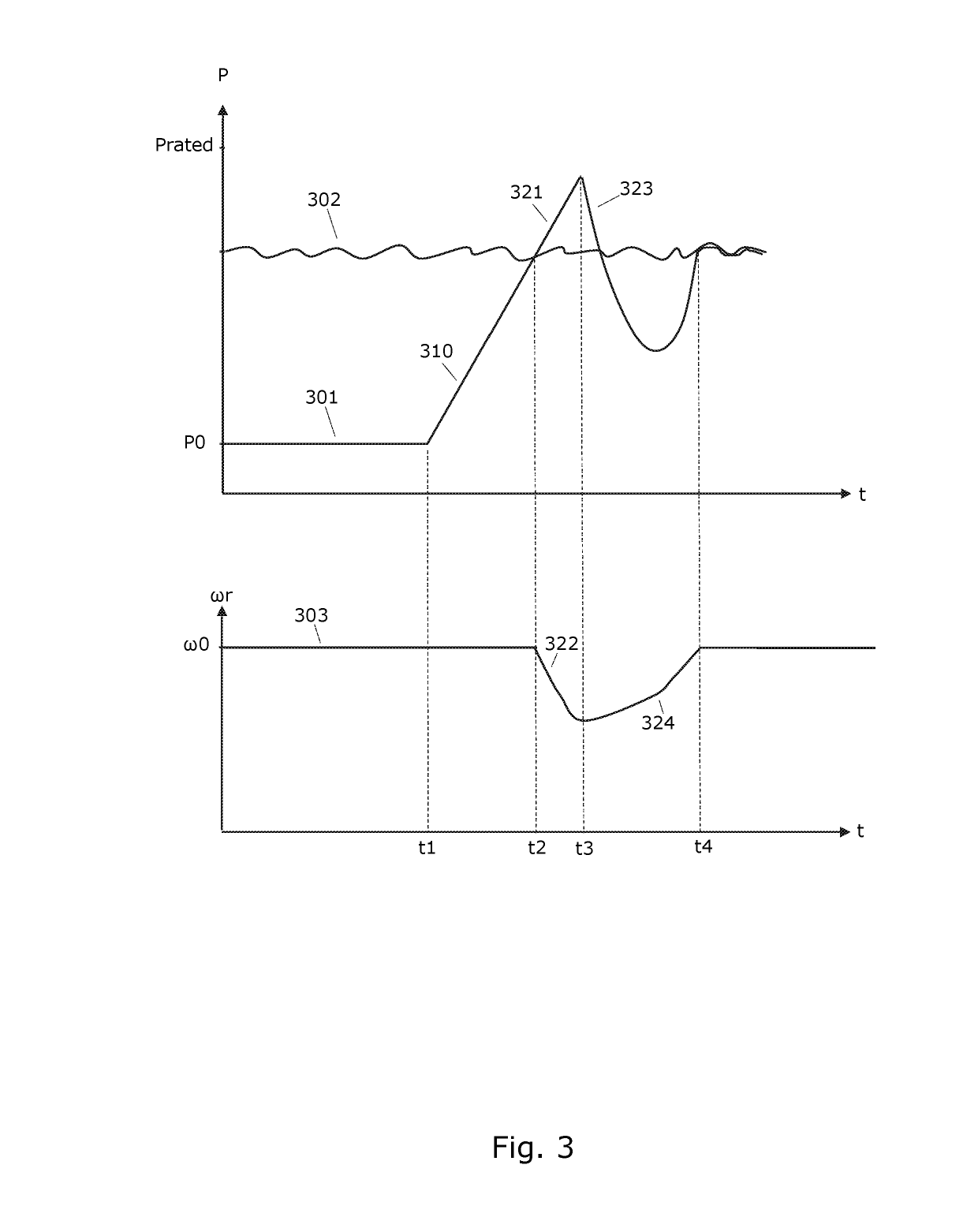

Wind turbine system with time distributed transitions

ActiveUS10808682B2Reduced life-timeExtended service lifeWind motor controlEngine fuctionsControl systemTime distribution

There is presented a wind turbine system, wherein the wind turbine system is comprising a support structure, a plurality of wind turbine modules mounted to the support structure wherein each of the plurality of wind turbine modules comprises a rotor, and wherein the wind turbine system further comprises a control system, wherein the control is arranged to execute a wind turbine system transition from a first system operational state of the wind turbine system to a second system operational state of the wind turbine system, and wherein the wind turbine system transition is performed by executing a plurality of wind turbine module transitions from a first module operational state of a wind turbine module to a second module operational state of the wind turbine module wherein the plurality of wind turbine module transitions are distributed in time with respect to each other.

Owner:VESTAS WIND SYST AS

Wind turbine system with time distributed transitions

ActiveUS20190003457A1Reduced life-timeExtended service lifeWind motor controlEngine fuctionsControl systemTime distribution

There is presented a wind turbine system, wherein the wind turbine system is comprising a support structure, a plurality of wind turbine modules mounted to the support structure wherein each of the plurality of wind turbine modules comprises a rotor, and wherein the wind turbine system further comprises a control system, wherein the control is arranged to execute a wind turbine system transition from a first system operational state of the wind turbine system to a second system operational state of the wind turbine system, and wherein the wind turbine system transition is performed by executing a plurality of wind turbine module transitions from a first module operational state of a wind turbine module to a second module operational state of the wind turbine module wherein the plurality of wind turbine module transitions are distributed in time with respect to each other.

Owner:VESTAS WIND SYST AS

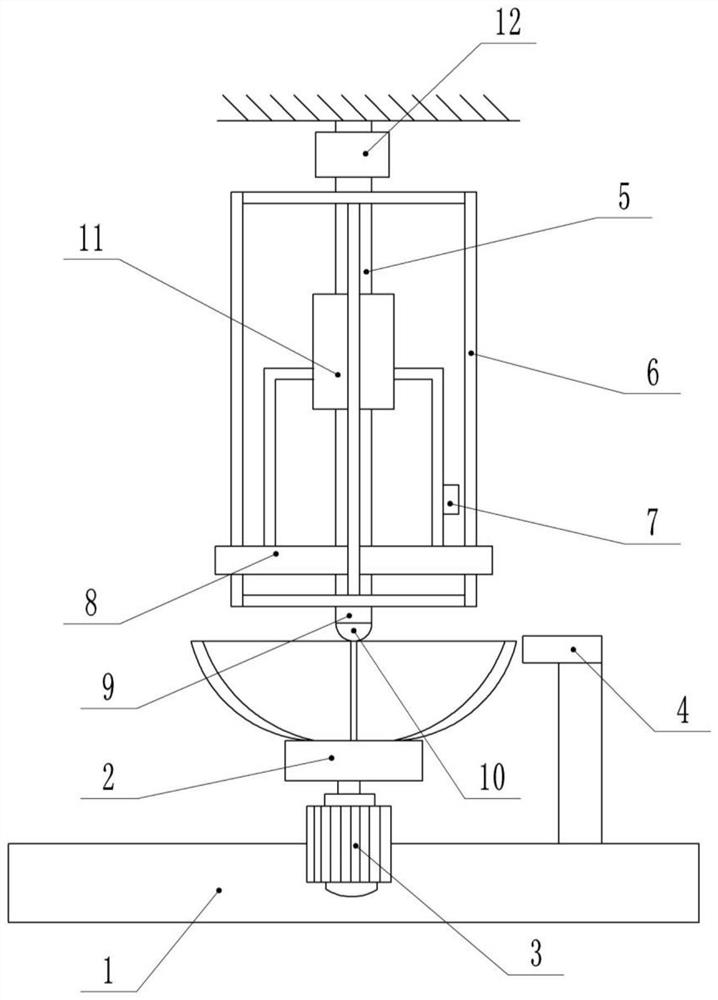

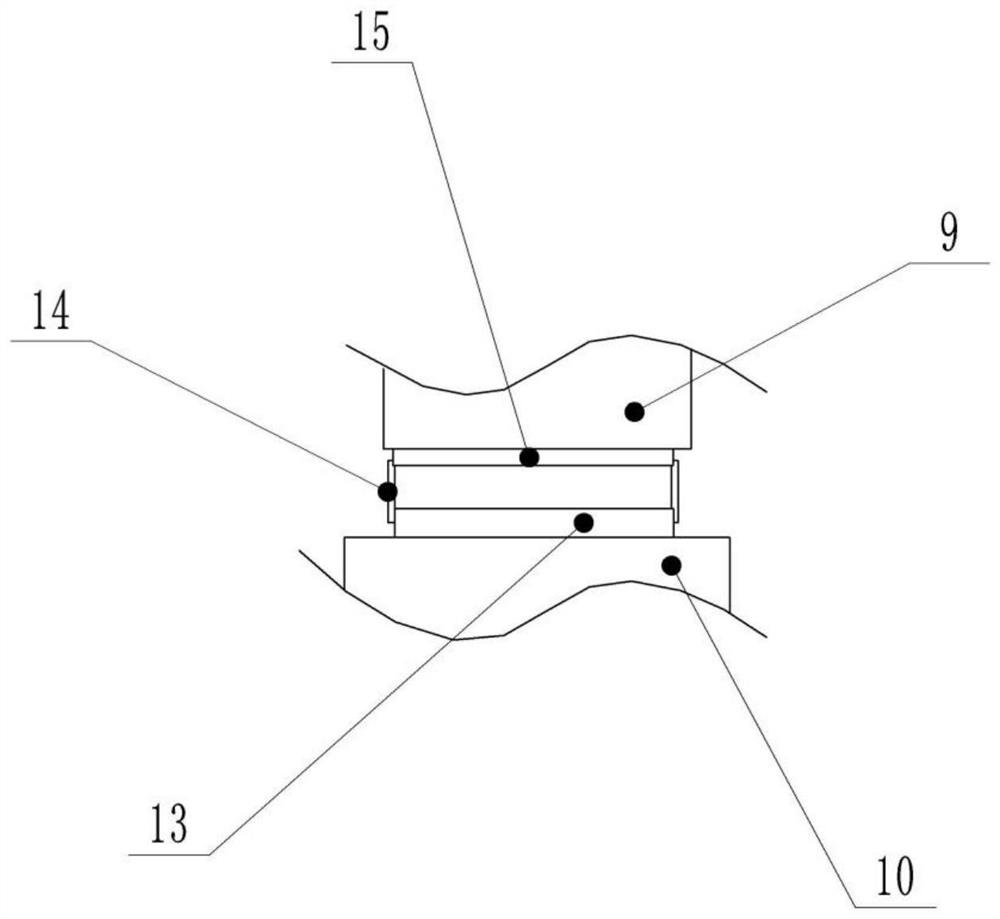

Intelligent pot trimming device

PendingCN113351892AReduce security risksImprove safety performanceWork clamping meansTurning machinesElectric machineryEngineering

The invention belongs to the field of pot processing equipment, and particularly relates to an intelligent pot trimming device. The intelligent pot trimming device comprises a trimmer and a rack, wherein a central shaft is fixedly mounted on the rack; a rotating disc and a motor for driving the rotating disc to rotate are arranged under the central shaft; a fixing frame is fixedly arranged on the rotating disc; a first pressure sensor is arranged at the bottom of the fixing frame; a first hydraulic cylinder is fixedly mounted on the central shaft; a pressing block is fixedly mounted on a piston rod of the first hydraulic cylinder; a ball shaft is fixedly mounted on the pressing block; a second hydraulic cylinder is fixedly mounted on the rack; a piston rod of the second hydraulic cylinder is fixedly connected with a pressing frame; a second pressure sensor is fixedly mounted on the rack; a PLC is fixedly mounted on the rack; and the PLC is electrically connected with the first hydraulic cylinder, the second hydraulic cylinder, the first pressure sensor and the second pressure sensor. According to the scheme, a pot is placed in the fixing frame in the forward direction, so that the pot rotates to rub with the trimmer, friction trimming is carried out, the pot is smooth, the safety performance is improved, and an operator is prevented from being injured.

Owner:重庆市玉叶厨具有限公司

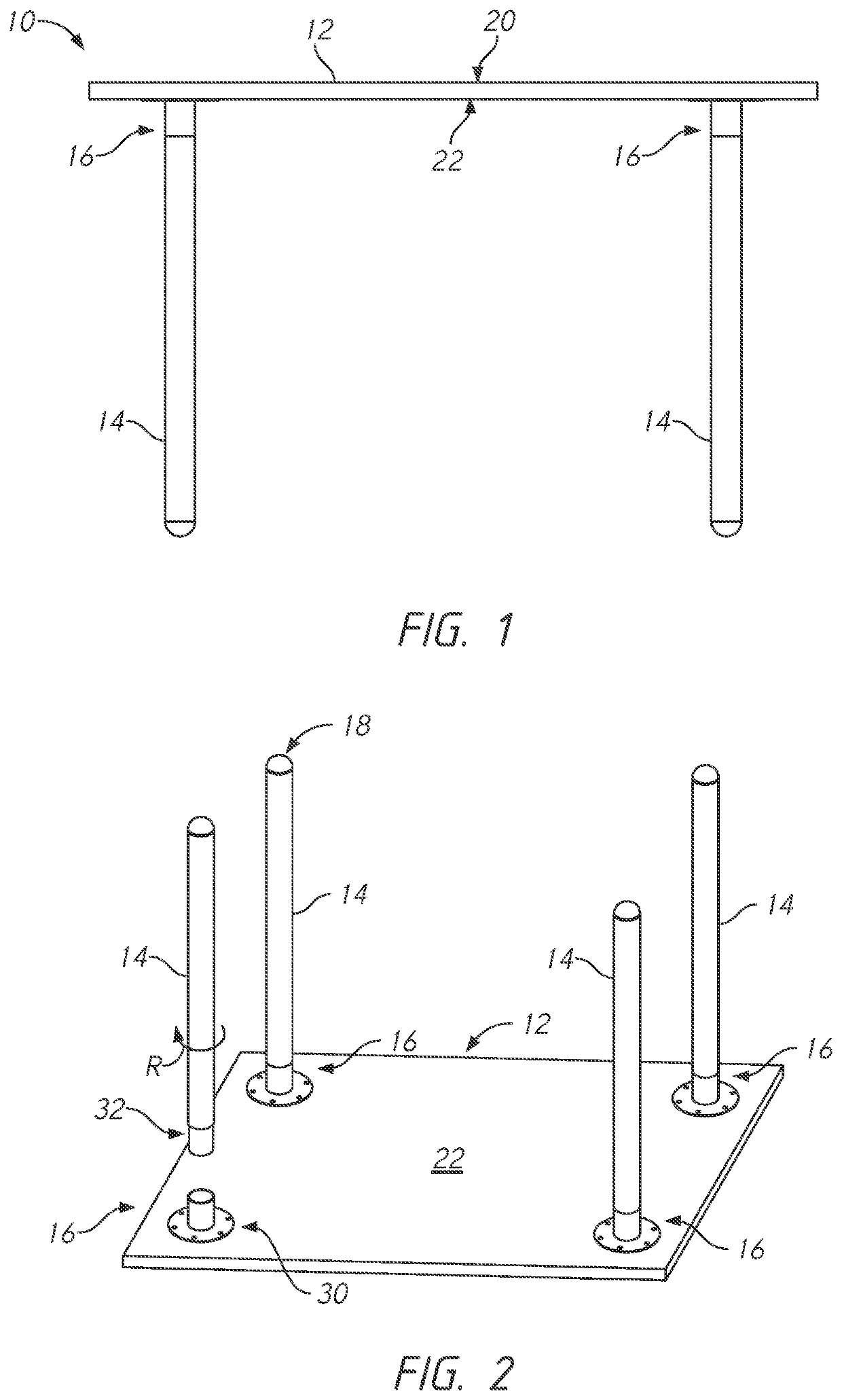

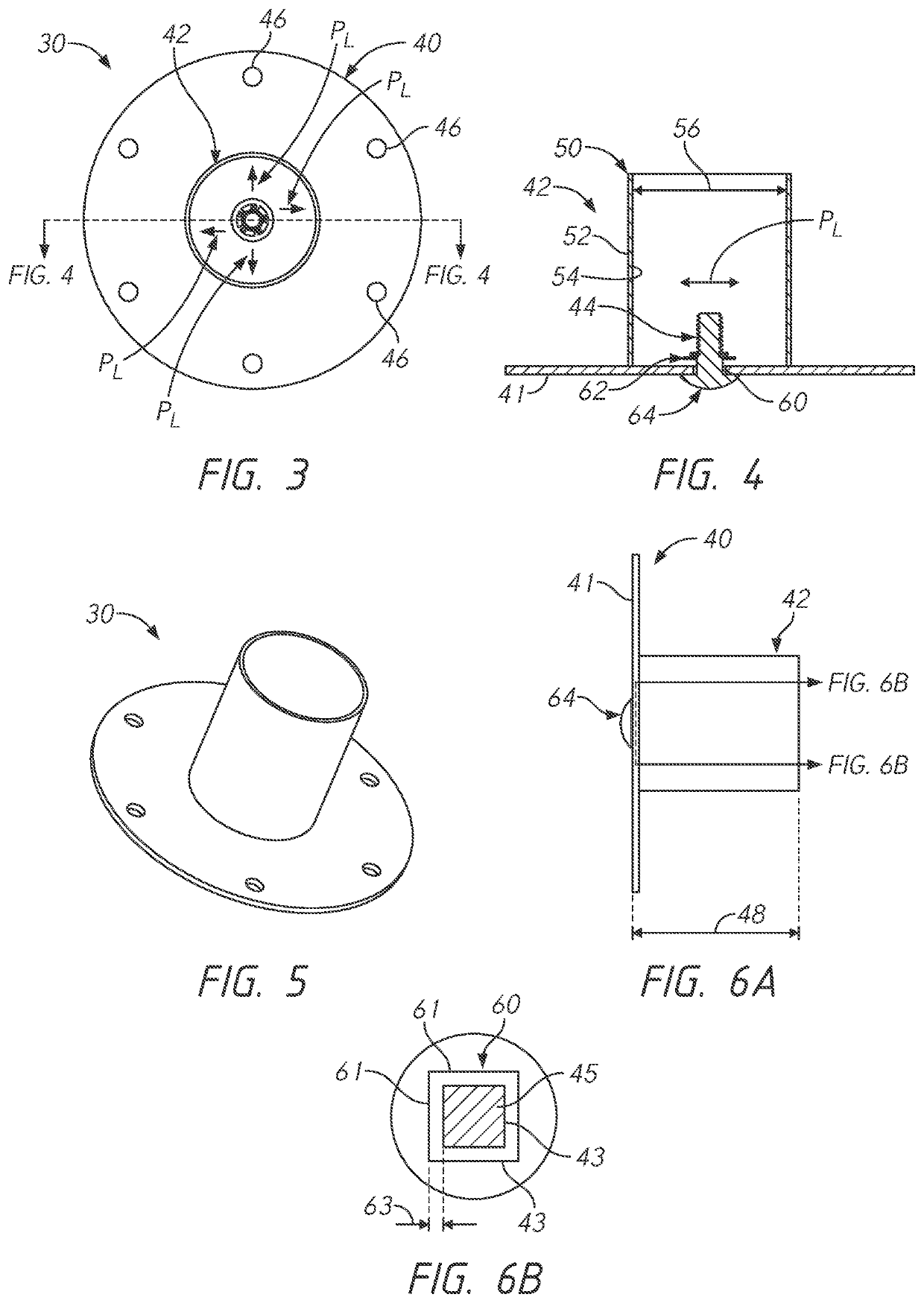

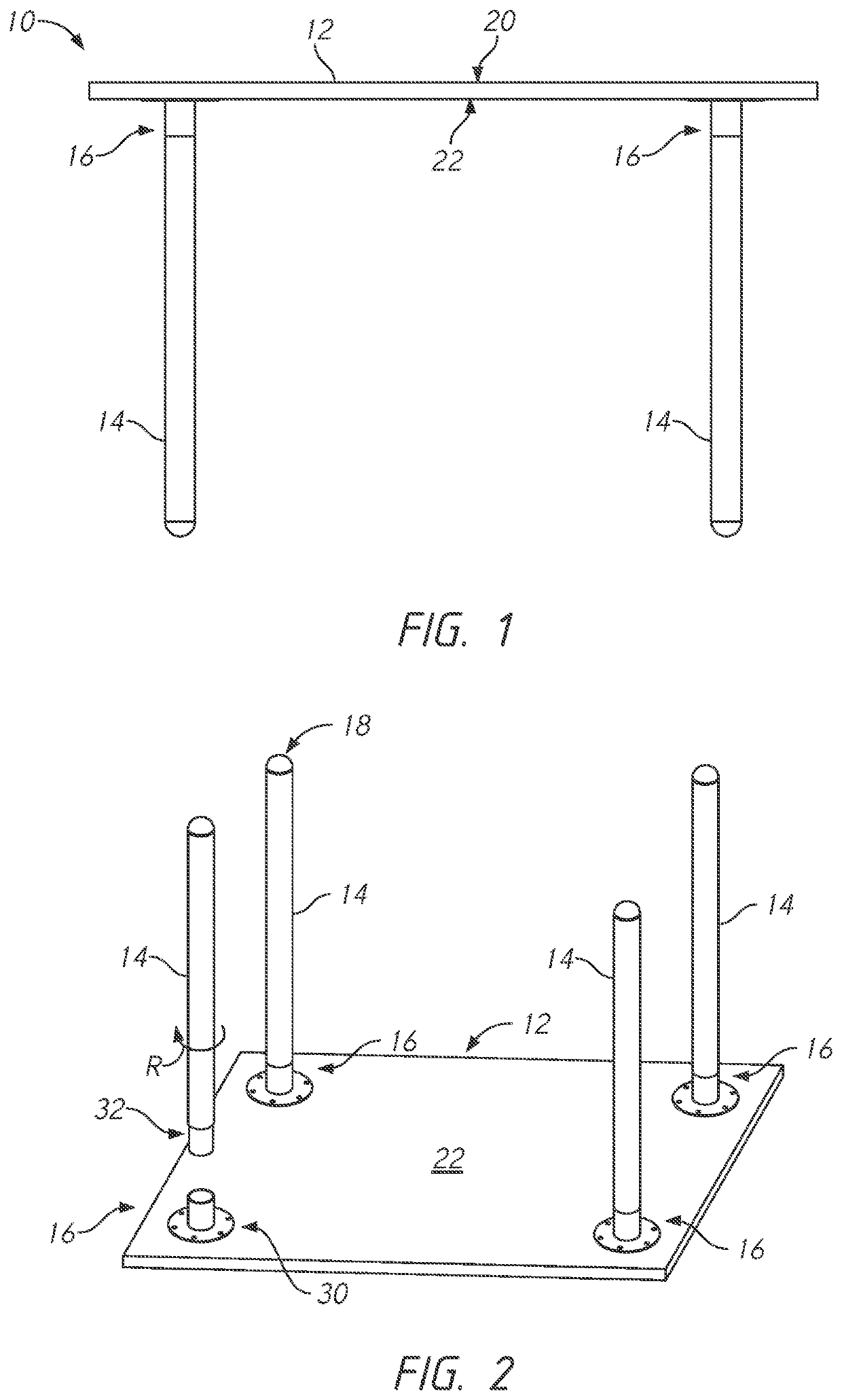

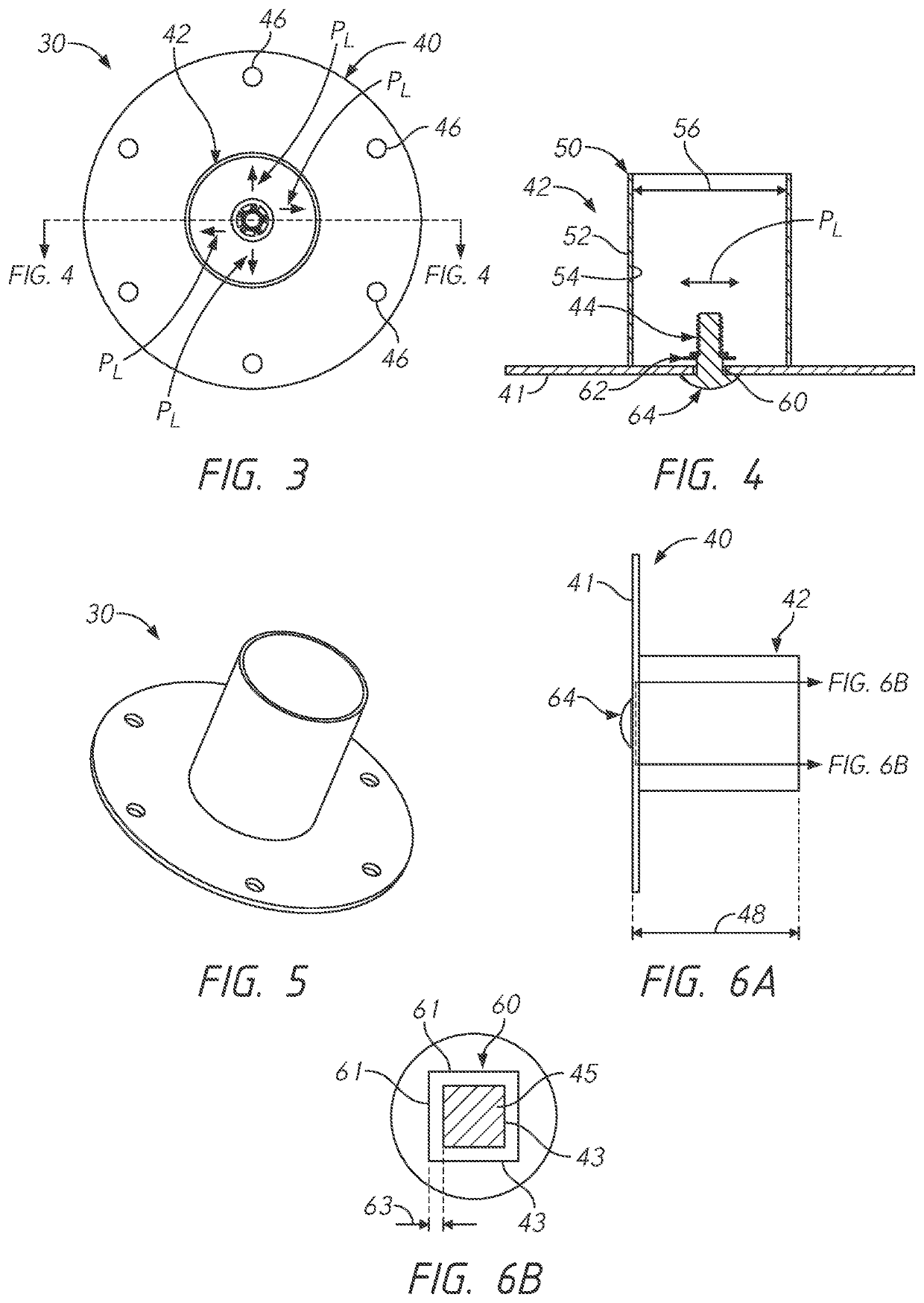

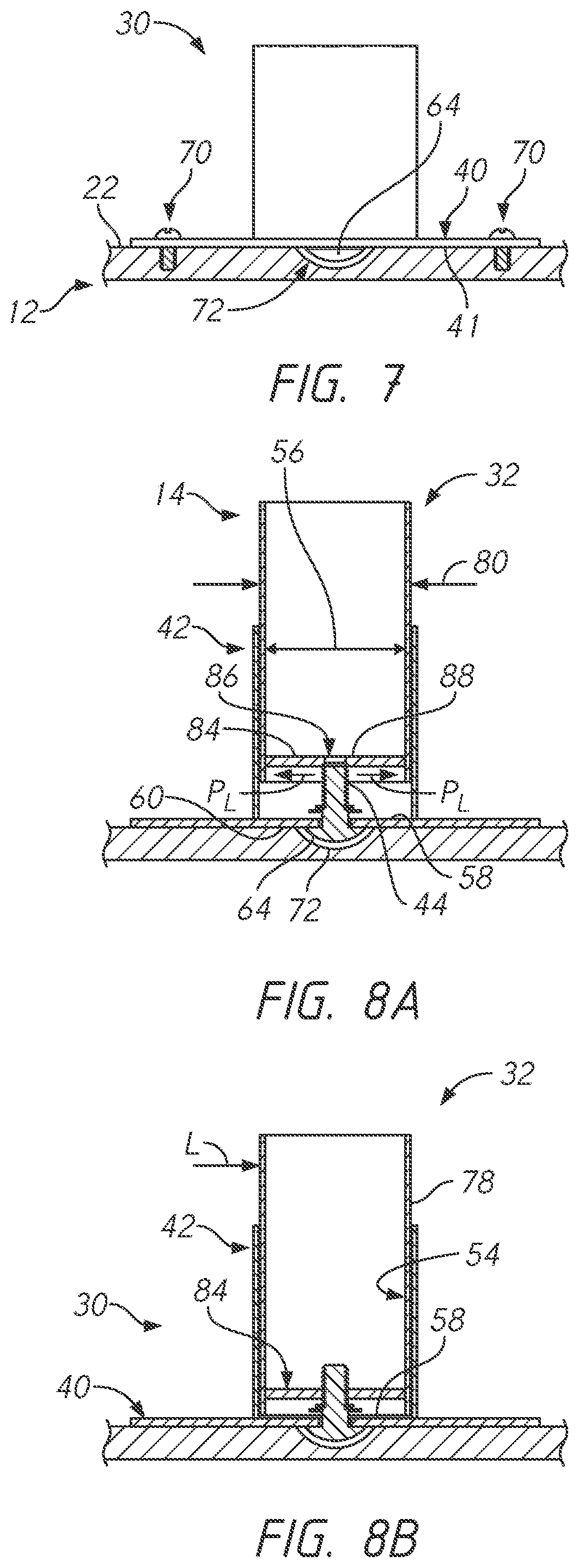

Table with removable legs

ActiveUS11478073B2Highly stable and secure connectionReduce structural loadsTablesFurniture joiningScrew threadThreaded fastener

A furniture assembly can include a tabletop with removable legs. The removable legs can be attached to the tabletop with a socket having a threaded member mounted in a non-fixed and anti-rotation registration at the bottom of the socket. The legs can be mounted to the socket by insertion and turning for threaded engagement. The floating engagement mechanism can allow the threaded fastener member to move during installation to provide for enhanced alignability between the leg and the threaded fastener member.

Owner:EXEMPLIS

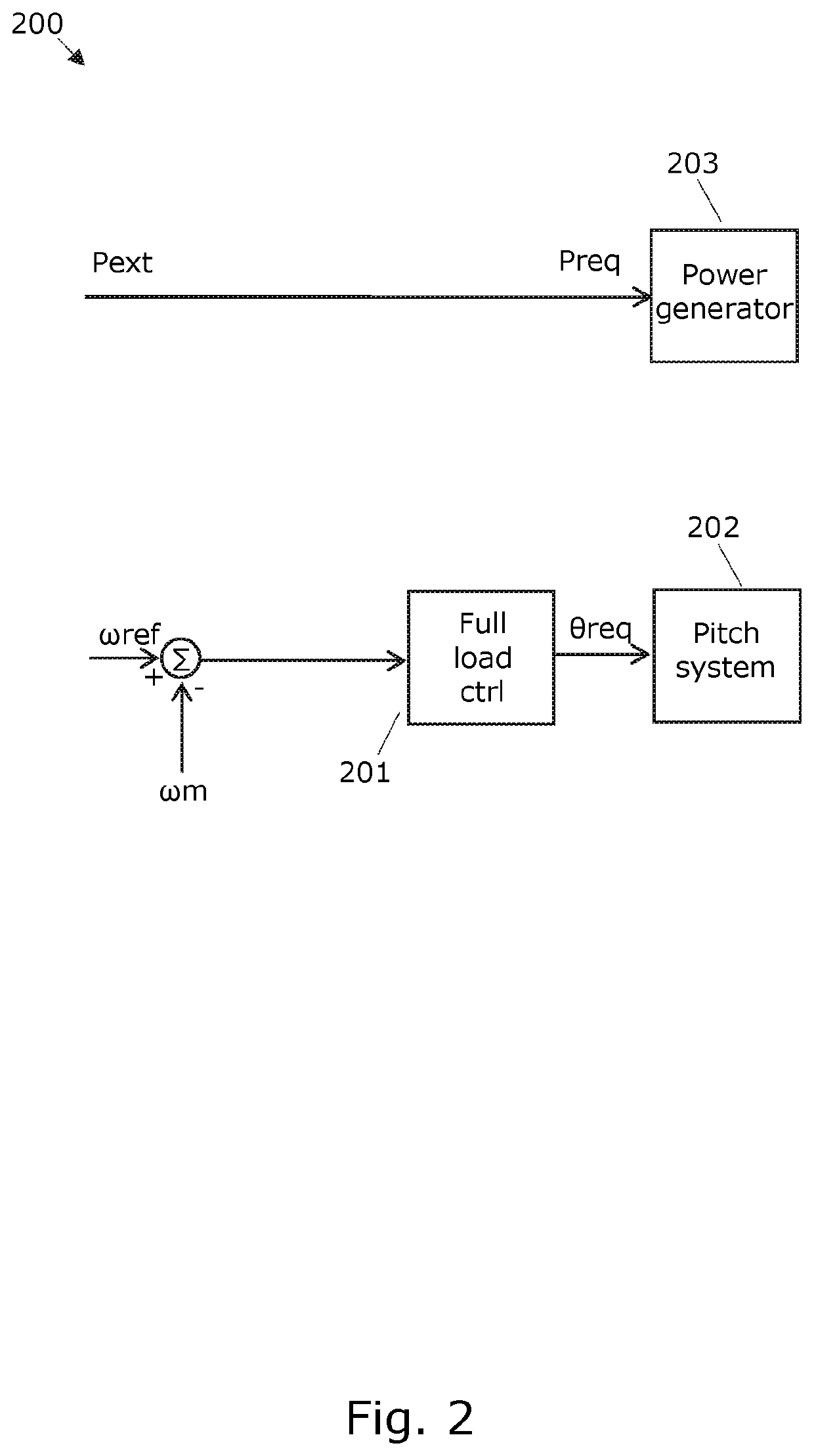

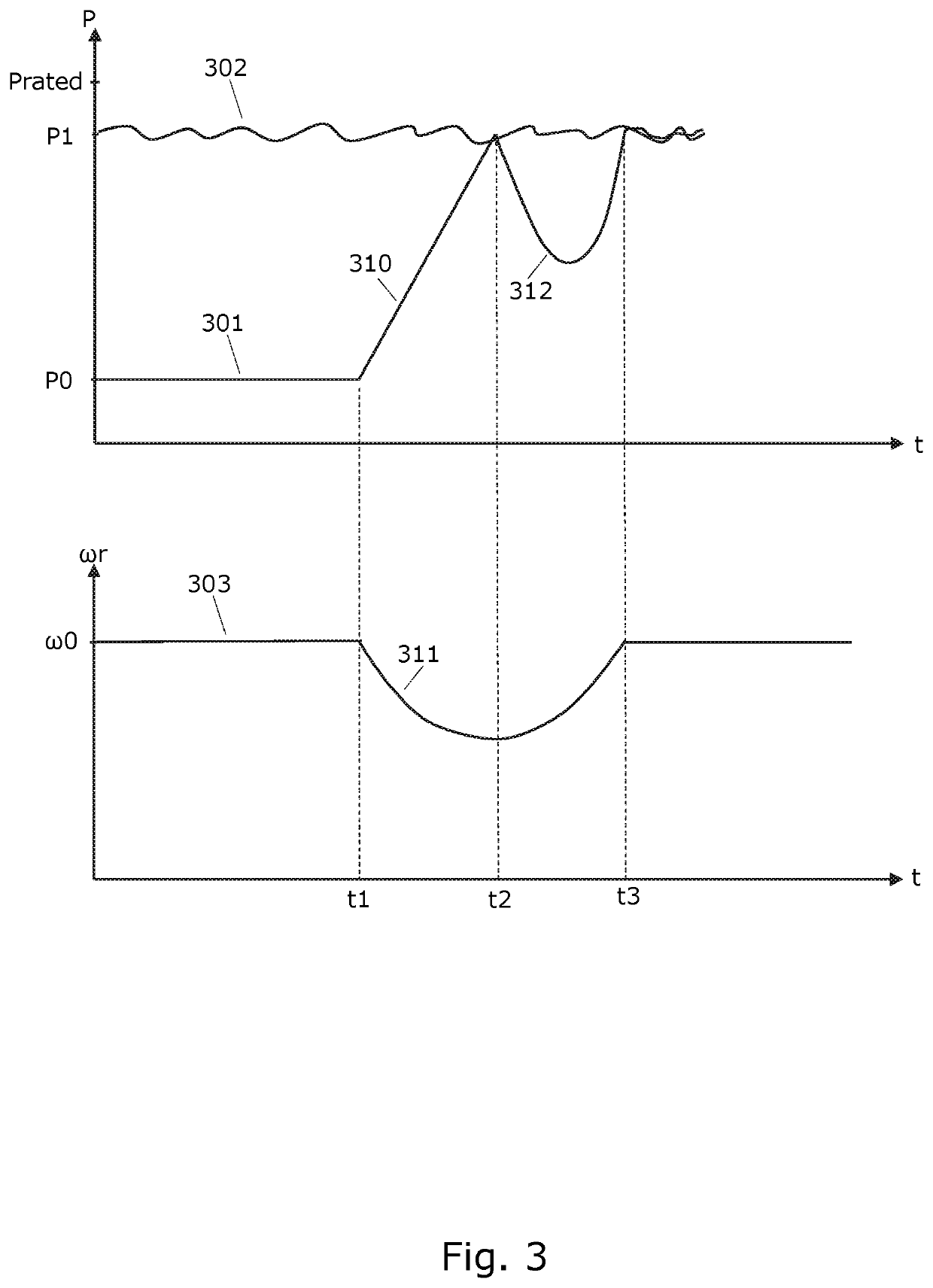

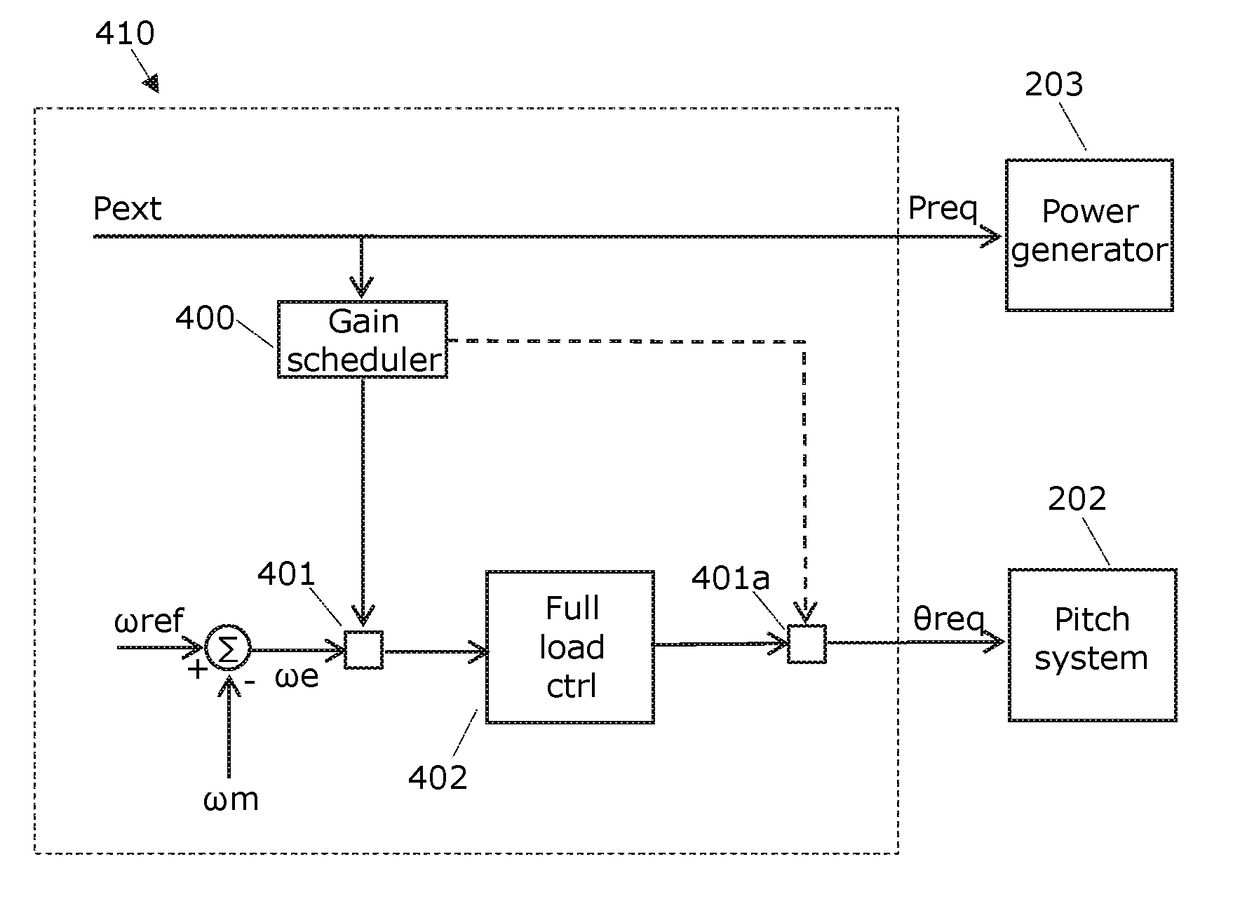

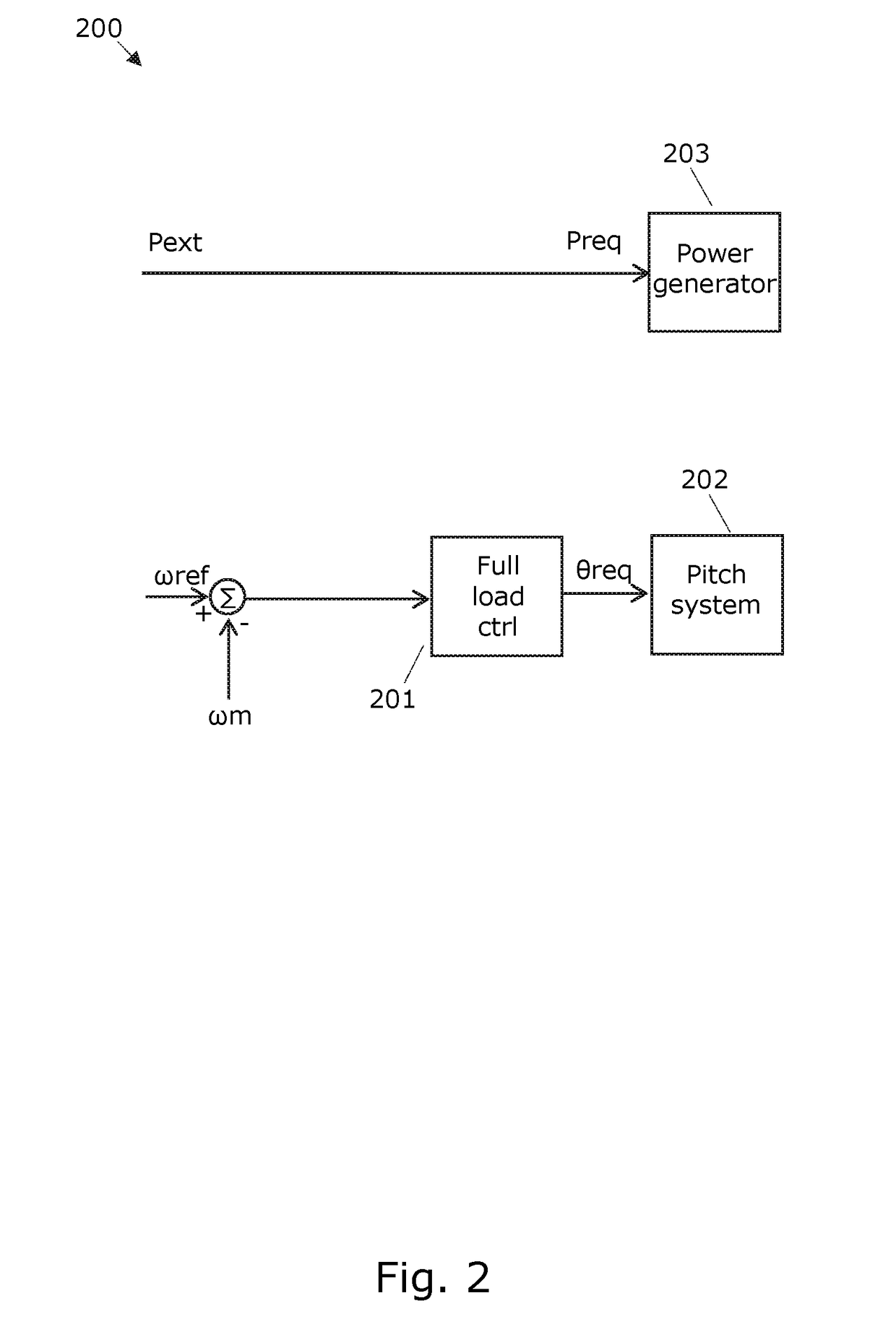

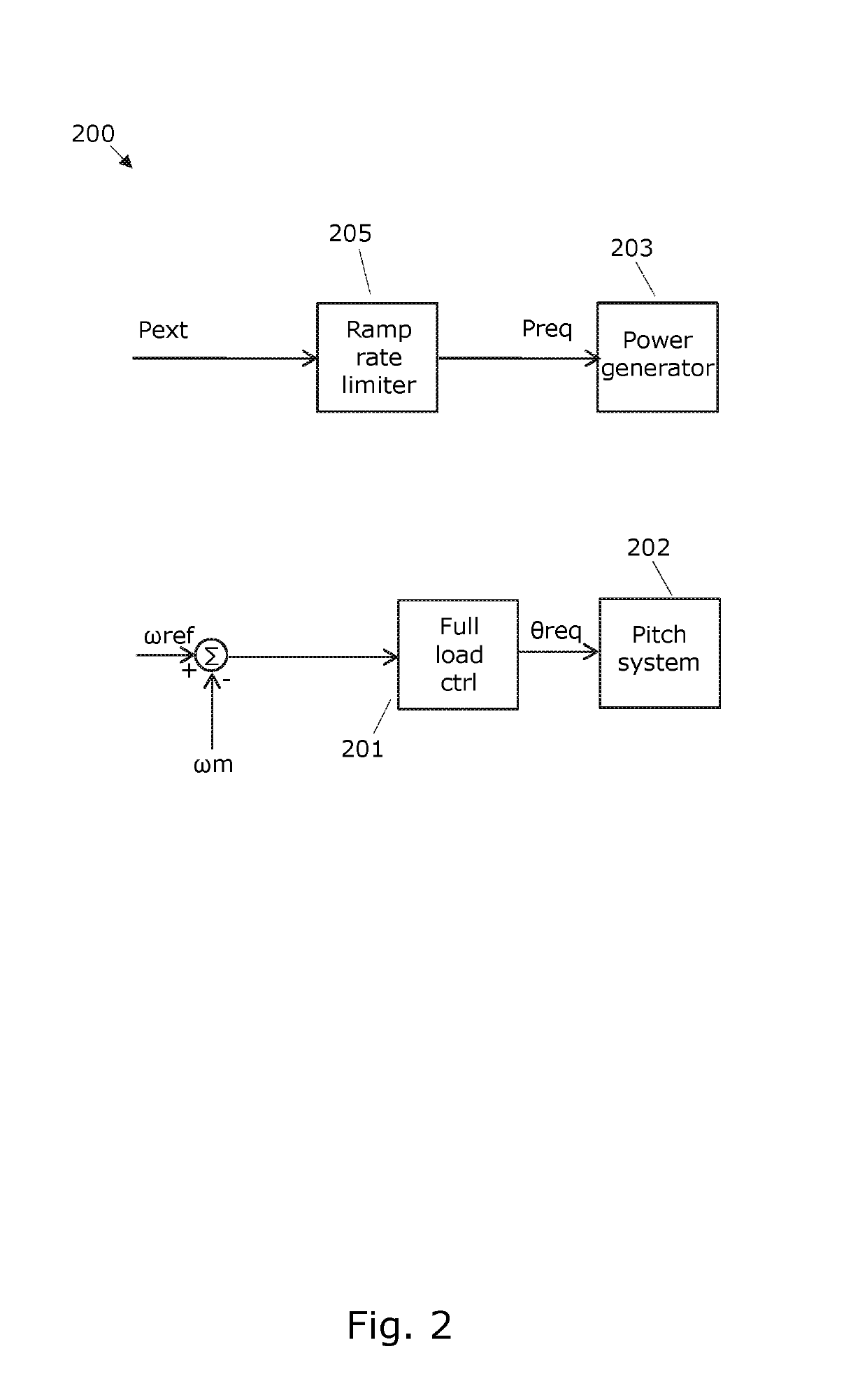

Ramping power in a wind turbine using gain scheduling

ActiveUS10669990B2Easy to controlImprove abilitiesWind motor controlEngine fuctionsClassical mechanicsTurbine

The invention relates to a control system for a wind turbine. The wind turbine comprises a power generator configured to generate power dependent on a power reference and a pitch system configured to adjust the pitch of a blade of the wind turbine dependent on a pitch request. The control system comprises a controller configured to determine the pitch request dependent on an adjustable gain. A gain scheduler comprised by the control system is configured to set the adjustable gain to an increased gain value if a rate of change of the power reference, e.g. an external power reference, exceeds a threshold.

Owner:VESTAS WIND SYST AS

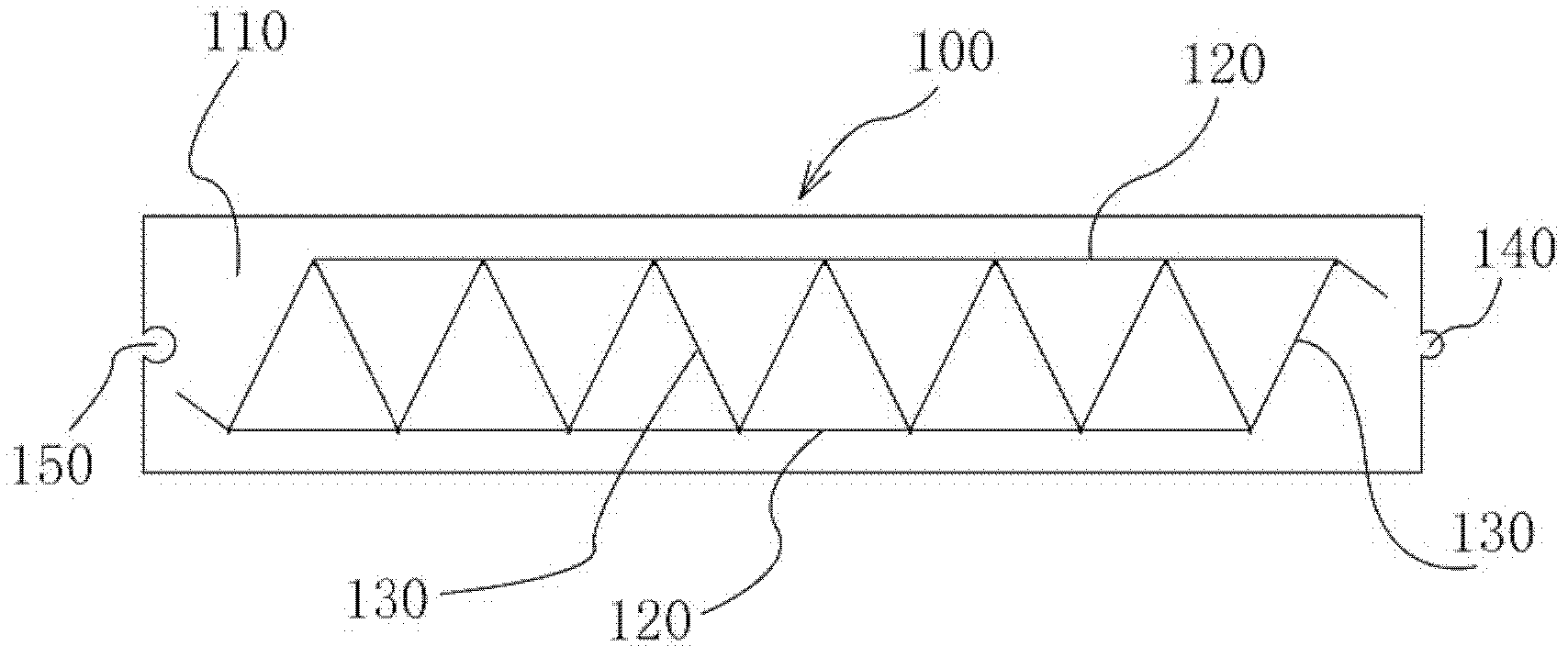

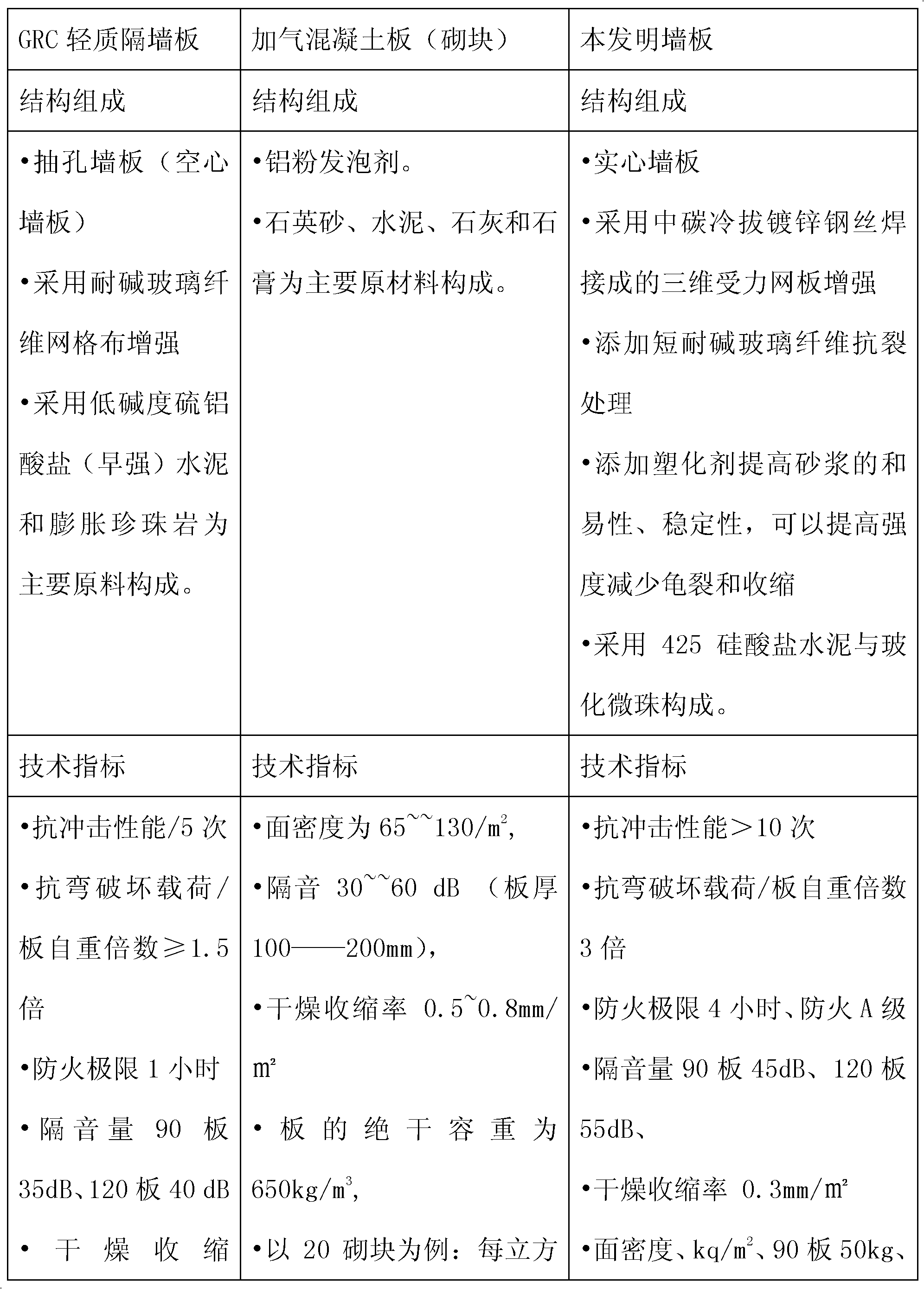

High strength light wall plate

InactiveCN102493594AReduce structural loadsReduce engineering costsConstruction materialMicro bubbleWall plate

Owner:上海大秦新型建材有限公司

Ramping power in a wind turbine using gain scheduling

ActiveUS20180156196A1Easy to controlImprove abilitiesWind motor controlEngine fuctionsTurbineWind force

The invention relates to a control system for a wind turbine. The wind turbine comprises a power generator configured to generate power dependent on a power reference and a pitch system configured to adjust the pitch of a blade of the wind turbine dependent on a pitch request. The control system comprises a controller configured to determine the pitch request dependent on an adjustable gain. A gain scheduler comprised by the control system is configured to set the adjustable gain to an increased gain value if a rate of change of the power reference, e.g. an external power reference, exceeds a threshold.

Owner:VESTAS WIND SYST AS

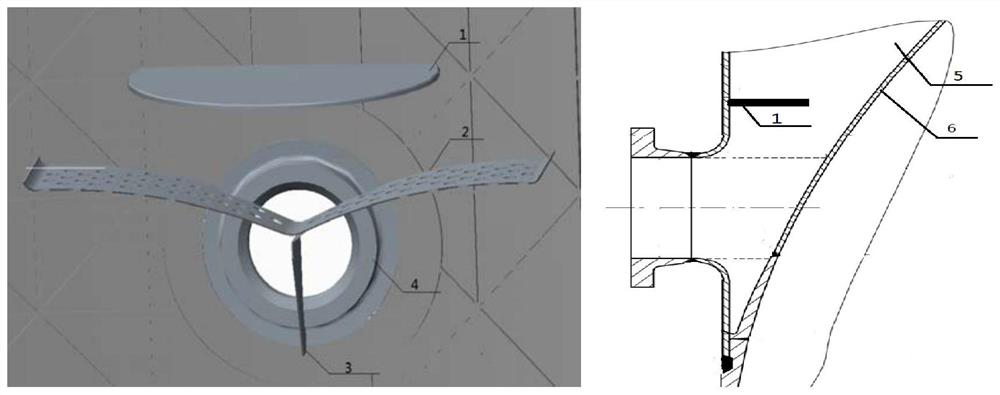

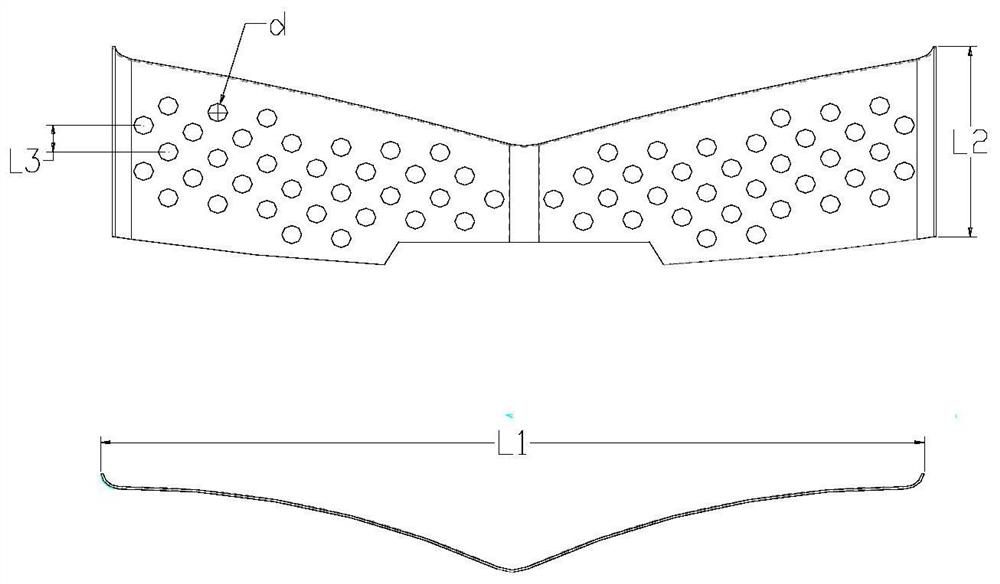

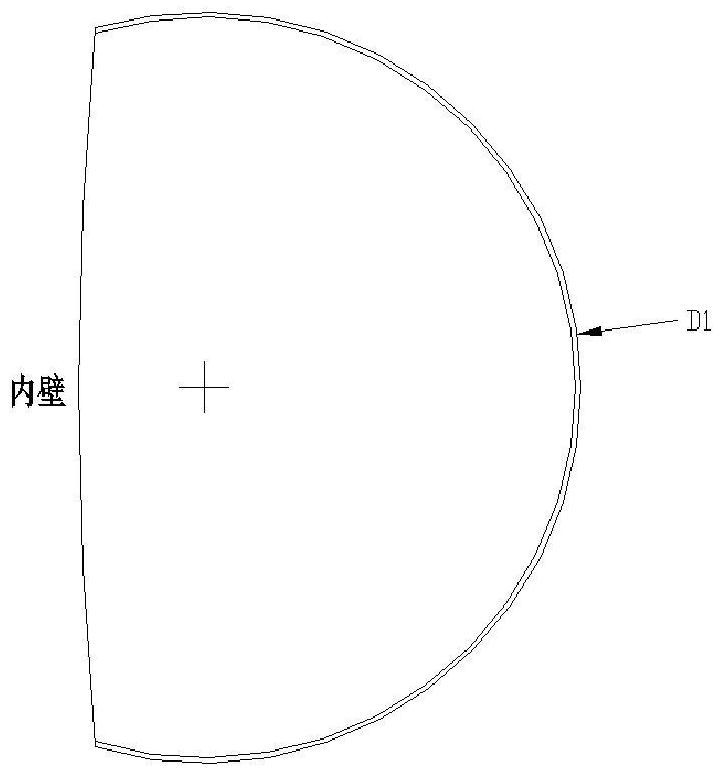

Special-shaped storage tank outflow device

ActiveCN112523897AReduce structural loadsReduce structural weightFluid dynamicsRocket engine plantsStructural loadEngineering

The invention discloses a special-shaped storage tank outflow device, and belongs to the technical field of liquid rocket pressurization conveying systems. A vortex eliminating plate and a partition plate are installed on a flow outlet of a common-bottom storage tank, holes are formed in the vortex eliminating plate, the structural load of the vortex eliminating plate is reduced, meanwhile, the structural weight of the vortex eliminating plate is reduced, meanwhile, the bearing capacity of the vortex eliminating plate is improved through reasonable layout of the holes, and the vortex eliminating plate is of a 120-degree V-shaped structure, so that fluid transition is smooth as much as possible; and meanwhile, liquid tends to be filled to the center, a cover plate is installed on the upperportion of the flow outlet (the axial direction of the storage tank) of the common-bottom storage tank, the liquid tends to flow downwards (accelerate), tangential force for forming vortexes is destroyed, the vortexes and collapse are restrained through the arrangement, and therefore the unusable amount of the liquid in the storage tank is reduced.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

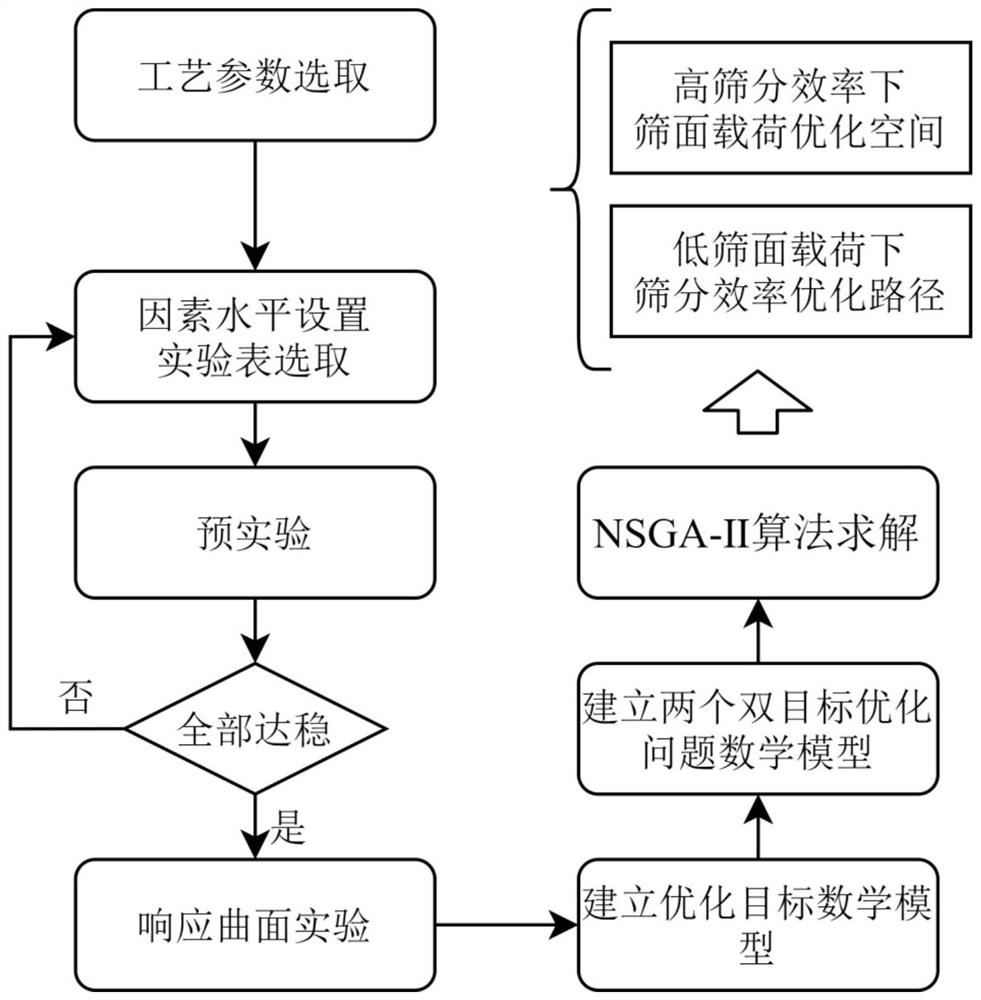

Vibrating screen surface dynamic load optimization method

ActiveCN113283114AImprove screening efficiencyLow screen dynamic loadGeometric CADDesign optimisation/simulationLoad optimizationSimulation

The invention discloses a vibrating screen surface dynamic load optimization method, which comprises the following steps of: 1, selecting a design variable, and establishing an experimental matrix; 2, carrying out a response curved surface experiment; step 3, establishing two double-objective optimization models and solving the two double-objective optimization models; obtaining two groups of Pareto solution sets, wherein the solution sets respectively represent the screening efficiency optimization path of the vibrating screen under the conditions of high screen surface dynamic load and low screen surface dynamic load; and 4, calculating the screen surface dynamic load optimization space under the high screening efficiency. The screen surface dynamic load can be directly reduced, the overall structural load of the screening machine is indirectly reduced, and the service life of the screen surface and the whole vibrating screen is prolonged.

Owner:WUHAN UNIV OF SCI & TECH

Ramping power in a wind turbine dependent on an estimated available wind power

ActiveUS10273938B2Easy to controlImprove abilitiesWind motor controlMachines/enginesControl systemTurbine

The invention relates to a control system for a wind turbine. The wind turbine comprises a power generator configured to generate power dependent on a power request. The control system comprises a ramp rate limiter configured to restrict a rate of change of the power request according to a rate of change limit and configured to determine the rate of change limit dependent on a power difference between the power request and an estimated available wind power.

Owner:VESTAS WIND SYST AS

Table with removable legs

ActiveUS20220151374A1Easy alignmentPositive engagementTablesFurniture joiningScrew threadThreaded fastener

A furniture assembly can include a tabletop with removable legs. The removable legs can be attached to the tabletop with a socket having a threaded member mounted in a non-fixed and anti-rotation registration at the bottom of the socket. The legs can be mounted to the socket by insertion and turning for threaded engagement. The floating engagement mechanism can allow the threaded fastener member to move during installation to provide for enhanced alignability between the leg and the threaded fastener member.

Owner:EXEMPLIS

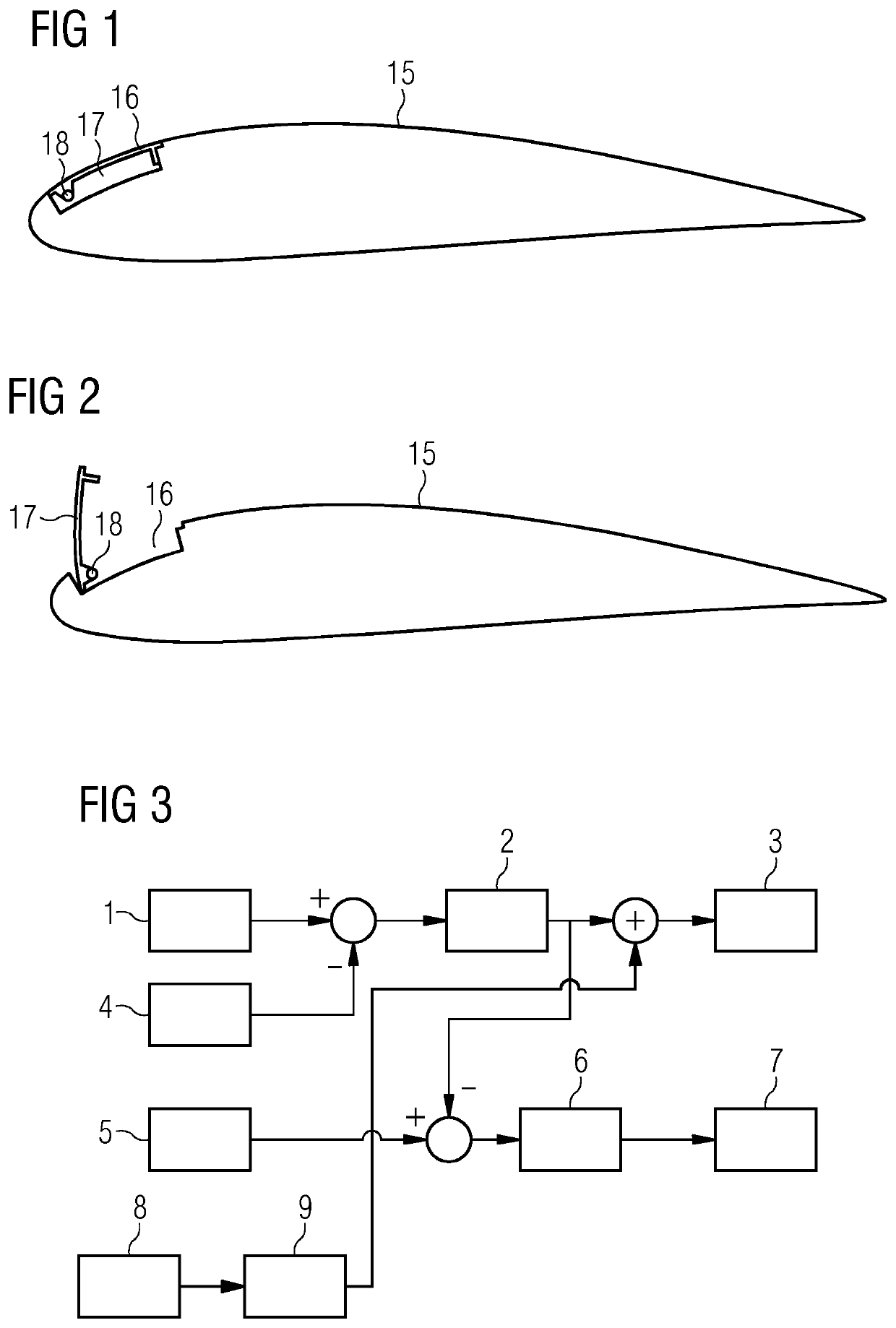

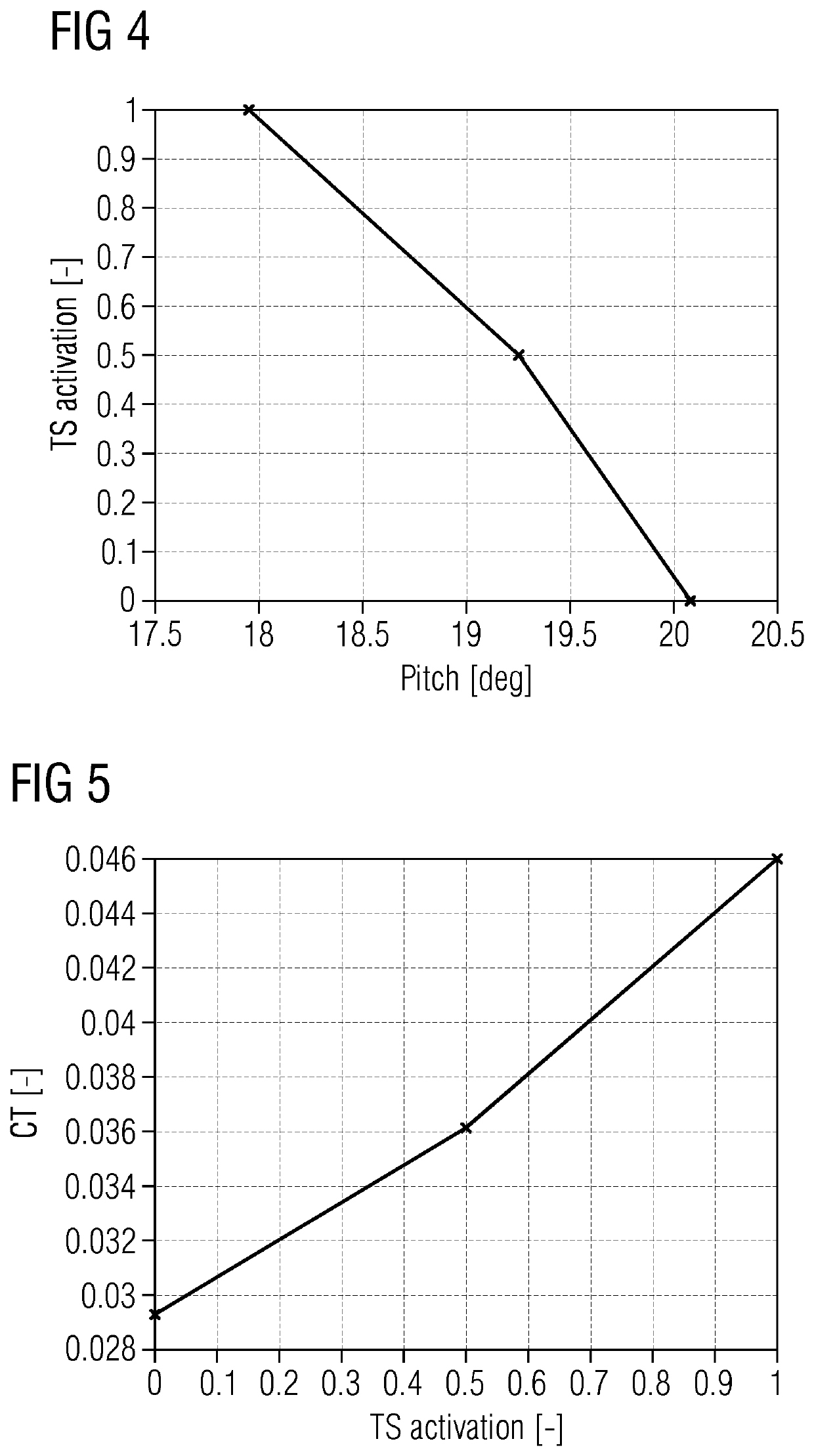

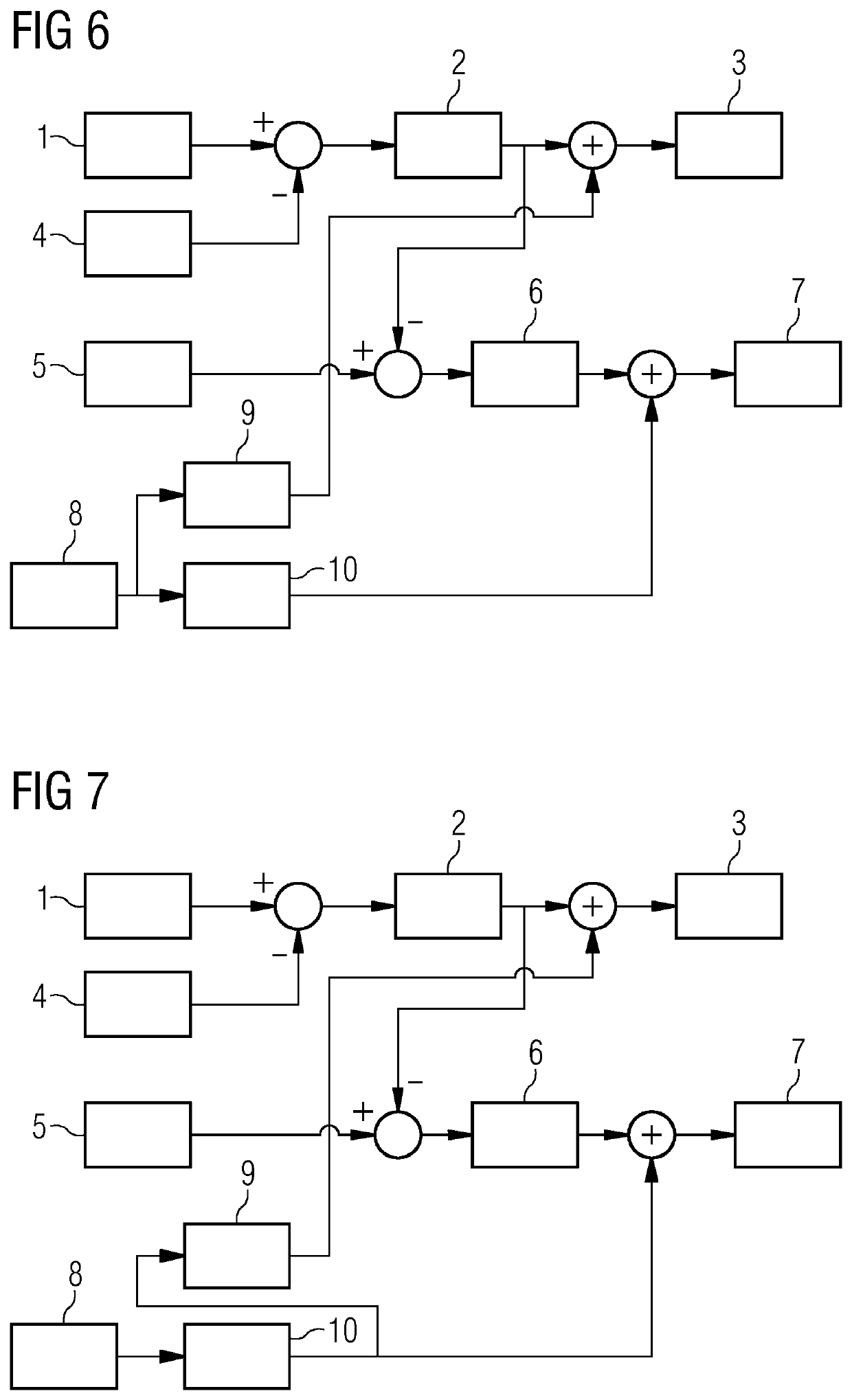

Device and method of damping front and backward movements of a tower of a wind turbine

ActiveUS20220025860A1Reduce structural loadsAvoid damageEngine manufactureWind motor controlRotational axisClassical mechanics

Provided is a device and a method of damping front and backward movements of a tower of a wind turbine, wherein the wind turbine includes the tower and a rotor, the rotor being mounted at the top of the tower to rotate about a rotational axis in which the front and backward movements of the tower occur, and the rotor has a plurality of blades, wherein each blade has at least one corresponding active add-on member which is actuated by a corresponding actuator to alter aerodynamic properties of the blade. Each add-on member is actuated by the corresponding actuator to alter the aerodynamic properties of the blade in a manner that the rotor is configured to damp the front and backward movements of the tower of the wind turbine.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com