Anchor system of a concrete wall formwork

A concrete and formwork technology, applied in the field of anchoring systems, can solve problems such as concrete outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

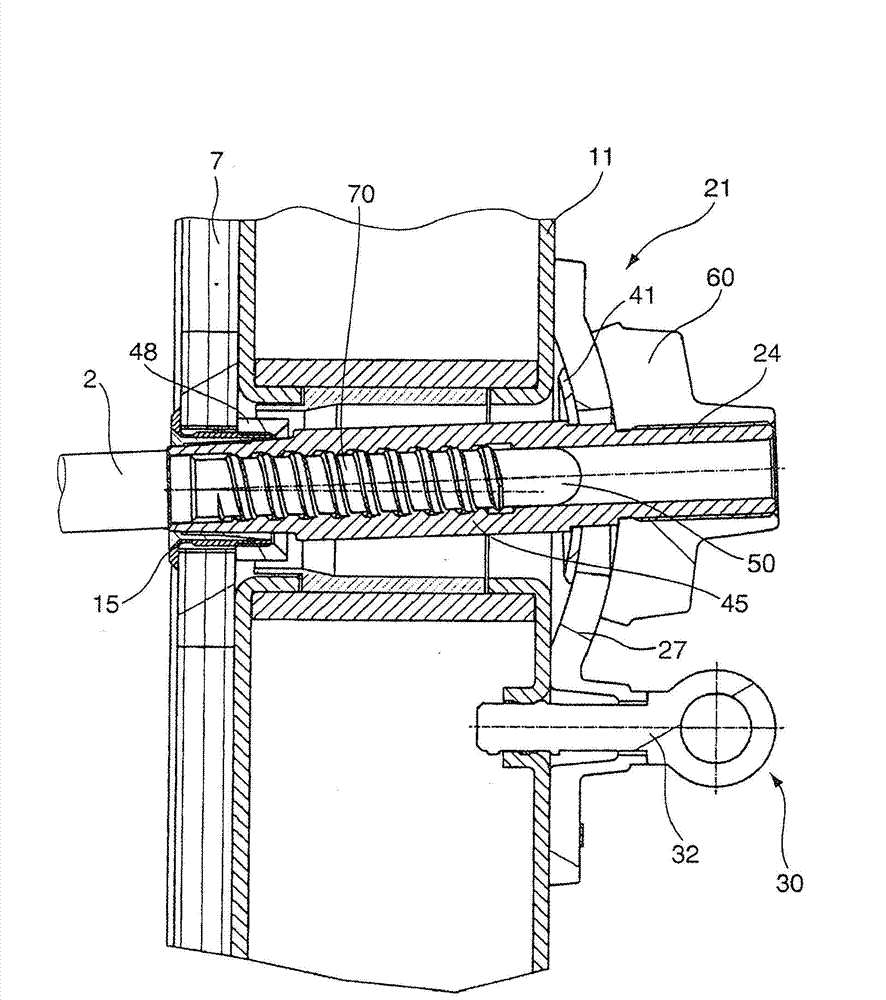

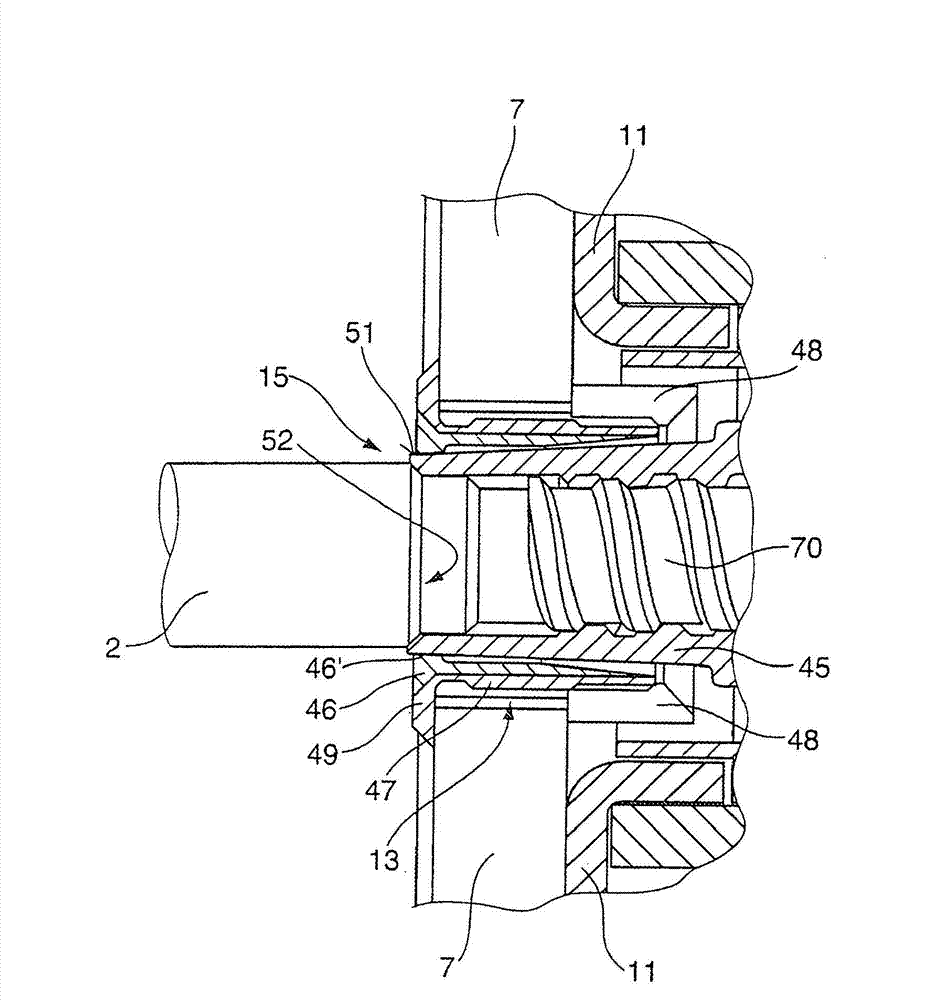

[0030] The figures show the subject matter according to the invention very schematically and are not to be understood to scale. The individual components of the subject matter according to the invention are shown in such a way that their structure can be clearly shown.

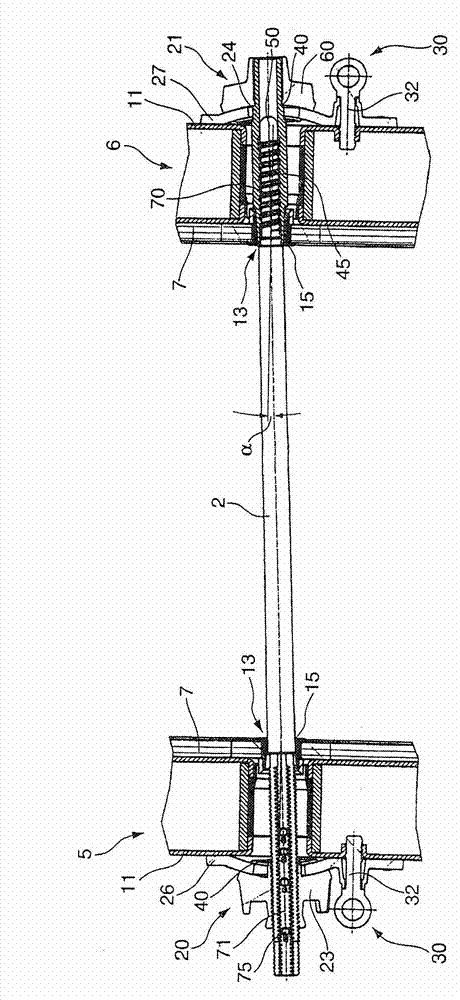

[0031] exist Figure 2a , 2b and 3 are shown in figure 1 A detailed view of the concrete wall formwork according to the invention shown in , wherein a sectional view at the height of the longitudinal axis of the anchor rod 2 of the anchor system according to the invention is shown, which attaches the concrete wall A first and a second formwork element 5, 6 of the formwork are connected to each other. The formwork elements 5 , 6 each have a formwork shell 7 and stringers. Possible cross beams are not shown due to the selected graphic partial sections. The formwork shell 7 is usually attached, in particular riveted, to the longitudinal and transverse beams. The anchor rod 2 is oriented obliquely at an angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com