Intelligent pot trimming device

An intelligent, cooking utensil technology, applied in the direction of positioning devices, clamping devices, manufacturing tools, etc., can solve the problems of easily injured operators, potential safety hazards, and burrs when handling them, so as to reduce the structural load of equipment and reduce potential safety hazards , the effect of preventing injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

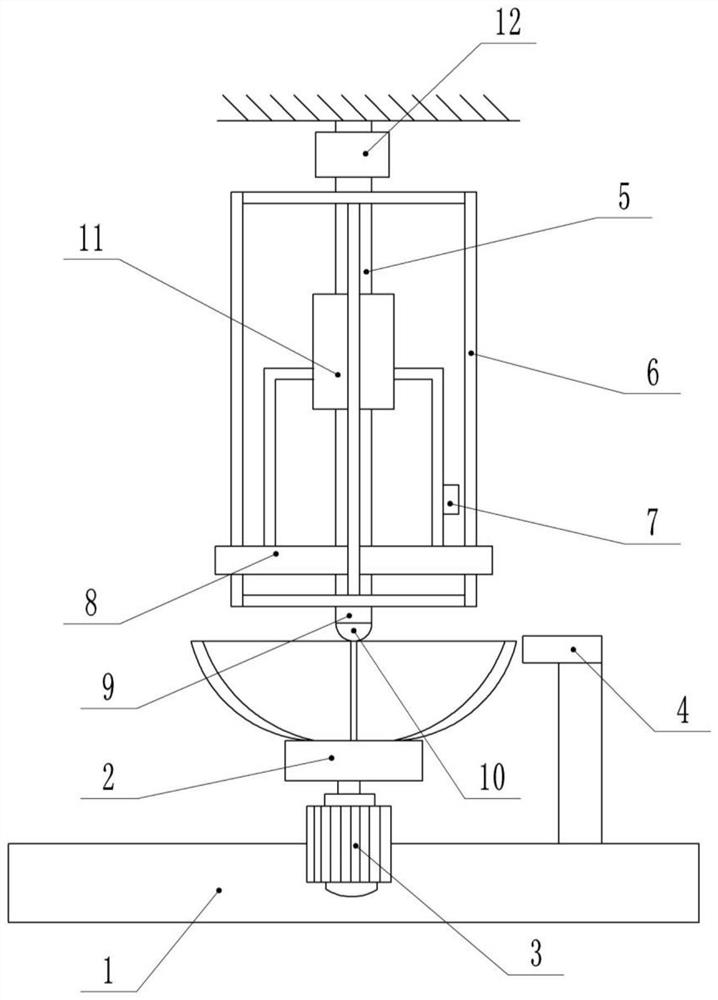

[0018] An intelligent edge trimming device for pots, as attached figure 1 As shown, the edge trimmer 4 and the frame are included, and the edge trimmer 4 and the frame are fixedly connected by bolts. The edge trimmer 4 friction trims the pot during the rotation of the pot, the edge trimmer 4 is easily damaged, and the bolt connection is convenient for quickly replacing the edge trimmer 4 . The edge trimmer 4 is a turning tool, and the turning tool of the corresponding model can be selected according to the specific pot. The frame is provided with three bolt holes for installing the edge trimmer 4, and multiple types of turning tools can be replaced.

[0019] The frame is welded with a central shaft 5, the central shaft 5 is made of aluminum alloy, the strength of the aluminum alloy is relatively high, approaching or exceeding high-quality steel, good plasticity, can be processed into various profiles, and has excellent electrical conductivity, thermal conductivity and Corrosi...

Embodiment 2

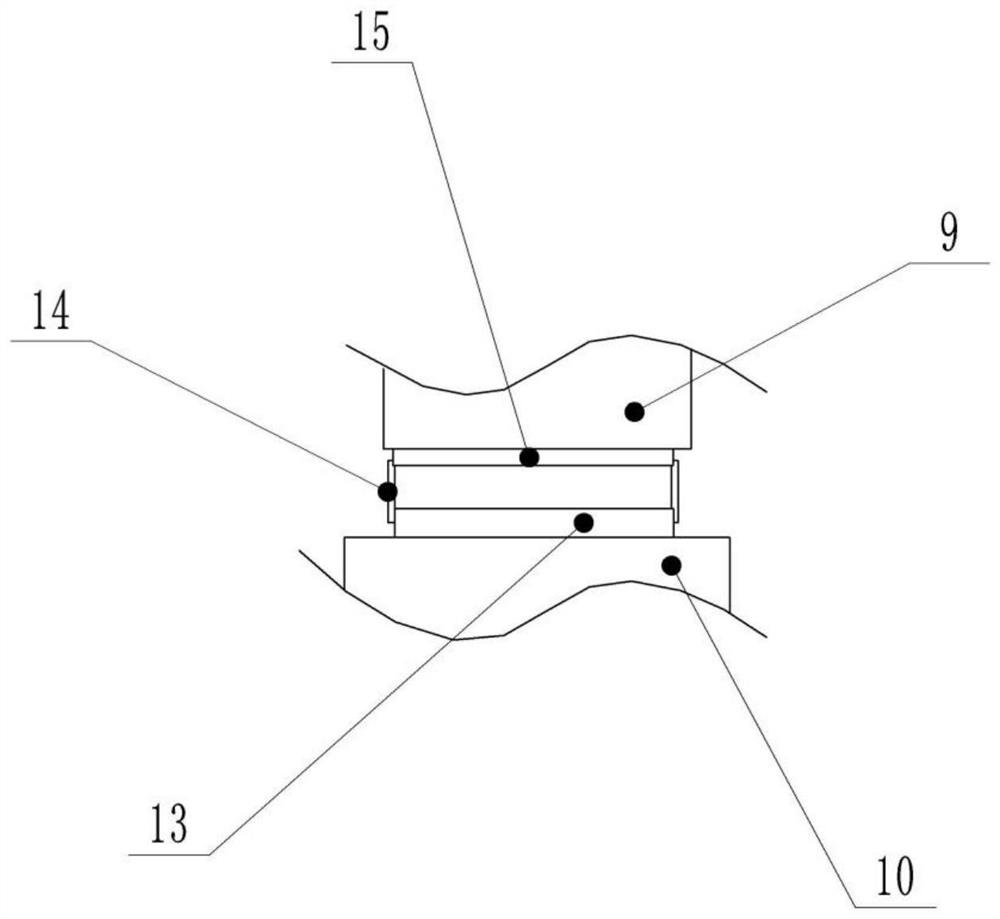

[0028] The difference between this embodiment and embodiment 1 is that, as attached figure 2As shown, it also includes a hydraulic power source. The first hydraulic cylinder 11 communicates with the hydraulic power source through hydraulic pipes. A flow meter is provided, the hydraulic power source is an electric hydraulic cylinder, and the hydraulic power source is electrically connected to the PLC controller. Between the pressing block 9 and the ball shaft 10, strain gauges 13, elastic sleeves 14 and piezoelectric devices 15 are fixedly installed on the pressing block 9, and the piezoelectric devices 15 are electrically connected to the PLC controller. One end of the elastic sleeve 14 is fixedly connected to the piezoelectric device 15 , the other end of the elastic sleeve 14 is fixedly connected to the strain gauge 13 , and the strain gauge 13 is fixedly connected to the ball shaft 10 . The flow meter is electrically connected to the PLC controller, and the flow meter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com