Special-shaped storage tank outflow device

A storage tank and special-shaped technology, which is applied in the field of liquid rocket pressurized delivery system, can solve the problems affecting the normal operation of the engine, propellant air entrainment, engine pump cavitation, etc., and achieve the benefits of carrying capacity, improving carrying capacity and strengthening the structure The effect of stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the above technical solutions, the technical solutions of the present application will be described in detail below through the accompanying drawings and specific examples. It should be understood that the embodiments of the present application and the specific features in the examples are detailed descriptions of the technical solutions of the present application, and It is not a limitation to the technical solutions of the present application, and the embodiments of the present application and the technical features in the embodiments can be combined without conflict.

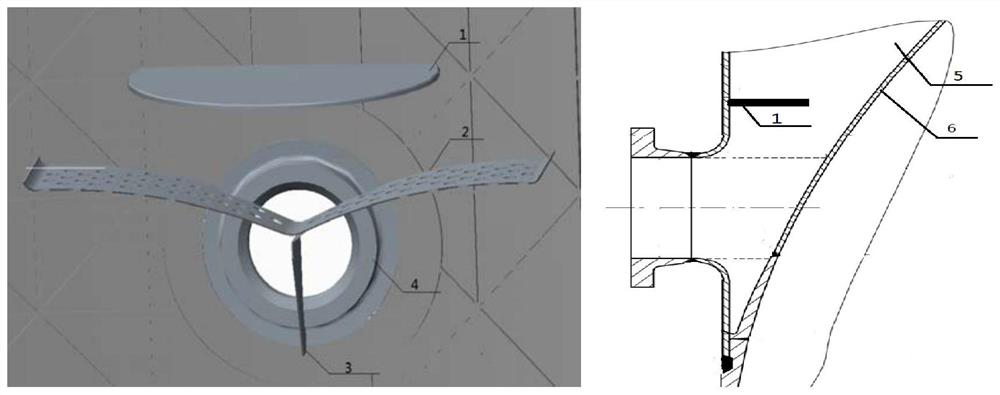

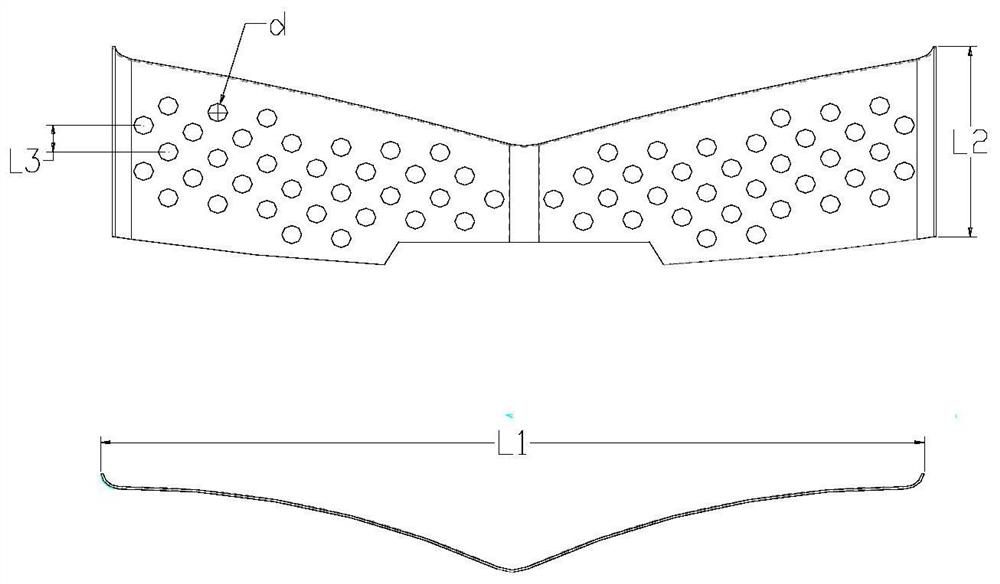

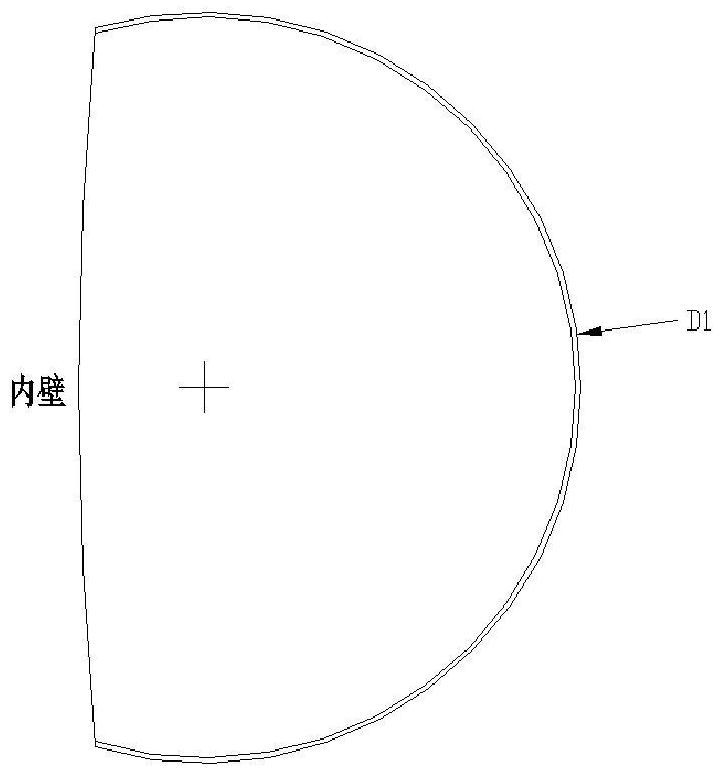

[0028] A further detailed description will be given below of a special-shaped storage tank outflow device provided by the embodiment of the present application in conjunction with the accompanying drawings. The specific implementation methods may include (such as figure 1 shown):

[0029] In the scheme provided by the embodiment of this application,

[0030] figure 1 It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com