High strength light wall plate

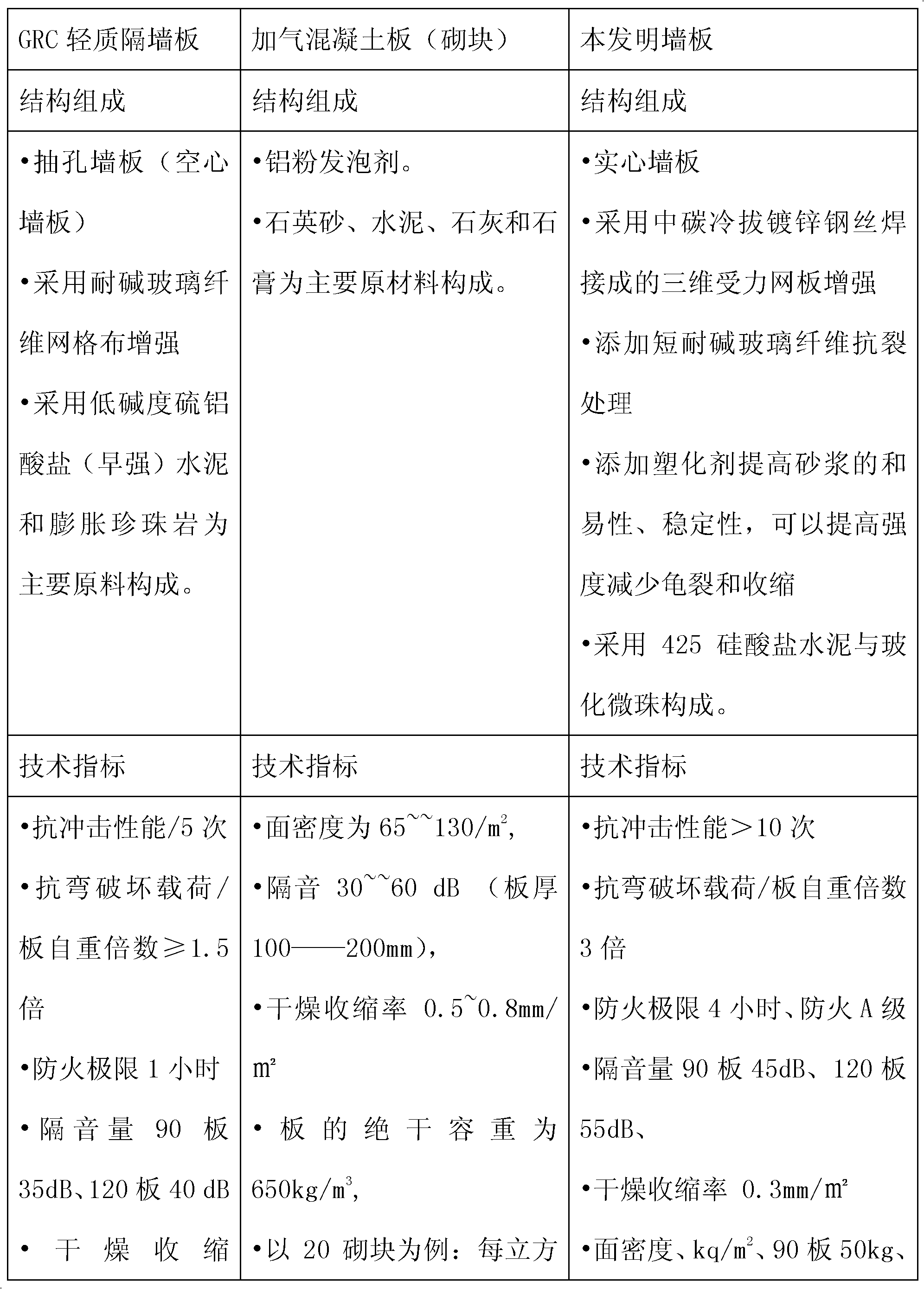

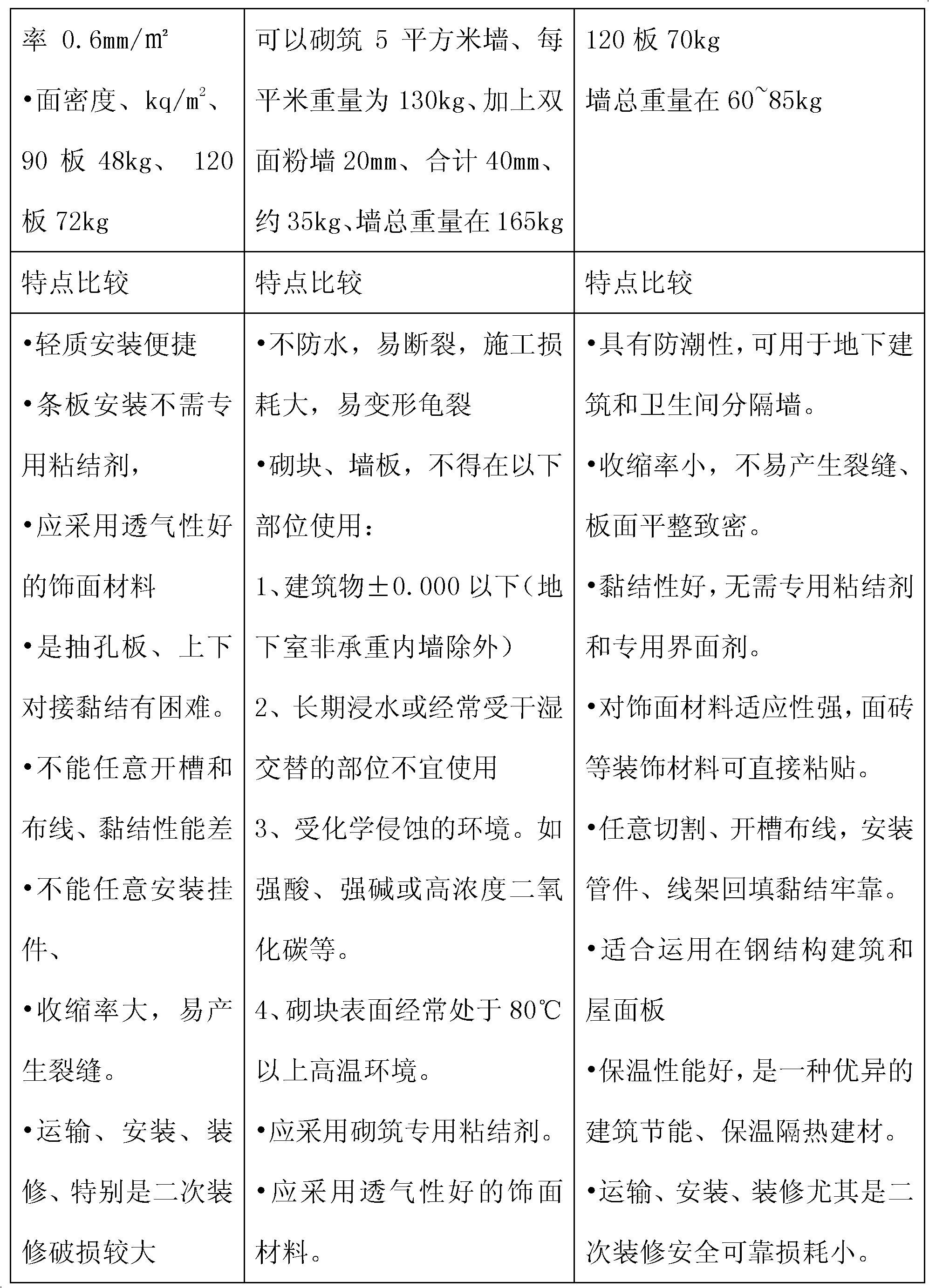

A light-weight wallboard and high-strength technology, applied in the direction of building materials, etc., can solve the problems of increasing construction costs, multiple building areas, and occupancy, and achieve the effects of reducing overall cost, less investment in environmental protection, and expanding indoor use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

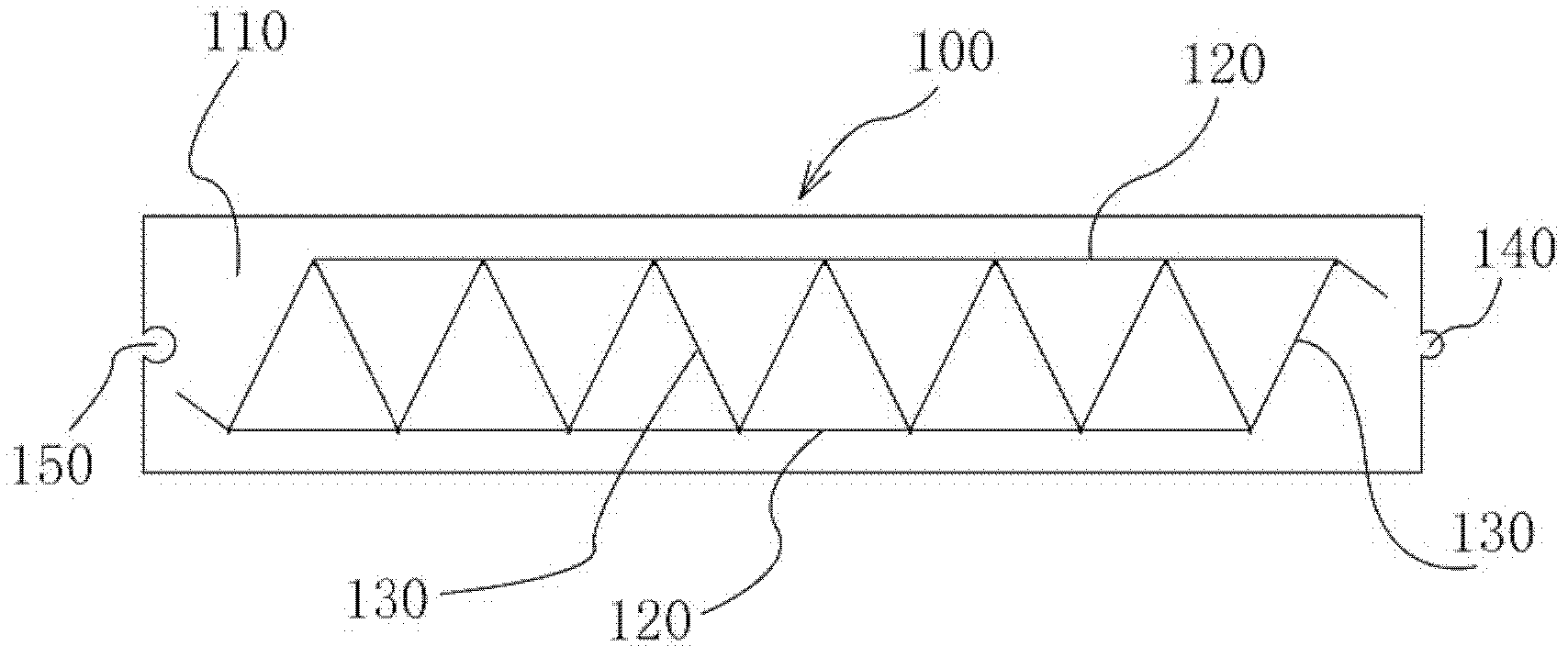

Image

Examples

Example Embodiment

[0029] Example 1:

[0030] Take 3 parts by weight of 425 Portland cement, 1 part by weight of vitrified microbeads, 0.001 part by weight of anti-cracking agent (wherein anti-cracking agent is the mixture of lignin fiber and redispersible latex powder, and is added with short alkali-resistant glass Fiber, the mixing weight ratio of the three is 1:3:1), 0.005 parts by weight of plasticizer (wherein the plasticizer is composed of sodium lauryl sulfate and carboxymethyl cellulose, and the weight ratio of the two is 1:1 ); fully mix the above substances into a liquid state for standby use, place the prepared three-dimensional mesh frame in the middle of the casting mold, inject the above-mentioned mixture into the mold, dry and demould; make a wallboard with a thickness of 90mm.

Example Embodiment

[0031] Example 2:

[0032] Get respectively 6 weight parts of 425 Portland cement, 1.5 weight parts of vitrified microbeads, 0.0005 weight parts of anti-cracking agent (wherein anti-cracking agent is lignin fiber, and is added with short alkali-resistant glass fiber, the mixing weight ratio of the two is be 4: 1), 0.01 weight portion of plasticizer (wherein plasticizer is made up of sodium lauryl sulfate and hydroxymethyl cellulose, and the weight ratio of the two is 1: 1); the above substances are fully mixed into a liquid state for subsequent use , put the prepared three-dimensional mesh frame in the middle of the casting mold, inject the above mixture into the mold, dry and demould;

Example Embodiment

[0033] Example 3:

[0034] Take 425 parts by weight of Portland cement, 1.1 parts by weight of vitrified microbeads, 0.001 parts by weight of anti-cracking agent (wherein the anti-cracking agent is redispersible latex powder, and is added with short alkali-resistant glass fibers, the mixing of the two is The weight ratio is 3:1), 0.005 parts by weight of plasticizer (wherein the plasticizer is composed of sodium lauryl sulfate and hydroxymethyl cellulose, and the weight ratio of the two is 7:3); the above substances are fully mixed into a For liquid preparation, place the prepared three-dimensional mesh frame in the middle of the casting mold, inject the above mixture into the mold, dry and demould;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Shrinkage value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com